-

Posts

779 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Lazeum

-

Nothing like this. It is just the 2 holes machined to hold the VR sensor are not at 6mm each. One is 6mm, the other one is 5mm. To accept the sensor, the 6mm hole needs to have a counterbore of 9mm, 5mm deep. The plate needs to have also one of the bean shape hole at 5mm wide instead of 6 to match the other piece. On the picture below, left hole is 6mm with counterbore required, right side is 5mm with oblong hole. If you've got a VR sensor handy, check it out and it will become obvious.

- 67 replies

-

- EDISMegajolt

- Ignition

-

(and 1 more)

Tagged with:

-

Weather is still unsure here... Today was nice but they expect some temp below 32°F soon again (with salt that goes with) Anyway, I'm still fighting with my gas tank, so good weather can wait a little. In 2 weeks, it should be done!

- 67 replies

-

- EDISMegajolt

- Ignition

-

(and 1 more)

Tagged with:

-

Just started playing with Innovate LM-2 on Mikuni 44 2.9L stroker

Lazeum replied to inline6's topic in Fuel Delivery

Could your rich AFR at high rpm due to air restriction? Could it be air starvation at high rpm instead of gas issue? Could it be an issue with fuel level inside carb too high? Air filtrer / induction? Air jet too small? you could also display AFR vs. rpm. To do so, you just overlay the area you'd like to plot with the "select tool" and you go to "View" menu to X-Y plot. Much easier to analyze. -

Let me quick get a patent on it, I'll sue you and you'll send me a 510 or a RX3 from Canada in compensation Seriously, if you need some CAD files in whatever format you'd like, let me know and I'll put them on the board. I can even correct the mistakes I've made during my attempt. Regarding TPS bracket, I haven't got any drawings or CAD. I took some measurements, I did some cardboard templates & I've reproduced it with steel afterwards. It took me 5 iterations to get it right - when you bend the metal, curvature radius makes the bracket not so easy to be right.

- 67 replies

-

- EDISMegajolt

- Ignition

-

(and 1 more)

Tagged with:

-

As far as I know, I'm waiting for spring to show up while I'm fixing for good my fuel tank. I just know that my engine runs for now, nothing more! They wasn't a lot of info about megajolt in a s30, so I did this thread. I'm glad it could help people to take this route. I also forgot to look at the tach when I've run the engine. I still don't know if it works... ....and thanks!

- 67 replies

-

- EDISMegajolt

- Ignition

-

(and 1 more)

Tagged with:

-

Removing Crank Pulley - World's Longest HG Replacement

Lazeum replied to Soup's topic in Nissan L6 Forum

I'm with TimZ. On my 2 pulleys, they are 6mm threaded holes. Everything stock in our Z are with metric sizes. -

So I need a daily driver... Thinking about a BRZ

Lazeum replied to Mikelly's topic in Non Tech Board

BRZ / FT86 has been elected Sport Car of the Year here in France. They say handling is superb but there's a lack of Power. I would look for BMW otherwise. A 330ci or Z4 could be nice also as DD. My dad had a Z3 Coupe with 3.0, it was a very nice DD. -

I agree with Tony's comments & others. Here, in Europe, Datsun's are quite rare. People who want to have one are usually people who likes japanese cars. Value is much higher than in the US. My Z was bought for $8k in 2007, which was already not cheap, it is worth 20k€ in France now. So importing a Z from the US makes totally sense since shipping overseas is usually around $1500 + taxes. I have to say, I've been looking on hemmings Z classifieds, I haven't seen good example for less than $10k. I believe price is going up on those cars. When I go to classic car show with mine, very few people know Datsun's but they like the shape, the noise & the concept. It is not so often you can see in Europe a car with good handling (it's relative, of course), with full independent suspension, 6 cylinder engine reving up to 6k rpm. S30 competitors is Europe froma Power / handling / period standpoint are 911, Triumph TR5/6, Healey's 3000 but their cost is x3 higher at least. So s30 starts to be known as a good alternative. You also have to know that it is forbidden to drive a modified car on the open roads in France. Changing the stock brakes with bigger ones for instance makes the car illegal to drive, even if it improves the stopping power/distance. Changes need to be validated by state company, it costs usually a lot to do without having any guarantee of success. We like to believe original cars are the only way to consider classic car. Somebody modifying a car destroys car heritage, it's like tuning up the Joconde with spray paint to make it look modern with fluo colors.

-

Checking on the internet, I found a source & it's quite affordable: 55€ shipped for 20 lbs. Anyway, the tank is almost clean, I won't be removing chunks anymore since the layers remaining are less than 0.040" thick.

- 15 replies

-

- gas tank

- restoration

-

(and 1 more)

Tagged with:

-

Dry ice, I thought about it while I was tearing up the gums out of the tank. Unfortunately, it is not so easy to get on this side of the ocean... As for mixing up CO2 & blasting, you're asking too much It is not as easy as in the US to find good source to work on cars. Some friends suggested to use paint stripper & gas to remove what remains. I'll give it a try this weekend but I'm not sure about the outcome.

- 15 replies

-

- gas tank

- restoration

-

(and 1 more)

Tagged with:

-

you might be right, I might have some crystalization occuring with such process since I don't control anything: metal chemistry, heat, air contaminants, etc.. I'm also worried about carbonization with wood burning & vaporizing carbon molecules to steel...

- 15 replies

-

- gas tank

- restoration

-

(and 1 more)

Tagged with:

-

I just come back from the shotblasting shop. They told me every residu of coating inside/out must be removed to make the blasting process efficient. They can get rid of them but they might destroy the tank this way. It is a pain to remove but it has to go. Shop owner adviced me to burn everything off. I'm thinking about using a butane torch but it might take ages. I've thought about making a fire in the yard and let the gas tank shells burning slowly.

- 15 replies

-

- gas tank

- restoration

-

(and 1 more)

Tagged with:

-

Porsche 904 racecar throwback based on the 987 Boxster platform

Lazeum replied to Nelsonian's topic in Non Tech Board

Somebody has to complain (see my location ) I think it looks great but wheel are too big IMHO. One size smaller would have probably be better. Afterwards, you can't go wrong with 904, they look (and sound!) awesome. I see some run at Le Mans Classic every two years - beautiful. -

I believe I will add some baffles inside but not sure about the swirl pot. I'm afraid to do more harm than good. I might end up with only an extra baffle to keep gas around fuel pick. Since I'll put also some resin as coating, I need to make sure I won't seal up baffles so I will drill 1 or 2 holes on every baffle to prevent it. Regarding the work done, I've removed the outer rubber coating & inner coating on bottom shell. I've used a heat gun, it was a pain with toxic vapors that made me sick. I've continued on the top side but I give up in the middle of process. I'll see with shot blasting company first if they can deal with it before. I've tried with my garage equipment, the coating is too soft & too thick to be removed with my tools. Regarding welding them back together, I'll give it a try as it is now with MIG. It might be qquicker and nice enough. I'll smooth everything up anyway afterwards.

- 15 replies

-

- gas tank

- restoration

-

(and 1 more)

Tagged with:

-

What to choose? Itb, tripples something else?

Lazeum replied to NorwegianZED's topic in Fuel Delivery

I think they would cost nearly the same. DCOE might be cheaper but not much and you'll need to add jets to tune them properly. ITB will also be more complex to run since you will need an ECU to control them with extra wiring & sensors. If you choose to do so, think also about ignition, this is where the potential of your engine is. -

The tank seems pinch welded. I did not see any signs of heat anywhere around. From a process stand point, it makes a lot of sense (quick, clean, easy) Sealant? I'll add resin that would seal if required but it is mainly to protect naked steel against rust over time Regarding the way it looks, as long as it looks clean & "professionnal", I'll be ok with it. Anybody who knows how the tank looks like will know it has been modified since it will miss the lip all around anyhow. I did not think about the lack of filler. TIG might be easier than expected then. Thanks!

- 15 replies

-

- gas tank

- restoration

-

(and 1 more)

Tagged with:

-

I had many issues with fuel starvation due to debris in my gas tank. It has already been coated with resin in the past so the only option to fix the issue for good was to open up the tank, shot-blast it & weld it back. So here are the steps taken so far. I need advice regarding how to weld it back. If somebody could chime in and let me know the best option, I would really appreciate First, obviously, tank was dropped from the car: I ground the lips to expose the factory welds: ...so I can use my angle grinder to cut the welds I've used a thick knife with a hammer to open up the tank ...to end up with tank in 2 pieces Shot blasting process is a no brainer, except I cannot do it myself. My shot blasting cabin is way to small... Next step will be to weld everything back together. So far, this is how the lip looks like (minus the chips I've cleaned up), both shells are cut in front of each other. Sheet metal thickness is 0.040" (1mm). Not sure what would be the best way of doing it: - MIG or TIG weld? - how should I setup the lips? Should I do it according to option #1 or option #2 on the following drawing? I'm wondering if I shouldn't mill some material out of one shell (the bottom side is easier since no outlets are on the way) and weld a corner instead of a "flat surface". Obviously, I need something sealed (I'll add resin inside the tank afterwards also). option #2 seems more appropriate. Extra question: since tank is wide open, I'm wondering if couldn't also add some metal sheet to create some baffles around fuel pickup. Easiest way would a be a simple flat sheet around pickup. More elegant solution would be 4 V-shape sheets to surround pickup, not sure how to make it happen on the lower shell while the pickup is on the top shell... Thanks!

- 15 replies

-

- gas tank

- restoration

-

(and 1 more)

Tagged with:

-

It looks awesome indeed with full of quality parts & attention to details! I'd love to get more details about how you've processed the parts? 1- regarding poly parts you've cast. how it is done? 2- plating process. How did you clean the parts especially? I've got a kit Chrome VI in my garage, if you've seen Erin Brockovich movie, you'll understand why I'm not so enthusiastic with my garage solution

-

Good luck with your project. It looks interesting I love 4g63! I drove an EVO for many years, It was amazing to drive, the torque from the engine was very good & it was "only" pushing 350 crank hp.

-

Me too! My biggest unknown will be carb behavior with correct/optimal timing under low loads. I'm wondering if I won't have to lean out a little my transition circuit. Now I need to fix my gas tank (full of junk - paint flakes from an attempt to coat the inside), I expect to open it up, sandblast it, TIG weld it, polyester resin coating inside & paint. I've also a short somewhere blowing my head light fuses to find.... It never stops! :'(

- 67 replies

-

- EDISMegajolt

- Ignition

-

(and 1 more)

Tagged with:

-

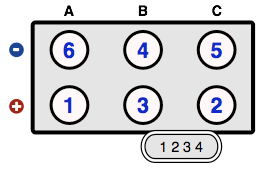

Car started for the first time with no distributor this past weekend! I've faced some issues that were easy too fix since they have been fixed by other members : - No sparks - VR sensor wires were not plugged the proper way. I have attached blue on gray & gray on blue. Since sensor & EDIS controller were coming from the same donor, the right way was blue on blue, gray on gray. I knew immediately what went wrong as soon as I've noticed no spark, it was easy to fix thanks to info found on the forum. - Backfires thru carbs without starting - I knew timing was off. I got confused with EDIS firing order A-C-B. Since nothing was written on the coils, I've also mixed up A with C & C with B, etc... it was a mess. For the record, here the correct diagram that works: Once those 2 items were sorted, the car started right up! it still pops from time to time but I've only run it for 20 seconds max. I was in the garage (closed), roads are covered with salt. Tuning will be for spring. Picture of the VR sensor & its support, I could have done it 1 or 2 mm taller (0.040 -0.080") , it would have put the sensor right in the center of the wheel. It is still in front of it though so I'm not concerned. VR sensor is using one M6 bolt & one M5 bolt (for slotted hole), it did not notice it during part design. I've attached the drawings for your information (they are messy but every details are inside). I've also forgotten in the drawing on the tower the counterbore for VR sensor recess (Ø9mm bore, 5mm deep)

- 67 replies

-

- EDISMegajolt

- Ignition

-

(and 1 more)

Tagged with:

-

Weber jets??All who live for their triples please read this

Lazeum replied to datfreak's topic in Nissan L6 Forum

Good to hear that. I'm quite surprised with the output but if it works, everything is fine. From my young Weber experience on L6, f8 idle jet are a little bit on the lean side. I had much better results with f9 that provides richer mixture. If it works for you now, don't change anything, I'm just saying. Have you also sync your carbs? Since I've done mine carefully, the engine runs much smoother at idle & low loads. -

You can adjust if you'd like to have the tensioner flush with its housing. It is how it is suppose to be after install. To do so, you can play with chain guide position on top of the tensioner. To check your chain, you should see if your sproket is timed correctly & if the guides are not worn out.

-

If you have a boost leak, you should check your system by pressuring it. This is what I was doing on my Evo before. I had built with rubber adapter found on hardware & a tire valve a tool that could be installed on my intake system before the compressor. You then need to apply pressure to it. If you do not have a compressor like I did (how come I could have worked on my car without one!?! ) you could purchase for around $20 a bottle to hold some air at high pressure you can fill up at a gas station & use in your garage. With your system pressurized, you can take your time to find the problem with soapy water & you ears.

-

I went thru this process myslef last year. Here are my advices: - Get the block, crank & head checked by a profesionnal (already done). - Make sure everything is clean inside/out, I've removed oil & water plugs out of the block to do so, I've also removed oil plugs on crank to clean the galleries. - Measure, measure, measure everything with reliable (=calibrated) tools; for stuffs such as piston/bore clearance, crank & rods journals ask your machinist to do it for you if you do not have the proper tools. - Do not assume anything, control everything, stuff such as crank axial play, piston/deck, bearing clearance, rings gaps, rings orientation are some of the critical data to track down. It means you need the right gages to measure everything with proper accuracy (a caliper to measure crank journal is not enough obviously). - Everything must be super clean all the time, use paper towel instead of rags. - Change all the bolts on the short block; those are cheap, no need any shortcuts on those. the only ones I've reused are caps bolts (I've been cheap here - they cost around $40-50), rod bolts & head studs from ARP & all other bolts are 8.8 grade purchased at regular hardware store. - Get quality & proper tools (to install rings for instance) & calibrated torque wrench - Take pictures of everything for reference - Never use brute force - Get organized. I've used tenth of plastic bags, boxes during the process. I've spreaded everything on a 12ft long work bench. - the "while I'm at it" syndrom is a good thing here, you could think for instance to increase oil flow in the head if you upgrade the pump with Tomei unit. I would add that if you have the money with all the bling you've collected (I'm jaleous ), you should make sure you've got some power too. The head/cam is where you would get your power aside from engine management. You should define what you want & get the head work, cam & valvetrain done accordingly. You're timing gears are a waste to me without proper head/cam. For instance on my engine, I wanted torque over power at high rpm so comp ratio is not crazy, cam is designed for efficiency between 3000 & 6000rpm and head port are not wide open to keep proper flow. There's nore to that also, intake manifold is ported slightly but I kept a small step to avoid flow reversion. If I wanted high HP output, I would have bumped Comp ratio, cam profile, port sizes & change my carbs for bigger units, etc...