All Activity

- Today

-

In case anyone's not paying attention, I'm up to Episode 5 published now. And in the backlog to be released weekly, the engine mounts are done, and I'm working on the transmission mount. I've got my digital whiteboard forming and will transfer to a common cardboard punch list soon. Definitely making progress!

- Last week

-

TR's 260z L28 Build Thread

TrumpetRhapsody replied to TrumpetRhapsody's topic in S30 Series - 240z, 260z, 280z

Looks like I missed some updates! In September I showed my car in a local event, TougeCon. They had a nighttime parking garage meet that I installed underglow for, and a daytime "car show" at the town square. Was the first time really getting the car out, and it garnered a lot of attention! I still haven't dug into diagnose whether I still have the noise issues (probably, I still see some spikes on CLT and AFR), but as mentioned in this thread I did finally resolve my jumpy tach. Turns out using a 12V zener was allowing noise through, and using the proper 18V zener cleaned up up. It's nice to finally have a solid tach. I picked up a cheap Chinese touchscreen head unit that runs android, so I could load ShadowDash and connect Bluetooth to Megasquirt for logging and some extra gauges. It's pretty slick! I have it auto-uploading logs to Google Drive when I hit Wi-Fi, and can download and burn tunes. In the last couple weeks I noticed a distinct whine after the engine got up to temp. It sounded like it was coming from the block area on the passenger side. Eventually I realized that back when I did the L28ET swap in 2009, I blocked off the inlet/outlet on the factory oil cooler since I didn't have a filter stud handy. It must have been bypassing oil the entire time I've run this engine. 🤦♂️ For now I got a stud from Nissan, and have an oil cooler coming from GRW. After the tail light swap, I realized the late-style license plate light wouldn't fit the early panels. I took inspiration from Skillard, and fabbed up a simple blanking plate using LEDs. I also pulled the trigger on a fuel system refurb. I'll be retrofitting an Aeromotive Stealth 340 into my factory tank, using a Radium stainless 10 micron filter, and upgrading to PTFE lines to eventually run E85. No more fuel slosh and starvation! In the meantime, now that the engine is broken in I've been working on dialing in my tune under boost. I set up some knock ears using a knock sensor, portable audio amplifier, and some headphones, and it seems to work pretty well! Once I hit around 10psi in any gear, I can clearly hear some ping. I'm holding steady at < 12:1 afr, and have backed my timing out to 19*, but still haven't gotten it to go away completely. I'm going to drastically pull timing and richen things up to work from the other direction, but that's already less timing than I'd expect necessary. -

I found out that the IAC plug in my throttle body is actually leaking air, possibly causing this RPM increase. I sent an email to Pro Tunerz asking if this is intentional or if their plug should be sealing the opening 100 percent.

-

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Painting the 1/64 scale 240Z- I masked off the Bottom of the car for the Bright Red Top Coat. I had to mask off the sections that would end up White. Next, After the Red Top Coar was sprayed and dried overnight, the masking paper was carefully removed. Now, the Red Section must masked off for the painting of the White Lower Section to be painted. At this point, the car should resemble something like this. While allowing the White Paint to dry 24Hours, I decided to work on the Engine Compartment. I had to fabricate the Aluminum Radiator. It made from Scrape Flat Plastic Sheet. I glued a tiny piece of fabric to give the radiator finned look. Then, I brushed it with Chrome Silver. Yes, the Radiator is Tiny. That small size of parts gave me the biggest headaches as parts were so easy to lose. Engine Compartment was also constructed with Flat Plastic Sheets. Note-Battery on the Left Side of the Firewall. The Radiator was mounted on the Fabricated Core Support which has the Holes on both sides of the Radiator. The Strut Tops were painted Red Metallic. Tweezers had to be used to installing all of the components (like brake master cylinder,etc) Brake Master Cylinder Finally, the LS3 motor (got from Ebay). but nobody made T-56 6speed transmission. So I craved on out of Balsa Wood. LS3 Motor detailed painted with Gloss Black on most engine components. LS3 AND T-56 Transmission installed in engine bay. Next-Detailing the Interior -

Jonahr joined the community

-

yes, same problem it seems with these intakes. I used a thin layer of Permatex Ultra Copper, the leak is stopped, i checked with my smoke leak detector. I fixed my timing table (more conservative numbers), re-calculated my Bosch 0280155968 injectors flow at 36 psi (without vacuum it is at 43 psi), and re-generated my VE table using the built-in TS calculator. 43.5 PSI (3 BAR) 430 cc / min = 41 lb / h Calculation: old/original fuel pressure = 43.5 New Fuel Pressure = 36 Size of Fuel Injector in lb/hr = 41 New flow/Size of Fuel Injector = 37.298 lb/hr or 392.01 cc/min The IAC is disabled, the valve opening is plugged. I can't re-check the idle startup with engine cold at the moment, but when warmed-up, I can't get the RPMs lower than 1.5-2k. The only air leak is at the throttle body with the blade which is barely open (if I close it more, the car dies). The engine's vacuum is at 15-16 at the 1500 rpm. My valve cover vents the gases via a small filter. The PCV valve is connected and operational. If someone has time to review my tune with a datalog and tune for any issues, I'd appreciate it. Should I proceed with turning my IAC on at this point? Or I need to test the cold startup before going with the IAC enabled? Thanks. PS With the throttle blade barely open, the car is making a loud annoying whistling noise. With IAC installed, the blade will be completely closed and this nonsense should stop, I hope. CurrentTune.msq 2024-10-27-no-IAC-VE-inj-changed-calculated-flow-7.mlg

-

Swedish Datsun 240z Restoration

Tebirkesueth replied to Tebirkesueth's topic in S30 Series - 240z, 260z, 280z

3 years later... took ages to find a good painter willing to take on the project. These days insurance jobs with small panel fixes seem to be more profitable. Luckily I found someone willing to do it in the summer months of this year while the insurance workload is reduced. Prepping... Overall quite happy with the result. Couldn't contain myself and started puzzling together the undercarriage the first chance I got. Pulled lines in the trans tunnel and assembled the suspension component. On the wheel first the first time since 2017! -

Better use some RTV or buy the expensive gasket they recommend . The flange is warped probably like mine . I used a machinist straight edge and there was .020 drop off on the end . I bought the 75$ gasket but some red RTV would probably l work also . my car makes all kinds of whistles and gear noises .

-

Replaced the MAP sensor, it is properly showing the kpas now. I have a bad air leak around cylinder 1, protunerz intake didn't seal the gasket. I did install it following the torque specs and order. While running, the air leak was audibly noticeable. I removed the intake, and didn't see any warpage. Ordered a new gasket. With GM IAC installed and in a closed position, the throttle body is making high pitched whistling noise. I guess the shape of the opening for the valve makes this bad harmonics issue. I also noticed my fuel pressure was around 50 psi. Adjusted the FPR, it is around 40-43 psi now.

-

Saleh joined the community

-

Hello everyone I have a nissan laurel c32 equipped with L24s 6 cylinder engine and I’m trying to find a replacement for my old carburetor, I’m here to ask if the weber 32 36 will fit, I noticed that i have a fuel inlet and outlet in the oem carb and most what i found only inlet i believe this is because i have electric fuel pump

-

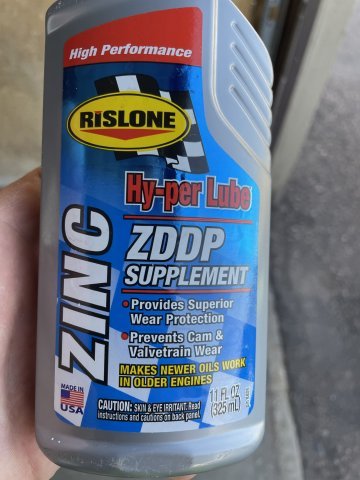

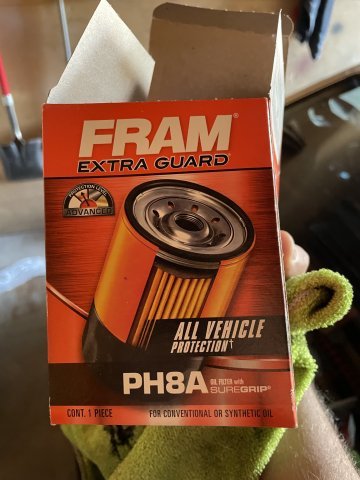

First oil change today. 523 miles. I pulled the drain plug and the oil came out BLACK as expected. I had a buildup on the end of the plug, which I also expected being a fresh engine. Topped her off again, with the Risilone ZDDP and went from 10W30 to some thicker 20W50 cheap oil "O'Reilley's 20W50" (hey its got the ratings....) to see if it raises the oil pressure up a tad. So, this will stay in for 1,000 miles, then I will switch to a synthetic and a new filter of course. The rear main seal weeps a tiny bit on the ground, but very acceptable. Perhaps this thicker oil will stop that. Overall, the engine has performed as expected. So, for those that have been following along, this is a pretty good way to go for a Z car engine. Pics to follow. Cheers!

-

The Factory manual states 18 degrees at idle. I did 20. It runs GREAT! 91 octane fuel up here, which is 93 everywhere else, 11.5 to 1 compression...no pinging, pulls like a frieght train. When all else fails, follow the manual I guess. Everyone told me the "A" cam was too weak.....my exhaust manifold won't work......well, it WORKS. Its a quick Z car.

- Earlier

-

I manufactured a bunch of them out of aluminum if anyone is looking for one: https://importbible.com/shop/spare-parts/sun-visor-clip-mount

-

36-38 max at 100 KPA ? If so I would back that off to about 34 . No problem to be at 40 at light cruise

-

Sounds good, thanks Steve. For now I will build a conservative timing table with max 36-38 degrees. I've been messing with my GM IAC I got from Protunerz. Managed to catapult the pintle into oblivion a few times. I didn't realize there is no stop. My max homing/closed/moving is at 160 steps. The IAC properly extends and stops at whatever CLT temperature is at. If I set the IAC at always on/hold current, it is making high pitched annoying noise. I will leave it at 'Moving' for now. I attached a fused 12V supply to it without my car running. What I _couldn't do_ is to use the 'Idle Warmup Duty' and put the max 160 steps in the 60-80F range to make the IAC completely close. Not sure, if this is because the car is not operational?

-

Be conservative with the timing under load . Yes the engine can run at 45 degrees at light cruise with low Kpas . I would agree that 34 at full load is more realistic . Make yourself some detonation headsets and listen to your engine . Make adjustments accordingly

-

A musician's therapist (The $300 Z)

Zetsaz replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

In other news. The bummer of hearing my brake option wasn't available made me want to see the other parts that showed up this summer the day after I left, so I asked my dad to open up the boxes and send some pics. Got new spindles and hubs from T3 in a scratch and dent sale. Literally days before I saw the Facebook post I had already messaged them about potentially needing parts while I was still stranded in Eastern Oregon when the bearing failure tore up the hub. Dad said they looked damn near perfect, so either T3 is super generous about their discounted products, or the guys picking the parts were the ones emailing me and took pity and grabbed the best examples for me knowing the story already. Alvin from Z Car Garage posted a reply to my Facebook post on dpan stating they're working with the same engineer from the previous brake kit for the next option, so I guess I'll just keep waiting in the meantime. -

This part of the Megamanual might help. https://www.megamanual.com/begintuning.htm#spark https://www.megamanual.com/ms2/tune.htm

-

You have to look at your MAP tables. At high vacuum (low pressure) you can run more advance for a cleaner burn and better efficiency and better throttle response. At higher RPM under open throttle most people have found that about 34 degrees is where you get the most power. You can read a bunch in the L6 FAQ sub-forum about having timing set "all-in" at about 2500 RPM or various numbers around that. Meaning that it stops advancing and just hold at that advance number from there to the high limit. If I was starting with an MS tune I might first just mimic a stock engine's timing curves. Nissan provides them in the Engine Electrical chapters. You have to do some translation. And the charts are in distributor speed so that's where you have to do the doubling. From back in the days when they had distributor tuning machines. The early FSMs have an actual graph. Later ones have just a table and let you imagine the lines. Here is 72 and 78. 78 would be like your engine probably if it's a stock 290Z engine. They have different options for different markets and different transmissions. Generally, lower advance is for emissions states, like CA. Reduced timing is cleaner. notice that they give the starting point, zero degrees at XX RPM. So the first entry shows vacuum advance starting at 200 mm Hg, and increasing to 15 engine RPM at 350 mmHg. Centrifugal starts at at 1200 RPM and rises to 17 degress at 2500 RPM. It's like a mini general physics course. It can be confusing, especially since centrifugal is tied to crankshaft rotation but vacuum is just tied to air pressure in the manifold. Sometimes I still wonder if I'm thinking about it right. It's easier to grasp if you have a stock distributor on a running engine with a timing light to learn on. Good luck. 1978 EE chapter. 1972 EE chapter.

-

Thanks, NewZed. Appreciate your input. I did arrive at the same conclusion about the cam timing finally - two different things. Appreciate confirming it. I was way overthinking it lol. I think I finally nailed the initial timing config using 0 commanded degrees in the Fixed Timing section of the TunerStudio. I set 60 degrees in the 36:1 section, tooth #1 Angle (deg BTDC), which confirms Chickenman's statement about counting the gaps times 10 degrees for 36 trigger wheels (I have 6 gaps, 60 degrees). If I count teeth, my hall sensor is pointed at the 7th tooth. Question: I checked some of the guys' tunes on this board (cyrgnus and madcaw's) being curious about their total timing on their engines, and most of them have 41-43 degrees by 3000 rpms. I have a stock n/a engine with a N47 head, should i go with a more conservative number like 36-38 degrees?

-

Not sure exactly where you're going or what the current problem is, but I think that the first comment above is incorrect, and the second one is correct. Also, you were talking about cam timing and ignition timing together at one point (the 4 degrees thing). They are completely separate as far as spark goes. You could move cam timng all over the place by switching holes on the sprocket and it would not affect when the spark occurs, relative to crankshaft position. Timing sensors are all measuring where the crankshaft is in its rotation. Cam timing is also relative to crankshaft position but adjusted separately from ignition timing. Just some hopefully helpful commentary.

-

Biggy8481 joined the community

-

Found some posts suggesting to use 0 degree fixed timing, this way I am avoiding any issues with timing light/wasted spark results. I don't have any timing marks (-10 to 10) besides the timing pointer I got with the trigger wheel. Tested with 0 degrees fixed advance and 0 degrees cranking advanced using 2 timing lights (old school with a variable knob on the back and the modern electronic one set at 0), both showed the TDC. My 36:1 Tooth #1 Angle (deg BTDC) was set at 60 degrees.

-

Tinchariot joined the community

-

-

I was able to run the car with 70 degrees trigger crank wheel, 10 fixed. With advance timing light set at 0 degrees, I was seeing synced timing marks. Now, back to the previous post about doubling the timing light to 20 degrees to check my timing? Is it needed or I am good to go? I turned off the fixed timing, the car ran very rich, stumbling. I realized my MAP sensor (intake mounted unit from a used LS1 vehicle) was not working, it was stuck on 100 kpa. I am going to get a GM wall mounted unit. Saga continues. Thanks! 2024-10-18-auto-timing.mlg

-

For what engine? For the L28ET It's a standard T3 flange. I think some of the 4 cylinder engines used a T25 flange.

-

Who's Online 3 Members, 0 Anonymous, 329 Guests (See full list)