-

Posts

637 -

Joined

-

Last visited

-

Days Won

1

ozconnection last won the day on May 9 2015

ozconnection had the most liked content!

About ozconnection

- Birthday 12/14/1965

Profile Information

-

Gender

Male

-

Location

Sydney, Australia

-

Interests

L Series engines and Nissan Cedrics

Recent Profile Visitors

9226 profile views

ozconnection's Achievements

-

ozconnection changed their profile photo

-

I have spent a lot of money on the head as it turns out. It's CNC ported by a Datsun specialist, SWR, here in Sydney Australia. I think the limiting factor is the crankshaft. Going to the expense of building a billet crankshaft, it would be cheaper to supercharge the motor.

-

I am also considering the virtues of an L28 destroked with the L20A crank It builds a 2.5 litre engine with a 40 thou overbore. The compression is suitable for boosting with a flat top piston and the E88 R30 L24E head, stock gasket I intend to keep it NA for the time being but a Rotrex supercharger isn't out of the question into the future. I track my machine and run a CD00A 6 speed and low 4.625 gears. A rev motor would be awesome and the song it sings, delicious....

-

L20A engines came in two variants...a robust and a gracile The robust version used L24 rods and a special piston to suit the small bore. Those rods are 133mm c to c The gracile version was like the Maxima L24 with the small big end and pin . The beam is very thin and that rod isn't ideal for performance work.

-

CD009 Bellhousing build thread Warning lots O pics

ozconnection replied to Derek's topic in Drivetrain

First test run on the track with the six speed. -

CD009 Bellhousing build thread Warning lots O pics

ozconnection replied to Derek's topic in Drivetrain

My 240C coupe now has a brand new CD00A 6 speed gearbox installed It runs with a H190 4.625 LSD with a 25 inch wheel. Love it! The low diff make all the ratio's super close, so it's quick out of the corners when I'm at the track. It's transformed the car...for the better. -

CD009 Bellhousing build thread Warning lots O pics

ozconnection replied to Derek's topic in Drivetrain

Just paid for the bellhousing BUT.....how does the rest of the gearbox attach to the cast bellhousing...I didn't catch that bit. -

Ah Ha....I thought I might find you here..You're 'always here' lol or so it says. I will go through this thread and it will possibly answer some if not all the questions I sent to you via PM on Facebook.

-

Hi, A general question. As the title suggests, what spark plugs do/can I use when running the Ford DG508 ignition coils? I had read elsewhere that a guy had converted his car to COP ignition but had encountered problems with a random backfire/misfire. A friend of his who was running a similar setup said he had encountered the same problem and had fixed it by selecting resistor type spark plugs. Now both gentlemen have engines that run without the backfire/misfire problem. Before I get my new motor up and running, I was wondering if the Ford coils are spark plug specific? If so, what plugs do you run with them? Thanks for your input.

-

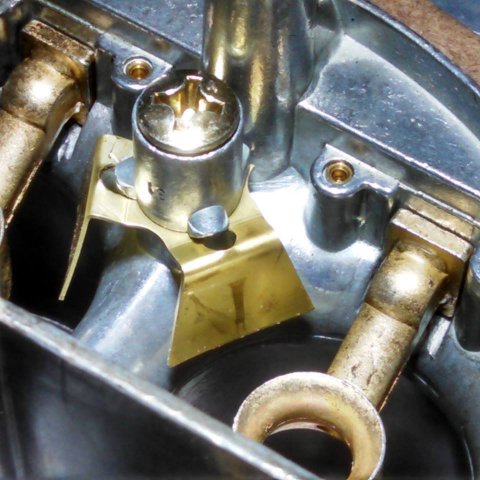

Well, this little Thompson Performance plate makes a difference. It's the first real attempt at improving the accelerator pump discharge for what seems like forever. I had to run a Reo (50cc/10 pump shots) pump through a standard #31 nozzle to get the balance I needed between volume and duration of fuel being injected into my Clifford manifold (large plenum volume). It ran well, with no stumble but the raw fuel droplets needed to broken up a bit better in my opinion to get a crisper throttle response. The fan effect seen in the video of fuel running off the plate makes a noticeable difference to the way the engine responds to the throttle and there is no fuel puddling which just sits in the manifold causing a soggy response and an overly rich condition afterwards. Get one of these plates and "viva la difference" Thompson Performance Holley.mp4

-

An old thread, perhaps a new vision. The factory Nissan PCV valve flows enough air to change the idle afr's by two whole numbers on my innovate wb. This is too much "un-metered" air entering into the intake manifold. I added an appropriately sized ball valve to reduce but not completely stop the flow of these gasses back into the intake manifold. You'll be surprised how little opening there is on the valve , that it still evacuates the engine of blowby gasses and what effect it has on the idle on my L26. Now, at idle, the Holley has its throttle plate correctly orientated with the transfer slot whereas before, the throttle was so closed, the transfer slot wasn't exposed. Previously the off idle characteristics were all wrong and it was hard to tune and drive at this point. The engine now bursts to life with just a flick from the starter motor. Almost all of the flow into the intake manifold is now through the carburetor, with just a whisk from the PCV. This little modification is like night and day for my engine, perhaps you could try it on yours if you're having idle/off idle tuning issues.

- 13 replies

-

Hi BJSZED, Thanks for your input man!. On the Clifford manifold, the PCV is positioned exactly behind the plenum divider in the manifold so that three cylinders receive half the gasses, the other three receive the rest...make sense? Ported vacuum signals are not used for this setup. At the moment the distributor is locked at 30 degrees. The throttle body configuration is setup on my track car so it really doesn't really need an advance curve for the track as it rarely ever drops the revs below 3.5K rpm Having said that, my next round of modifications will include a balancer 36-1 timing wheel to allow for adjustable ignition timing. The car gets driven to the track so some low speed tractability will be useful in those circumstances. The engine is managed by a Megasquirt ECU. Cheers!

-

Playing around with throttle bodies.....

-

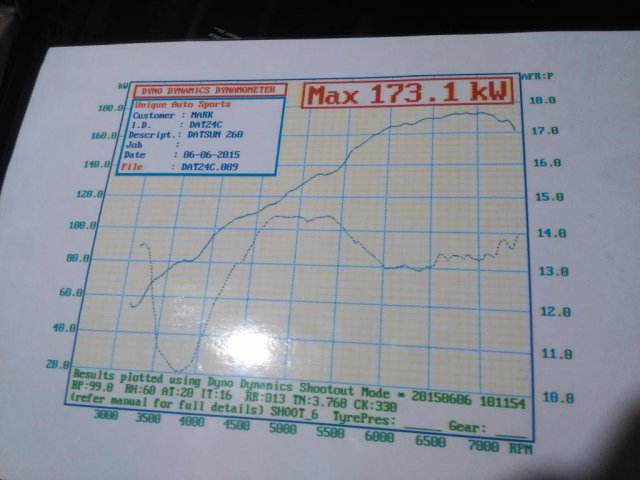

L28 87.5mm bore 79mm stroke 2850cc's JE 300zxtt forged pistons, custom rods RSR 1.72 Australian delivered late model E88 head. CNC ported flowed stainless 44mm/35mm valves 300 degree 590 lift camshaft 10 to 1 compression 98 octane unleaded petrol (pump grade) Clifford 6=8 four barrel manifold Injection Perfection 1000cfm four barrel throttle body 280 zx distributor locked @ 30 degrees MS2 3.5.7 Ebay generic headers 3 inch pipe Varex muffler It's that induction man.......that's where the power is. (oh, and the head,,,and cam. lol)

-

Very interesting. There is actually less power from 4500 to 6500 but where the power dived before just after 6.5K rpm, the new graph keeps pulling the numbers. Probably advancing the cam timing a little and maybe a little richer would pick that difference back up The ignition timing was the same for both runs, so nothing to be gained or lost there. Compression is up a smidge with the MLS gasket (1mm vs 1.2)

-

Yep, same dyno. That's an AFR measurement. Only power is displayed. Sorry for pointing that out Mr Dee I have the old dyno sheet too, will have a look and compare. thanks!