All Activity

- Today

-

Not quite yet! We are still working on getting the prototype piece just right before we mold it. Here is a rough first draft of the outer border, we are still making tweaks to make sure it fills as much as possible height wise, while keeping the OEM grill width. The cross blades will fill perfectly while allowing more airflow than OEM grills with larger gaps an will be all exposed carbon fiber!

- Yesterday

-

I think you'd be better off parting it all out. You'll make more and sell it faster.

-

05-16-2024 UPDATE: I re-installed the door latches after a cleanup and clear coating. New mounting bolts for them as well as matching washers. I also ordered from Skillard the door sill plates in brushed stainless with "DATSUN" cut out of both. They are enroute. Couple pics, you can see I put on the new data plate I ordered off of eBay Motors. Very nice piece. I have a couple of runs I need to sand out once the paint is hard. Cheers.

-

Thanks!

- Last week

-

Sorry for asking a silly question, I had a stock 280z now thinking go for 15 x8 wheel, just curious what is your experience for a tire size which won't get rubbing when with stock suspension?

-

Thank you, Mike. Ya, I kinda thought they were welded. OK, I'll look into the bimini pads.

-

My oil pan gasket has started to leak a little bit. Last night, my oil dipstick also blew out. I check my pvc valve and hose. They both seemed ok, but I'm going to replace both regardless. Going to do a compression test ASAP, praying I don't have low compression after all of this. I really haven't even gone over 4psi boost.

-

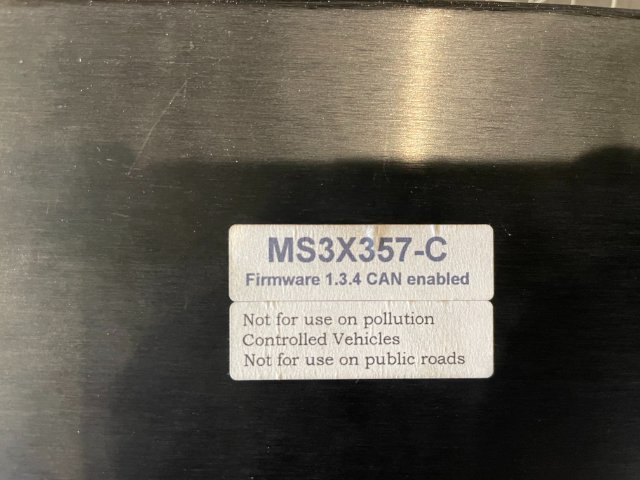

Megasquirt 3.57 ECU with MS3x Expansion

dereckwestairinc replied to Ben280's topic in Parts for Sale

Still available? -

Megasquirt 3.57 ECU with MS3x Expansion

dereckwestairinc replied to Ben280's topic in Parts for Sale

Still available? -

Megasquirt 3.57 ECU with MS3x Expansion

dereckwestairinc replied to Ben280's topic in Parts for Sale

Still available? -

It's welded on. Mine looks like one of these (called a bimini pad). If you could find one that was the right dimensions, it might work. Mike is welded on via the two screw mounting holes.

-

Selling my ECU! This has successfully run 2 versions of my L28 (one with ITB's) and a LS V8. Megasquirts are known for being very powerful for the price and have a huge community behind them. Lots of details, here's a link to the data sheets: https://www.diyautotune.com/product/megasquirt-iii-ems-system-with-ms3x-expansion-v3-57-assembled/ New is $700, I'm asking $500 shipped.

-

If you got the torque I’d go with the 3.54

-

Yet another LS 260z swap :)

christianmoller replied to christianmoller's topic in Gen III & IV Chevy V8Z Tech Board

I have now started the NOT so fun job with removing old paint from the engine bay, it has been painted with some black paint that sticks in the paper of the sanding machine so a knife, elbow grease and hours................but need to be done😴. I read Toolmans post about the media blaster from Auto Zone, could be usable for the surface rust under the former battery tray. Heater has also been solved, new bracket and hoses -

cant figure out steering clunk/pop

kaibiagi replied to kaibiagi's topic in Brakes, Wheels, Suspension and Chassis

I haven't done anything yet. The car is actually in storage for the summer at my college and I'm on a ship for the entire summer, so it's gonna be like a first thing as soon as I get back. Thanks for the tips, I will certainly do that. I'm also glad it looks cheap and easy, its too bad I found it after replacing basically all the wear components on the front end of the car though haha. They needed to be replaced anyway though, even if they weren't the source of the noise. -

Alright, I've been going over the harness the past few days, refreshing the grounds, making sure connections are tight. I have also been rigorously tuning, both manually and using autotune. My fuel pump issue has mostly resolved itself! I believe it was a combination of the grounds and the base tune I got from the map sticky. Car cruises very nice with good AFR's. A bit rich, but ok for now. It still happens here and there, and throws a sync loss error of 2, so I will still research into that. This car is quick!!!! I can only build about 4psi of boost atm, I think I have an exhaust leak before the turbo. Either way, with my zx tranny and the matching 3.9 rear diff, this thing moves. It chirps tires off the rip and will even twist a little in 2nd or third if I don't miss my shifts lol. I'm thinking about throwing my stock 3.54 diff back in, it revs almost too fast. Took her for some overpriced burgers yesterday.

-

A little tip that I learned years ago. If you plan on stuff being painted or coated, the use of anything in a rattle can should be avoided. It's just a extremely poor paint, and your just causing yourself more work in the future. When I have parts I need painted, I have a local smaller auto body should that sprays black parts for me with high end 2 part paint. I drop them off and as long as I am not in a hurry, he sprays my parts when he is spraying anything black. Or I have the powder coater do the same. I think the 60% gloss black powder coating looks almost identical to stock Nissan black.

-

Heavy Duty frame rails and connectors

jhm replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

$150 is a steal — nice find! IMHO, the Autopower bar is the nicest roll bar produced for the Z…it’s what I’ve had in my last two cars. Thanks for the update!! -

Heavy Duty frame rails and connectors

toolman replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

ROLL BAR INSTALLATION- While I was at a local 240z gathering, I found one Z owner who was selling a AutoPower style 240z Roll Bar for $150. It was missing the Four Mounting Pads and mounting bolts. The Roll Bar was first stripped of existing old flat paint using an Orbital Sander. I used 80 grit sandpaper for this process. Next, a small portable Speed Blaster air powered sand blaster. Similar sand blasters are sold at Harbor Freight and on Amazon for about $30. These sand blasters do a great job for rust and paint removal especially in tight areas. After paint removal, the Roll Bar was primered and preparred for color. As the Bottom Mounting Pads were missing , substitute plates had to fabricated from 1/4" Steel Plate. A 5lb Sledge Hammer and 12 ton Press were utilized to form the matching shape of the Roll Bar pads. !/4" thick Rubber Mat was used to go between Upper and Lower Mounting Plates to seal water from coming in the wheel wells. Cadmium Coated 3/4" NC x 1 1/2" bolts, Flat Washers and Lock Washers provided the mounting hardware. To hold the Roll Bar in position while marking the mounting blots hole with a Felt Pen, !/4" Rope Ratchets were used. They are sold at Home depot for about $20 each. They are super useful (holding up driveshafts, calipers, keep hoses out of your way,etc). One of the Rope Ratchet hook was attached the Rear Strut Tower Support. The other hook was wrapped around the Roll Bar Tubing. Adjustment is made by slowly tightening the Rope Ratchet to get the correct height. Shifting the Roll Bar side to side is done to obtain similar spacing on both sides of the mounting pads to the interior walls. Once the Correct height and Side Clearance is established, a Felt Pen is used to mark all the mounting holes. Then a Center Punch is used to prevent drill bit to drifting due the curved surface of the wheel housing. A slightly larger than 3/8" drill bit is utilized to drill all of the mounting holes. When assembling the Roll Bar on, One 3/8" bolt for each side is inserted thread first and tightened slightly to the Bar in place while installing the other bolts upward from the inside side of the wheel housing. Left Wheel Housing with Lower Mounts installed- Looking Sideways in car -checking Roll Bar Height Looking Forward at Roll Bar Viewing the Right Inside Wheel Well Left Side Looking Back Passenger Seat Looking Backwards View from Rear forward I posted a lot of pics of the Roll Bar installed so people can see the clearance available with this model. Many Custom Roll Bars don't have enough clearance for Tall Drivers. Interior View of Roll Bar without seats installed. -

Thoughts about installing carbs on an na2j?

chatapokai replied to chatapokai's topic in Toyota L6 Forum

Well well well, it's been a hell of a couple years for me personally and a lot has changed since then (jobs, world on fire, etc). Regarding the Z, I bought a 73 240Z frame in decent shape and have been putting it together. Took the rear end off the 260z scrap I had and currently am trying to put it on the 240z (and of course I'm stuck on the spindle pin holding the strut assembly to the lower control arm. Already broke the zcar depot tool...) Anyway back on the carbed 2j. I basically finished it and figured out how to get it running. So I cannot make it fully mechanical and will need a crank sensor + an ecu to make it go. The good news is that I can get the cheapest ecu, turn off fuel, and input the alternator points, aftermarket crank sensor for the 2j (i have the older one that doesnt have one), and the knock sensors for it to run. -

cant figure out steering clunk/pop

jhm replied to kaibiagi's topic in Brakes, Wheels, Suspension and Chassis

Oh, yeah...that's loose....REALLY loose. Silly question, but did you try tightening the 4 bolts that secure the coupler? You usually need to experiment with the right combination of box -end and open-end wrenches (because of the tight clearances and angularity of the joint). It also makes the job a lot easier if you rotate the steering shaft to get full exposure of each of the four nuts/bolts, as you tighten them. I do them in 180 deg pairings (like you would your lug nuts)....probably not necessary...just my engineering obsessive/compulsiveness. Glad you found the issue, and that it seems to be something cheap & easy to fix! -

05-11-2024 UPDATE: One of the last things on the punch list is to get the door jambs cleaned up, so I did that today. I also drained out the transmission oil as it is GLP-5 and is bad for brass syncros. I then refilled it with RedLine MT-90, which is of course synthetic, and is GL-4 rated....safe for brass internals. I also went ahead and undercoated the bottoms of my door sill plates. I will take them down to J&S Polishing to see if they can be polished, as you know they are very thin, we'll see! Pics:

-

Who's Online 0 Members, 0 Anonymous, 183 Guests (See full list)

- There are no registered users currently online