-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

Return line is too small by the sounds of it. With high volume pumps and big boost you normally require at least a 3/8 return line. OEM fuel rail suspect. I believe it's only 5/16 on the return side. Plus it has lots of bends and each bend restricts fluid flow. Order a Pallnet fuel rail and run the FPR on the return side. - 6AN Hose both inlet and return. May also be a restriction at the tank. Make sure no hose is pinched at tank. You may have to modify the return line at the tank if it is too small. Edit: Check the return line under the chassis. Pretty sure it's only 5/16". Too small.

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

I didn't say that dampers affect squat MORE than springs. Both shocks and springs work together. Dampers not only control spring motion, but they also highly affect ALL Transition phases. Shocks control dynamic weight transfer rate and have a great effect on all aspects of handling. Slow Damping is especially critical for transitional phases. Dampers are just one part of the tuning equation, as are springs, suspension geometry etc. . But if you have ANY weak link in the equation ( IE: weak and blown shocks ) then that throws everything out of whack. Squat is a transition phase just as Nose lift or Roll is. Dead or weak shocks will negatively affect all transition phases, including Squat, Dive and Roll. You can't get any meaningful data with dead shocks. Put the new shocks in first. Test and then decide if you need to change spring rates. There used to be an excellent article on Sim Racing for setting up Race Car simulators. The damper section was written by a Koni engineer and was taken from a Koni setup guide for real race cars. I'll see if I can find the link. Edit: Found it. Well worth saving and printing. Enjoy: http://alison.hine.net/sims/gp2-jw.htm

-

Coil Overs. MR2 or Rabbit inserts.

Chickenman replied to Chickenman's topic in Brakes, Wheels, Suspension and Chassis

Never mind. Found part of the answer. The rabbit struts are shorter than the MR2 struts -

The blown and weak dampners aren't helping the situation diddly Squat ( Pun intended ) . With new shocks and ones that aren't blown, I think you'll find the rear squat is much less. With big HP RWD cars I've always preferred a rear spring combo that is more subtle ( softer ) helps put the power down on corner exit and over bumps. Rain is another concern in the PNW, something that you probably don't have to deal with in sunny California. But weather does have to be taken in consideration for setup. I'm thinking 300F/275R myself..... Whatever you choose, nothing beats Test time on the Track.

-

I'm about to send my spare 280Z front struts off to get converted to coil overs. Have decided on Koni's. What are the Pro's and Cons of the VW Rabbit struts ( 8641-1048Sport ) compared to Toyota MR2 struts ( 8641-1142SPORT )? Prices are the same. Is one better than the other ( valving ) or have a thicker shaft?

-

shaved intake 280zx, now won't start

Chickenman replied to Mobious5's topic in Trouble Shooting / General Engine

^ The factory Nissan PCV system is very good. It's very well designed with lots of internal baffling, both in VC and engine block. . Just maintain it and keep it stock. Including all routing -

T3 Coil overs vs DIY Ground control kit

Chickenman replied to turbogrill's topic in Brakes, Wheels, Suspension and Chassis

Was this with the pre-assembled kit by TT3 or the DIY kit? Either way, unloaded springs are really no issue IMHO. Doesn't affect anything mechanically or handling wise. Also, you can install " Helper " springs. These are very low pressure springs that keep the springs seated when a car is jacked up. As soon as the car is lowered, they collapse all the way, effectively becoming a spacer that minimally affects spring rate. Common part made by numerous companies for 2.5" and 2.25" coil overs. Used all the time. Helper spring rates vary from 5 lbs upwards. https://www.google.ca/search?q=Coilover+helper+springs&sa=X&biw=1536&bih=736&tbm=isch&tbo=u&source=univ&ved=0ahUKEwjfsN7Cm_PRAhVLVWMKHS3KCA4QsAQITg http://pitstopusa.com/c-133004-chassis-suspension-springs-coil-spring-accessories-take-up-springs.html -

shaved intake 280zx, now won't start

Chickenman replied to Mobious5's topic in Trouble Shooting / General Engine

-

shaved intake 280zx, now won't start

Chickenman replied to Mobious5's topic in Trouble Shooting / General Engine

Yes, but you don't want to ever do that ( remove PCV system and replace with VTA ) on Daily Driver car. You will get much quicker contamination of the oil. Carbon particle contamination, water vapor and acid buildup. As wee the piston ring seal will be affected, negative crankcase pressure aids ring seal. The crank seal and rear main seal will all be less effective as the sealing lips are designed to operate at negative crankcase pressures. Note: the odd WOT pass is usally only for a short time, and any pressure buildup in the crankcase will be relived once the throttle is lifted. Oil contamination is the main effect though. Carbon particles and acid buildup are nasty. Rod and main bearing life will be shortened. The following article explains the benefits of a Positive Crankcase system: http://www.agcoauto.com/content/news/p2_articleid/197 In addition; With race cars it is not such a big issue ( using Vent to Atmosphere of Cranccase and Valve cover ): 1: Race cars change oil frequently. Usually after one race. 2: Real race cars have Dry sumps or Vacuum pumps for the sump. The scavenge stage in a Dry Sump creates a strong negative pressure in the sump. This helps with ring seal immensely. Some NASCAR engines are pulling well over 14 inches of vacuum in the sump. HP gains of 20 to 23 HP on a 600 HP engine with 12 to 14 inches of vacuum are common. Better ring seal, enabling the use of low tension rings and reduced windage in the sump are the reasons for the HP gain. The following article explains the importance of maintaining a negative pressure in the cranckcase. http://www.enginelabs.com/engine-tech/engine/tech-crankcase-pressure-control-oil-and-air-control/ -

Juts a few of tips on the oil cooler mounting. Earl's may cover this in their FAQ 1: Do not mount the oil cooler falt against the Rad or AC condenser. Space it away by a minimum of 1" . Flush mounting reduces air flow considerably. Same with Auto Trans coolers or PS coolers. Those through the Rad zip ties that come in some kits are a quick, but inefficinet means of mounting. You need some gap for proper airflow. Lots of room in the Z nose to make a proper mounting bracket. 2: When running the hoses, avoid using turns as much as possible. Every time you add an angled fitting you cause a fluid restriction. It can all add up. If you must use an angle for clearance, try and avoid using an Angled adapter fitting. These can be very restrictive. Use a bent tube fitting on the end of the hose instead. These flow much better than the cast adapters. If you must use a bent Tube, try the minimum angle possible;e. A 30 degree or 45 degree bent Tube is prferred over a 90 degree. The sharper the turn the more the restriction. Ideally, if you can use all straight adapters and hose end fittings that is best. 3: Do run a thermostatic sandwich plate if ambient temps get on the cool side. Lots of good suppliers, but Mocal is a good brand. So is Canton, Eral's Setrab etc: Lots of places to buy them, but this gives you an idea of what is available: http://www.racerpartswholesale.com/category/Mocal_Sandwich_Plate http://www.racerpartswholesale.com/product/13462/Mocal_Sandwich_Plate

-

Dramier: BobIsTheOilGuy is an excellent resource for technical information on lubricants. Intelligent discussions, lab analysis and active/retired Petro-Chemical engineers frequent the site. Well worth adding to favorites: https://www.bobistheoilguy.com/forums/ubbthreads.php?ubb=cfrm Yes, the oil coolers sticking exposed out front are just a " Fan Boy " trend. Tons of space in the nose for an oil cooler on a Z.

-

1985 300ZX Turbo Auto transmission cars come equipped with an Air to Oil cooler.... Again this is the odd situation of Nissan not using an engine oil cooler on the manual transmission models but not the Auto transmission models. I have no idea why they would have done that. Very strange. Engine oil temps can get just as high on a Manual tranny car as an Auto. So why would Nissan choose to not put one on the Manual transmission models. Doesn't make sound engineering sense. Edit: Having a think about this and I just realized why the Auto tranny cars came with an external engine oil cooler and the NA cars did not. . The Thermal load of the hot transmission fluid running through the radiator likely cause cooling issues with water temp and/or oil temps. Thermal " run away " is the term I believe. So the engineers were forced to add an external oil cooler as cooling package was borderline with the Automatic cars. The extra Thermal load of the Auto tranny just put things over the edge for daily commutes. Many European cars use water to oil engine coolers instead of Air to oil engine coolers. Even NA engines. A lot of them also come equipped with Factory engine oil temperature gauges. High speed Autobahn running makes an oil temp gauge almost a necessity. Run a oil temp gauge on a Track car that does not have an oil cooler and I think you'll be shocked at the oil temps you see. Bottom line.... we all know that Turbo cars build higher engine oil temps than the NA versions. That's a fact. . An external oil temp cooler ( with a temp modulated plate ) is just common sense. Especially on modded cars. Not arguing either and it's just my .02c. Take it for what it's worth. Cheers..

-

Valvoline VR is a very good Dino oil. Fine for a NA engine. But personally, I would never run a Dino oil in a Turbo car, especially a high boost Turbo car. Synthetics can withstand the high oil temps found at the Turbo journals much better than Dino oils. Thta is where your paek oil temps are. Not the temps measured in the oil pan. But the temps at the Turbo journals. Speaking of heat. Why wouldn't you run a Synthetic oil in Texas? Synthetic oils excel in high temperature conditions. They are far superior to any Dino oils in that aspect. Naturally you have to choose the correct viscosity for the conditions you run and the modifications made to the engine. And buy a a high quality Synthetic. Some of the " off the shelf " brands sold in North America can't even be sold as Synthetics in Europe and Asia. USA big oil companies convinced Congress to " Relax " the Synthetic standards back in the 1990;s so they could manufacture " Synthetic " products cheaper. Long story, but you can look it up at BobIsTheOilGuy. Juts my .02c.

-

I should have said, you will never find a modern factory Turbo car without and oil cooler. Is that better? You guys know what I'm talking about.

-

I'm quite familiar with the ZDDP issue, and it is certainly true that you must be aware of this issue these days. . All the oils I recommended have adequate amounts of ZDDP . Note I did not recommend any " off the shelf " synthetic oils such Mobile 1, or Castrol . Energy Star rated oils in the thinner weights ( less than a 10w-30 ) are the prime candidates for ZDDP reduction. " Most 10w-40 " oils are not Energy Star rated and contain higher levels of ZDDP. The three oil brands I recommended are have more than adequate protection. Many manufacturers such as Redline, Amsoil, and Joe Gibbs makes niche market oils that are specifically formulated for Flat Tappet High performance engines and include more than adequate amounts of ZDDP. Rotella T6 full synthetic is also a very, very good oil in Turbo cars. It's an HDEO ( Heavy Duty Engine Oil ) recommended for Diesels but can be used in most Gasoline engines. Rated very highly on Turbo forums, Bike forums, Diesel forums and oil analysis readings always come out very good. Unfortunately it is only available in a 5w-40 ( for the FULL synthetic ) and I feel that the cold weight is a bit thin for the bearing clearances on an older design motor. I'm a firn believer in high quality Synthetic oils. Been that way since the 1980's and it's repaid me many times over. My DD Audi A4 has had a steady diet of either Amsoil or Rotella T6 synthetics since the day I owned it ( 126,00 KM ). Previous owner also used Synthetics. ( Mobile 1... not my favorite choice for various reasons... but decent stuff ). Car now has 253,000 KM on it. Has been chipped and boosting 15 to 18 lbs daily. Still has the factory BW K03 Turbo on it with zero shaft play and compression is 180 PSI across the board. Gotta be happy with that!!

-

IMHO, I'd give it a bit more fuel. Just make it happy. Running Stoich at idle can be done on Modern engines that are designed for it. Combustion chamber design with high squish and a prei-ignitor chamber and a killer powerful ignition system are three things that an old engine design like the L-series lacks. Spark Plug gaps in modern engines are often in the .060 range. I've seen some engines ( Ford's ) running .075" gaps from the factory. Got a CDI Ignition or COP ignition on your engine? That's part of what it takes to run an engine that lean at idle. May not be worth it. You may be able to do it with .045" plug gaps, but you still need a ton of spark with lots of Current flow. Edit: And of course you're running a Turbo. Probably with increased boost and for that you naturally want to reduce the plug gap to prevent spark blowout. Well that's just not going to work with trying to run Stoich or close to it at idle. You need a big fat spark kernel with a wide gap ( .040" and higher ).

-

Greg Banish. What are the Titles of the books he published? I'll have to look around my Library. Edit: Never mind. Found the info. Have just about everything except his publications.

-

I just grabbed my EFI tuning manual from DIYAutoTuning, and the exact procedure that I mentioned above is noted on page 106 under " No Load Idle Tuning ". If you don't already have this book , get it. It's by Matt Cramer and Jerry Hoffman of DiyAutoTuning. Awesome technical book that is easy to figure out for the Layman. Performance Fuel Injection Susyems. Publisher HP Books . ISBN: 978-1-55788-557-9 You can order it online from Amazon and other Book retailers or order it direct from DiyAutoTuning. https://www.diyautotune.com/shop/apparel-merchandise/books/

-

Golden rule in engine tuning. Give the engine what it wants. If it's happier with a bit richer idle or a bit less timing. Then give it what it wants. I do seen one error in your methodology though. Idle mixtures are typically richer than Stoich or Lambda 1.0. They have to be because the throttle blade is nearly closed. This reduces mixture density and VE. The decreased density require a slightly richer idle mixture to provide good combustion. Typical idle AFR on petrol are usually around 13.5 or 13.1. Stoich is only an effective baseline under Cruise conditions. I just punched a 13.5 AFR ( gasoline ) into my face engine calculation site and it came up with a Lambda value of .92. 13.0 AFR is Lambda .88 . So your engine is trying to tell you it wants more fuel, just as tuning manuals predict. Thta's why the misfire goes away at .9 Lambda...because you are finally giving it the fuel the engine wants. Here is a very good site with a Lambda to AFR conversion for various types of fuels. http://www.wallaceracing.com/air-fuel-lambda.php Big overlap cams often require around 12.5 or 12.0 AFR at idle ( gasoline ) . Dilution of mixture due to valve over-lap requires a richer mixture. EGR also requires a richer mixture than Stoich. There are other modifications that can affect idle Lambda values as well. Tune with a vacuum gauge and and your AFR meter. Adjust the Vacuum gauge until you have the highest reading possible. It should be nice and steady with na stock or mild camshaft.That is Best Idle. Tuning richer or leaner than that point will reduce the Vacuum reading.Tuning slightly ricer gives " Rich best idle " and is sometimes beneficial on cars that have big cam shafts. Tuning leaner than the best Vacuum point is " Lean best idle " and is often used to meet emissions specs. Note that lean idle mixtures require a POWERFUL spark to ignite the falme front properly. CD ignitions like Crane Hi-6 and MSD allow leaner idle mixtures because the high enrgy spark can ignite a diluted and low density mixture.

-

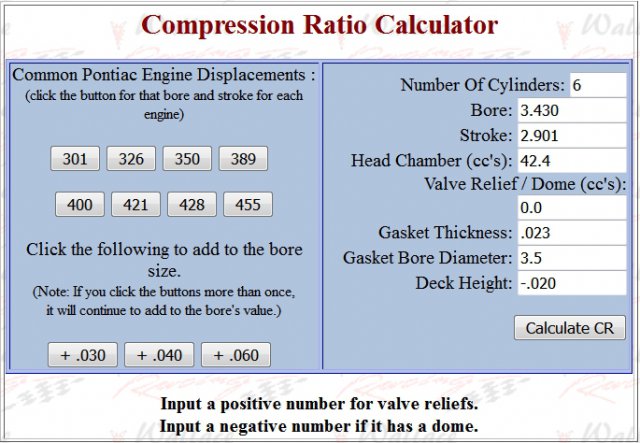

There are much easier ways to get a reasonable CR without running swapping cranks and rods. I take it you're worried about detonation on pump gas? If your running Flat Tops on a L28, do a trial assembly to get an ACTUAL measurement on piston deck height, and then machine the piston to get a zero deck height ( or what ever you need ) . It's no big deal to machine .020" to .040" off a piston top. Have your machinist measure the piston crown thickness, but there is usually more than enough meat there. Some hybrid motors machine the piston tops .100" with no issues. If you have to machine valve reliefs for a big camshaft, that usually involves quite a deep cut. Measure twice... cut once.

-

PayPal sent for 11 mm O-Ring Fuel rail plus two -6 AN adapters. ( -6 Male to NPT ) Richard Boyk

-

L28ET not reliable as a endurance track car

Chickenman replied to turbogrill's topic in Nissan L6 Forum

XNKE; Good call on not over-sizing the intercooler. When I suggested the largest Intercooler that you can fit, I had a vision of a reasonably sized one that does not block Rad flow. Then you made me think of the barn door types that some guys put on and I edited my original post. You need something decent with a low pressure drop. Observation on stock Rad is interesting. If stock ZX rad holds up to Road Racing, that's great. Hasn't been my experience though in other Hillclimb/Road Race cars. I've never found a factory rad that can adequately cool a car used for Hillclimbs or Road Racing. Track days may be a different matter. They are relatively short. I've used Aluminium and custom made copper rads for various Race cars. Thermally, copper does cools better than aluminium. But when you start running thicker cores a copper rad gets really, really heavy. All that weight up front is not good. BTW, I have a custom double core copper rad in my 280Z. I can run the AC on 100 F days at freeway speeds and temp stays rock solid at 185 to 190 degrees. Rad weighs a ton though. What shape the old rad is in plays a big part as well. A 40 year old corroded and leaky ZX factory rad is not worth the time and bother to fix IMHO. If you have a pristine factory ZX rad, well that may be different. But I still stand with my recommendation to get a GOOD quality aluminium rad for Endurance or Road Racing racing. I ( used to ) Hillclimb, and that is EXTREMELY hard on an engine and it's cooling system. High quality aluminium rads prevail as the choice for cooling for all the big HP cars. . Unfortunately, there is some cheap junk out there as well. Radiators from CR Racing, Griffin and Ron Davis radiators are top quality but can cost big $$$. A lot of local racers have had good success with Northern Radiators. They make custom rads, with high efficiency cores at a reasonable cost. http://www.northernfactory.com/HIGH_PERFORMANCE -

I plugged your combo in and got 11.22 to 1 CR: Used Nismo head gasket with compressed thickness of .6mm ( .023" )

-

Delete. Wrong screenshot.