-

Posts

2483 -

Joined

-

Last visited

-

Days Won

24

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Leon

-

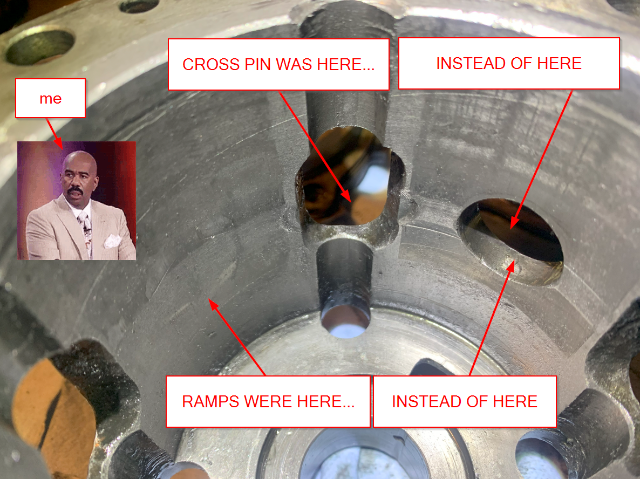

Unfortunately, more unhappy diff news this evening. It seems whoever assembled this diff majorly screwed up, to put it lightly. As I said, a local diff shop was the last to touch this diff when I had them inspect it... 10 years ago. So the costs may very well be sunk at this point which is disappointing. There is heavy embedment of the friction plate ears against the carrier and damage to the cover itself (perhaps due to mishandling during install?), I have a feeling the clutch vs washer vs plate stackup was done incorrectly. Elongation of clearance holes in carrier due to loose ring gear bolts And the mystery of where in the world are the LSD ramps was solved... the pressure ring was installed 90° off and the cross pin was put in the wrong place. INSERT REGRET AND DISAPPOINTMENT HERE.

-

HybridZ Apparel Order Thread - 100% of Profits Will Be Donated, round 5

Leon replied to cockerstar's topic in Vendor's Forum

(1) Hoodie Size: XL Color: Dark Heather Zip: 94010 I'm glad you're doing another run, Ryan! I was bummed when my hoodie from the original group buy took some damage last year, wasn't sure I'd have a chance to replace it. -

Thanks for the heads up! Should be fixed now, let me know if you still can't see them.

-

Done. :)

-

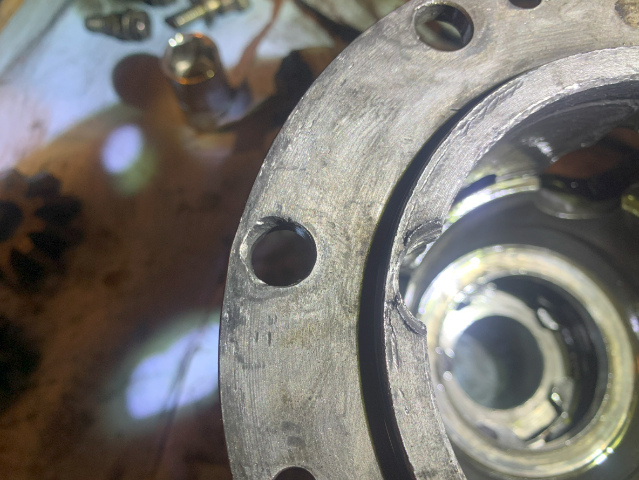

Looks like a year and a half is about my post cadence these days. I've been driving the Z sparingly but with much enjoyment since fixing the throttle hang. It's finally feeling close to getting to the level of refinement I want out of it. Unfortunately the diff started making some extra whiny noises beyond what it was already making so I pulled it this past Saturday. I got the chance to pop the cover off and found that I'm the lucky winner of 6/8 loose/snapped ring gear bolts. 😱 I'm not sure whether it's salvageable but I'm going to tear into it as time allows. The last time this diff was opened was by a local diff shop but I can't say for certain whether they had removed the ring gear... This is a Datsun Comp R180 3.9 CLSD so I'm hoping I can save it and run it but it looks a bit grim at the moment. The cross pin position is not centered and doesn't seem to have any ramps? It's late and I'm confused, will be looking into this later. The spot faces have heavy embedment from the loose bolts. If this LSD carrier can be reused, it will need machining. I pulled these bolts out by hand, their ends are broken off and lodged in the ring gear.

-

Sorry, I'm being a bit cheeky there. I may actually be interested. Let me know if you're willing to ship and what you might want for it. I've got a few bits of harness on my early 260Z that need servicing. Most interested in everything going to the steering column, headlight and taillight wiring although it seems that some of that may not be available.

-

I'll give you $3.50. 😁

-

17 month update! The Z hasn't seen much action as I've been dealing with a perpetual throttle-hang problem and inconsistent low-speed fueling--lots of popping out the carbs at low load/throttle openings. The low-speed fueling was dealt with by a trip to Keith Franck's house on New Years Eve 2021 to use his custom progression-hole drill fixture. The first p-hole in my 45DCOE 152's was too far upstream, you couldn't even see the throttle plate through it at idle. This is a common problem with the 152's and Keith's fixture was the perfect tool to fix it. It turned out to be the correct diagnosis! I was rewarded with virtually no more popping out the carbs during low-load operation, the freeway cruise home was the smoothest it's ever been... besides the fresh rock chip in the windshield. But now the rev-hang problem was even worse, although the engine would return to idle after a sharp throttle blip which hadn't been the case before. This is an issue I've been dealing with, at various severity levels, for the entirety of the 9+ years I've owned this Z. I was invited to a cars and coffee event this past Sunday, 5/29/22, which was inspiration for the next round of trying to fix it. So the carbs came off for the 132nd time, this time with the intent of resetting the throttle butterflies. I decided to pull the carbs off the manifold while on the car as to not waste the manifold gasket which had been port-matched when I had it apart last year. What I also discovered were some slight interferences with the TWM manifold (would love to replace this janky manifold with a Datsun comp or Harada piece) as well as a non-functional accelerator pump on the #2 carb. I ground down the manifold in the offending areas with a file and radiused Dremel burr, this worked very well. Swapping accel pump pistons from carb #2 and #3 did the trick for making the #2 pump function again! I chalked it up to slight tolerancing issues. I then spent a good amount of time with a flashlight backlighting the butterflies, trying to get them as sealed as possible. I first set all the bearing preloads with the throttle shaft nuts as to set the throttle shaft in place. Then I loosened the butterfly screws enough to get the butterflies moving. Setting the butterflies was a matter of seeing where the light was coming through and trying to set it in a position where the light "leak" was even and minimize. The butterflies are eccentric in shape so turning them a bit here and there helped find the optimal position, along with snapping the throttle shaft for a bit of self-alignment. And I finally have the crisp throttle response I've always wanted! It could be better but it's a massive improvement over what it was. I'm still missing that "zzzzz" noise on overrun when snapping the throttles closed but at this point, I'm happy. I made it to the C&C yesterday and did about 160 miles of excellent ripping through the East Bay and Santa Cruz Mountains! Photos from recent drives: My son likes to service his car while I work on mine, we ensure that safety best practices are always followed.

-

Nice work Phil, your home-brew solutions never cease to amaze.

-

What kind of shape are the door cards in? Is the chrome trim still intact? More detailed pics would be great. Thanks!

-

I was going to suggest NASA ST but it would be a tall task to make a Z competitive against GT3's and Viper ACR's. Not saying it can't be done but... anyway, we've gone way off topic on this fantastic thread.

-

240z SCCA vintage race car, restoration

Leon replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Yup, exactly. -

Mother of god, that thing F***ING RIPS.

-

240z SCCA vintage race car, restoration

Leon replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Just keep an eye on those gland nuts. I'd suggest checking torque after each event. You should be able to easily get a wrench through the spring in order to do so. Minimal disassembly required. -

Inspirational work as always Derek, well done! I enjoy following along with your design process. Is there any recent footage of your heads on a running motor? Aydin, Rebello is fantastic. They can take a long time to get things out the door and are pretty old-school but they've been thorough and accommodating to work with in my experience. They did a great job on my P90. Rob @ ZCG is incredibly into what he does. He can be intense but I respect his passion and tenacity in doing top notch work.

-

You will not be disappointed with Thunderhill nor Sonoma. Laguna is fourth on my list of local tracks, with Sonoma the top dog, then Buttonwillow and Thunderhill ("local" meaning within 4 hours). Laguna is the famous one with the corkscrew and all but it's by far the least technical track of the four. With that said, they're all great to drive and if you have the option to hit any one of them, you should do it.

-

Love the build, any plans to make it down to any Norcal road courses?

-

Looking for good vintage Datsun mechanic in california

Leon replied to sch4400's topic in S30 Series - 240z, 260z, 280z

Rob @ ZCar Garage -

Hey Aydin, I have a buddy looking for a 3.54 R200 in the SF bay area. Are you willing to ship?

-

Interesting, thanks!

-

I can provide two lines of reasoning: 1) this kit is clearly designed by someone with more of a propensity for fabrication rather than engineering/vehicle dynamics. It's going to be a lot of money spent on something that doesn't look fully thought-out and will still take additional work to make it "right". IMSA GTU S30's wore fat race slicks and won races back in the day without going to a double A-arm suspension. Example of a chassis with IMSU GTU history: http://www.finecars.cc/en/detail/car/7313/index.html 2) the car was not originally designed to handle 600hp nor wide sticky tires, so you're going to incur R&D costs regardless. It comes down to how much of your own work/hiring out you want to do vs slapping in pre-made OTS bits and hope they're good enough (but expecting lots of tuning and rework). Final thoughts: there sure are a lot of ways to make a from-scratch suspension worse than what you started with...

-

It's not the camber gain that's necessarily the problem, it's more of a benefit if not a big one. What happens is the short upper arm creates more vertical roll center migration. This will affect with the handling balance of the car because the spring and bar contribution to roll stiffness will more dramatically change during suspension travel. This is not a great characteristic to have on your front axle unless you balance it with the rear which I'm not at all confident is being done nor thought of. And to those saying weight distribution doesn't matter that much, you're being very silly. The amount of conjecture in this thread has my head spinning. As to Porsche, the 911 descended from the VW Type 1, aka the Beetle, which was not really designed with sporting intentions. Have they been successful? Very. Does that mean that the layout they've chosen is somehow optimal or even good for vehicle dynamics. Not at all. Money has a way of covering up mistakes. Look at any serious sports car conceived in the last three decades and tell me how many are rear-engined. EDIT: I'd forgotten to say, Porsche themselves wanted to very much kill off the 911 in the '80s as they didn't see a technical benefit of continuing with the platform. The only reason it's still around is because it'd become the face of Porsche and they realized they can keep milking it for what it's worth.

-

Nice! Yeah, it just works and fits well with the car. This feels like a "if it ain't broke, don't fix it" situation.

-

I should say, I also FINALLY went to mount my Compe handle (steering wheel) and I may be called a heathen, but I think I prefer my Grant! I like the thicker grip, larger offset, and larger diameter of the Grant. Considering putting the Compe wheel on the market or hanging it on the wall in my garage...

-

Thanks Ross! Looks like you've been making some serious progress on your end as well. I am not envious but much respect.