AydinZ71

Members-

Posts

1073 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by AydinZ71

-

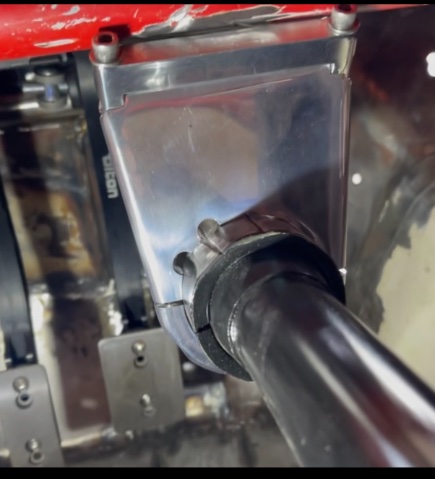

I also have the Tilton pedal assembly. I just finished by firewall area so I will share some pictures. This is definitely a custom install so if you are anxious about metal work, welding, cutting, etc. you might want to steer clear. The BIG plus is the dual brake master cylinders (one for front and one for rear) which will allow you to MECHANICALLY adjust the amount of travel going to each cylinder (the assembly comes with a see-saw proportioning lever). This is a repeatable means of changing and fixing your front/rear brake bias which will not "wander" like the hydraulic proportioning valve. Since the pedal assembly ditches the brake booster, it has a longer pedal lever as well. Not quite as easy as OEM, but easier to "push" than if you removed the booster on an OEM pedal assembly. Also, not including the additional master cylinder the Tilton assembly is 4lbs where as the OEM is 8. You would also need to mock-up a new column drop (the thing that grabs the end of the steering column) since the OEM unit came with this connection point. All said, don't recommend it unless you are building a track car or really care about brake performance. As a point of reference, I just sold my OEM pedal assembly for $180. The Tilton assembly is close to $400 when including 2 new master cylinders. You will need to modify the threads on your existing clutch master or get a new one with 5/16 SAE.

-

^this I do the same. Use high-heat setting and do very very quick taps. Low heat settings will have poor fusion and leave holes when you grind flush. As always, be very cautious adding too much heat at once. If you get more than a 1/8” blob glowing red, you are adding too much heat. The metal 2” away should be hot to the touch but not enough to burn you. Go sloooooow….. this is an exercise in patience.

-

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

@JMortensen @tube80z Man the tilted fuel cell is brilliant! Maybe on the next build… I gotta get mine on the road. I can’t run a fuel cooler in EP but maybe Clark can in GTU? -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

10-4. Maybe I need to shove something in the opposite direction down the shaft to release the spring load. Il figure it out Just not familiar with the assembly. Il look for a cross section or something. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Ok so I made a boo boo. My steering column got some grit in it and makes a light pepper-grinder sound when I turn the wheel. Like an idiot, I pulled the retaining clip on the steering-wheel side of the column. So apparently there is a spring in there that immediately shoved the shaft into the column and now I can’t get the retaining clip back on. Crap. Anyone know how I can pull the shaft out to get the retaining clip back on? -

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

@clarkspeed Hey thanks A bunch Clark! Means a lot. Yep… diffusers are illegal in EP I had the whole rear end torn apart so I figured why not add attachment tabs in case I ever try a diffuser in a non SCCA sanctioned event. At a minimum, it is much more ridged and “catches” less air at speed as a result. For the reinforcement, I cut a 5/8” steel tube (1/16” wall) down the centerline to create two semi-circle cross sections. I figured the full tube itself was overkill. Along the length of the skirt (Kinda hard to make-out in the photo) I bent a 1” wide strip on 18-gauge sheet into 90-deg angle stock and welded it lengthwise to the skirt. The angle stick makes the skirt more ridged, and the vertical semi-circle beam keeps the leading edge of the skirt “put”. I need to read the GCR more carefully. All the restrictions on body panels seem to be limited to extending “beyond OEM” panels. Il see if there are restrictions on underbody plates. Even if I can’t run a true diffuser, I’d love to seal the cavity between my fuel cell and the rear skirt. It’s just a tornado of Eddie currents back there. I know we can run a front-end splitter from the leading edge of the air dam up to the axle/steering crossmember. -

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

speaking of diffuser, I reinforced the rear skirt and added welded tabs with nuts ready to go, for a diffuser to be attached. Curious what you and Clark may do differently. Here are a few pics -

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

@clarkspeed when I spoke to John at Ztrix (I have his frp hatch), he mentioned how complicated the resin process is and how he has perfected a super lightweight means of preparing an s30 hood. Something special about the resin if I recall. I’m going to be ordering a hood soon and il ask him more about it in detail. I believe he sells a super-light version as well for more $$. He mentioned the hood doesn’t really benefit from carbon fiber since it’s not a true structural part. I tend to agree. It’s all about rigidity (stiffness) vs resisting stress (yield strength) like a structural piece would require. A crossmember for example would benifit more from carbon fiber. You certainly get my respect Sir! I thought rust repair was tedious… not compared to moulding FG body panels through to filler & paint -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@tube80z hey thanks Cary! I really appreciate the feedback! No appologies necessary, as any feedback is appreciated. I will certainly look into the go-pro and racetechnology! @rossman thanks!! -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

-

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Yeah 18-gauge with that curvature will be pretty strong good luck and looking good Clark! -

IMSA GTU vintage racer build

AydinZ71 replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Looking good Clark! Here is my usual PPE look. I truly appreciate the hours of work this kind of detailed metalwork takes. It’s a jigsaw puzzle, and with heat… nothing stays put the way you expect it to. what gauge steel did you use for the rocker skin? 18? 20? I find 20 to be reasonable as far as weight and stiffness for skin material, but 18 is so much easier to weld-to. I completely rebuilt my rockers too, with internal bracing. You probably saw those photos in my thread. I used the thin “slip-on” rocker cover for my rocker skin since they were cheap ($35 a pop?) and are no longer a key structural component. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

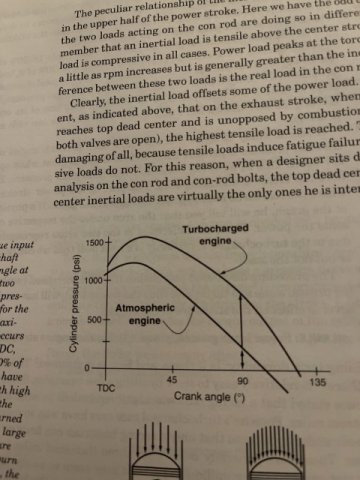

100% Clark I wasn’t planning to overbore at all if I ran a turbo. ~2960cc. No more than necessary to seat a new set of pistons and rigs, plus hone. That extra displacement is not worth the risk at 30psi. I may still blow a block, but at least then I’d know it was from water jacket corrosion, and not my own doing. I would also have the walls ultrasonic tested to ensure I had enough wall left. NA engine has significantly less pressure/heat over the full power stroke, so I might try 1.5MM overbore. The weakest part on the cylinder is about halfway down the stroke, where the walls are furthest from the end flanges, and surrounded by water jackets. Here is a shot from Corky Bell’s book for reference. Most of my experience is from turbo applications. The EP motor is my first attempt at a race engine, and I plan to burn out the rings before I throw in lightweight rods for 8k+ rpm. I will keep an open mind for now Good to know it can likely run it in Vintage Racing as an easy swap for the 2.4L EP engine. Thanks for that feedback! -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@clarkspeed sounds good! Il probably go with the Z-TRIX hood then I already have so much body work il need to do, anything I can do to shed hours by purchasing I’m all for it! Especially if someone else’s skill can be leveraged to save time Hence purchasing, but I like your idea of FG doors! That might be something I take a crack at in the future. I got the Mishimoto Radiator on order. Surprising… a quality radiator for 300 bucks shipped… really hard to believe! Maybe they are made hubdreds at a time in china 🤷🏽♂️ too bad the roof can’t be replaced with FRP in EP. Lot of weight up there. Thicker gauge of steel, and a lot of unnecessary stiffening/reinforcement. Could just use the nearby roll cage halo for that purpose. still eyeing that darn hatch mount crossmember. With a FG hatch and Lexan, I’m sure it doesn’t need to be as beefy as it is now. I could even use the roll cage as the hinge point and ditch the OEM steel altogether. funny how you start obsessing over details the deeper you tear into a car. I guess once you have had your hands on every square inch of OEM steel, you start seeing things in a while different light. On an unrelated note, I traded a bunch of turbo parts with a nice kid for his V07 crank. It’s at Mountune (socal race engine machine shop) right now being checked out. Need to decide if I’m going to keep it for my new turbo rebuild for the street Z, or build an NA race engine with it. Would not meet any classes I’m familiar with, but it would be fun to have a quick swap 3.0-3.1L for the race car just for shits and giggles. With carbs, I could swap it with the L24 in a few hours. Only reason I’m considering it for the turbo build is the added displacement will help with spool-up. Otherwise, the marginal gain at boost is not all that remarkable, since the head quickly becomes the limiting component. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@clarkspeed thanks Clark! Il go with Mishimoto. I wish I knew more about their quality/construction. I’m surprised their cost is not as high as I would expect from a top-end vendor. I looked into accusump and watched Jesse Prathers video. It’s kind of a PITA, but certainly makes a difference if your pressure drops! I was surprised folks were not using a small bladder-filled accumulator. I have used them in other engineering applications. Worrying about the oil volume was my biggest concern. Who did you source your dry-sump system from if you don’t mind me asking? thanks again for the feedback! I really do appreciate it. here are a few shots of my drivers side seat mount and rails/stiffener. Also a shot of the Tilton pedals and steering column. I created a 3/4” rise on the front relative to the back. Personal preference, I like leaning back a bit with a harness. These will be welded in as soon as I get gas. Also a shot of the Tilton pedals and steering column. settled on a 4” drop from the roll bar, and getting that collar on order. -

No worries! Yeah rust on a Datsun rarely becomes an easy fix LOL! I’m a year into rust repair… if you TIG, then you are ahead of me friend! Once you hit that spot with a wire wheel, I suspect the metal will peel back like an orange but if you get a solid surface, more power to you!! since it’s a tiny spot, you could also save a few bucks and get a rust converting spray can. Most manufacturers sell one for 5-8 bucks. Although to be honest, if you wire-wheel it you won’t need any converter at all. Just something to seal the metal. good luck!

-

As a topical application I use rust-mort. It is phosphoric acid. It must be removed after it has done its thing. The metal in the windshield sill is pretty thin (20-gauge?) so I would wire-wheel the rust and make sure the remaining metal is not too thin. If it is, you could add some metal with a MIG and grind flush, or use a fiberglass filler. Rust needs exposed metal, oxygen, and water/moisture to propagate. If you eliminate the existing rust, seal the exposed metal with epoxy (por-15 or 2-component sealer/paint) then make sure your windshield seal works 100% so you don't get moisture trapped between the windshield/seal and the window sill. Adding a really thin filet bead of sealant between the rubber seal and the metal may help prevent moisture from getting trapped back there again. I suspect the moisture is being wicked (capillary action) into the gap.

-

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Sorry for the late reply! @tube80z @clarkspeed Thank you both so much! Cary, your long winded e-mail is very much appreciated! Detail is great! Always good as a reference in hindsight. I am going to add oil temp and fuel pressure as well, based on your feedback. Thankfully FP is not as critical on carbs since I just need to keep the float full (>1psi, regulator set to 5psi). but if the float drops and fuel does not come in, the fuel head will change and they will fall out of tune (SU's). Cary, I will be pushing the data acquisition and analysis to a later phase of the build. I feel like I need to get out there and get some seat time before I can truly appreciate what metrics will mater most to me. That will save me some time to save up for a fancy new electronics package as well (leaning AIM). Important thing is to purchase/install the right sensors into the build now, so I can avoid new brackets/mechanical connections in the future (if possible). That way, adding electronics becomes a purely electrical exercise vs. re-work. Latest updates and questions (if you have time!): 1) Steering, pedals, and seat are all prelim. mounted to check fitment, and adjust the seat position based on my dimensions. 2) Tilton pedal assembly is 100% installed w/ reinforcement added to the firewall. Steering column is bolted in as part of the mock-up, and I will be purchasing a "column drop" with the right dimensions based on my preference. That will "set" the height of the steering wheel. I am happy with the reach, so no need to adjust the telescoping. Going to keep the stock column for now, but will make plans to incorporate a smaller diameter shaft w/external bearings in the future. I see an easy 3-4lbs weight savings here, so I'm a fan. Just need to dedicate time to getting her up and running first. 3) Moving forward with the Ford EDIS-type crank-fire ignition. Electromotive is great, but at $850 as a starting cost, I see the EDIS approach costing less than 1/3. I have the EDIS module and a crank trigger wheel that should work with my ATI dampener, ordered. Anyone have a recommendation on what model or where to buy a VR crank sensor? I could just buy a Ford OEM unit, but wanted to get your feedback. How about the coil packs? Looks like I can get OEM for 50, and there seems to be some A/M performance units for $100-150. Would love some feedback on what's good and what's garbage! 4) The race car was dead-heading fuel to the carbs at 5psi before I tore everything apart and started restoring it. My other option is to install a return line, and have the drain from the FPR return fuel back to the inlet of the pumps. I have two independent redundant pumps (with outbound check valves) adjacent to my fuel cell. Any strong feelings about a fuel return line back to the fuel cell? I assume this will help eliminate vapor-lock and recirculate the fuel to keep the temp in the line consistent. 5) Cooling: I just sold my OEM radiator. Any suggestions on a radiator? Mishimoto? Anyone running the head-to-block cooling mod for cylinders 5 & 6 on an NA race engine? 6) Oil: I have an external oil filter bracket, and the oil filter remote adapter. I also have a copper/AL oil cooler I plan to use. How about oil pans? I hear some folks have had trouble with oil pressure blips at high G's, so I was looking into a Moroso or make my own custom (since its carbon steel). Also, anyone have a recommendation on an A/M cam oiler? I still have the OEM unit on the heavily modified N42 head, but it requires gaskets to seal and I am not thrilled about the stamped/punched construction. I would be happier with a billet unit with larger galley's. 6) FRP hood: I already have an Z-trix FRP hatch since the OEM unit was pretty banged up. Any suggestions on a quality and affordable RFP hood? thought I would look around a bit before I went with Z-trix again. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@clarkspeed hey I really appreciate that Clark! I’m a complete novice driver, and after seeing the cost on data acquisition/logging, I feel I need a bit more experience before I make the investment. I Absolutly will hit you up after i get some seat time! I also saw Jesse Prather is running trackmate on his Miata. The programmable alarms are neat, but the tech does look a bit dated. Having to extract the data the way you described to graph in excel definitely sounds like a pain. I think I’m going to go old-school and employ analog gauges for now. If I install electronic sensors, Best-case I can integrate them with a data dash in the future. I figure as long as The analog inputs have a voltage min/max adjustment, software can adjust for scaling and boundary limits. What all do you run on sensors/gauges? I’m thinking tach w/light, oil pressure w/light, water temp, volts (confirm over 12 for charging), dual O2’s for the SU’s.Can’t imagine anything else would be critical enough to know, but open to your thoughts! Only way I could get a speedo in here is from axle/wheel speed and that seems like a PITA. Hey by the way, I got an Instagram page up and running for Greg. @gregiraracing least I could do for all the help he has given me. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

That’s a great question Jon. I am looking for something lighter than OEM. Something just big enough to keep up with the ignition system amp draw. Ideal solution is to have enough juice on board to not need an alternator at all, but I don’t have the budget for Li batteries at this time. In theory, the alternator only “steals” the power it needs to maintain a 14.5amp voltage. So, certainly nothing wrong with the OEM unit, just looking for weight savings I will keep looking around maybe I can find a creative solution. It will be worthwhile to check my current amp draw when she is running as a baseline for the smallest unit I can employ. -

What's the difference between a 1978 and 1981-83 l28et engine?

AydinZ71 replied to Junleung123's topic in New Members Forum

@jhm 100% agree. It’s painful to say, but I would pass on this car. The race car I’m restoring has significantly less rust than what you are dealing with, and I am Still 1-year into chassis rust replacement. We are talking 6-10 hours a week, every week, for a year. Still have not found a “rust free” S30, but you can get close! Look in Southern California, Nevada, arizona for cars that remained here. L28ET’s are becoming rare. Pick a torque/power target and we can help you build a turbo engine around an NA long block. other than the P90 head and pistons with raised deck (rings are lower), not a big advantage to the L28et long block compared to say, a 280z long block with an N42 head. It’s all expensive to be honest. You can hobble together an OEM EFI system to work (Z31 turbo MAF & ECU) but I have no experience How well the AF tracks. I only have experience with independent EFI’s . when I built my original L24et, I tried to use the L28et harness and ECU. Fail… I bought an SDS EFI and it has been running for 20 years. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@tube80z hey thanks a bunch Cary! Definitely looking into the alternator now! No EFI (I wish). Unfortunately our spec. Line for a 240z in EP still has SU’s listed. Somehow, Greg was able to squeeze out 260hp out of them, which is phenomenal considering the head restrictions in EP. I very much have contemplated ditching the stock steering column! Only reason I kept it is I have so many other priorities on the list, that fabricating something from scratch merely to save weight didn’t make it on the list yet. A few folks here recommended a Sweet column. Do you have a parts list/concept for the replacement column? Is it just a 3/4” diameter tube with the steering rod riding inside with pressed in bearings on each end? Or… are you talking a 3/4” tube as the steering shaft itself, where the mounting bearings are on the outside? The car still has a LONG way to go on optimization. Always looking for new ideas to employ! -

Toyota front brake upgrade - still relevant?

AydinZ71 replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

My experience: I have the 4X4 front calipers, and 300zx vented rotors on my street Z. Much larger and heavier than Stock. I find the setup adds too much weight up front and the car understeers worse than before. Next upgrade will involve reducing the rotor and caliper weight. -

240z SCCA vintage race car, restoration

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

@clarkspeed ah! Hey that’s great! I didn’t realize you were still so involved! I saw your name under “special thanks” along with Guy and Sam on his nationals victory. I bet that was a great experience. I just realized the link didn’t get posted. Here is what I had found: https://performancedistributors.com/product/mini-racing-alternator/ Problem is, I have no idea if 7lbs is light for an alternator (need to weigh my OEM unit) or whether these are quality. one idea I had was using an amp meter when the car is finally running, and size the alternator just a hair over. Since all we are running is ignition and instrumentation, I’m betting we are less than 30A peak. If that were true, I would look for any 12v alternator in a 35-40A frame. Might still use up juice at idle, but once you are ripping, RPM/amps are not longer an issue I looked in to AIM, and immediately realized it’s not something I can afford at this time, hahaha. Failed start. My main reason is to eliminate analog gauges, store data for off-track analysis, and rough-tune suspension with the lateral G data. Ideally I could use the axial G’s to tune my valve and ignition timing, but I doubt it is sensitive enough. I will be running dual O2’s for tuning the SU’s. Tilton assembly is in, so now I can add reinforcing around it and tie a thin tube to the roll cage to resist (tension) my leg force on the firewall. -

I got one I traded my L28et manifolds, turbo, IC, IC piping and custom 3" downpipe.