-

Posts

13742 -

Joined

-

Last visited

-

Days Won

67

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by JMortensen

-

It will be thinner, not sure if that matters. You could shim it back up if you wanted. Some of the LSDs had no springs at all: http://www.gordon-glasgow.org/lsd2.asp

-

Wide wheel and tire thread

JMortensen replied to thezguy's topic in Brakes, Wheels, Suspension and Chassis

Basically what you're saying is you're going to build a 1000 hp car and not use the hp, so you don't need to build it like it has 1000 hp. Except when you take it to the drag strip. But you're not serious about dragging it. Kinda doesn't make a lot of sense. I sincerely believe the R230 is weaker than the longnose R200 due to its crush sleeve. Regardless, in all likelihood you'll be running some sort of CV conversion so you can choose which lug pattern. To choose the 4 lug is to leave strength on the table that you might very well need down the line, because your hp number is so extreme. -

I have a 4.11 R200 out of a 200SX. I think it might have come in the turbo version, not sure. It's rare, but not as rare as the 3.36 R200. You can find one if you keep your eye out.

-

The Z31 open is a 4 pinion and stronger than the 2 pinion used in the S30 and S130 R200s

-

Brake Line fittings question

JMortensen replied to Chaparral2f's topic in Brakes, Wheels, Suspension and Chassis

There is an inverted or double flare and a bubble flare. They are different, and Japanese cars use inverted flares. Datsun stuff is 10 x 1 mm. Jag I don't know. -

I'm sure the loops are just to keep the belts from sliding around on the larger bar. SCCA has some weird rules, I'm sure the cage is strong enough with the diag as it is, but it is technically not correct. Door bars would need some work but you can work with what is there already, don't have to cut that stuff out to fix it. I totally agree with you about the tubes that go all the way out to the ends of the car. Unnecessary and less safe, particularly in the rear as you said. I do think that a tech inspector would probably let it go though, if they let Mike Kelly's go. I believe he said an inspector signed off on his.

-

Talk to Savage42.

-

FIA Cylinder head on race car in US? More info?

JMortensen replied to Bob_H's topic in Nissan L6 Forum

A friend of a co-worker had one. I was probably 22 at the time. Tried real hard to buy it from him but I think he thought my Z was going to end up in a ditch and didn't want to sell it to me. Still have the car 17 years later... they are out there. -

That's a really crappy way to try and check backlash. I wouldn't do anything at all based on that. You could pull the driveshaft and see what it does when connected to the trans, and then pull the CVs and try to feel the backlash at the pinion, but even that is hard to do because of the resistance of the pinion seal.

-

ZCC JDM Outer tie rod issue

JMortensen replied to Rob L's topic in Brakes, Wheels, Suspension and Chassis

Sounds like you'll be pretty set up if you install what you have. If you're really interested in the minutia, read the FAQ stuff. If you just want a nice handling Z, a good alignment on a car with coilovers and camber plates and adjustable control arms should be all you need. -

ZCC JDM Outer tie rod issue

JMortensen replied to Rob L's topic in Brakes, Wheels, Suspension and Chassis

Deceide what you're after first, then read through the suspension part of the FAQs. Then post a question in the relevant thread or start a new one. -

I think part of the problem is ignition too, but I wouldn't expect an extra 100 hp from fixing it. Read zredbaron's thread. He went from a 3.1 that made 150 whp or something like that to one that made 280 something and documented the whole thing. http://forums.hybridz.org/topic/24798-na-31lhead-camshaft-questions-no-shortcuts-max/

-

ZCC JDM Outer tie rod issue

JMortensen replied to Rob L's topic in Brakes, Wheels, Suspension and Chassis

Camber gain will hardly change at all by adding a bumpsteer spacer. Check out the graph that Dan McGrath produced. It's pretty damn linear. Adding a bumpsteer spacer just moves you up or down the graph 3/4 or one inch depending on which spacer you use. The spacer moves BOTH outer pivots (ball joint and tie rod) the same amount, so it doesn't adjust bumpsteer, it only adjusts where on the bumpsteer curve you're driving. The spacer is a roll center adjuster more than a bumpsteer changer. http://album.hybridz.org/data/500/Camber_curves.JPG Moving the LCA pivot is not at all the same as using a spacer. Moving the LCA pivot changes the relationship between the LCA and tie rod. It will change the camber gain, but again, without actually having a graph to prove it, I think you're vastly overestimating the effect. You compared tie rods to bumpsteer spacers, and that's a bad analogy. Setting toe is different than bumpsteer because bumpsteer is determined by the non-adjustable geometry in the front end. If you know the geometry (LCA vs inner tie rod height, ball joint vs outer tie rod height for strut suspension), you really can make a tie rod that adjusts out bumpsteer pretty closely. It might not be optimized for a particular car at a particular ride height, but there is no question that if the suspension isn't bent or modified, you can vastly improve things. Put a non-adjustable bumpsteer kit on a mid 80s 911. It'll get better. Been there, done that. If you had a front end that was free of bumpsteer, in theory toe could be adjusted the same way. You might buy one set of tie rods that would give you 0 toe, a slightly longer set that would give you 1/8" toe out, or a shorter that gives 1/8" toe in. Since Z's have a lot of bumpsteer, setting toe that way isn't the best idea because ride height would change the static toe setting (not to mention the issues involved in getting the wheel straight). -

ZCC JDM Outer tie rod issue

JMortensen replied to Rob L's topic in Brakes, Wheels, Suspension and Chassis

The part that I bolded previously is untrue IMO; that your chance of noticing bumpsteer is essentially zero if you don't measure it. I haven't driving one of these excessively lowered cars personally, but I have to imagine that there is a problem just based on my own experience. FWIW, I bumpsteered my car by slotting the front xmember and then moving the pivots up until the bumpsteer was minimized on the gauge. Took about 7/16" movement in my case. You seem to be saying that it is a bad idea to move the LCA pivot to make this adjustment. Yeah, it affects the roll center, but the benefit of reducing severe bumpsteer overshadowed the literally unnoticeable effect of the increased roll resistance or jacking that came from the higher roll center. In theory, it really should be the same for every Z that shares the same chassis geometry, and that is why you will find similar kits for all sorts of different cars, but as you said, Z's are mostly bent or modded at this point. You really can dial in the bumpsteer just by moving the LCA pivot if you do it correctly with a gauge and all that. And for the OP, I did it just the way someone suggested. Pulled the springs, jacked the xmember up and down and used dial indicators on the rotor (but a $5 DIY wood tool which uses a feeler gauge to measure change would work just as well). I totally agree that if you're buying this part you should measure it and dial it in. -

ZCC JDM Outer tie rod issue

JMortensen replied to Rob L's topic in Brakes, Wheels, Suspension and Chassis

The kit you have probably is a proper bumpsteer kit. -

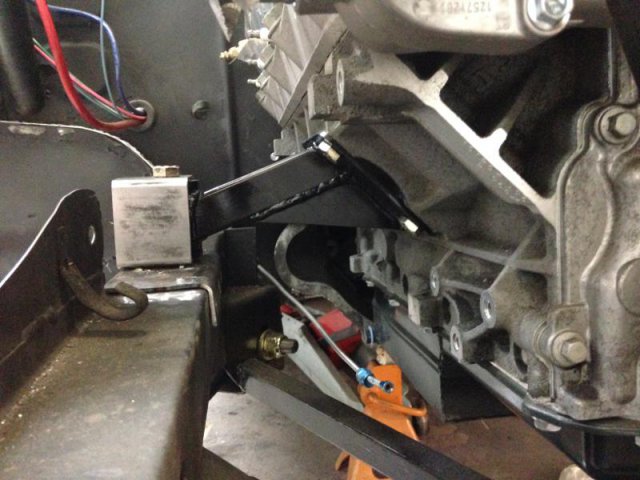

Thanks for the input. I would have put the mount the other way and I agree that would have been better, but the issue is that I have tubes welded from the dash bar to the strut towers. There just isn't enough room to lift the engine very far before it hits those tubes, and I didn't want to paint myself into a corner and make it really hard to get the motor in and out.

-

ZCC JDM Outer tie rod issue

JMortensen replied to Rob L's topic in Brakes, Wheels, Suspension and Chassis

I don't think this is true at all. If you lower the car a lot (which seems to be the trend) then it can be REALLY bad, and fixing it is a good idea. On my Z with stock length struts run at about an inch off the bumpstops, there was one part of a particular track where my car was doing an emergency lane change maneuver all by itself. Some might argue that I was pushing harder than most people would, but the issue with bumpsteer isn't how hard you push, it's where the suspension is in its travel. You get some of these guys who are running the super short struts to get lower and they have to be lower than I was, so they're probably driving around town in a spot in the curve that is worse than what I had going on at the track. And when you start talking bumpsteer a lot of them seem to want to come back with "I put in bumpsteer spacers" to end the criticism. Those of us who know better are aware that doesn't fix the issue. It's likely that if the car is lowered, using a bumpsteer kit manufactured by someone who knew WTF they were doing is going to improve things, just as the JTR up 3/4" out 1/4" xmember mod probably improves things without being exactly the right answer. To really know you have to measure, it's true. Also true that it doesn't take a lot of $$$ to measure. -

New design. I'm going to run a brace from the top of the box to the strut tower too. After I got it in there I realized how easy it would be. One side down...

-

Chassis Setup (corner weights)

JMortensen replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

I wouldn't take it for granted that heavier in the front is the right thing. Depends on what sway bar you run in front. With some front bars you might still end up stiffer in the rear to get the weight transfer balanced, which is really what it is all about. -

When you measure rear toe you get a number, but it doesn't tell you the whole story. On front toe the number is all that matters, because the front end will automatically equalize whatever you have left and right, but in the rear, you might have the left side pointing straight ahead and the right side toed in .5", and you come out with a .5" toe in figure. It's not safe to assume that the toe is equal on both sides, and judging by your tire wear, it isn't. They call this "thrust angle". If your thrust angle is 0 then your tires point straight ahead. If it's 7 degrees, that means that you car is crabbing down the road. I'm betting that is the case for you. You need to find a shop that will actually take some time to figure this out and isn't just looking to get you in and out the door. I'd suggest you google "race alignment slidell" and see what comes up. Maybe throw in "porsche" in your search. If you find a shop that sets up race cars, they won't just turn you around because you have something funky going on. The camber bushings should adjust out .5" toe without any trouble, and it is the simplest way out of this mess.

-

Aluminum or JTR driveshaft

JMortensen replied to JMortensen's topic in Gen III & IV Chevy V8Z Tech Board

That definitely gets the point across, thanks for posting. I might have a look at that down the line. Want to see where my weight is first. Looks like a lot of metal there, even if it were aluminum it would be a chunk of weight. -

Aluminum or JTR driveshaft

JMortensen replied to JMortensen's topic in Gen III & IV Chevy V8Z Tech Board

One cool thing about the internet is you can put pictures on it... -

Aluminum or JTR driveshaft

JMortensen replied to JMortensen's topic in Gen III & IV Chevy V8Z Tech Board

Probably would have helped to say that I'm not drag racing, nor am I running huge power. I'm pretty comfortable with 1310 joints for my build.