-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

Any cam experts? Colt Cams adv duration vs @0.05"

Chickenman replied to turbogrill's topic in Nissan L6 Forum

Ok, finally got some answers back from the Old Fart experts at The510Realm who use M445 Cams regularly. Yes you can use Flat Top pistons with no valve reliefs. Got that from any engine builder who regularly built 510 motors with L24 FT pistons. I would check the piston to valve clearance though, just to be 100% sure. He also mentioned that new stock valve springs could be used, That I'm a little wary of. You do have to check for coil bind very carefully with stock springs. I think I would follow Rebello's recommendation on valve springs. You don't need anything super strong, but you do need a slight increase in pressure if you want to pull 7,000 RPM or so. IMHO that is. When I was Racing 510's and 240Z's back in the day, we always upgraded to the Roadster springs. The Roadster springs would handle more lift before coil bind and were a bit stiffer than the stock L series springs. They are still available at DatsunParts.com Standard Roadster springs: http://www.datsunparts.com/2109 Uprated aftermarket Roadster springs: http://www.datsunparts.com/1665 Of course you may want to pressure check the springs that are on that head. may have been upgraded already. That would be nice .180" Lash pads are the size you need. Stock Steel retainers are fine. You may want to trim the bottom of the retainers for more retainer to stem clearance. Check your retainers first. PO may have already done that. Or you can use a shorter seal. Ford V6 are popular as are Datsun A12 seals. -

What HP level are you aiming for? There are several Injector size calculators on the net. Here's one I like. Here's a couple I use: http://www.dainst.com/info/programs/pw_calc/pw_calc.html https://www.rbracing-rsr.com/calcinjpulse.html

-

Call the machine shop and ask them if they replaced the valve seals. Not replacing them could certainly be an issue. Is this a Normally aspirated engine or a Turbo. Comment about headers made me think it was NA, but then SeattleJester was mentioning a Turbo???

-

Not running a PCV system certainly doesn't help matters. Headers shouldn't make any difference. You can still run the PCV system. I have headers on my 1976 280Z and run the factory PCV system. I did however replace the section that runs close to the headers with high temperature silicon vent hose. I cut the factory hose off just after the section where it necked down from the block breather tube and joined the two pieces of hose together with a brass coupler. The factory 280Z PCV hose appears to be made out of rubber, with some sort of heat reflective coating sprayed on. The Hi-Temp silicone hose works better and is cheaper. I use it on my Audi 1.8 Turbo engine as well. A couple of the factory vent hoses run near the Turbo. They are rubber and are always cracking. The Hi-Temp silicone hose solves that issue nicely. As mentioned. 80 miles is nothing in regards to ring seat. A rebuilt engine is still seating rings up to 1,000 miles of street use.

-

You may want to check this out: https://www.ecstuning.com/Volkswagen-Golf_IV--VR6_24v/Engine/Intake/Sensors/

-

Pretty sure a lot of VW and Audi have what you are looking for. Late 1990's to mid 2000 model years. Golf with a VR6 comes with a 3" MAF housing. VW/Audi 1.8T are a 2.75" housing. 1.8T guys upgrade to the VR6 MAF housing and Guys pull 400+ HP out of them no problem. Audi/VW 1.8Turbo = 2.75 OD / 2.5" ID Audi TT 225/Audi S3/ VW Golf & Jetta VR6 OBD-II = 3" Outer diameter / 2.75" Inner Diameter S4 MAF = 3.25" outer diameter / 3" inner Diameter Edit: You can find the housings at the JY or E-Bay. The MAF's tend to last forever, unless the PO used a K&N style and over oiled it.

-

Doesn't always happen that way. You can blow a hose, lose most of the coolant and the water temp stays at 100 c, which isn't all that hot. Steam heats the temp sensor and gives a false reading. Motor can be melting down and temp stays at 100C. Happened on my Audi recently. I've seen it a couple of other times on race motors. Steam will nicely fool a water Temp sender. Catastrophic loss of coolant or W/Pump failure can cause this issue. Rare... but it happens.

-

From the same Adaptronic article. The last Paragraph is extremely important:

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

The following link should be Bookmarked and read several times. It addresses the issues of proper grounding procedures and how common grounding mistakes can cause, sensor deviations, noisy Trigger signals and even inadvertent Ignition coil discharges ( Part of the LS2/Yukon Coil self-discharge problem ). http://www.adaptronic.com.au/ecu-grounding-tips/ Grounding locations are EXTREMELY important with ECU's. Star grounding, all grounds located at a single point is critical. Nissan CAS systems are very specific to the ground location, due to the Dizzy body being bolted to the engine and the CAS ground being connected to the Dizzy body. Those all grounds from the ECU should be bolted to a Star point mounted on the engine. Not to the Chassis or Battery negative terminal. Otherwise you induce voltage offsets and noise.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

Another couple of links. Consider joining the " Guild of EFI Tuners " on FB. This is the FB page for High Performance Academy. A well respected tuning company in New Zealand. They are generally an advanced group, so I would advise just lurking and absorbing information for a while. They have free Web Seminars where they explain how to tune various aspects of EFI. A lot of info there for both the Noobie and advanced Tuner. Some of their seminars are free, but they also have Paid subscriptions suitable for Professionals who Tune cars for a living. FB Link for Guild of EFI Tuners: https://www.facebook.com/groups/737420992943719/ Link to free web seminars at Horse Power Academy. You may have to Register ( Free ) to access these videos and join the notification group for up coming Web Seminars. https://www.hpacademy.com/webinars/ Edit: Do your have the Tuning book from DIYAutoTune? If not get it ASAP: https://www.diyautotune.com/shop/apparel-merchandise/books/

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

^ MS 2 can control all of those functions itself. Relays are the simplest parts. EFI relay is just the fuel pump relay. Cylinder Head Temp sensor is not really necessary. You use the Coolant Temp Sensor instead. Vehicle Speed sensor. Not really required but MS can handle it . Pressure Regulator Control Valve is your Electronic Boost control valve. It's a simple Pulse Width Modulated solenoid and again, MS can handle it. You can also use an aftermarket Electronic Boost controller or Manual Boost controller to adjust boost. Detonation sensor is just a Knock sensor and MS can handle it. The real trouble is I think you ar in way over your head. All of these functions you should have known about and should have had some working knowledge of how they operate before you got into this process. . You really should be asking for advice on MS/Extra forums. That is where the real experts like Matt Cramer reside. They also have a Tuner " location " forum where you can see if any Tuners or Members with experience live near you. Then they can come over and have a hands on look at your system. Sometimes money is exchanged. Sometimes Beer and Pizza. Standalone systems, particularly on Turbo cars , are not something a Noobie should get them selves into. No offense meant. But it's so easy to melt down a Turbo engine with just a single wrong setting. Tony D and myself agree. If you have a big $$S Turbo engine built with all the fancy pistons, rods, heads etc. It's better to let that big $$$ engine sit on an engine stand and buy a couple of Junk Yard " Mule engines " or at at least short blocks. Cause you're gonna melt one or two down when you make a mistake. And you will make mistakes. Sacrifice the JY short block to the Gods of Detonation while you learn to tune. Again no offense. Justs some sound advice. Here's a link to the MS/Extra forums. I would advise going there, registering and start reading and asking questions there. Everything, and I mean everything is covered there somewhere. Read, Read and Read some more. http://www.msextra.com/forums/index.php?sid=ccfe77dd9149308893877abac105345f Here's the link to the " Find a Tuner/Member page. Find someone good in your area and stock up on Beer and Pizza. http://www.msextra.com/forums/viewforum.php?f=137 Tuning and knowledge wise, you are basically at Baby steps right now. Tuning s high boost Turbo engine is the equivalent of an Olympic runner. It's not something that is gonna happen overnight. Good Luck.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

Oh.. I think there are a lot of things that could be causing the sporadic readings. Trigger wires are particularly sensitive to EMI. Grounds MUST be in specific locations as per the ECU ( in this case MS ) instructions. The Trigger wires must be shielded or have twisted pair wires. Often they have both. You can not run Trigger wires near any High Tension ( Spark plug or coil ) leads or near the Ignition coil. Trigger wires should not be run close to +12V leads NEVER mount an ECU close to an Ignition Box, CDI Box or Ignition Module. Ignition boxes and modules create a ton of EMI. Look at the Factory ECU and Trignition Unit on a 280Z. ECU is in drivers footwell. Trignition Unit is in passengers footwell. That's all to eliminate EMI interference. You want the same type of separation with CDI Boxes. 3 feet minimum. You must run resistor leads or preferably spiral core HT Leads. Never run " old school " solid core stranded HT Leads. You must run resister plugs. failure to do so will create a lot of EMI and create Trigger noise. The OP has a very steep learning curve ahead of him. The devil is in the details. Instructions must be followed to the letter. The slightest setting wrong, poor grounds, Ground Loops ( many people don't understand those ), or instruction not followed to the letter, will cause you grief with electronics. All I can say is Read, Read and Read some more. You really should have a good understanding of Electronics before trying to build any stand alone system. Hands on experience of building circuit boards and repairing electronic devices really helps.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

The answer is Yes. Just like any other ECU that controls ignition timing. They all use the same principles. When using Electronic Timing control, there are no mechanical or Vacuum advance units built into the Dizzy. The rotor is fixed solidly to a shaft and always stays locked to the same position, relative to the crankshaft. There are no mechanical advance mechanisms inside the Nissan CAS dizzy's. MS adjusts timing electronically just like the factory ECU. The design of the rotor tip ( any Dizzy rotor tip ) is in an arc, and allows it to direct the spark to the correct terminal over a fairly large range of timing variation. Technically, Electronic timing control is done by retard only. That's why you have a trigger offset of 50 to 70 degrees. IE: Trigger offset 60 degrees, actual trigger signal is at 60 degrees BTDC. To get the spark at 10 degrees BTDC, the ECU simply delays or retards the output signal for a time period that equals 50 degrees of crank rotation. The ECU is constantly adjusting the output delay value from the Input trigger signal to give the amount of spark BTDC or after TDC. The Trigger offset must always be higher than what the maximum spark advance the engine requires will ever be. ( At cruise some engines will tolerate 45 to 50 degrees of total advance. Low mixture density and lean mixtures contribute to a very slow combustion burn ). Edit: Wasted spark and individual coils are all done the same way. Old style Dizzy's with mechanical advance and vacuum pots physically moved the Trigger point with a rotating breaker plate. So the Trigger point starts off low, lets say 0 degrees BTDC. Then the mechanical and vacuum advance mechanisms physically rotates the Trigger device ( points or sensor ) and advances it's position. If you've worked on old time dizzy's you remember how to check to see if the advance mechanism is working properly If the rotor turns clockwise, you grabbed it and see if you can twist it counter-clockwise with no sticking. Then you released it and the rotor should snap back to the original position. That's the trigger point being moved mechanically by cams and weights etc. You actually do add timing with the old mechanical and vacuum methods. ECU timing control is done with a fixed Trigger point and then timing is subtracted from that point by electronic delay. The dizzy in an ECU controlled timing system ( any make ) is only used to send the spark to the correct cylinder via the rotor and terminals. This allows the use of a single coil. Distributor less systems, ( Waste Spark or COP ) just have multiple coils. The spark timing is still delayed fro the Trigger point, just like in the CAS type of Dizzy.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

Open the MS case and see if slot Q16 has the BIP373. Transistor in there. If not buy it and follow the directions from DIY. Easiest way by far. If you don't know how to solder small electrical components properly. Find someone who does. It's literally a 5 minute job. Here's the link on how to Use MS 2 on 280ZX Turbo and Z31 Turbo Optical dizzy's: https://www.diyautotune.com/support/tech/install/nissan-datsun/megasquirt-your-280zx-turbo/ And here's the relevant instructions. This may already be done to your board.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

Are you absolutely sure you don't have a BIP373 driver? They are internal and are built onto the MS Mother Board.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

For Lord's sake man. Follow the instructions as clearly listed by Mega Squirt. Quit trying to out think the designers.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

Ok.. That explains and simplifies things. I was just having a look at your .Basic tune again. Your spark Table is a bit aggressive for a start up tuning file. IMHO, knock the total advance down from 38 to around 32 or 30. Even the NA engines don't use any where near 38 degrees total advance. And of course 32 degrees is just a starting point with ZERO boost. As you add boost you have to retard total timing accordingly. There should be some Basic Tunes that you can download from MS Forums for a stock 300ZX Turbo... that would be a good starting point. Of course bear in mind that someone else's tune is only as good a the guy tuning it. Always stay on the conservative side when tuning and work your way up. That means conservative ignition advance, low boost ( start out at 5 - 10 lbs and work upwards ) , and a safe rich AFR curve ( 10.5 to 11.0 is Rich Safe under Boost ). Just an FYI. A stock 2007 Subaru Forester with factory Turbo engine runs 10.5 to 1 AFR at WOT. This is often called " Idiot" mode... Manufacturers have to be very conservative. so they don't burn holes in pistons. That's why a good Hi Perf Tune can gain so much on Turbo engines. Less so on NA engines these days.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

Make it work as intended... depends how the software interprets that setting. Best to follow DIY's instructions. You know instuctions? Those things us Male species never read? LOL. Edit: The reason may be that the DIY wheel is actually a 24 plus 2 trigger wheel, But the software is written to recognise the Trigger wheel as a 12 plus 1. That's just an educated guess. I didn't write the software.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

What was the reason for installing the MS in the first place? Is it a Turbo Engine running higher boost? Or Normally aspirated engine with modifications that the stock ECU can't compensate properly for?

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

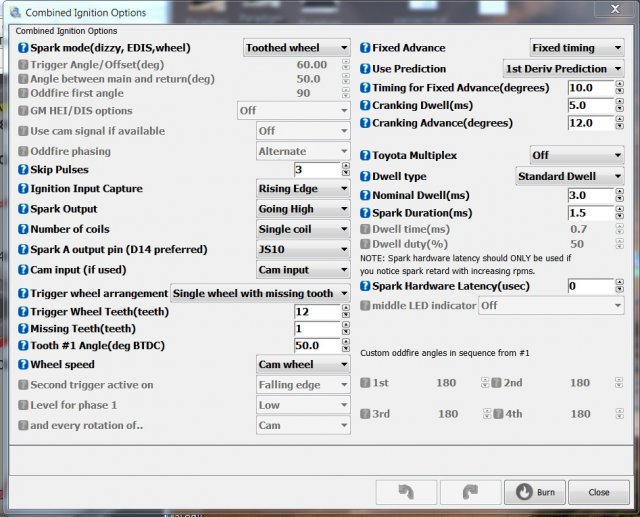

TunerStudio settings (Batch fire / wated spark or single coil) Settings under Basic Setup -> Tach Input / Ignition Settings: Spark mode: Toothed Wheel Ignition input capture: Rising Edge You have Falling Edge selected Spark output will depend on what output setup you’re using. BIP373s and QuadSparks both use Going High / Inverted.Getting this setting wrong can damage the ignition module and/or coils. If the ignition module or coils get hot with the key on and the engine off, turn the key off immediately and select the opposite output setting. Settings under Basic Setup -> Trigger Wheel Settings: Trigger wheel arrangement: Single wheel with missing tooth Trigger wheel teeth: 12 Missing Teeth: 1 Tooth #1 angle: 345 (This varies slightly between individual engines. Check with a timing light and adjust as needed.) You have 50 selected Wheel speed: Crank wheel You have Cam Wheel selected

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

Your Tuner Studio Settings under basic Ignition settings have several fields set wrong as well.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

Take the Factory ECU out of the equation first. You can't have it piggy backed with the MS. You may not have to do anything at all to the MS. It's likley configured properly already. Doesn't hurt to check though. We may be typing at the same time.... You replied to my last question while I was still typing it.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

Baggedgoods. Going back to the original Post in September 2016, you stated that you only had 1 wire from the CAS unit hooked up to your MS. The other 3 wires still went to the Nissan ECU. Are you telling us that it STILL hooked up that way? That thread ended with a pretty clear explanation that you had to have all FOUR wires of the CAS hooked up to the MS 2 and let it handle all timing. Factory ECU and Power Transister should be out of the equation COMPLETELY. OP was typing his reply as I typed this. All cleared up now. I think baggedgoods is on the right trcak now.

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with: