-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

[help/opinions needed] Oil pressure won't go past 40psi.

Chickenman replied to Jazz86's topic in Nissan L6 Forum

I've seen Oil Pump Screens partially blocked Silicone Sealant. Especially by so called " Mecahnics " who goop the Oil Pan with the stuff. Draining Oil will sometimes allow silicone to drop off screen. Thne float around till it partially clogs screen again. Oil screen pickup too close to bottom of pan can also cause an Vortex effect that affects oil pressure. Screen should be no closer than 1/2 inch from bottom of pan . You also say you have a Turbo Oil Pump. But is it an OEM Nissan Aluminium Pump. I seen some of the Cast Iron aftermarket pumps lacking in pressure output because Internal ports or claerance are machined wrong. Surprisingly some of the Melling pumps are causing issues at higher RPM's. I've had a couple of customers have issues with Melling Crat Iron Pumps. Strange, because thye are normally good quality. You can still purchase OEM Nissan Aluminium Turbo Oil Pumps from Nissan. 15010-S8000. And Rock Auto sells Hitachi made OEM Nissan Turbo Pumps. Hitcahi is an OEM Maufcaturer for Nissan. -

Took a well needed break for a while, but still doing MS3Pro, MS3 and MS2 tunes. As well as Haltech, Link, Holley and Maxx-ECU.

-

You can run a standard 280Z Distributor in that as well since you have a single coil setup. Just use the VR sensor setup. You will set your Trigger settings up as up as a Standard Distributor with Single coil and Batch Fire injection. Then no Home signal is required. You really only need a Turbo dizzy if you want to run Sequentail Fuel and/ or COP or Wastespark Ignition. But then the tactful ECU has to be BULIT with the proper " Modules " or optional hardware in place. Everything on MS-2 is " A La Carte " . You have to find out EXACTLY how it was specced out and built. Build info should be included with your ECU. See below. MS-2 from Godzilla usually come with standard Injector drivers ( A and B bank ) and a single High Amperage Coil driver ( BIP-373 ) already installed. Go to the MSExtra.com home site and download the Hardware manual for your Mother Board. On the case it should say if you have a 3.0 Main Board or a 3.57 Main Board. Download the correct hardware instructions. https://www.msextra.com/manuals/ms2manuals/

-

Haven't been around to this forum in a while Nice to see those numbers. Did you get a chart of the AFR readings?

-

Just going back to injector wiring for a moment. Yes it's fine to run all injectors off of one Power Lead. But that goes through a Relay direct from the battery. But the ECU triggers injectors by grounding. And you should be using BOTH injector driver banks with that. Even if using Multi Point ( all injectors fire at once ). Batch fire requires one bank of cylinders ( usually 1,2,3, ) firing from Bank A and the other Bank ( 3,4,5 ) firing from Bank B. But remember it's the ground side of the injector drivers that does the triggering. Once you have the injector wiring corrected, choose 2 squirts alternating as Tony mentioned. . That will enable batch fire. Multi-point is the least desirable method, particularly with larger injectors. The " Water Hammer " effect gets pretty bad. will cause spikes in actual Fuel Rail pressure. Batch fire is much better and of course true sequential injection is best for emissions quality and smooth idle. Negligible difference in power output at WOT between Batch Fire and Sequential at high RPM though. Everything is just happening so fast. Sequential does reduce available time to inject fuel over a 720 degree combustion event because it is Timed injection. By about 30% if memory serves me correct. If IDC are getting high, you can reduce them by switching to Batch Fire. Just an interesting but possibly irrelevant point in your situation.

-

Misfire /breakup and high rpm with stand alone AEM infinity

Chickenman replied to tioga's topic in Nissan L6 Forum

Don't think you have a engine internal problem Stephen. Other than possibly a slightly leaking oil seal on #6. But I don't think that is the main issue. Funny, I was just thinking about coils on your FB thread. Seems you had a lot of problems with those COP's. Going single coil with dizzy should be a good way to check to see if its' anything related to the coils. And yes, D585 coils are sensitive to EMI and electrical noise from large ground loops. . It can trigger Auto Discharge. One of the big things is that the Main ground for the GM Coils ( Not the Trigger ground ) MUST be grounded to the cylinder head. Grounding elsewhere creates a larger ground Loop and thus more EMI. Might be a good idea to double check the ground wires on all of the coils. Especially #6. Also had a couple of thoughts on the injector drivers in your FB thread. -

Aftermarket Front Control Arms

Chickenman replied to Ben280's topic in Brakes, Wheels, Suspension and Chassis

On our Third Gen Camaro spindles we used to get a lot of spindle flex with Big sticky DOTs and slicks. We used thick walled ( 0.250" wall ) bearing spacers that were machined to slip over the the Bearing spindle with a matched Tapered ID . We used shims to get the preload correct. -

You shouldn't need to drill the oil restrictor out at all. Plenty of oil available by Spray Bar system or internal oiling of Camshaft. One caveat, idle speed. With higher pressure springs or ven stock springs with a more aggressive profile, increase idle speed to no less than 1,000 RPM. Local Datsun Engine guru Andy Pearson ( Specialty Engineering ) recommends this on all of his modified engine builds. Since Andy's car have hold 5 SCCA GT3 runoff titles in 5 invites ( An SCCA record ) ... pretty sure he knows what he talking about. BTW, he's done a lot of oil testing with Big Camshafts. Motul 300V has proven the best oil to use on REALLY big Camshafts. Some of his " Street " stroker engines have over 0.600" valve lift. Rockers will sometimes fail before cams with OEM Japanese cam cores . This is a result of either oil film failure or Valve floating. You will see a pitting or flaking of rocker pad. This is a metal fatigue failure. Either oil film breaks down, or you have Valve float. Usually valve float. You get a hammering effect on Cam Lobe and Rocker arm when Valve bounces on seat. Pound the s**t out of the Valvetarin.

-

280zx ignition module with Megasquirt - is it necessary?

Chickenman replied to supernova_6969's topic in Nissan L6 Forum

Use the DIY Custom L28ET trigger disc. That will give your the necessary Crank and Home signal to run either Direct COP or WastSpark COP. The LS coils have their own built in Ignitors. So you would NOT install any BIP 373' inside the ECU. The BIP373's are 12 volt DUMB coil igniters by themselves. You need to build Logic Level coil drivers circuits ( Low amperage 0v to 5v ) in the ECU. Read the MSextra Hardware Manual on how to do this. May as well build 6 Logic Levels drivers and use Direct fore COP instead of Waste Spark COP. There are a number of advantages including the Option to use separate Ignition Timing Trims per cylinder when you do it that way. Edit: Read section 5.3.1.3 ( Page 77 ) in the MSExtra 3.42 hardware manual on how to build Logic Level Spark outputs. Use the FET method. You may have to add an extra DB15 connector if you run out of pins on the DB37 ( Section 5.3.1.5 Page 80 ) There are 3D printed covers and Biller aluminium covers to replace the dizzy cap available.- 30 replies

-

- megasquirt

- ignition module

-

(and 1 more)

Tagged with:

-

Possible spark blow out. How small of a gap can I run

Chickenman replied to dpuma8's topic in Turbo / Supercharger

Exactly. Coil secondary output can drop up to 15% with a voltage drop of only 1.0 volt. A correctly operating charging circuit on a Datsun should put out 13.5 volts easily. ALL the way from idle to Redline. At 11.5 volts you could be seeing over a 30% drop in Coil output. European cars typically put out a bit higher voltage. 14.1 to 14.2 volts charging is not uncommon on most European cars since the mid 90's. -

Steve Bonk is on FB page Church of L-Series. He normally has a few Don Potter cams for sale. Juts awesome cams if you don't know Don Potters history...

-

For a true test of ride comfort. drive your Z car from Blaine Washington to Seattle on the I5. Rough concrete with expansion joints for most of the way. Just came back from SOVREN Vintage races at Pacific Raceways. My 76 280Z has front DIY TT3 Coil overs, 250 lb/in Eibachs and Koni Sport Yellow shocks . Rear is " temporarily " Eibach Pro springs ( Don't know rate but they are pretty soft ) with KYB gas struts. Edit: Forgot front Camber plates . Rear temporarily has the front Nissan top insulators installed to lower rear. Will be getting Camber plates as well. Front was very comfortable on the street and on the I5 . I5 is brutal on cars with too stiff of springs and shocks.. Koni's are on setting 1 at the moment, but I will probably be turning them up to a 1.5 or 2. Rear shocks and springs are comfortable, but too soft. I'll probably go to 225 or 250lb/in on the rear as well with Koni Yellow sports. TT3 Coil over kit. Soft rear springs show up on track days when I get a bit too much rear squat exiting corners. 1.125" ST front Bar and 0.875" ST Rear Bar. Tires are Continental Extreme Contact DW in a 225/50x16" . The taller sidewall really soaks up bumps and expansion joints well. Very good Traction in Dry and Wet. Wet traction is important in the PNW. I may switch to a 225/45x16 in the Future. The Conti's are just a tad too Tall at 24.9". Considering amount that car is lowered. I'm using new stock rubber bushings all around for noise isolation and comfort. The stock rubber LCA bushings are far better than Poly. Monoballs transmit too much road noise for " my personal " street car. Been down that Road before. This is just going to be a nice, quiet GT Touring Car. As you get older you appreciate comfort more and more. Picture of Camber Plates used for front and rear:

-

Race Car Brake Assistance, no vacuum available

Chickenman replied to 260DET's topic in Brakes, Wheels, Suspension and Chassis

Like John M, I also used a Non-Booster equipped Road Race 240Z back in the Day. You have to eliminate the Booster. Make a Custom length Pushrod. Depending on you Pedal effort, you may want to relocate the Clevis Pin hole in the Brake pedal upwards a bit to change the Pedal ratio. About 0.750" to 1.0" is enough. We used a standard 7/8" Master on our ICSCC D-Prod Z . Worked out very well. Good modulation with proper setup. -

Getting my own Haltech E11 dialed in. Very powerful ECU ( Full Seq Fuel on a V12 and wasted spark with V12 ) , but old school. No VE Calculation. Uses Raw Injection Time... which took a bit of head scratching to work out. But it's all just Mathematical calculations in the end. Kinda like using DOS... but it works just fine. Think it's an Ozzie thing ( Haltech is Australian based ) as even the latest Hatech's still use Raw Injection Time... plus VE Calculation and Mass Airflow calculation methods of course. Nice to have choice. Dialed it in by driving the same 100 Mile Loop over and over. Data Logging the whole way. First 200 miles I used a Co-driver, and just worked the Tuning software in Real Time as we drove. After 200 miles, the Tune was good enough that I could just go Solo and DataLog. After 500 miles of Data Logging , Tune was good enough that I was pulling Cruise AFR at 15.0 to 15.5 ( Getting 30+ MPG ) and 12.5 to 13.5 at WOT ( Normally aspirated ). I've since been playing with fiddly little stuff such as Hot Start enrichment and Cruise AE tip-in values. Hot and Cold starts are now instant. Way better than stock Nissan ECU ( 75 280Z NA with engine Mods ) . Hoping to get on a private Race Teams Dyno soon. Dyna-Pak Hub dyno soon. Waiting on a couple of Ford GT's so a Tuner friend can Tune those and then I'll pop the 280Z on the Hub Dyno at the end of the day. Hub Dyno's are so cool.

-

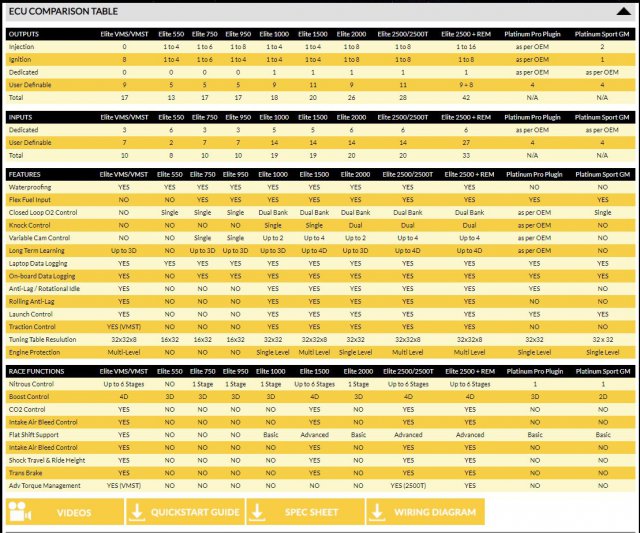

You can compare the different Haltech ECU's here: https://www.haltech.com/product-overviews/ They also have Videos and a comparison chart. The Elite 1000 has a few more advanced I/O features than the Elite 750, but not as many Inj drivers and coil drivers. The 750 is also cheaper than the 1000 . There is a trade-off between more features or more drivers. There are comparison Charts at Haltech. You may not need the Launch control, Traction Control or Knock control. ( Since the L28 has no knock sensors )

-

Elite 1000 only has 4 Ignition Drivers and 4 Injection drivers. I would go with the Elite 750. It is purpose built for 6 cylinder engine and will do everything you need. Go to the Haltech Group on FB. Look up Claudio Taverus Peynado . He used to work for Haltech and has his own shop now. He is a Haltech distributor. https://www.facebook.com/groups/haltechtuningandtips/ https://www.haltech.com/product-overviews/

-

1: What are you using for Spec Torque? FSM says 87 to 116 Ft Lbs. 87 ft/lbs is NOT enough. Use a new bolt and go to Maximum Torque. Or even a Tad Over. Threads inside and out MUST be cleaned and lubricated with either oil or Loctite. Dirty threads will result in bolt being under torqued and it will not reach it's Stretch or " Plastic " specification. 2: Do you have the correct length Factory bolt with factory thick washer? Washer is very important. Threads will bottom out in crank if you use the wrong washer. 3: Buy a new Factory Nissan bolt. Bolt may have stretched beyond it's " Plastic " state. Once that happens they will not maintain torque. 4: Is the Harmonic balancer stock? Some of the aftermarket hubs have a thicker hub and require a longer crank bolt. Found that out the hard way on a Tilton damper. Damper loosened and bent the crank snout. It was a Tilton crank... so BIG $$$$$ 5: What type of Loctite are you using> Medium strength ( Blue ) is not good enough. You need the Red high Strength Loctite 462. Just a couple of drops. Make sure threads are clean. Inside of crank and on bolt. Use Brake Clean. Really, on a street engine, the Loctite should not be necessary. I would suspect that the Bolt is " Stretchy " , threads may be worn or you are using the wrong bolt and washer. These things should not back out... unless you are constantly twisting over 8,000 RPM. One other thing I just thought of. If the damper came loose onec... you may have bent the snout of the crank. Check the radial runout with a dial indicator. I'll have to double check.. but I think the limit is .002" . If snout is bent it will setup vibrations that will keep loosening the damper

-

Link G4+ Storm is also a good alternative. But the Elite 750 is a very nice ECU. I've tuned both... which is one reason I'm getting away from tuning a different " Build it yourself " brand. The difference in quality of a " REAL " ECU is amazing. Haltech and Link just work properly out of the box. Period.

-

Haltech Elite 750. One of Health's entry level ECU's, but it is purpose built for 6 cylinder engine. Comes with 6 logic coil drivers and 6 High or Low Z injectors drivers. The Low Z injector drivers are true Peak and Hold drivers. Not the cheaper, slower and less accurate PWM Current limiting drivers found on some popular " Build it yourself " ECU's. For a single Ignition coil you will need an external power amplifier. 0v to 5v logic level. The Nissan PRW-2 module is a perfect match. You can find them used for about $10 on E-bay. The Nissan OEM PRW-2 modules are powerful and last forever. Used original Nissan Modules are preferred over Chinea manufactured crappola. Like OEM GM LS-2 coils over aftermarket clones.

-

Post your currenttune.msq

-

Looks like your Spark A ( Cylinders 1 and 6 ) coil pack isn't firing for some reason. Or is misfiring. Misfires will always show Lean on an O2 meter... even though plugs are wet with fuel. Check your Ignition settings for the Quadspark. Pay attention to proper grounding. https://www.diyautotune.com/support/tech/hardware/quadspark-ignition/megasquirt/

-

One of the interesting things the Audi BT guys are doing is putting a 4" expansion section on the downpipe. This really results in a drop in Exhaust back pressure. Quicker spool and higher WHP. They are transverse mount, so limited by space. But even a shortish ( 12" ) expansion pipe made a noticeable difference. I suspect a 4" downpipe on an L-6 then taper to 3" or 3.5" exhaust would certainly help.

-

Finally got my 280Z sorted and took it out for an Initial 100 mile Road Tuning session. Went quite well. Ancient Haltech E11 with none of the fancy Tuning aids is certainly a challenge to Tune. But I like a challenge. Good and very powerful ECU... just very basic software. Raw Injector Timing tuning. No VE tables.. Slide Rule and abacus stuff... but it works. What you see is what you get. It's kind of like DOS compared to Windows XP. New stuff is just so much easier... Now to enjoy some cruising on week ends.

-

Run the MS3 ECU main grounds to the engine. ( As per MS Extra Hardware manual ) . Intake manifold or cylinder head preferred. " Star Ground " the Speed Hut gauges to the same point on the engine as MS ECU ground. Voila. No voltage potential difference. Gauges can be grounded to engine, battery or Chassis. When running as a stand alone gauge it doesn't matter where you ground the gauge. But when tied into an ECU they need to be on the same ground plane. Chassis grounds on 40+ year old Vintage cars are the worst place to ground ECU's and other engine devices. .

-

Just want to thank all of my past customers and current customers for their support. But I am taking an indefinite break from Remote Tuning. It's turned out to be too successful, so much that I no longer have time for my own projects. I haven't driven worked on my own 280Z in Ages, and I find I'm spending far too many hours staring at Computer screens. So I'm going to take an extended break and enjoy life . Time to travel and enjoy my retirement. I'll be finishing off Tunes and details with past and current customers. But I will not be taking on any new customers in the foreseeable future:. Thank you all for your support. Richard Boyk