-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

Yeah... I was kinda getting to that in a round about way. I just don't see the point in using a non-programmable ECU these days, particularly in a Turbo car with that many Mods. E85 and a programmable stand alone are in OP future me thinks...

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

That's actually quite reasonable IMHO. If he does a proper job. Getting harder and harder to find guys that work on the older stuff these days. At least it is up in my neck of the woods....

-

Tender + main springs on an S30?

Chickenman replied to rundwark's topic in Brakes, Wheels, Suspension and Chassis

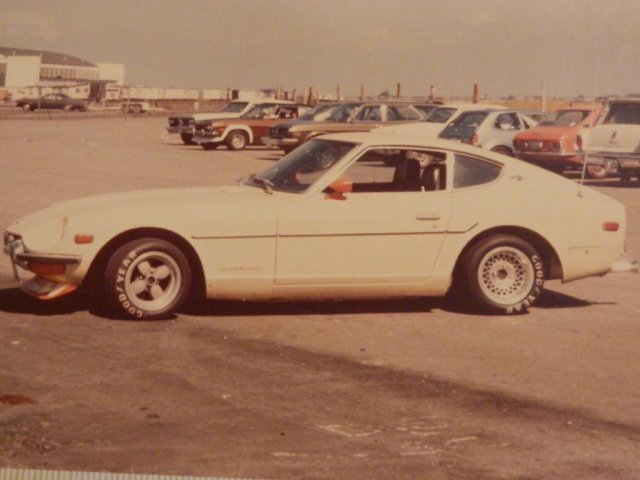

Topic got me interested in some of my old Autocross cars. Attached are a couple of pictures of my 09/70 240z. I ran this in B-Mod in the PNW and it was a podium contender back in the day ( Mid 1970's ) . Car was very low and handled like a go kart. Ride was very comfortable on street tires. Autocross setup. Goodyear 21x 8.0 x13 soft compound slicks on 13 x 7" rims ( Max Rim width regulated by rules ). Later on I got some Cantilever slicks. My Lord they stuck!! Street tires were 205/60x14's. That gained some ground clearance for the street. Nissan competition struts front and rear. Struts were pre-shortened from Nissan and had stiffer valving. These were the early models with non threaded collars, but spring seats were raised and shorter springs used to gain Tire clearance. Rare pieces!! Spring rates were not astronomical. Probably in the 200 to 225 lb range max. Nissan Competition 22mm front bar. Nissan Competition 23mm rear bar. R180 with 3.9 gears. No LSD. Interestingly, inside rear tire spin was never an issue. Front LCA angles corrected by drilling mount holes higher in K member. 1/16" Toe-in front, -2.0 Camber... Castor probably around +2.5 . I liked to keep Castor low for Autocross. easier steering. 1/8" Toe-in rear, -1.5 to -2.0 Camber. Car turned in very rapidly with no trace of under-steer. I apologize for the poor picture quality. Pictures taken from old photo album. Pictures are from around 1975 to 1976- 25 replies

-

- suspension

- spring_rates

-

(and 4 more)

Tagged with:

-

Tender + main springs on an S30?

Chickenman replied to rundwark's topic in Brakes, Wheels, Suspension and Chassis

I've Autocrossed, Hillclimbed and Road Raced for many years and a lot of guys up here in Vancouver run very fast 510's up here. Different area's have different setups. There is definitely a big bar/soft spring approach and a big spring/ small bar approach. Here in the PNW we have leaned towards the latter and it works very well. I would not recommend the tender and main spring setup. Basically that gives you a progressive spring, which in theory gives you a comfortable ride ( which it does ) and a stiffer rate when you corner hard. Neat?? ... far from it. What it does do is give you a non-linear feel to the car that is difficult to drive fast. It is definitely spooky when cornering fast. The car takes a big, quick bite on turn in as the soft coils compress, then it steadies up mid corner as the rate increase, then on corner exit the front end suddenly unloads as the soft coils expand. It is not a good feeling. A linera spring rate front and rear is much more consistent. The main problems I see on your car are lack of a rear bar and too soft of front springs and too high of a CG. For track days I would try the following. Bear in mind there will probably be a dozen more suggestions. Bottom line it's all about balance. Get the car neutral and you can make it " dance " from there. You need to reduce tire diameter. That will reduce CG, which will reduce roll dramatically. Change tires and rims to a 205/50 x15 or 225/45 -15 . 205/50x15 have a rolling diameter of 23.1" Your 205/55x16's have a diameter of 24.9". That's just too tall. The shorter tires and rims will also give you a gear ratio advantage and lesson rotational inertia. Both good points. Edit: Just realized you must have Coil overs and Camber plates, although you didn't mention them. Lower the car some more....if you can You can drop a Z 1.5" to 2" from stock easily. Going lower depends on strut clearance. You may have to shorten the struts to prevent bottoming out if you want it to competition heights. That can get expensive. Spring rate #300 front sounds fine. Most of the Hard Core 510 guys up here run #300 up front for street and track. And 510's are lighter on the front end than Z cars. Surprisingly it's not uncomfortable on the street. Good shocks like your Koni's 8610's are required. #350 rear rate sounds a bit high. Stiff springs in the rear are what make for a choppy ride on the street. I would suggest anything from a #250 rear spring or a #275. #300 may be getting up there. Too much rear spring adversely affects cornering under bumps and putting power down exiting corners. You definitely need a rear bar with the lower rate springs. A 22 mm front bar seems too small. You want around a 25mm for Road courses. a 22 mm front bar can work for Autocross if the car is low enough and has the proper rear bar. I would suggest a 25mm front bar with about a 20 to 22 mm rear bar. Maybe 23mm if you have a LSD Depends on your driving style. I've found that getting the rear setup correct requires much more finesse than the front. Up here in the PNW we have something called rain. You tend to go softer on roll bars in wet weather... unless you like drifting and spinning out a lot. Correct the front LCA angle of course as you lower car more. RCA's or by re-drilling LCA mounting holes higher in front cross member. Tension Rods with proper ball and socket joint are ideal for track. May be a bit noisy on the street. Poly tension rod bushings can break the tension rod. Some guys only install half the kit and that helps. But I'll only use new rubber bushings ( for street ) or ball and socket for Race. Personal choice. Camber and Castor specs seem fine. Strut braces front and rear are good. Poly rack bushings needed and in steering coupler.- 25 replies

-

- 1

-

-

- suspension

- spring_rates

-

(and 4 more)

Tagged with:

-

Instead of multiple O 2 sensors you could use electronic Pyro's in each exhausts header. Much easier to hook up with auxilary inputs in a stand alone than WB controllers. Most Dyno shops have test headers for engines with individual Pyro's. Nascar, WEC and F1 engines all are tested with individual Pyro's per exhaust port. I've seen video's of Renault V8 and V10 F1 engines on the Dyno, and they only used 1 WB O2 sensor per bank, FWIW These days F1 engines are using Turbulent Jet Ignition. Big hush hush stuff. Main reason why Mercedes has had such a dominant engine the last few years. http://www.enginelabs.com/news/f1-tech-what-is-turbulent-jet-ignition/

-

I used to Hillclimb and the heat from that beat the snot out of the oil and cause viscosity loss in some oils. Some of the " off the shelf " synthetics lose a lot of viscosity under heat. Mobile 1 ( new formulation ) and Castrol Synthetics seem to be the worst. Amsoil products are affected very little by heat. Used to pull a trailer loaded with all my Tires and extra gear up the Coquihalla . Long, long steep high speed mountain climb ( See Discovery Channels " Highway Thru Hell ) . Mobile 1 10w-30 would lose 10 psi by the top of the pull. Would slowly recovery when we got to the flats. Amsoil 10w-30 under same conditions lost only 2 psi. All of the true esters like Amsoil, Redline, Motul and Joe Gibbs seem to retain viscosity under extreme heat loads very well.

-

Yeah, Reddish Brown on the plugs is a sure sign of MMT. Sounds like your tune is safe rich though. I assume you're running Water Meth? Some of the Big Boost Turbo guys run an Auxilary tank that is just used for real Race Fuel when they really crank the boost. A small 5 to 8 gallon fuel cell for Track Days or Autocross. We can't get E85 in BC. E85 may be the way to go eventually for you, since you live in Cali. It's readily available there isn't it? That would require a different ECU ( and injectors ) , but a MS 2 Pro assembled is only $445 from DIYAUTOTUNE. And you could sell the JWT ECU for good money. Would give you a lot more Tuning Options. https://www.diyautotune.com/product/megasquirt-ii-ems-system-smd-pcb3-57-assembled-ecu/ A MS 3 Assembled is $659. Thta adds a lot more outputs and allows you to run COP ignition and full sequentail fuel injection $659 at DIY: https://www.diyautotune.com/shop/megasquirt-assembled/megasquirt-3-megasquirt-assembled/ E85 would be the way to go IMHO....

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

That's very interesting. Contrary to what I've read in several cooling articles in reputable articles in Race Car engineering, Circle Track racing and other Technical books. Those recommendations apply to racing cars though, where heat management is critical. Carroll Smith recommends to avoid mounting any auxilary cooler in front of the water radiator. That's relatively easy to design in a Race car, but not always practical in a passenger car. Nice installation of the Setrab. I like how you've used rubber mounts to isolate the oil cooler from vibration. A critical point often over looked.

-

Silver Mine Electric PS kit

Chickenman replied to Chickenman's topic in Brakes, Wheels, Suspension and Chassis

Looks like it uses a Factory Nissan upper column, so I would say yes. Contact Silver Mine and ask them. -

In addition to the above: Lack of fuel will also cause cause misfiring, lack of power under boost. Clogged fuel filter or a Fuel Pump going bad are just two of the causes. Boosted engines will really show any weakness in fuel area. Can be fine under light load, but will get worse with higher engine loads. An instrument panel Fuel Pressure gauge is as valuable as a Boost Gauge on a forced induction car. You can get remote units with reliable sending units that do not present the interior fire hazard as the old mechanical units. Problem is, weak ignition and weak fuel pressure/volume can cause almost identical symptoms. That is why you need to monitor Fuel Pressure in real time. Are you running a Boost Gauge? How much boost do you run and what do you have for a fuel pump etc? High Boost needs LOTS of fuel.

-

Since you JWT ECU does not have any real time feedback control... the only real thing affected by any O2 contamination is likely your O2 sensor for your AFR meter. If the engine is happy... don't screw it up with possible erroneous Instrument readings. Would still like to see pictures of those plugs...

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

Got it now. But 4 to 5 psi varience in Fuel pressure really doesn't affect AFR all that much. Edit: Octane additives also change AFR values. Could still be an O2 sensor going south due to contamination. Particularily if you are using Octane Boosters on a regular basis. . Personally I don't trust Torco products. If an Octane Booster contains MMT even small amounts, then the O2 sensor contaminates the O2 sensor. Apparently Torco contains a fairly large amount of MMT and that is not good news for O2 longevity. Google: " Does Torco Octane Booster contain MMT ". Lots of people seem to be having issues with it and O2 sensors. Contrary to Torco's advertisement claims that it won't harm sensors and Ctalytic convertors..... take it with a grain of salt... but something to consider. MMT is one of the most effective Octane Boosters... but it has drawbacks. MMT was banned from pump gas in Canada around 2006 and I believe earlier in the USA. Pull the O2 sensor. If it looks Reddish Brown or Orange Brown, that is likely MMT deposits and WB O2 sensors do not like it. https://www.svtperformance.com/forums/threads/anyoe-use-the-torco-fuel-additive-in-place-of-race-gas.647110/page-2#post-9016727

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

The above points to a reason why a good stand-alone can be an advantage for the weekend warrior over a converted factory ECU. Particularily an older style such as the JWT. The ability to run multiple fuel and spark Maps is huge. You can tune your car to run at reduced boost and optimized fuel tables for 91 pump gas. And then flick a switch and have it optimized for Race Fuel or even E85. Might be something to consider down the road.

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

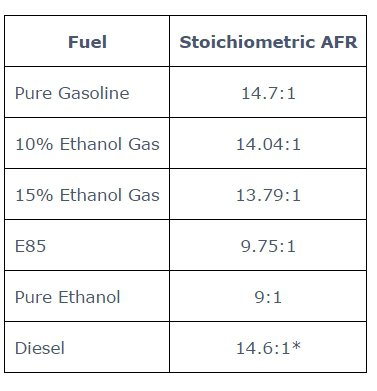

Knowing exactly what fuel you are running is extremely important with AFR meters. Less so with Lambda meters. They are NOT the same thing. WB O2 sensors output Lambda values. Stoich is always 1.0 Lambda However, depending on fuel, a Lambda value of 1.0 can vary greatly when converted to AFR. AFR meters convert the Lambda value to a table for a specific fuel. Usually pump gas. Some has switchable tables for E15, E85 Diesel etc. There lies the problem. Even pump gas varies quite a lot in formulation. A Lambda value of 1.0 with Shell pump fuel may output a different AFR reading than Chevron pump gas. Race Gas does not have the same AFR values as Pump gas at Stoich. That of course affects values at WOT when mixture is richer. The following article explains the difference between Lamda values and AFR. Be sure to read the complete article. It's very interesting, and shows why AFR meters should be taken ONLY as a guide and not an absolute. http://www.ultra-gauge.com/customer_support/knowledgebase.php?article=29 Hope I'm not confusing things to much... but accurate data and accurate data interpretation is all important. Bottom line. Always give the engine what it wants. Instruments can lie... the engine won't.

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

Delete

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

Edit: ECU and Lambda AFR Meter could very well be using separate O2 sensors. WB sensors did not start to be commonly used until 2000, when OBD-2 spece was brought in. Previous to that NB was used in most cars. However, most modern AFR gauges are all WB now. Some have auxiliary outputs for an extra WB output and/or an emulated NB output. I believe that the OP bought a JWT kit that includes a modified 88 -89 Z31 ECU core. Part # E280U-TMU4F . These would use a Narrow Band O2 sensor. I don't think they can be converted to WB. Is this correct?

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

Innovate and OBX carries WB heat sinks. You may be able to find them cheaper elsewhere. If WB O2 sensor is close to Turbo, you may be over heating it. Innovates is $89.95. OBX is $49.95. Read the Innovate tech information though. http://www.innovatemotorsports.com/xcart/product.php?productid=16148 http://www.ebay.ca/itm/OBX-Racing-Sports-O2-Sensor-Heat-Sink-Bung-Extender-for-Wideband-Controllers-NEW-/191165135135

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

Obvious question, but is the Race Gas Lead free? If not O2 sensor is likely contaminated. What race gas is it. Is it E85 by chance? How close is the O2 sensor to the Turbo? You may need a Heat Sink for it. WB sensors are more sensitive to excess heat than NB sensors. I'll try and find a link. Another question, and we need this one answered please. What was the exact pressure that the FPR was set to at idle and was the vaccuum reference line to the FPR disconnected or connected when you set the Fuel pressure? Curious. If you have a Lambda gauge and the minimum reading is 1.0. That equals 14.7 AFR with Gasoline. So how are you measuring any numbers less than that?

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

I agree with ZH. I wonder if you're chasing ghosts. Car seems to run strong?? You see no black smoke from tail pipe. Could be an instrumentation error. I've had O2 sensor get contaminated and give false readings before. It doesn't take much. Silicone used in the wrong place, leaded fuel ( race track fuel or Aviation Gas ) of course, over heating of WB sensor ( this is often over looked on Turbo cars ) will all cause inaccurate readings and drive you nuts. If it's really that rich (9.5 to 10 ) the plugs should show it. Pull the plugs and take a picture with a good quality camera. No flash. Flash will skew the colors. Have you ever done a WOT plug cut with fresh plugs? That will tell you what's really happening in the engine. For the gauges. I'm only seeing a Lambda gauge. ( Top dash panel left gauge ). Can't tell what the minimal reading is... but it looks like 1.0. Is that correct? As for the FP gauge, that is the left hand digital gauge in the passenger foot-well correct?

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

Video clarifies a lot of things. FPR seems to be working fine. No over pressure that I can see. 22 lbs boost and 62 lbs FP. Perfect. Turbo spools quickly and FP keeps right up with it. Fuel Pressure at idle with Vacuum hose disconnected is 40 PSI correct? Add 22 lbs boost and FP should be 62 lbs. which is what we are seeing. Not seeing 27 lbs of boost in this video. Boost to FP correlation seems correct, 1: How tunable is the JWT ECU? Can you plug in, data log and tune with a Laptop or programming pad? I'd be looking at injector duty cycle closely. I'm not familiar with this ECU. If you can't program it with a Laptop or Pad, then you need a better ECU for a modification of this level. Edit: Found some info on the JWT 550 kit and reading . Looks like no data logging and no real time programming. In other words, 1990's technology. Not good. IMHO, get a better ECU. If budget can afford it Haltech , AEM, MicroTech are all very good. If you're on a budget, go Megasquirt. Lots of good technology available these days. You sometimes find a good deal on used HalTechs on E-Bay. The Honda crowd are always updating to the latest and greatest systems. Most systems these days have " AutoTune" where you set the AFR required and system will self tune to that level. PS: Love how you've integrated the gauges. What pod did you use on the lower right side.

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

1: I agree with that for the most part, but you can have situations where an electric fuel pump has higher voltage applied to it at higher boost. Kenne Bell " Boost-A-Pump" and PWM controllers in EFI ECU are just two examples. Since we don't know all the details in the engine I thought I would mention that. Asked about that in post #5. Return lines need to be at least -6. 3" OP mentioned in Post #3 that he pulls 27 lbs of Maximum boost. 10 lbs boost was only starting point . OP. why don't you give Aeromotives Tech line a call. See what they say? Bit of a head scratchier. Edit: Notice you are using an electrical fuel pressure sender off the AFR. Do you have a secondary sending mechanical unit plumbed from the fuel rail to confirm pressure readings? Not the first time I've seen instrument failures drive you crazy. Don't use a Liquid Filled mechanical gauge. Inaccurate due to temperature fluctuations. Unless you buy a high dollar Liquid Filled gauge with a dial pressure bleed.

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

I purchased an A1-Cardone 280ZX Turbo dizzy from RA. Assembly quality was not all that great. Some clearance issues between trigger wheel and CAS. However, it's probably as good as any other reman dizzy. In other words. You receive it. Check everything for proper clearances ( air gap ) and lubrication. Re-manufacturers are infamous for insufficient lubes on things like centrifugal advance mechanisms and vacuum advance plates. Juts my experience. I often take reman alternators apart and re-pack the shielded end bearing. Seldom do they have sufficient grease. In fact, ANY shielded pre-packed bearing, I always check these days. .

-

Coil Overs. MR2 or Rabbit inserts.

Chickenman replied to Chickenman's topic in Brakes, Wheels, Suspension and Chassis

Koni 8641-1142Sport . 1988 Toyota MR2 rear shocks. $332 USD a pair from Trend Auto ( E-Bay Store ) with free(ish) shipping. Was going to get Koni 8610-1437RACE shocks. But live in Canada and take 35% hit on dollar. 8610's just not in the budget. Rabbit struts are apparently for cars that are REALLY slammed. -

What CC are those injectors?

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with:

-

Where do you have the Fuel Pressure Regulator plumbed in? To the Inlet side of the Fuel Rail or after the return side of the Fuel Rail. Can't really tell tell from pictures. That is a bypass regulator and should be plumbed to the return side to operate correctly. This gets more critical the more Boost you run. As per Aeromotives instructions: https://www.aeromotiveinc.com/tech-help/faqs/faq-efi-regulators/ I think you may have more than one issue. BTW, do you have a voltage Booster hooked up to the Fuel Pump. Like Kenne Belle Boost-A-Pump? You need big return lines with those.

- 57 replies

-

- fpr

- fuel lines

-

(and 6 more)

Tagged with: