280zex

Members-

Posts

399 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by 280zex

-

Show Off Your Engine Bay! Pics Wanted, L-series

280zex replied to philipl's topic in Nissan L6 Forum

-

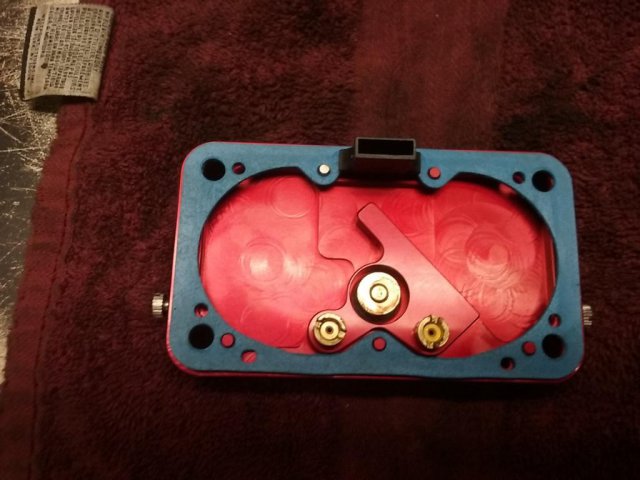

ok this is my mods and adjustments for a Holley model 4150 390cfm 4bbl double pumper for turbo charging, blow thru style BUY the blue reuseable metering block and fuel bowl gaskets along with the teflon fuel bowl screw gaskets, your going to need them. Main Body Mods: Mill off the choke horn, fill in the linkage holes in the main body from the choke. use fuel resistant epoxy Block off the secondary side vacuum channel for the power valve in the bottom of the main body. Block off all 4 high speed air bleeds. IF you do not have adjustable low speed air bleeds: remove the brass inserts (air bleeds) from the 4 low speed air bleeds, drill and tap holes to accept Idle Feed Restrictors with a 1/8 tap. This is a less expensive mod because standard size low speed air bleeds cost more than the smaller sized idle feed restrictors. AND most hot rod shops keep Idle feed restrictors on hand, so hopefully no special order stuff Primary side low speed air bleeds are 77 Secondary side low speed air bleeds are 52 Metering blocks: I use 2 primary Quick Fuel no vac port metering blocks because I need a standard power valve for the primary side, and a modified Boost regulated power valve (BRPV) for the secondary side. Google hangar 18 mods for BRPV mods, or goto theturboforums.com and do some reading there... Primary Metering Block: Main Jet #51.2 Idle feed Restrictors #33 Power Valve #10.5 Power Valve Channel Restrictors #55 Secondary Metering Block: Main Jet #60 Idle Feed Restrictors #55 Boost Regulated Power Valve #1.5 -------- I.E. I modified a #1.5 Holley power valve to work with boost pressure, GOOGLE BRPV!!!! Boost Valve Channel Restrictors #77 Float Bowls: single fuel feed float bowls with #130 viton needles and seats. Nytrile floats 30 cc accel pump shot for both fuel bowls, remove the pump arm from the secondary accel pump diafram, I didnt need the double pump action. Throttle Base Plate: Install new throttle shaft bushings, dont be cheap, just do it!!! Remove the secondary side accel pump cam and arm Install the Blue accel pump cam on hole 1 for the primary accel pump shot Install an adjustable secondary throttle shaft link arm and adjust to where the slack is just barely taught Install a back fire protection check valve for the primary power valve if you dont have one, YOU NEED IT!! MY base plate is set up for 2 corner idle mixture adjustment. I tried the 4 corner idle base and it didnt work for me. IF your confused, just google it....or go to theturboforums.com Idle screw adjustment: 1 turn out from closed position on the primary side, CLOSE the secondary side completely or it can flood out your idle mixture. This is my current running setup. Im at about 150-200 feet above sea level You also need a boost refrenced rising rate ( 1 to 1 ) adjustable fuel pressure regulator, Low pressure-high volume, fuel return style. I use AEM I use the stock Nissan fuel injection fuel pump for the 280Z, stock fuel lines. 50 micron Edelbrock fuel filter with replaceable filter element. My idle fuel pressure is 6lbs. TO NOTE: use caution during assembly of the metering block and fuel bowls to the main body. The gaskets can bunch up around the air flute holes at the top middle section of the metering block ON BOTH SIDES. IF you dont get this right you will push fuel out of this area and have a 400 HP FLAME THROWER!!! The primary side metering block is pictured first in order, front to back.

-

I am about to do a gasket job on my blow thru Holley carb. I run a 4150 model 390cfm double pumper. I will take some pix and write down my current jets and air bleeds for you. That vac secondary system just is not going to work with blow thru. Google Hangar 18 mods for Holley blow thru carb setup. IF your carb is a true 4150 Holley model, the mods are easy and only take 1 day to do.....

-

sounds like the clutch is not fully disengaging (duh) git the beast down to my place, we can fix it!!

-

email sent. I have a cooling mist pump for sale..

-

Longer hose, or the shorter one?? sorry IDK what is what, but I do have a complete factory A/C system i am parting out...

-

I got lucky this morning. I got another 1 owner 720 4x4 with 192000 miles. All stock factory, unmolested rust bucket....Strong engine the owner said it was dying on him......I found 1 bad vac line, HA!!! Factory WORKING A/C........ Time for an engine swap, and sell the rest for parts......

-

Found one D21 here in Seattle on CL with 310,000 miles, DAMN!!!

-

It was a good engine while it lasted, RIP napz z24. 250,000 miles, 2 owners. Nothing lasts for ever. im not sure if she spun a rod or crank bearing, but the beast got me home. Nissan makes some tough engines, thats for sure!!! Maybe time for a 302 swap???? 1985 720 4x4, the best damn truck i have ever owned...

-

This topic should clear up any mis-understanding. http://forums.hybridz.org/topic/115160-l6-cooling-system-diagrams/?do=findComment&comment=1140780

-

I did step 1 first. New coolant, new t-stat. Had same wierd temp spike. I then installed the t-stat bypass line and closed off the heater core line. No more wierd temp spikes. There is a topic around here i found about the importance of having that t-stat bypass line installed, and the size of the line too.

-

To note: i am still going to install an electric pump and control system to help remove after run coolant temp spikes.

-

No. If you dont have coolant flow thru your heater core, a t-stat bypass line is a must have. Basicly a t-stat bypass line is just a good idea. My Z never had one from when i got it from the wrecking yard. I never had any cooling issues until i installed the blow thru turbo setup. My Z will stay 202f temp IF im going 100+mph, OR if it is hotter than 80f outside air temp. The coolant temps usualy swings between 190f and 210-215f if im just cruzing down the road, and its a very active fluctuation. I installed an inline ball valve to the heater core and shut that off, its summer time and i dont use it. I then installed a t-stat bypass line in 3/8inch diameter from off the bottom of the t-stat housing to a T fitting at the water pump/heater core coolant junction. I used some ugly fittings and fuel line just for the testing.

-

Yes i have a 12x12 inch oil cooler, mounted in front of the car...

-

T-stat bypass hose fixed my issue, or maybe there was an air bubble traped some where inside the cooling system. Either way i still plan on installing an electric water pump setup. After run shut down temps spike to 230f behind the t-stat, even with the after run fans on...

-

Ok here is the plan: 1-Drain coolant and replace the thermostat and new coolant. 2-if new t-stat doent help then i can install a ball valve inline with the heater core. 3-if not the heater core then i will install the small t-stat bypass line. Right now step 1 is done and today its test drive time. I hope it was just a bad t-stat...

-

Now that is something I didnt take into consideration. I can go do some testing. I took the car for a drive and its warm enough outside that i only seen a 8F deg fluctuation on the temp gauge today. Oddly enough I only see ugly thermal spikes when its below 80F. I live in Washington and most of the year it satys below 70F, and thats when my Z coolant temp has a nasty thermal spike, or so says the autometer coolant temp gauge.

-

I think I will go shoot some video, just so people can get a better idea of what I am seeing. It may come down to the fact that I am being to hyper-sensitive to what may be a good working coolant system????

-

I dont have an EGT sensor, I will look into that. I did re-tune my ignition timing map last weekend on the dyno. I was able to pull a lot of fuel from the idle circuit. FYI-my turbo system is a blow thru Holley carb not EFI...

-

Here are some pix of my current coolant system. I dont have the t-stat bypass hose installed. From the reading here on HBZ I assume that I didnt need the t-stat bypass due to my heater core has no shut off valve like the stock factory system. I assume that this is not an issue?? maybe it is?? I get heat out from the core with-in 1 minute of start-up from being cold. I will go buy another factory Nissan t-stat and install that later today just to see what happens. I can also install that small t-stat bypass hose just to see if that helps equalize the temps better. I will also get some new coolant and flush the system. I did the vinegar block flushing trick when I rebuilt the engine. I will look into finding a way to completely flush the coolant system with the t-stat removed, just to see what may be cleaned out....

-

Every single part in question is brand new, with less than 6k miles. I can pull the t-stat and test it. I remove the water pump belt when flushing my coolant so i can spin it by hand. This can possibly help remove any air bubbles. I am assuming that the new aluminum radiator is really good at removing heat. My Z runs a perfect 200f as long as the ambiant temp is atleast 80f, any colder and the temp guage shows a lot of thermal cycling. the system may possibly have an air bubble stuck some place..... My turbo is oil cooled, so that is not an issue, or is it?? i have a 1.1 bar radiator cap. i use sierra premix coolant with 1 bottle of wetter water. i use an 14 inch electric puller fan on the passenger side of the radiator.

-

I have been on the hunt for an electric water pump for my Z. I found that if you look for a 12vdc high volume, high temp, low pressure fluid transfer pump, your options get really varied. I also found this control unit for electric pumps: http://daviescraig.com.au/media/760/1427255690.ControllerSwitchesSpecs2011.pdf Some times you have to use exact, and use specific wording when using Google search....

-

I did find an old post about the CSR electric water pump here : http://forums.hybridz.org/topic/43305-csr-water-pump/ Just wondering who else runs an electric pump setup?? My reasons why I am looking into going electric. 1- an attempt to control heat spike cycling, and reduce head gasket wear. 2- free up wasted HP I have also seen a setup around HBZ that a guy made a bracket and used an electric motor to turn the stock water pump. Right now I am researching water flow values for the stock nissan water pump. I ASSUME ABOUT 33 TO 36GPH?? The stand alone water pump from MSA: http://www.thezstore.com/page/TZS/PROD/16-7025 I like this unit and coupled with a Davies electronic control unit it should work with what I am planning.. My current setup: Turbo charged L28, ebay 3 row aluminum radiator, 1982 turbo water pump, custom heater core (all in 1 unit for a jeep). I do not use the thermostat bypass hose setup as my heater core is free flowing I.E. it has no off valves. It flows from off the back of the head, thru the dash core, and then back to the water pump. 190F thermostat. My Z has a thermal cycle from 190F to about 220 if I'm driving hard, and 190F to 205F on cruze. The temp guage shows a lot of thermal temp cycling unless its 85F+ outside, then it stays about 200F solid. I am concerned about all that thermal cycling and premature head gasket failure. My hope is that I may be able to control that thermal cycle better with a stand alone electric water pump and control system...

-

Wow, right on admins!!!!! Thanks much

-

This is what I'm talking about, thanks Google!! https://www.google.com/webhp?sourceid=chrome-instant&ion=1&espv=2&ie=UTF-8#q=water+pump+flow+hybridz+site:forums.hybridz.org