-

Posts

13742 -

Joined

-

Last visited

-

Days Won

68

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JMortensen

-

Kris is right. Duration and when the valve is open is the killer, not lift. Years ago BRAAP showed me a tool to fly cut the pistons without removing them. It was a tool that fit into the valve guides and you would just hook a drill motor to it and then cut the piston right there. Tape over the piston and bore area, and then just vacuum/blow out the aluminum bits. Still have to take the head off, of course. I seem to recall you can make your own tool by simply notching the rim of an old valve and just use that.

-

Rear stub axle bearing source?

JMortensen replied to seattlejester's topic in Brakes, Wheels, Suspension and Chassis

www.rockauto.com is always good on prices. If you look online you'll find 5% coupons really easy too. Looks like Timken runs about $80 per wheel through RA, they have cheaper too. -

I think the sliding air dam is a potentially dangerous idea. If it's doing its job and making a bunch of downforce and then it loses contact, or if it hits a bump in the road and fails (on one side even), you're going to have a real issue. I know it's apples and oranges, but as I recall one of the main reasons that ground effects was banned in F1 was their sliding fences which maintained contact with the ground failed, causing a sudden lack of downforce and big crashes. Still, if you're going 170 mph, your risk tolerance should be adjusted to match the new conditions.

-

Grinding the axle doesn't gain you very much at all. I showed pictures of the axle in both positions in this other thread. Flipping the cage looks impressive, but the axle sticks out about as far as the cage does, and although I don't have a tape measure in the pics on this thread, but the specs on the old M2 replacements were about .220" from the end of the shaft to the snap ring groove. So you take 1/8" off the axle and you get maybe 3/16" total shorter if you're lucky. When I measured, the CV was too long by something like 3/8" and 1/2". More than you could get by flipping cages and grinding the axles. Who knows with the variance in the cars, the LCAs, bushings, etc what kind of clearance your car really has, but to check you really should remove the spring and move the suspension through it's motion by hand to feel if the CV binds. http://forums.hybridz.org/topic/105657-300-zx-turbo-cv-shaft-disassembly-and-reassembly/ Here is another old thread I found in looking for the disassembly thread. Problems included handling issues and wiping out the pinion by side loading the carrier. I don't remember what mayolives issue was and couldn't find his thread. http://forums.hybridz.org/topic/65177-300zxt-cv-issue/

-

Yes, that would be good if it fit, but the diffusers would make it illegal for lots of different racing categories, including mine (X Prepared). Another option is the NASCAR COT splitters. I bought one and it was too narrow for my car, but essentially it is just the front lip and a little more, probably 10 or 12" deep, then you could do your own diffusers on the backside if you wanted, or just run it back to the x member. Just to update on my splitter, I found that the turnbuckles were too long even at the shortest setting, so now I'm thinking I'll make different length supports so that I can move the splitter down in 1/2" increments. Thinking of just pinching the ends of some -8 fuel line that I have and screwing that to the splitter and the dam.

-

Link: http://forums.hybridz.org/topic/47525-how-to-mount-them-there-zg-flares/

-

Read 240hoke's FAQ post in the Paint/Body section. He did it wrong and then had to redo it and showed both attempts. I did something pretty similar. Seems like 95% of people with ZG flare have them mounted too low.

-

If the circlip doesn't slip past its hole and the axle is held at the min length, then just bolting it up should be stressing everything from the control arm bushings to the uprights to the strut housings, etc. In the diff itself it would put pressure on the spider gears essentially squeezing the gears together, and you would think it would fight the actual compression of the clutch stack in the LSD which pushes the spiders outward. Although we had a couple people report problems (mayolives comes to mind) I don't recall anyone disassembling and taking pics of the innards of one after having issues, so can't say exactly what fails first, etc.

-

Flipping the cage gains you about 1/8". You can grind another 1/8" or so off of the end of the shaft. It should still be too long, based on the measurements I did years ago, but then I still can't explain how so many people ran Ross's adapters with stock length shafts for so many years. Does it make the noise going straight or turning or both? If going straight, it's probably the ring and pinion. Pinion would have a higher frequency. Ring gear goes same speed as tires, so you might be able to figure out which is the culprit that way. If it's while turning only, then either it's clutch chatter (pops and clunks) which you can fix by adding LSD additive, or it's something else wrong inside the LSD.

-

Possible New Fiberglass Hood for Z cars

JMortensen replied to HarveyZ's topic in S30 Series - 240z, 260z, 280z

Hmm... I guess I got lucky or something. I had 44's with MSA 6-1 header, no shield, rubber line to carbs, electric pump and no mechanical and I raced mine in 114 degree heat (never again) and didn't have any issues. -

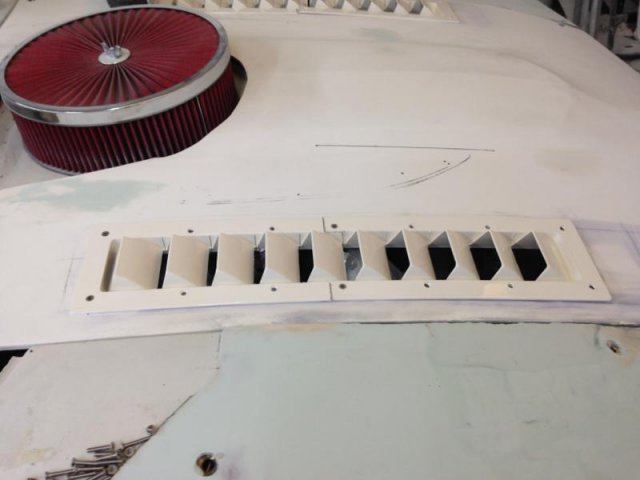

I pretty much post about every project I do, so there are tons of pics here, but I tend to neglect my build thread. Here's a couple more.

-

Possible New Fiberglass Hood for Z cars

JMortensen replied to HarveyZ's topic in S30 Series - 240z, 260z, 280z

They are the ones that you saw, 5.25" wide on the flange. You might have a look at these: http://www.hoodlouvers.com/. They come in a bunch of sizes. The holes in the louvers aren't very big, but they're definitely big enough to cover the 8" wide hole. Kind of a sidetrack, but if you use carb insulators and don't run a metal fuel rail that's bolted to the head or the mechanical fuel pump, you should be alright. -

Possible New Fiberglass Hood for Z cars

JMortensen replied to HarveyZ's topic in S30 Series - 240z, 260z, 280z

I am working on a cowl and ram hood L88 scoop with vents for my autox car. It has a 5.3 with carb, so the scoop is functional, and the reason I wanted one open in both directions is that I had heard that a front facing scoop can cause issues with the secondaries on the carb. Had to modify it to clear the air cleaner. It was way too short out of the box. Vents to exhaust air had to be narrow and kinda side mounted so they don't feed hot air to the carb. They are modified boat bilge exhaust louvers. If I ever go FI I'd like to get rid of the scoop, and if it's allowed then, make a radiator duct to the hood. Only problem with the central rad exhaust is that it feeds hot air to the wing, which means less downforce. The car with the nostrils a couple posts up is Peter's, and he's a member here, FWIW. -

I know you weren't asking me, but I had a flat top/E31 combo. I shaved the head a bit, used different valves that gave higher compression and did a lot of work cc'ing the chambers and knocking all the rough spots down. It was around 11:1 when done. Ran it with triples and a .490/280 cam. It pinged with anything less than 95 octane. I think Canadian octane is the same as US, RON+MON/2, as opposed to European where they use the higher of those component measures. What I would suggest if you want to run that combo is a bigger cam, but that only works if you have the induction to go with it. So basically, if you have triples or ITBs or some custom high flow FI, then do it. With SU's or stock FI, I'd stick with the 9.5:1 compression. The gains from the compression will be quickly lost if you have to dial back the timing. Rebello sells a cam that is something like .520 lift, BRAAP has mentioned it before, and there are other options for bigger cams too. New engines have better chamber designs, x flow heads, and better cooling, and all of that plus the more complicated FI systems allow them to run a lot more compression a lot more safely than we can.

-

I hope there is more structure to that on the bottom side. Looks like you missed the frame rail and just have the strut tower connected to the fenderwell.

-

Z handling benefits from an increase in caster, which would be moving the plates to the rear. I don't think you'd be able to move it very far to get a large caster change, but if you want the front end to grip better, you can increase caster by lengthening the TC rods under the car as well. There are some nice adjustable setups out there.

-

Get yourself some LSD additive aka friction modifier.

-

Get 4 unless your originals are stripped. Spring plates fatigued? Doubt it.

-

I would get the clutches. I think it's worth doing. Never seen or heard or worn xpins or pressure rings in a Nissan LSD. I bought mine with 200K on it and those parts weren't worn at all. The 18 ft lbs is just the breakaway pressure with no spreading of the pressure rings. What happens in that test is that you're forcing the xpins up the ramps, spreading the pressure rings against the clutch packs, so breakaway pressure when under load is comparatively huge. If I had to guess, I'd say look at the transmission, but that really is a guess.

-

The lsd acts by moving the crosspin to squeeze the clutch packs. So it might move nearly as much as that totally screwed open diff that Miles posted and be totally fine. You can pull it apart and look for worn parts if you want, but the only real weak part of the 300ZXT diff is the clutches. If you upgraded the clutches with Savage42's parts, then I really doubt the LSD is to blame.

-

Wow. That one is hosed.

-

What the pinion does when you rock the car back and forth has very little to do with the backlash. LSDs will perform worse on your clutch test than open diffs as well. You haven't really tested anything with what you've done. Not that familiar with the Z31 so don't have any great ideas of what to check next, but I can tell you that your videos don't show you anything useful. If you haven't already seen it, here is a write up I did on S30s with clunks: http://forums.hybridz.org/topic/105207-the-dreaded-diff-clunk/

-

Sounds like you may have the axles switched side to side. One of them is about 3/8 longer than the other, so if you have them switched one will click into place while not fully inserted, and the other will go all the way in but won't click into place.

-

I had cut the splitter out of 1/4 plywood and then put one layer of FG on it and it was still pretty flexy, so I put it aside and started focusing on the FG front end. Now that the front FG is almost finished, and I gotta say, for being the first thing I ever made from FG, I'm feeling pretty good about it. Went to bolt my splitter on, realized that it was cut uneven so it was where I wanted on one side and not long enough of the other. At this point I just want the thing driving, so I bought a 1/2" piece of birch instead of the thinner wood + FG idea. Read online that birch wood is the stuff to use, and the wisdom of crowds came through again. Very stiff. Bolted it up and although I designed the splitter to move up and down about 2" so I could set the height off of the ground, I'm finding that I'm hittting the swaybar with the rear of the splitter. Could get it up another .75" or so, will have to redo the swaybar mounts. The swaybar is mounted on heims, so I can change the brackets, maybe even just redrill the holes. The splitter also pivots so that if I hit something it hopefully won't get destroyed. To allow for this I was going to use cables in the front, but then thought carabiners and a turnbuckle would be good so that I could adjust the height with the threaded clevises in back and then just lengthen or shorten the turnbuckles, but the issue I'm having with that is that the carabiner and turnbuckle setup is too long at its shortest setting, so might have to go back to fixed length cables. There will be a skirt to close off the gap between the splitter and the bottom of the air dam, slotted so that I can move the splitter up and down. End goal is to have the xmember at about 2 or 2.5" off the ground. The skid plate I put under the rack hangs down another 1". Would actually like to run the xmember at more like 1.5 or 1.75, but can't do it due to the skid plate. When I get to aligning and bumpsteering, I might try to move the rack up so that I can remove the skid plate altogether (xmember is slotted too so I could move the control arm up and not screw up bumpsteer), but this aftermarket rack hangs down below the xmember and I didn't want to smack it on a curb and disconnect it from the car...