-

Posts

115 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Lukaniuk

-

Please help - I think I've been sold a bad turbo

Lukaniuk replied to Lukaniuk's topic in Turbo / Supercharger

Compression is good on all cylinders and from what I can tell all the cylinders are clean. Also, I was driving the car with the stock turbo before I put this one on. -

Please help - I think I've been sold a bad turbo

Lukaniuk replied to Lukaniuk's topic in Turbo / Supercharger

Its a garrett t3/t04e. I tightened all the nuts and bolts because I needed to clock the compressor housing. -

Well first some good news. I got my megasquirt installed and idling, but it was idling SUPER rich (7.6 on the WB o2) and no matter what I tried to do I couldn't lean it out. It was smoking white a little bit, but I figured that was just because it was running so rich. Well I go to the back of the car and I realize why I'm reading so rich End good news Its spraying oil out of the exhaust pipe! Its going at least 2.5'. I put my finger in the pipe and the pipe is coated with oil. I had the car running 10-15 minutes max So the new rebuilt turbo I bought is no good, and my new WB O2 sensor is probably toast now too. I'm so frustrated right now - I thought that if I was going to have problems it would be with the megasquirt. Could this be something easy to fix? or is this turbo no good? I'm going to get a hold of the shop I bought if from and see what they'll do, if anything, for me. I'm not really excited about dicking around shipping though!

-

Incredible! A true inspiration!

-

I'm in awe!!! you're a madman!!!

-

btw thanks for all the input guys

-

I couldn't sleep almost all night last night because I was racking my brain trying to figure out what was wrong and then it dawned on me I'm sure the timing is WAY off for some reason (and then I couldn't sleep b/c I was too excited). I got to go out to the car tonight and after a little bit of tinkering around with flooded cylinders and weak spark I got the timing light on it again and sure enough something was way off with the timing. I honestly don't know how I had it so messed up. So now in order to get the timing light to match the value in MS for the cranking angle I needed to set the trigger angle at 65 degrees with 0 trigger angle addition. This kind of seemed funny to me because it was so far off of the values that I have seen other people using - but I figure its worth a shot. and BAM! there it is, idling first try! not a very nice idle but idling. I didn't let it run for long (maybe 10 15 seconds) because it didn't seem to me like it was firing on all cylinders. I hope this is just due to the weak spark I had to deal with when I first started working tonight b/c I don't think that will be too hard to fix. My new questions are: 1) are the values I have for my trigger angle reasonable? (65 degrees 0 addition) or am I way out to lunch with something here? 2)Where does MS get most of its current from +12V or +12V switched? I know I've got a connection with lots of power for +12V but I'm not so sure about the switched power and I'm not sure how much this will affect my spark. I'm using a relay board from DIY if that makes a difference

-

oh wow! Congrats

-

Ya I'm sure its flooding. I pulled one of the plugs out and it was very wet so I took the injection fuses out of the relay board and turned it over a bunch. When I put them back in I tried low values then kept increasing them until it was flooded again. Here's my tables for ignition and spark. I wasn't adjusting these at all because I didn't think that they were used at all for starting. I'll try searching for Cygnus' settings

-

Hughdogz I tried with trying to crack the throttle a little bit, it seemed like it was helping, but it didn't start. I'm not using a idle air controller. I'm going to try adjusting the idle screw next I think Jeffer I did calibrate the TPS but it didn't seem to do anything. Will that make a difference for starting?

-

I was just thinking after I posted the first question. I'm also kind of confused on how to setup the throttle body. If the butterfly is closed, will enough air get through for the engine to run? and if not, how much do I have to open the throttle body for enough air to get by? and then how is the TPS supposed to be set?

-

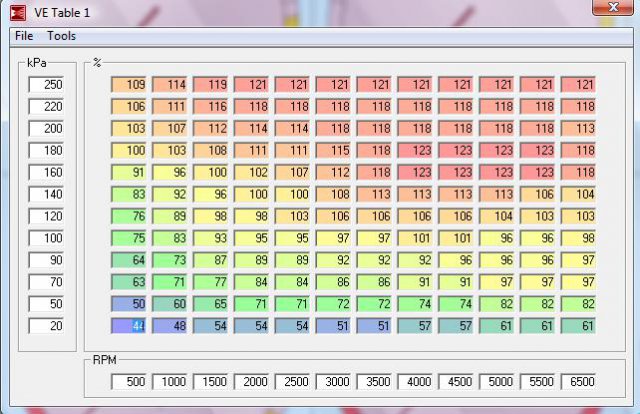

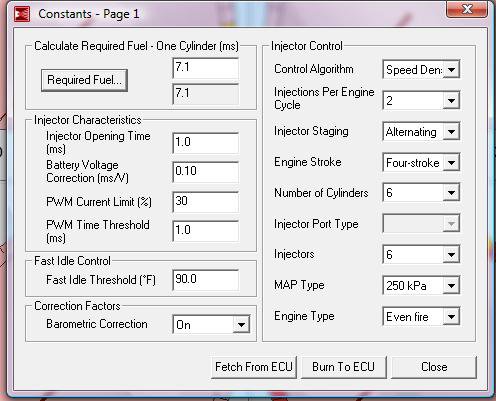

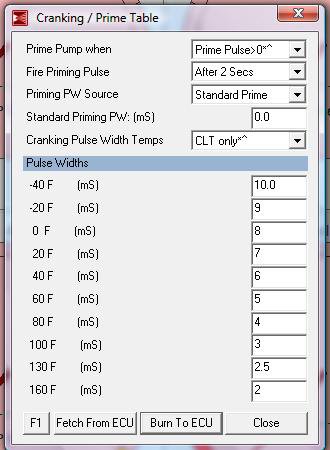

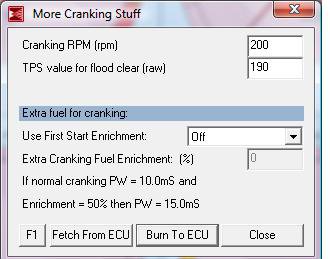

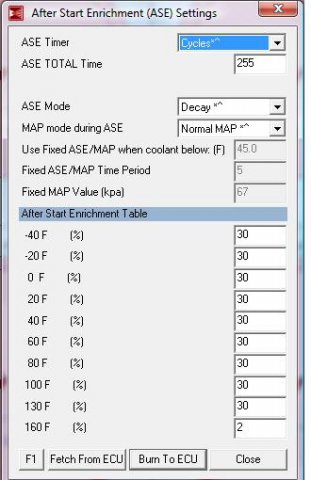

I cranked and cranked all afternoon, changing all the values in the cranking and after start enrichment tables but no luck. It seems like I'm always flooding it. Sometimes it sounds like it wants to start and it will get around 350rpm sputtering and spurting but it won't go anywhere near an idle. Could the MS Guru's take a look at some of my settings and help me figure this out please!!!!! It was wierd - sometimes it would seem to work good with what seemed like extremely rich numbers and then later what seemed extremely lean. Details: 82 L28ET stock internals and cam 440 supra injectors + Pallnet FR T3/T04E 60mm TB MS1 V3.0 MSnS extra (29y4) Triggered from the distributor Followed the write up and wired like shown at http://www.diyautotune.com/tech_articles/how_to_megasquirt_your_280zx_turbo.htm Here's some jpegs of my settings. This is just the last numbers I tried before I gave up this evening. I feel like I've tried a million different combinations for the cranking and after start enrichment tables with no luck. I feel like I've just overlooked something simple and any input would be appreciated. Has anybody had any luck with a similar setup using the 29y4 code?

-

I think my "ahem" Z's rear should look like this!

Lukaniuk replied to G.I.jonas's topic in Body Kits & Paint

I've got a couple old cougar lights (they're basically the same except they have vertical chrome accents) I'll try and find them this weekend and take some photos holding them up to the Z -

I think my "ahem" Z's rear should look like this!

Lukaniuk replied to G.I.jonas's topic in Body Kits & Paint

I always liked the look of the Mustang GT500s. Just a quick cut and paste in paint. I'm confident the scale is off, but I think it would look pretty sharp. -

Sorry, I took another look today and the female part is attached to the tunnel on the 260z

-

I hope there's going to be a video

-

installed new fuselinks ,car won't start

Lukaniuk replied to midnight-z's topic in Ignition and Electrical

Have you tried to start the car with another battery that you know is good? or boosting it with another car? -

What car do you have? On my 260 the female part is attached to the seat.

-

hahaha I guess that pretty much sums it up. I read about some people on other forums having success with it but who knows how it will hold after a year, hot day, large bump etc. I'm leaning towards trying the Dura Fix stuff. I was pretty impressed by that video.

-

I've been having a hard time finding someone locally who could TIG weld my alum. BOV onto alum. tubing. A friend recommended just using JB Weld but I'm a little weary. Does anybody have any experience with this? Thoughts?

-

-