All Activity

- Past hour

-

Getting the right oil pan for a big HP RB swap in a 240Z is not easy!

primaz replied to primaz's topic in Nissan RB Forum

I do want to give a big thumbs up and shout out to "artishard" here on the HybridZ, I kept searching to find anyone whom had one of RIPS old custom oil pans and it turns out that "artishard" here on the HybridZ has that very pan and was kind enough to share several pictures. Those pictures were amazing as it looks like they are enough for Robbie at RIPS Racing to make a custom oil pan for my application! This is why HybridZ is so great to learn from others mistakes and share information so valuable in our pursuit of performance! -

Datsun 240Z RB30 oil pan For my 1972 240Z, I wanted to create a reliable big horsepower streetcar capable of 800-1000 HP. To meet those goals I choose RIPS Racing whom has the proven track record in creating reliable high HP street cars, exactly what I was wanting. One of the issues I faced was that Robbie of RIPS had lost his template for a rear high-capacity oil pan for a 240Z swap. There does not seem to be any good oil pans for a 240Z RB swap. If you are building a big horsepower RB engine to be swapped into a 240Z PLEASE BE CAREFUL AS I PERSONALLY DO NOT THINK THERE ARE ANY GOOD PANS AVAILABLE AND YOU WILL NEED TO GO HAVE A CUSTOM OIL PAN MADE! Here is my sad experience thus far... After spending weeks online reviewing so many oil pans only to find that all of them were not adequate based on RIPS observations. I found this one JHK pan from U.P. Garage that appeared that it might work so I took a chance after they told me it would work, https://upgarageusa.com/collections/jhk-oil-pans/products/jhk-rear-sump-rb-cast-oil-pan When I received it, I shipped it straight to RIPS as I did not want to undo their professional packing. I did not open the box, as I just brought it to DHL and they put their label over where your label was. I sent it to Robbie at RIPS Racing in New Zealand. Unfortunately when it arrived to New Zealand it was damaged. I told Eric, & Doug @ UP Garage via email, The oil pan you shipped to me was damaged. I did not open the box, as just brought it to DHL and they put their label over where your label was. I sent it to Robbie at RIPS Racing in New Zealand. Additionally, Rob told me that this design would not work as there is insufficient clearance between the oil tube and also between the baffle and engine. I have attached pictures and an MP4 where Robbie shows the box damaged before fully opening it. This was an unfortunate expensive mistake as it cost me over $700 to ship it only to find out it was damaged and would not have been a good pan for my application. When I get my fully built engine towards the later part of this year Robbie will send your pan and I can return it. I would hope that I get a refund. Now we need to source a better pan that has more oil capacity, and a better design to provide the oil flow needed for my engine. On a phone call UP Garage said it was my fault for not opening the box before I shipped it to New Zealand. I told them I examined the box it was not damaged in anyway, so I reshipped it without opening it in order to not disturb their packaging, but they still denied any liability. I then sent them the following email, Eric, & Doug, I sent the pics you texted me to Robbie, and I am glad he explained the issues technically with the oil pan. Doug was telling me that your pan would work fine on a more stock build but reading Robbie’s great explanation, I doubt that would be the case on my 2 WD RB block. Regardless, the oil pan was damaged and if you feel that it can be resold to someone as Doug stated, I will send it to you after I receive my complete engine with the damaged oil pan from RIPS. You are specializing in a local RB market would be better suited to find a new home for this oil pan than me here in Northern CA. Doug claimed it should be easy to sell it as the damage was cosmetic, then it would make sense that afterward you resell the oil pan, you could reimburse me for my purchase or at least most of that cost. U.P. Garage sent this email to RIPS, We are, and have been, huge fans of your hard work to bring HP to the RB world!! So glad that the JHK pan has found it's way to your examination table. Here are the measurements we have taken on the RB25(rear drive block) screen configuration. Keep up the great work!! Feel free to call us: +1 253 565 9823 Doug/Erik Fatty Fat Cat www.upgarageusa.com From: RIPS Racing The pictures you have sent are not from a 2wd block, they are from a AWD block, possibly a RB26 with the longer AWD pickup. The measurements you have are with the pickup you have on your block and quite different to the measurements I have with the pickup and oil pan I have received. As stated, with the pickup bolted on (without a gasket) the pan will not go down all the way to the block, the pickup screen is holding the sump up a little bit meaning the screen is already touching the bottom of the sump before its even bolted down flat. There should be about 10mm clearance when the sump is bolted down meaning as it is, bolting the sump down will put load on the pickup and be squashing the screen and the tube inside the screen will be pretty much hard against the floor of the sump meaning a massive restriction in oil flow. RIPS also sent them this email, Hi, Just to add to this, with the oil pickup installed on the block (even without a gasket) the sump would not sit flat on the block, the oil pickup was ever so slightly holding it up so the screen on the pickup was hard against the bottom of the oil pan. This means if the sump was bolted up tight the pickup tube itself (inside the screen) would also be basically hard up against the bottom of the sump meaning major restriction is oil flow. There should be around 12-15mm clearance between the end of the oil pickup tube and usually around 5mm clearance between the screen and the bottom of the oil pan. As it was supplied there is no way it could have worked and would have surely led to an engine failure.

- Today

-

That's a great suggestion. Adam's very responsive; it seems like FB is his preferred medium -- here's his page: https://www.facebook.com/DatsunRescue

-

1977 280z driving project from the Netherlands

Mitchel0407 replied to Mitchel0407's topic in S30 Series - 240z, 260z, 280z

I spend the last few days cleaning the electrical connections and timing the ignition again as it was out of spec. The car runs way better but the AFR gauge still shows 11,5 at idle. I'd like to bring that down (or up depending how you look at it) to 14,7 as the car stinks of gas. The previous owner mentioned that that was the reason it didn't pass inspection (auction company didn't mention that). I tried messing with the idle air mixture screw but that didn't help. When turning clockwise a bunch the car did start to run richer but when turning anti clockwise it didn't get past 11,5 AFR. I did notice the ignition coil is a 1,5 ohm unit with a total resistance of 2 ohm with the external resistor. I believe it needs to be closer to 1 ohm total so I'll probably replace the coil with a 0,5 ohm one. -

Mitchel0407 started following '77 280z running rich at idle

-

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

The Follow Up Road Test went fine. There was no CV Axle Grease leak and the Diffferential performed well. The Differential Gear Ratio was now 3:55 compared to the old r200 3:70 so my shift points were now more spread out. I think that 3:55 gear ratio for city driving by providing less gear shifting. Highway driving was better by running at less RPMs too. The Blue Angels-the Navy Stunt F16 planes were coming to participate in an Air Show at Kaneohe Marine Base. There also had a Car Show along with the Two Day Air Show. Although, the show was on the other side of my island , I decided to enter my 240z in the Car Show. The trip would take about one Hour but most of it was on freeway roads. The Freeway would take me over the mountain to the other side of my island. On the downward leg of the trip, I noticed that a lot of pedal effort was necessary to slow down, My conclusion was that a Bigger Brake Power booster would be needed. The OEM Brake Booster was 7" booster so the next size booster would be 1978 280z booster which is 8 !/2". The local auto places did not have a 280Z booster available so I ordered one from Z Depot. The Good News is that I won the TOP TEN Trophy for Aloha Mother Fest 2025 at this show. Next- Upgrading the 7" OEM Booster with the 78280z 8 1/2"Brake Booster Next-Upgrading the Brake Power Booster with a 78 280Z Unit - Yesterday

-

Hi mate, Low profile alloy air cleaner top with a carbon fibre air cleaner with the collection point in front of the radiator. Flexible rubber joiner between the alloy top hat and the carbon fibre air cleaner. The alloy piece is only about 2.5 inches high. Just another idea for cold air induction. Regards David.

-

Was looking for an old post from you because of the Panasport wheels you had and remembered this great thread. Any good progress since last year?

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Got rotors and calipers on. A few minor challenges making it fit for the 240Z, but very happy how it came out. -

Adam Sylvester at Datsun Rescue or Jenny at Junkyard Jenny's.

-

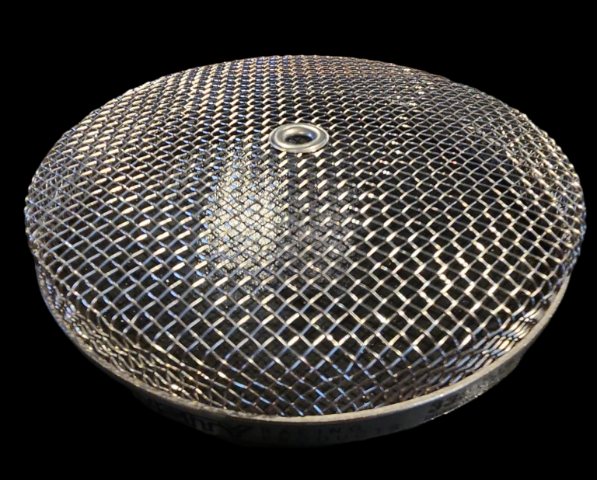

Ok, so update....thanks to those who warned me about these Edelbrock foam air cleaners. I started reading, one back fire and they will catch fire and turn into goo and run down into your carb/TBI !!!!! oh no! So, i looked online, because this filter was also hitting my hood. I found this company: Pro Series Screens - Intensity Racing Products I bought the mesh screen to work on my carb mouth. So glad you guys said something. WHEW! see pic, I got the low profile with the single hole.. 98 bucks....115 shipped. Saved my life.

- Last week

-

2jz gte ecu?? Continuity across crank and ground?

sharkys280 replied to sharkys280's topic in Toyota L6 Forum

Continuity was from the ecu to the plug that connects at the sensor, when the ecu was plugged into the harness. When the ecu was unplugged there was no continuity from the plug end at the ecu, to the plug end at the sensor. That led me to think the ecu was shorting to ground inside the ecu. I'll check out the video and test out the crank sensor, and its gap. I'm assuming their ok, as i am using a new crank gear, new crank sensor and new oil pump...but I know assuming is a dangerous game so I'll test it. Thanks for the link! -

2jz gte ecu?? Continuity across crank and ground?

NewZed replied to sharkys280's topic in Toyota L6 Forum

Barely know what you're working with but I did find a crankshaft position sensor online for the 2jz and see that it's a two wire unit. That means it's a variable reluctor system. There will be continuity across those two pins in the sensor harness to the sensor. There should be a resistance of a few hundred ohms, typically. It's not clear what you mean when you say you measured with the plug connected and got continuity. Can't tell which side of the plug you're measuring, to the sensor or to the ECU. Anyway, the signal to the ECU is generated when the metal teeth of the trigger wheel pass by the sensor. The sensor has to be within a certain distance from the sensor, that's very important. There's spec but it's usually a few thousandths. Pretty close. The basic testing is to measure resistance across the two pins to be sure the coil is intact and will work. Then set the air gap. Then test that a signal is being generated. https://www.jdmgarageuk.com/90919-05037.html Here's a pretty good video about the basics. . -

I'm a bit stuck and not sure the best direction to move with my swap, hoping someone can help me figure out where my problem is. I've got a 2jz ge that im swapping into a 280z, im going the nat route with an aristo gte ecu. I reworked the wire harness and got the the point of startup, but it only cranks and doesn't fire. I wired a check engine light and got a "1..2.." code. So I checked the crank position plug and was getting continuity from the two terminals on the plug. Thought maybe I wired it wrong, so unplugged the ecu and checked the plug again, no continuity. Then I checked the ecu and was getting continuity with pin 4, 5, 6 and 7. 4 is a ground, 5,6 are cam position, and 7 is crank. So I thought maybe the capacitor that sits on those pins was bad, went to an electronics store that gave me a capacitor that "should" work, then had a place remove the old and put in the new. After all that, Im still in the same place as I started. Crank, no fire, code "12". Any thoughts as to a next step, other than another ecu (which i did but on ebay, waiting for it to show)? Any help would be awesome!

-

Hello everyone, maybe somebody can help me. My 1977 280z is running rich at idle and the idle mixture on the AFM doesn't seem to help. I spend the last few days cleaning the electrical connections and timing the ignition again as it was out of spec. The car runs way better but the AFR gauge still shows 11,5 at idle. I'd like to bring that down (or up depending how you look at it) to 14,7 as the car stinks of gas. The previous owner mentioned that that was the reason it didn't pass inspection (auction company didn't mention that). I tried messing with the idle air mixture screw but that didn't help. When turning clockwise a bunch the car did start to run richer but when turning anti clockwise it didn't get past 11,5 AFR. Does anybody have any tips or things I should look at? The AFR does seem to be working alright as far as I can tell. I did notice the ignition coil is a 1,5 ohm unit with a total resistance of 2 ohm with the external resistor. I believe it needs to be closer to 1 ohm total so I'll probably replace the coil.

-

I disconnected my throttle cable and lubed it up, now it moves freely with no drag, in doing so, I re-arranged some of the items attached to the carb thus cleaning it up. A short amount of time to work on stuff today and I'm happy I was able to get it done. Also was able to tighten the spring for the secondary butterflies which is basically required to keep them working right. My thermostat probe adapter that goes into the top radiator hose also arrived and snapped a few pics.

-

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Its already fixed. I have these unusual gnose wide body panels i think are fairly aero efficient. So really the only decisions are if I want to run a cowl induction hood vs. standard no vents. And tall rear 7" spoiler vs whale tail. Input is welcome. Leaning standard hood and big spoiler. Working on mounting these NOW. -

EastWaZ joined the community

-

1978 Datsun 280Z RB25 Restomod

EastWaZ replied to Jethoncho's topic in S30 Series - 240z, 260z, 280z

any updates? Would love to see where this went. -

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

I was over in Orlando today for work and found a Z shop and picked up a used rear diff and axel. Was supposed to be 2 axels, but they stripped one getting it off an old Z. I’ll probably get the other one off eBay. I’ll be sending the diff to Z1 and getting it rebuilt with a wavetrac lsd and some new gears. -

280Z2J started following 280z RH door down stopper

-

part number 80581-E4100 looking for a good little plastic block assembly that the RH door dovetail slides on when closing the door. Cant find any new ones

-

@jhm. I appreciate that, Ive been putting out feelers on a few Z car forums trying to locate one, I know its sort of an obscure and delicate piece but its worth a shot anyway

-

@GavinG, if you don't find one here; I would also check on ClassicZCars: https://www.classiczcars.com/

-

Agreed! It's looking great....can't wait to see what kind of wild bodywork you have planned for it.

-

Who's Online 5 Members, 0 Anonymous, 230 Guests (See full list)