All Activity

- Today

-

Getting the right oil pan for a big HP RB swap in a 240Z is not easy!

primaz replied to primaz's topic in Nissan RB Forum

Keep in mind for a 240Z it is rear wheel drive so to me the best RB swap would be an 2 WD RB 30, or a 2WD RB25. For a more demanding big HP version of those the pan must be rear sump, larger capacity, have the oil pickup designed to match the 2WD RB30 or 2WD RB25 at a minimum. I literally spent days searching the web and so did Robbie at RIPS Racing. I sent him so many links and none of them had what he knows is needed to keep the RB engine reliable, especially when it will be putting down big horsepower numbers. The JHK from UP Garage had one their website that it was for a 2WD RB20 or 25 block which is the same as a 2WD RB30 but that was not as claimed; If I had used that pan it would have severely damaged my expensive engine. Thus plan on a custom pan if you want the engine to last... - Yesterday

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

-

New to forum - potentially a Z owner soon!

FastFloridian replied to Zappingbaby's topic in S30 Series - 240z, 260z, 280z

Looks good and sounds good. Wouldn’t buy without a test drive though, he’ll start it though right? Hopefully just fluids and new tires and you should be good to go. Good luck!- 1 reply

-

- 1

-

-

Always liked the early Zs especially a 240z a this guy came up for sale recently - seeing it in person tomorrow so I'll have a better idea then - apparently being sold because the guy is retiring and getting rid of all his toys Pros: 1. Bodywork done - "12k, 1 year spent at body shop to cut out all rust and install new metal" 2. Modifications: Small block chev. 600 lift Roller cam, Gold roller rockers,202 aluminum heads, MSD ignition&box, H.P electric full pump, 150 shot NOS system (Not used). Purge lighting built 700R Trans&Convertor, B.M. Shifter, I.R.S. 3.9 Gears Custom built half shafts (Good for 600HP), New weather stripping/INT/Roll Bar. 3. Looks on pictures that it's done right - looks like a very clean install Con: 1. Sat for 10 years since 2015, 3000km after the build (Drove the F-type jag he got instead). Apparently just started couple of times a year to keep things "lubed". Recommends all fluids changed, brakes bled etc before driving - so I won't get to test drive it and make sure everything's working properly before I buy it. Looking for recommendations on what to look out for, and key things to prep to get it ready to get back on the road.

- 1 reply

-

- 1

-

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Thanks guys. Making me feel confident in my set up. @74_5.0L_Z good info and impressive dyno on old engine, I’m hoping for something close when I’m done. What is your new engine, still a ford 302? Slight change to my diff setup. Didn’t do enough homework, but I think it’s actually going to come out better, just by dumb luck. I didn’t realize auto vs manual was a different sized pumkin on the 370Z. I bought an auto diff, and the wavetrac doesn’t fit an auto. Good news is I really wanted the 3.3 gearing and that only fits in the auto pumpkin (dumb luck). An OS Giken diff fits with the 3.3 gearing in an auto diff, so it looks like I’m going that route. A little more money, but the OS Giken is better for a track car anyway. - Last week

-

Zappingbaby joined the community

-

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

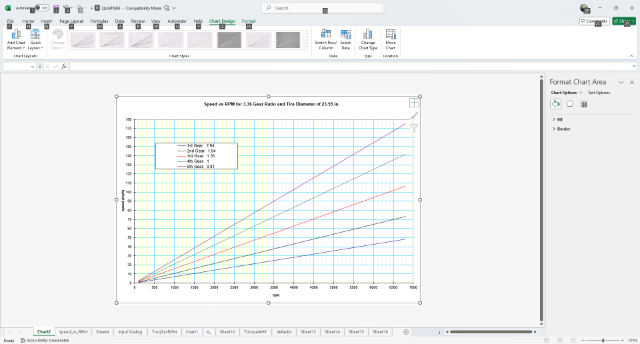

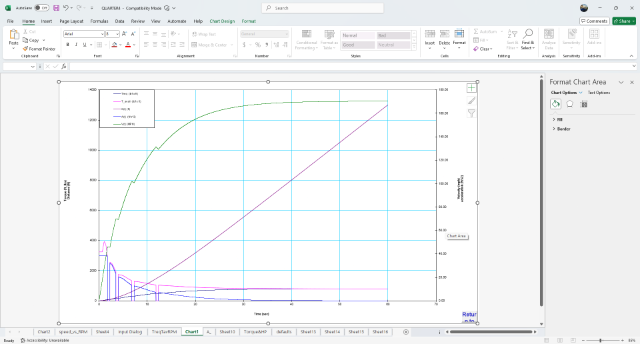

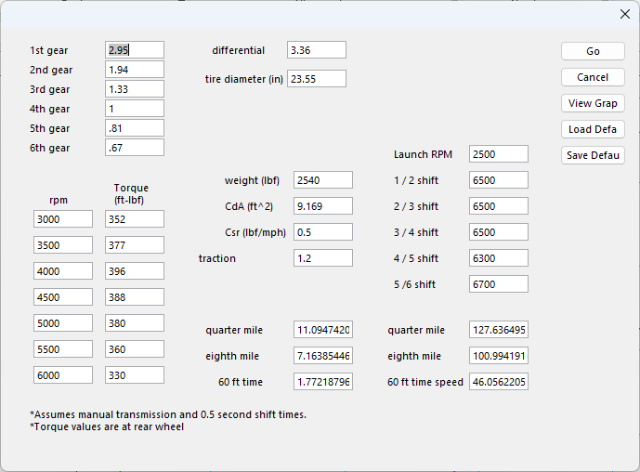

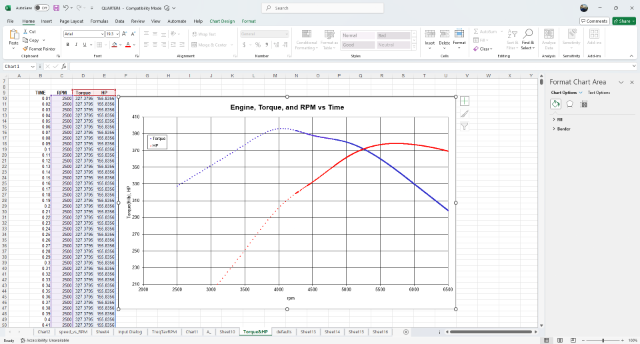

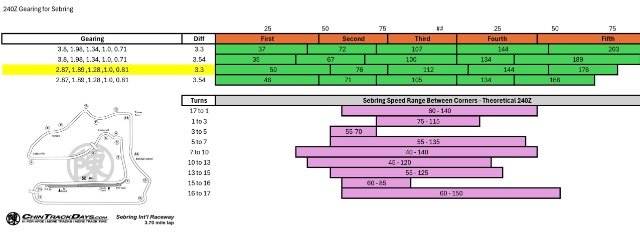

With a good 5th gear, overdrive is wonderful... I have the mythical R200 with 3.36 rear gear. The transmission is a T5 with the G-Force Shafts and gears 1 through 4. I run short tires Avon 23 /10.5-15 on all four corners. When I first installed the G-Force gears I was only auto crossing the car, and really only used 2nd gear. When I started doing track days (Daytona and Sebring), I quickly discovered that 5th gear was horrible. With the stock gears, 5th wasn't optimal but wasn't too terrible (3.35, 1.94, 1.44, 1.0, .67). When I changed to the G-Force Gears, 1st gear was improved but 5th gear sucked (2.95, 1.95, 1.33, 1.0, .58) First time at Daytona, I was redlining 4th gear by the time I came off the banking onto the front and rear straights, and the .58 5th gear would drop my rpms and torque too much to be useful. The .58 5th gear was horrible, so I pulled the transmission and took it to Astro Performance in Tavares, Fl and had them install the A5 5th gear (0.81). The difference was night and day. Overdrive went from a total buzz kill to being my Warp Drive... If you get a transmission with a good 5th gear (TKX with .81 5th), then you'll be fine. This is what the gear spread (speed versus rpm) looks like: Here is what a full acceleration run looks like if you assume 0.25 second shifts: The above uses numbers from my old dyno chart and the following inputs: Dyno graph from my old engine (my new engine makes more power and torque): -

Fast Floridian's 240Z Track Build

clarkspeed replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

The tranny/rear is a trade off. You really dont want to shift to 5th at 120+mph. The wind resistance will drop you 10+ mph and if you are not in power band you will not accelerate much after that. Not good for Daytona. Rule of thumb is the more peaky your engine is, the closer tranny ratios you need to keep it in power band. The other rule is select gearing to be well into power band or just over in top gear, top speed. Depending on engine you may need a different rear/and or tire ratio to run Daytona, it is different than other tracks. Many club racers run the final 1000-2000 ft at redline, but that can be risky. -

ideas on how to get this rusty bolt out

NewZed replied to adsdsasdasdasda's topic in S130 Series - 280ZX

Seems like you might need a better wrench. A six point box end would be best. 12 mm I believe. p.s. forgot to mention the original impact wrench. Tighten up the wrench on the nut. Then hit it with a hammer. p.s. 2 - it will take a lot of heat to get the flange hot enough to hurt the seal. A torch on the nut should help. Doesn't have to be red hot. https://www.lowes.com/pd/Capri-Tools-12mm-WaveDrive-Pro-Combination-Wrench-for-Regular-and-Rounded-Bolts/5001577325 -

ideas on how to get this rusty bolt out

tube80z replied to adsdsasdasdasda's topic in S130 Series - 280ZX

I have a set of extractor wrenches that come in handy for things like this. Here's a link https://olsatools.com/products/7pc-offset-extractor-wrench-set?variant=41307851161651&country=US¤cy=USD. Cary -

I really think you should move to an overhead bar.

-

Linkage is what I am calling the small arms between throttle bodies and the shafts. You need to remove everything connecting each throttle to the overhead bar. Then sync. Then check again once hot. Also blip each throttle, see if they stick or bind once hot. You should have the cable going to a cam on the overhead bar. If that isn't what you are doing, I would highly suggest that route. Setting butterflys is extremely difficult to do perfectly. I would print the 3D file I posted for syncing, then set each off the car. Then put each in an oven to 185 and check each again. Do you have an injector company in your town? Have them checked for flow matching?

-

ideas on how to get this rusty bolt out

jhm replied to adsdsasdasdasda's topic in S130 Series - 280ZX

Can you fit vice grips on the nut? That may work. Otherwise, your idea of grinding/cutting the nut off with a cutting wheel should work as long as you have room to get it in there. -

Hey folks trying to take out the drive shaft so i can take out my transmission and engine. been trying to throw a wrench on the nut (at the end) and use a screwdrive to turn the shaft so the bolts can loosen up. how ever this isnt working. tried pb blaster, wd40, wd40 penetrate. next thing ill try is heat but im worried about the grease, oils from earlier and the break lines near by. alternatively im thinking about grinding off the nuts but not sure if there are any other ideas. please lmk! P.S. I started stripping the nut head. https://imgur.com/a/w9CVTiL

-

I’m using cable control on the linkage. So the issue with them is the cascading effect of using cable on one ITB that has direct linkage to the other two . It causes #1 ITB to open up sooner no matter how I try to adjust . I also have #4 port that doesn’t flow as much air as the rest . Maybe a butterfly issue - slightly off. I would go with rod linkage but I’m pushing it for time to make it to ZCON . I’ve tried syncing the best I can at lower TPS by just holding throttle open with cable adjustment and calibrating 3-6 . Once I’m around 12+ TPS - AFRS blend much better . As far as #4 - I will address this with injection trim . It’s just light cruise where I have to pull some fuel . I’d love to try the rod linkage but I’ll have to see how much time I have . It won’t help with the center ITB . I’ll have to take it off and see about doing something with the throttle plate . Again - it much time for that right now

-

How close are they synced now? Are you removing linkage to do that? Are dog bones the exact same lenght?

-

Any Reason to find one if you havent been running one? Asking for a friend....

-

Ls1 swapped 280zx exhaust issues

nismoluv replied to bajajoas's topic in Gen III & IV Chevy V8Z Tech Board

I used his list plus a angled bearing plate from jegs or summit for like 10 bucks. I couldn't use the location he used. Still a work in progress so Ill post when i get it all welded up. https://forums.hybridz.org/topic/124248-steering-shaft-relocation/ -

Ls1 swapped 280zx exhaust issues

bajajoas replied to bajajoas's topic in Gen III & IV Chevy V8Z Tech Board

Thanks for the tip..what is the steering shaft modification? -

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Ordered the Apex track attack kit for the rear, and sent out my 370Z diff to be rebuilt with a wavetrac LSD. Going with the 3.3 gears. Did some more research and I was thinking about the gearing wrong. I’m sure it’s common sense to those with experience but I was including the overdrive gear in my analysis. For a track car, I learned you should gear it for redline in 4th on the longest straight, then you have overdrive if you need it. So going with the highlighted option below. Planning to work more on brakes this weekend, I unboxed my dual master cylinder set up, trying to understand how it all goes together and figure out plumbing. I have my new brake lines too, so hopefully replacing all the lines and get them plumbed to the master cylinders in the next few weeks. -

Ls1 swapped 280zx exhaust issues

nismoluv replied to bajajoas's topic in Gen III & IV Chevy V8Z Tech Board

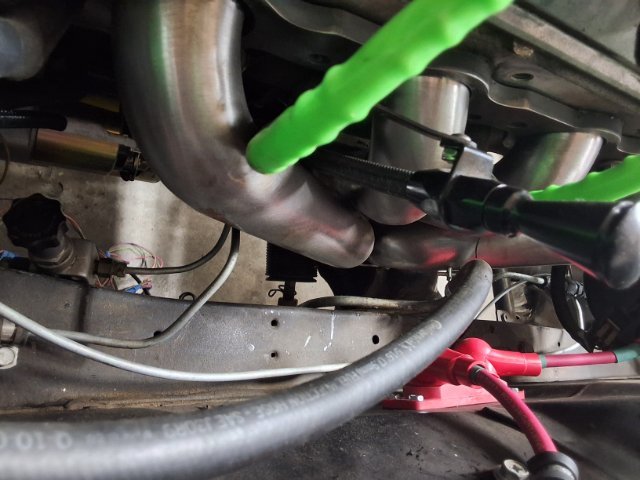

I am currently working on this same issue. I got sandersons D1 headers uncoated since I knew there would be issues, just based off the photos. On the passanger side I dented the backside to clear the mounts. It was just above the collector, I can't remember which cylinder. It was a pain since thats there the collector and primary overlaped. I also got to a point that i didnt want to dent it any more and cut a section off the motor mount. The mounts are lsbillet swap plates and jags that run chevy put together. The portion I cut off shouldnt affect the mounts, unless the engine spontaneously shifts back an inch.... The driver side I am going to modify the steering shaft based off another post. Its pretty good post. Not sure of the link, I copied it into my offline notes. Dont mind the fuel line returnin the photoes still moving things around. Ive been delayed on this project since spring. The wife to do list was piling up. -

.jpg.b34f27553f5960421801c8ab2cbf5db3.thumb.jpg.7889e8073010b6a0d8d6aae0626e768b.jpg)

Ls1 swapped 280zx exhaust issues

G-Tech replied to bajajoas's topic in Gen III & IV Chevy V8Z Tech Board

Not many take on this challenge, good for you! It is for sure a challenge. If you have rack and pinion steering, you have the worst. There is manual which is not bad and i dont exactly remember the name of the other style. Its like reciprocating, or something like that. Bottom line is, i found that a "block Hugger" style fits well on Pass side. It's the driver side that i had the most issue with. 1st thing is to pin the steering shaft (I drilled and tapped through it for a screw) so you can cut-off the clamping ear. Then get rid of the Rubber Rag joint on the steering shaft. Techno toy tuning makes a solid piece to put in place. I don't know anything about the size of it though. I made mine and made it smaller diameter for clearance. I have modified a couple different sets of headers. I 1st had a Hooker High Flow Manifold that i still had to cut a window in it and have a plate welded in from the back side. Then i didn't like that i had 2 different style headers so i bought BillyBoat headers for a C5 vette. Still had to cut a tube off and re-route a new one to avoid the steering shaft. Then i was worried thet 1-5/8" primaries were not big enough and i had someone make me a set of long tube 1-3/4" headers and found that it was not worth it. I went from 375whp to 387hp (very disappointing results for the $) Take a look at all the pics. There is a pic for everything i just explained. Worse case you can run manifolds upside down and they will point fwd. If you are turboing, this will work well. If not, you have to run the exhaust fwd and down around the front, which i'm not a fan of. -

Can anybody share what they used for exhaust headers for a ls1 5.7l motor in a 280zx? I knew this would be a challenge but coming up short or should I say shorty

-

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Finished up the 17x8 wheel conversion on a turbo 280z. Got the geometry perfect. All the TTT suspension parts made it easy. https://www.facebook.com/share/p/15JMLRNJpd/ -

Getting the right oil pan for a big HP RB swap in a 240Z is not easy!

primaz replied to primaz's topic in Nissan RB Forum

I do want to give a big thumbs up and shout out to "artishard" here on the HybridZ, I kept searching to find anyone whom had one of RIPS old custom oil pans and it turns out that "artishard" here on the HybridZ has that very pan and was kind enough to share several pictures. Those pictures were amazing as it looks like they are enough for Robbie at RIPS Racing to make a custom oil pan for my application! This is why HybridZ is so great to learn from others mistakes and share information so valuable in our pursuit of performance!

-

Who's Online 1 Member, 0 Anonymous, 291 Guests (See full list)