-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

Camber change after 1.5" drop?

Chickenman replied to mtnickel's topic in Brakes, Wheels, Suspension and Chassis

Edit: Another product that is readily available now, is bump steer spacers. These correct the geometry of the A-Arm on lowered cars so it has a downwards slope again ( important for Camber gain during cornering, particularly on Mac struts ) and they also reduce Bump steer. It's a bit more elegant solution than moving the pivot location upwards. Relocating the pivot upwards corrects the Camber curve in roll, but does nothing to correct Bump steer. Something to consider. You can get software programs to analyze suspension movement. Price varies all over the map and depends on complexity. A little searching on Google will even find some Free programs. Usually Trial periods with limitations on function, but there are some Fully functional " Freeware" or Shareware programs that are fully functional. I personally haven't tried them though. Formula SAE sites are usually good. Student rates are also available. Here is one Free version that may be useful: http://suspensioncalculator.com/download.html There are also some basic " Real Time " models/calculators that you don't even have to download. This looks promising: Note: Logging in unlocks some more functions. http://www.racingaspirations.com/ And the Mac Strut calculator: http://www.racingaspirations.com/apps/macpherson-geometry-calculator -

Camber change after 1.5" drop?

Chickenman replied to mtnickel's topic in Brakes, Wheels, Suspension and Chassis

Aurora is hard to beat for quality and longevity. Get the best you can for the control arm Heims as they get a lot of constant movement. For a DD, I would get Teflon lined and use seals. For a Panhard rod, you don't really need Teflon lined because thye don't get the movement that A-Arms do. One thing that will extend the life of your Heim joints are dirt seals . There are two types. A saucer shaped type and a full boot type. You can order them online ( Summit, Jegs etc ) or get them at most 4x4 Performance shops. I think Mopac carries them locally. " Seals-It is a popular brand. . http://www.speedwaymotors.com/Seals-It-WS3125-Heim-Joint-Rod-End-Seals-5-16-Inch-Hole-Set-6,1528.html -

Camber change after 1.5" drop?

Chickenman replied to mtnickel's topic in Brakes, Wheels, Suspension and Chassis

Truer words were never spoken.. LOL -

Camber change after 1.5" drop?

Chickenman replied to mtnickel's topic in Brakes, Wheels, Suspension and Chassis

Yeah, I did that to my Race 510's and 1200's. Works very well. Doesn't matter on a Street car , but some Autocross and Race classes don't allow modifying of stock suspension mounting points -

Camber change after 1.5" drop?

Chickenman replied to mtnickel's topic in Brakes, Wheels, Suspension and Chassis

You can get Camber plates that replace the Top isolator mount. No major cutting or welding of strut towers required. I have a set of these ready to install this winter. You can make these work with stock springs or 2.5" Coil overs. They also gain you some shock travel. http://www.ebay.com/itm/MK1-PillowBall-Bearing-Strut-Upper-Mount-For-Coilover-Kit-Mounts-Plates-240Z-/161203739866?fits=Model%3A240Z&hash=item25887ddcda:g:CwUAAOxygPtS3Kbw&vxp=mtr -

Here is an interesting technical tidbit from Bosch. Pin #86 should always be connected to power and pin #85 to ground. Could it be so simple???

-

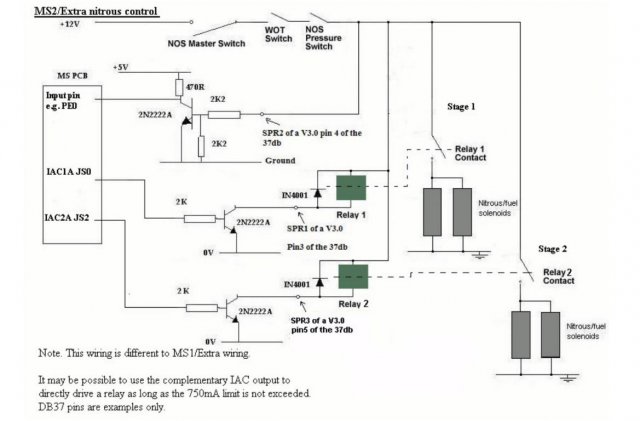

I don't know if this will help. But read page 162 of the following .PDF: https://www.google.ca/url?sa=t&rct=j&q=&esrc=s&source=web&cd=2&ved=0ahUKEwis6aWB8o3OAhVD4mMKHXkUAZkQFggkMAE&url=http%3A%2F%2Fwww.msextra.com%2Fdoc%2Fpdf%2FMS2V357_Hardware-3.3.pdf&usg=AFQjCNFGXeSKlg67qXwkE4cOeTpG4Tk65Q&sig2=fagImR11ddUweRK4t74U8A&cad=rja

-

Never mind... this is getting boring now. Some people I'm sure will get that. We " Trolls " have to stick together...

-

The outputs for switching on ECUs are normally always to ground. Pin #86 needs to be connected to a +12v source.

-

Yep. Some were trying to have fun with it. Myself included. I knew what Tony meant right from the get go. I think this Forum needs more Emoticons. Like : and Edit: I've always said that If Kruschev and Kennedy had E-Mail back in the " Bay of Pigs " era, that the earth would still be a glowing slag heap of molten Lava. Over and out...

-

Camber change after 1.5" drop?

Chickenman replied to mtnickel's topic in Brakes, Wheels, Suspension and Chassis

I think I'm going to drag my copy of Herb's book off the book shelf and read through it again. I've forgotten just how excellent that book is... -

Camber change after 1.5" drop?

Chickenman replied to mtnickel's topic in Brakes, Wheels, Suspension and Chassis

Hmm... this could be an interesting Technical discsussion Interesting because the Z is a front steer ( Steering arms ahead of axle centerline ). Front steer cars normally have neutral or Toe-in under braking. Thrust forces under braking, push control arm rearwards as suspension bushing compressed. Steering Tie Rods are shortened in Arc, which pulls steering arms closer to each other . This adds Toe-in under braking to counter-act the natural Drag forces on the tire that is trying to add Toe out. Rear steer cars ( Steering arms behind axle center--line ) can be a bit more problematic. Deflection changes in the control arm tend to add Toe-Out unders braking ( and cornering ) There are a few examples of this type of discussion on FSAE forums, but Herb Adams mentioned some of the advantages of Front Steer in his book " Chassis Engineering " on page 58. Interesting reading: https://books.google.ca/books?id=rY2ujnNrhf0C&pg=PA58&lpg=PA58&dq=Effect+of+Front+steer+and+rear+steer&source=bl&ots=HgODf6wQ6C&sig=VD1jWdUzvn0i9OrrvmtN7ww1XXs&hl=en&sa=X&ved=0ahUKEwihk5mNwYfOAhVV92MKHXwGDFQQ6AEIJzAB#v=onepage&q=Effect%20of%20Front%20steer%20and%20rear%20steer&f=false -

^ Actually the stock throttle body does have a TPS. It's just an very early style and quite crude. But it still has to be adjusted properly

-

^ I was referring to how it was listed... 72c being at the Top. Weird how people interpret things differently...

-

Camber change after 1.5" drop?

Chickenman replied to mtnickel's topic in Brakes, Wheels, Suspension and Chassis

Yes, there is definitely more than one way to skin a cat. I don't like car with really heavy steering. I prefer steering that is reasonably light so I can initiate quick corrections. I can't drive a non-Power Steering car with 5 degrees of Camber the way I like. I tend to drive more with my wrists than my arms. I don't use a lot of steering turn angle. Plus I don't have big arm Muscles... I like a car that is very much " On the nose " and a little " Loose ". .Fellow Autocrossers have driven my cars and most don't " initially " like how twitchy my cars are. Once they get some seat time tough, it gets a lot more comfortable and quicker. It makes for very quick turning car and one that excels in lineal slaloms and tight corners. Car is on a knife edge though and you have to be very precise on fast sweepers. And most important... it works for me and brings home the Trophies Strange thing is, I've never had to resort to Toe-Out, or a large amount of Castor or Camber to get the Nose to turn on hard and take a set...on any of my Race cars. But I also run a LOT of rear brake Bias ( that really helps rotate the car ), Trail Brake and I will often run rubber frame bushings on the front bar. Depending on the thickness of the bushing, this will reduce the initial stiffness of the front bar by 10 to 20% on initial turn-in ( Compared to Poly bushings ), but as it compresses the rubber stiffens. Give a type of progressive front bar rate, so the car turns in quickly initially , then once the front end has taken a set, stiffens up to prevent roll. IME this has worked well over the years.... for me. I also use a smaller bar for the front when Autocrossing than when I am Road Racing or Hillclimbing. EG: On my heavily Modified Camaro, I would run a 32 mm hollow Front bar with Rubber frame bushings ( They aren't very thick ). At Hillclimbs or Track Days I would run a 34mm hollow Front bar with Poly frame bushings. Both bars were adjustable. For the higher speed events a tad of under-steer is nice. Just a tad though for me... I hate under-steer. One thing I do highly believe in is fine tuning car rotation with rear brake bias. Probably comes from my Rally Car days, but it is very effective... especially in Autocross. The most important thing is to get a setup that you are comfortable with.... and is fast of course. That takes seat time and test days. Fortunately our local scene has lots of both. -

Camber change after 1.5" drop?

Chickenman replied to mtnickel's topic in Brakes, Wheels, Suspension and Chassis

If you get the spring and bar rates correct, you shouldn't really have to run much Castor. Stock castor settings are more than enough for Autocross from my experiences ( and my setups ) . Any extra, really just makes them a bear to steer with wider sticky tires. I've seen way too many guys crank in a bunch of Castor because of articles they've read on extra Castor inducing Negative Camber on Mac struts. It's not needed in my experiences and you can do far more with balanced Spring rates, reasonable bar settings, Camber settings.and .... proper rear Brake Bias ( the last one is very important ) Extra Castor increases steering effort a lot and it also adds weight jacking to the outside tire, which can be detrimental. I always like to keep Castor settings and steering effort reasonable for Autocross. My Autocross cars ( Datsun 510's, Datsun 1200's, 240Z's, Big HP 2nd and 3rd Gen Camaro's and Audi A4 Quattro's ) have all had great turn-in, and are very much on the nose. Quick directional change, crisp Turn-in with no under-steer is very important in Autocross. The AWD Audi A4 is well known to be an under-steering pig, but with a few setup changes to springs and bars, even those can be tamed. I hate under-steer with a passion.... Personally, I have never been had to use " Toe-out " or any other Tricks to get the nose to Turn-in on any car I've ever competed in. Autocross, Road Race or Hillclimb. Those who do have to use Toe-out to get crisp Turn-in usually have their springs rates out of balance or have some underlying geometry problems that need to be corrected. Toe-out is a bitch on a daily driver, especially in the rain. Not that we get much of that here...right? One thing that will definitely help the front end bite is a Strut Tower brace. A strut bar that is triangulated to the firewall is the best of course, but even a strut bar just between the two towers makes a noticeable difference. . Triangulating the steering rack mounts to the frame horns also adds rigidity. If you plan to compete on a regular basis, check your local rules to see if you are allowed to do this. BC Region runs SCCA rules now... -

The big change in oils for high performance cars has been since the early to mid 2000's, when the EPA mandated the reduction of ZDDP in engine oils. This was to extend the lifetime of factory catalytic convertors. Reduction in ZDDP levels have caused countless problems in the High Performance and Vintage world. All due to the reduction in ZDDP levels. For high performance cars and Vintage cars with flat tappet or finger follower valve trains it can be a big issue. Particularly with higher rate valve springs. The oils back in the 70's through 90's were actaully better in High Load camshaft to lifter protection than todays " off the shelf " engine oils. Avoid anything Energy Star rated. Period. Research what Hot Rodders and Vintage car owners are using. Myself and others have made some good recommendations in this thread. . I wouldn't go with a straight 30wt as a regular oil . Multi-Weights have many advantages. Cold start lubrication being much better. And synthetics jsut win hands down. Use a high ZDDP 10w-40 , 15W-50 or a 20w-50 depending on ambient temp. You can get away with a 10w-30 is you use a high ZDDP content " Niche " oil such a Joe Gibbs and others. Stay away from " off the shelf oils " of 10w-30 or lighter on the cold weight as these are nearly all Eber4gy Star oils with reduced levels of ZDDP. Here are a couple of sites to get your reserach started: http://www.bobistheoilguy.com/forums/ubbthreads.php?ubb=cfrm The following has databases on ZDDP levels of some popular oils and quite a bit of discussion on the ZDDP issue with Vintage and High Performance motors: http://forums.vwvortex.com/showthread.php?5867396-Built-Engine-Big-Turbo-Heavily-Modified-engines%28aftermarket-cams%29-what-Engine-Oil:

-

The 15w-40 is an HDEO Dino oil correct? Yeah, even the Diesel and HDEO engines are getting ZDDP reduced, although not nearly as much as oils for Petrol engines. I wish Rotella made the T6 Synthetic in something other than a 5w-40. A 10w-40 or a 15w-50, 20w-50 would be awesome. The 5w on the cold spec is just a wee bit too thin for my comfort with the fairly large bearing clearances that L-Series engines were designed with. I use the Rotella T6 5w-40 on my Audi Turbo. Awesome oil. 10/40 Joe Gibbs Hot-Rod Synthetic on the 280z. using the above break-in in procedures, I've gone 4,000 miles since my first synthetic oil change with out burning a DROP of oil. ( Brand new engine built from ground up ) Pretty impressed with that.

-

In the early 1980's... when your engine was built, engine oils had a TON of ZDDP in them. Camshaft breahin was not really an issue. Today in 2016 things are a LOT different. ZDDP content has dropped tremendously in most motor oils. Looking at the pictures of the camshaft, that engine has nearly zero hours on it. As the FSM states. the first 1,000 miles is the most important and it still is. However, you have to take extra measures to break in the valve train properly because of the current lack of ZDDP in most oils. This would be some of my procedures for starting an engine that has sat for 35 years. 1: Drain and replace all lubricants, fuels coolants and change the oil filter. Remove plugs, disable ignition and injectors. You may want to change the W/Pump as a precaution. If the engine sat with no coolant in it for a long time, the W/Pump seal has probably died out. 2: Fog the cylinder bores with a winter storage lube or squirt some ATF in the cylinders. Cylinder walls are likely going to be bone dry after sitting for 35 years, unless the engine was fogged before hand. 3: Remove the rockers and lube all the pivot ends on ball studs and rocker cups with Cam break-in lube or a good Moly based grease. Reassemble and do an initial valve adjust. 4: Coat the Cam lobes liberally with Camshaft break-in Lube from Isky, Comp Cams Edelbrock etc. Pour a full quart of your favorite Dino break-in oil liberally over the Camshaft, rockers, rocker pivots and chain. 5: Use a high ZDDP Dino oil such as Delo 400 30wt, Pennzoil 20w-50 or any of the purpose built break-in oils made by Brad Penn, Joe Gibbs etc. 6: Prime the engine by pressurizing the oil gallery or using a modified distributor shaft with the gear machined. Off Pull the valve cover and prime that baby until you see oil coming out of the oil spray bar or cam lube holes. Have a mechanical gauge hooked up so you can see the actual pressure as well. If you use a pressure feed through the oil gallery, make sure you don't over fill the sump. That is very important. 7: Once you have oil coming out of the top end, turn the engine over by hand to distribute oil in the cylinder bores and all around journals. Don't use the starter motor until you are absolutely sure that you do not have any stuck rings. The starter motor has enough Torque to break a partially stuck ring. 8: After turning over by hand, coat the Camshaft AGAIN with cam break in lube. 9: Prepare engine for starting. Top up all fluid levels. Install fresh plugs. Base time engine at 10 BTDC. Make sure battery is fully charged and has a HD charger attached. Prime fuel system. Have extra jugs of coolant ready to top up Rad system when it burps.You want this sucker to fire up at first crank and STAY running for 20 minutes with out having to shut it down or worse, let it idle for any length of time. Have a Fire Extinguisher or two ready to go. 10: Start engine and as soon as you have oil pressure, raise engine speed to 1,500 rpm. Check oil pressure!! Have helpers checking for fluid leaks etc while you monitor gauges and control throttle. After about 30 seconds. Shut off engine. Let oil drain and recheck engine oil level. All galleries and Oil filter should now be full and the level may have dropped a bit. Top up oil level as necessary. Do NOT over fill the sump!! 11: Start her up again and raise engine speed to 2,000 RPM. This ensure a good supply of oil reaches the Camshaft, rocker pads and valve springs( V/Springs are cooled by oil spray ). Do NOT let engine idle. Once water temp starts to move start varying engine speed between 2,000 RPM and 3,000 RPM ( no need to go higher ) . This is better than maintaining one constant speed. Helpers should be ready to add coolant when the rad burps. 12: Run the engine for 20 minutes with out shutting off if possible. Constantly varying speed. 13: At the end of 20 minutes, shut her down and drain all engine oil into a clean pan.Remove oil filter. Examine engine oil and filter pleats. Install fresh DINO break-in oil and a new oil filter. Set your timing and re-adjust valves. Fix any minor issues etc. 14: Drive car for 75 to 100 miles, constantly varying engine RPM. Do not take on freeway and do not lug engine. Vary engine speed and load. Don't let RPM get too high. Fisrt 50 miles no more than 4,000 RPM As you near 100 miles you can increase RPM to short bursts to 5,000 rpm. 15: After 100 miles change oil and filter again. Inspect oil and filter pleats. Install fresh Dino break-in oil and a new oil filter. Drive for 1,000 miles, varying RPM's is best, but you can use the freeway now. Juts don't keep the engine at constant RPM's for long periods. Shift up and down on Freway to vary engine RPMs. Engine RPM limit can be raise to 6,000 RPM as you pass 500 miles. 16: At 1,0000 miles... guess what? Change oil and filter again. But this time you can change to a good synthetic Ester oil. Engine should be fully broken in and can be used to Redline. Regarding oils, Synthetic or Dino. Do not use Energy Star oils and stick the the thicker weights. ( Thicker weights 10w-40 and above are generally not Energy Star compliant and contain more ZDDP ) . There is a ton of info out there on what to use. But as far as Synthetic oils, the same names always come up to the to the top of the list. Amsoil, Redline, Motul, Joe Gibbs Brad Penn. For those who prefer Dino oils, Joe Gibbs conventional, Valvoline VR ( change it often though ) , Pennzoil 20w-50, Brad Penn and a few others are pretty good. I haven't used Dino oils since the 1980's though...and I never will. Synthetics are just so much superior. Particularly Esters, PAO's and MAO formulations. Your opinion may vary and that's fine and dandy. Hope this helps.

-

Camber change after 1.5" drop?

Chickenman replied to mtnickel's topic in Brakes, Wheels, Suspension and Chassis

These are what I ended up getting. Not as much adjustment as some, but you don't have to cut out the strut towers. http://www.ebay.com/itm/MK1-PillowBall-Bearing-Strut-Upper-Mount-For-Coilover-Kit-Mounts-Plates-240Z-/381703716541?hash=item58df507ebd:g:CwUAAOxygPtS3Kbw&vxp=mtr -

Camber change after 1.5" drop?

Chickenman replied to mtnickel's topic in Brakes, Wheels, Suspension and Chassis

I've been Autocrossing in BC since the mid 70's. We have a very Healthy Autocross scene here with many Test Sessions and driver training courses. Velocity by VCMC for example. Personally I think a 175 front 200 rear spring combo is too soft in the front for our events and tracks. I'd go with at least a 250 frt 200 rr combo. The hot setup for VERY fast street and Autocross 510's is a 300 lb front spring on ZX struts. The 510 is much lighter than a Z up front, yet the ride isn't too bad. Surpringly smooth as a matter of fact. You're going to get different theories on spring and bar combo's, but the current PNW Coast Autocross " Hot " setup on 510's and Z's seems to favor a " moderately " stiff spring with the softest front bar you can get away with. This gives good initial turn-in due to the soft front bar, yet still supports the outer corner. And it prevents nose dive. A big consideration is that we run a lot in the wet. Big front bars just make the car under-steer in the rain. I'll give you a PM with some contact info. I'm a BC Z Registry member. We may have already met at some of of the Club's meets??? Richard -

kona41: What size rims and tires are you running?

- 18 replies

-

Shouldn't that read the bottom two?

-

Integrated Engineering makes some external mount Surge tanks that will house one or two Bosch 044 EFI pumps. These really quiet the pumps down and alos allow them to run cooler. http://www.performancebyie.com/ie-submerged-044-billet-surge-tank

-

I can see the parting lines fine. And they are wide like most forgings are. Those are OEM Nissan rockers and I highly, highly doubt that Nissan would be using cast parts. Or allow any of their manufacturing partners to deviate from factory specs. Forging dies and moulds do wear out over time. It's certainly no big deal for a manufacturer to have new ones made. It's done all the time. And as mentioned the 13257-W0300 is the superceded number for all L-Series rockers.