-

Posts

9963 -

Joined

-

Last visited

-

Days Won

74

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Tony D

-

That Dutch 260 left Holland in 1975 or you bought a Dutch firewall section with a lot of rust repair! Those things turn to earth worse than I've seen most anywhere!

-

Mary Jane Kopeckne...

-

Texas residents, what are you doing for registration without insurance?

Tony D replied to josh817's topic in Non Tech Board

Have you asked? Why guass and ussume? -

It's Turdalicious!

-

Lacquer doesn't hold up? I better strip it off my 62 Microbus (my first paint job in 1982? 83?) before all these terrible things start happening. 1982 VW Mars Red Acrylic Lacquer... Redder than red could be, no chalking, still glossy, uncovered, in the SoCal sun since 1989... It must be on the verge of jumping off the car and lighting it on fire as it runs and hides...

-

I hoarde parts because I don't want to deal with selling them. So I'm guilty of the second part...or am described by it I guess...

-

Named "Attic Wh ores"...

-

Texas residents, what are you doing for registration without insurance?

Tony D replied to josh817's topic in Non Tech Board

Classic Insurance from Haggerty for road usage is like $80 a year if you have multiples. Is $80 a year... $6.67 a month, going to break your bank? Insure through a classic policy, for the cost per year I have cars insured that haven't Ben on the road in over a decade. Because why? Storage insurance! And if I get a wild hair one day to take the yellow 249z "2YANXXX" out fr a spin, not only does it have the 23$ registration current, the insurance is good to go as well! -

The only reason I have this photo is the owner died and the entire car is for sale. Remember I rode in this car sometime in 97-2002. Not a lot of hi-res digital photography at that time. My Sony filled a diskette with four "high res" 1280x960 photos at that time...

-

Muahahaha ha! Aluminum"engine plate" style mounting of SC with 3/4 wrap and ability to run above 15psi. Serpentine belt on aux pulley in front f standard pulley (ATI or BJC better choice) Water pump stayed on standard V Belt as did alternator. Serpentine was "forward" those two pulleys. As for "double key" I mean axial position. The Japanese commonly DO NOT use woodruff keys on the high performance motors, they use a SINGLE key way and fully cut key in the crank snout. This gives TREMENDOUS area to,take orchestra should anything come loose. It's not so much a "torque transmission" reasoning on high rpm NA engines, but a ay to prevent damage from the woodruff keys wobbling and eating up your expensive prepped crank! For torque transmission, though, a single key is nice and functional. Double keys is one step below pulling the crank to make the key way fully through all front-end components. There are reversal forces here on-off throttle, add driving a 45HP compressor demand and you see a full key way is good idea (or double keys) The problem with slinger s "embedment" it can squash or peen out. Once that happens compression clamping on the pulley lessens, and that sets up the dynamic whereby the bolt comes completely loose or he key way then wobbles because the pulley can start "working"on it. The slinger IS NOT a hardened component, it's simply stamped sheet metal. As little as 0.003" embedment can SERIOUSLY lessen tension on the fastener and consequently face-clamping forces (the reason for thick washer!) The problem with the stock L-Crank Washer is its thin and flexes. That flexing is what pens the slinger in the first place. Flexing is just like embedment in terms of tension load on the fastener...compounded by the fact that it's now putting cyclic loading on the fastener as well! Not good...

-

Indeed! Like others replied 50 posts ago: that sn't what this site is for (kiwi303 nails it!) Go where it's appropriate and use the forum as not ended. Eventually the nipper at you pocket going "mistermistermistermistermistermister!" While you're trying to carry on a conversation with another adult needs a whack. If they never get the whack, they never learn. As the merchant seaman's manual states " if one may only be moved by a kick, then a kick is rightly applied and is within the spirit of the law!" It's called "school of hard knocks" for a reason. It's not called "Barney give you a hug and a kiss for refusing to read the rules and disrespect the forum school"! As I said: how hard is it to think. If they are too stupid (as YOUR classification states), then I posit SWIFT KICK or Harsh Flame is necessary to get "the stupid" to learn.

-

What to do with 240 engine with P30 cracked block?

Tony D replied to jerzee's topic in Nissan L6 Forum

News to me. I don't think cracked locks are "common" by any stretch. Ventilated? Maybe. This crack?very odd...- 21 replies

-

- 240 cracked block

- p30 block

-

(and 2 more)

Tagged with:

-

It makes perfect sense. Valves beat into the seats. Lash closes. Lash is engineered to remain adequate to prevent overheating of the valve due to insufficient seat time (the only time the valve. An cool down) and to prevent the valve from going to zero-lash before. Next planned-maintenance interval. "Quiet valves are hot valves, and valves getting ready to fail!" Noisy valves are happy valves. The Nissan OHC has a noisy valve train. Get used to it.

-

I run single grade based on factory recommendation since it never gets -40 here. My air cooled experience has led me to not trust mineral-based multi-Vis... Synthetics are a different matter.

-

Your numbers are almost EXACTLY what mine were. 1980 280ZX 2+2 with 225,000 miles: 185 across the board. At around 275,000 miles it has not changed. You can smell oil behind it, it burns oil but only smokes on startup and hard throttle on-off. Worse after Big Throat TB conversion removed the BCDD... Personally I think it's stem seals in my engine myself... I'm not in any rush to pull this apart, it just runs too damn good. Pushes my 76 2+2 to rock solid consistent 15.50's all day and night long, gets 22mpg towing an 800# trailer at 80mph, and spun a Dynojet to 147! Yeah, it uses oil, maybe a quart in 1,000 miles. Yours is 4x that... I'd say you got stuck oil control rings, especially with the look of the plugs. My 73 would do that on ONE cylinder after the engine was stored for 5 years. That engine had 26,000 miles on it (yes, you read it right, 26K, not 126K...I pulled then engine and had all the Nissan Maintenance records, bought in Japan out of a 77 Cedric in 1987 42,000 km on it) that engine on the same compression gauge runs 160. Pfffft!

-

I worried about the noises my 73 made until I went on a ride at an SCCA Auto-X in Eric Messley's BSP car (later AKA John C's "Rusty Old Datsun") After that ride, I realised my similar street driving style elicited the same noises... Alles normal, mein herr!

-

My wisdom is vindicated! I wanted to say 76 inch-pounds for a 1/4-28 thread as that spec stuck in my head from MC1-A GTC's, A/N PSM-60A GTC/Gensets, etc.... But all those years of having "go by the work cards" had me not consciously remember that specific number. But it was there... Lurking... Those were the problems on the GTC and most Combustor-Cap V-Bands: 1) Threads Strip in nut from over torque 2) Clamp bends from over torque due to someone thinking adding anti seize on the threads and not adequately compensating for "dry vs lubed" friction coefficients and still using un-lubed numbers while lubricating the threads. Example: Hardened Coupling Bolts torque spec DRY: 68 ft-lbs Same Hardened Coupling Bolts torque lubed with Coupling Grease: 22ft-lbs Result of trying to get 68 ft-lbs on threads lubed with coupling grease: thread failure inside nut at between approximately 35-42 ft-lbs observed on beam-indicating torque wrench. Use a good beam-indicating wrench pulling these up, you will see the band seat, clamp take-up, and threads yield... I'm always full of good news, ain't I?

-

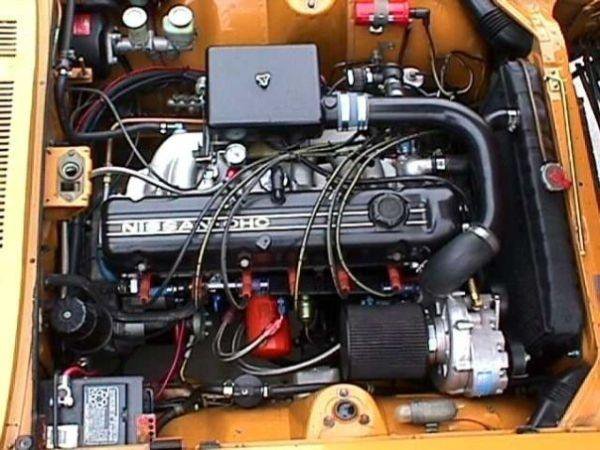

I knew I could find this if I looked hard enough. Setup sent the car sideways at will... In 1997. I forget who it was, but someone flamed me because they were "doing something nobody has done before" ( Centrifugal SC on L28) and was not enamoured itch my "it's been done"... They wanted proof. Here it is! Car would break pulleys at the key way. Use a double key, and thick hardened washer with proper bolt TIGHTENED PROPERLY and with Loctite 608 Cylindrical Parts Locker on the shaft, with 242 Blue n the bolt. Looseness on the drive pulley will kill it.

-

This is standard or industrial compressors. Some people used turbocharger tachometers on their car....wonder why.... "What is Surge" in the FAQ. DEADARSE sent me the instruction manuals for his system, and my laptop promptly DIED within a month without a backup. During that month me and another engineer did 65 gearbox overhauls in Shanghai...so I never even looked at what he sent to be able to give you a name. There was a Puerto Rican company claiming to make a controller that did this. It is always easier to,dump boost than to control boost via controlling turbine speed. Do what you can to optimise turbine speed (reduce variability) and tune the PID for boost control. You get a MUCH better control of pressure ( and anti-surge)

-

I find cutting solves most interference problems quickly, cleanly, and permanently. Bending was never my style either. Cutting was! And you forgot "in a snowstorm, after walking uphill from school five miles, during an eclipse"!

-

Zinc, ZDDP and camshafts - Does anybody worry about this any more?

Tony D replied to NewZed's topic in Nissan L6 Forum

No lie, people, there is a line on the CA Tax form for recovering SALES TAX for "items bought on the internet, out of state and brought into the state, ..." Luckily Ohio has full reciprocity with CA, and the Tax collected in OH will not be RE-PAID in CA upon registration of the Vehicle there! Oblay EEmay, Aliforniakay! Good thing I don't buy anything outside the state. Always traveling for work, long days. Never get a chance to shop. Good thing, too! Don't need more accounting headaches! -

Topic? This had a topic? What was that again?

-

And that assembly John C talks about means six more bolts and the cutting of a couple of flexible brake lines to drop it as an assembly. But those aren't on your back!

-

If I was offered $200 on a counter offer, you would have wasted an hour's drive plus the gas. And when you came back at $250, it would then be $300... Note he said CALIFORNIA PRICES, not Pennsylvania Prices. You pay a penalty for living where you do (and rightly so...) If you expect California Prices, factor in SHIPPING and time, possibly LABOR to pull them. The price for $250 for ALL THE PARTS for the conversion is a STEAL. The differential alone sells for that much. If you're not serious about wanting the parts, you shouldn't waste the sellers time or your own. I know I know "nothing ventured nothing gained".... And remember the first two lines of this post. What goes for you, is fair for him as well. DON'T COMPLAIN if that is the response you get. It's just as valid as you trying to skin the guy for $50. Dropping it all out as an assembly is FAST. Half hour maybe. The longest thing is removing the halfshaft bolts. Once those 8 are done, the moustache bar, front mount come free and it DROPS, give a tug, the driveshaft pulls out of the tranny and drag it to the truck. I have done this in 5 minutes on cars where someone has taken the axle shafts...

-

In AMERICA, this is the case. That is what I'm trying to say. America isn't the end-all-be-all of Automotive Endeavor. Toyota is now the biggest....due to the "America First" mentality. Elsewhere, it's a rare vehicle, and sports car....and treated as such with great respect and a reputation for powerful engines that don't break.