-

Posts

1193 -

Joined

-

Last visited

-

Days Won

30

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by 74_5.0L_Z

-

From the album: Parts For Sale

1973 240Z Rear Bumper -

From the album: Parts For Sale

1973 240Z Rear Bumper -

From the album: Parts For Sale

1973 240Z Rear Bumper -

From the album: Parts For Sale

1973 240Z Rear Bumper -

Relocating LCA inner pivot point

74_5.0L_Z replied to socorob's topic in Brakes, Wheels, Suspension and Chassis

Looks good. Except for the two picture that look like neck X-Rays. What is the side to side distance between your LCA mounting holes? How Long is the slot? -

Front Suspension Kinematics

74_5.0L_Z replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

I am ready for others to enter the discussion. Specifically, if you have dimensions of components or chassis points, please post them here. We can begin to use the tool to compare suspension geometry modifications. -

From the album: Kinematics

© This analysis is the intellectual property of Daniel McGrath (AKA 74_5.0L_Z). It may be freely distributed, but may not be sold or altered without my express permission.

-

From the album: Kinematics

© This analysis is the intellectual property of Daniel McGrath (AKA 74_5.0L_Z). It may be freely distributed, but may not be sold or altered without my express permission.

-

From the album: Kinematics

© This analysis is the intellectual property of Daniel McGrath (AKA 74_5.0L_Z). It may be freely distributed, but may not be sold or altered without my express permission.

-

From the album: Kinematics

© This analysis is the intellectual property of Daniel McGrath (AKA 74_5.0L_Z). It may be freely distributed, but may not be sold or altered without my express permission.

-

From the album: Kinematics

© This analysis is the intellectual property of Daniel McGrath (AKA 74_5.0L_Z). It may be freely distributed, but may not be sold or altered without my express permission.

-

From the album: Kinematics

© This analysis is the intellectual property of Daniel McGrath (AKA 74_5.0L_Z). It may be freely distributed, but may not be sold or altered without my express permission.

-

From the album: Kinematics

Discussion of S30 Front Suspension Analysis© This analysis is the intellectual property of Daniel McGrath (AKA 74_5.0L_Z). It may be freely distributed, but may not be sold or altered without my express permission.

-

Front Suspension Kinematics

74_5.0L_Z replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

Before I distribute this to the whole community, I would like to test drive it with some of the senior members. Specifically, I would like to give copies of the Suspension Analysis tool to Jon Mortensen, Cary McCallister, John Coffee, and other with significant suspension experience or with knowledge of the stock S30 geometry. If you guys could PM me with email addresses, then I will send you a copy. I am ready for other to enter the discussion. Specifically, if you have dimensions of components or chassis points, please post them here. -

Front Suspension Kinematics

74_5.0L_Z replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

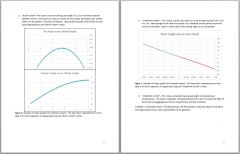

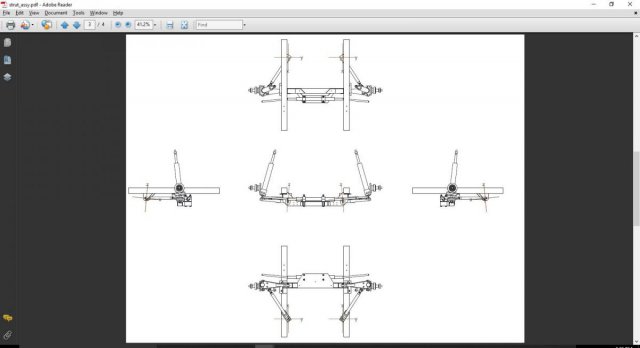

Discussion of Math Model in images below. If you are an engineer, a math geek, or a glutton for punishment, feel free to read the discussion below. If you only care about the end result start at page 9 and 10 to skip the math. The only way I could present the discussion of the analysis was using images of my analysis in word. -

Front Suspension Kinematics

74_5.0L_Z replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

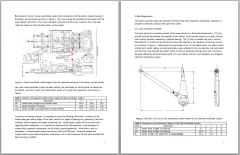

Steering Rack The critical dimension of the steering rack is the spacing between the centers of the inner ball joints. The measured spacing of the stock S30 rack is 24.25 inches center to center. The rack is placed via the cross member such that its center line runs parallel to the chassis Y axis of the base coordinate system. When the steering wheel is centered and the wheels are straight ahead, the centers of the inner tie rods (in my car) are located such the right inner tie rod is located at (80.75, -12.13, 3.12), and the left inner tie rod center is located at (80.75, 12.13, 3.12). When the steering wheel is turned clockwise, the right side of the rack extends, and the left side retracts from the rack housing. The rack can extend a total 2.39 inches in each direction. So, when the steering wheel is turned all the way to the right the center of the right inner tie rod ends is located at (80.75, -14.52, 3.12), and the left at (80.75, 9.74, 3.12). -

Front Suspension Kinematics

74_5.0L_Z replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

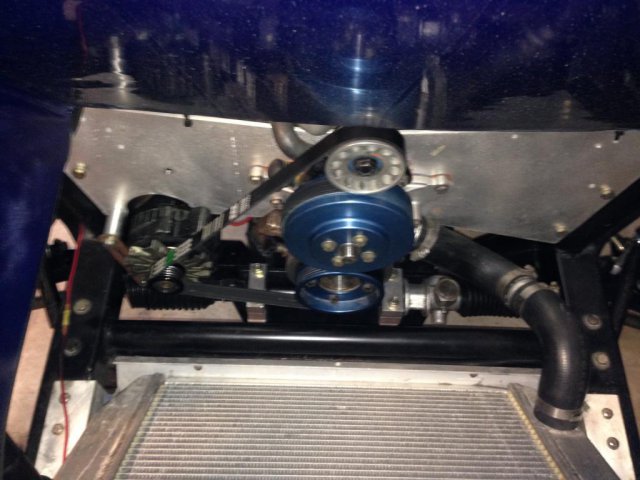

Front Cross member The factory drawing does not provide the dimensions of the front cross member nor does it give the coordinates of the attach points between the frame and the cross member. On my car the entire front frame has been recreated using tubing, but I used the FSM dimensions as a general guide. The height and spacing of my frame rails are the same as stock. They are 25.1 inches apart and the bottom surface of the frame rails are 5.12 inches above the base coordinate system. The attach points between the frame and my cross member (which are not stock) are as follows: The front mounting hole is 23.625 inches forward of the firewall and 15.063 inches from the car's centerline. The rear hole is 3.5 inches aft of the front hole. When I was measuring all of this stuff to try and get a handle on my geometry, I found that the old cross member was pretty distorted from years of abuse and several cycle of modification, so I decided to make my own to allow me to easily change the LCA mount height and to easily change the mounting position of the steering rack. The cross member moves the attach point of the LCA forward, but leaves the rack in its original fore and aft location. The rack height is adjustable by changing the thickness of the spacers below the clamps around the rack. The slot is located 12.13" from the centerline of the car and allows the height to be adjusted from 1.21 " to 2.21 inches above the base coordinate system. The height of the LCA attach point is adjustable in a slot that accepts Allstar Performance Caster slugs. Currently, the LCA is as high as the slot allows. The table below give the locations of the LCA hole in the stock cross member, the JTR modified cross member, and my cross member. Table 2: Position of LCA Attach Point relative to Base Coordinate System. My Cross Member Stock Cross Member JTR Modified Crossmember Point Description X Y Z X Y Z X Y Z LCAR Center of Right LCA attachment to Cross-member 77.2 -12.13 2.12 TBD -11.625 1.56 TBD -11.875 2.31 -

Front Suspension Kinematics

74_5.0L_Z replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

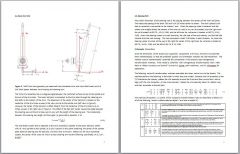

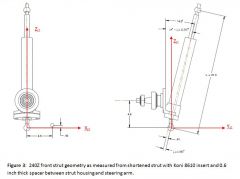

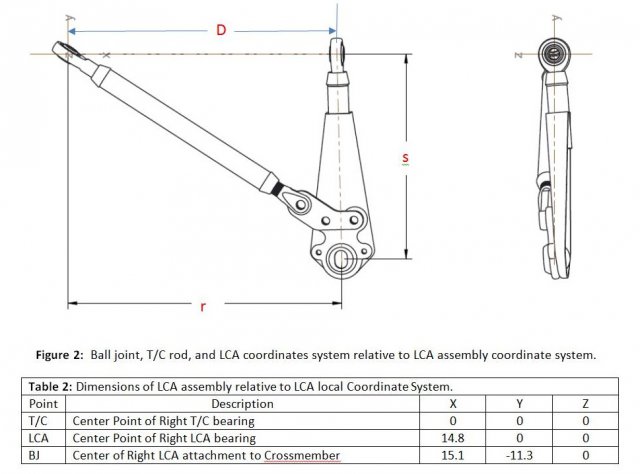

Strut Assembly: The front strut assembly has a 14 degree angle between the machined surface normal to the spindle and the axis of the strut tube. The lower ball joint is connected to the strut tube through the steering arm that bolts to the bottom of the strut. The placement of the center of the ball joint is located on the centerline of the strut tube as seen in the view normal to the spindle axis (left view in Figure 3). However, the center of the ball joint is offset inboard from the centerline of the strut tube by 0.41 inches as seen in the right view in Figure 2. The offset of the ball joint center causes the angle between the steering axis and the strut tube axis to vary with the length of the steering axis. The relationship between the steering axis length and the angle zeta is governed by the following equation: The length L in the equation is the length of the steering axis. The dimension shown (21.3 inches) is the value for my suspension at ride height. The coordinate system that is attached to the strut assembly is located at the lower ball joint center with its Y axis parallel to the spindle, its Z axis is upward in the plane containing the center of the camber plate spherical bearing and the ball joint, and the X-axis is forward. Relative to the strut coordinate system, the center of the outer tie rod on a stock right front steering arm has the following coordinates (4.5”, 0.0”, 0.433”). -

Front Suspension Kinematics

74_5.0L_Z replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

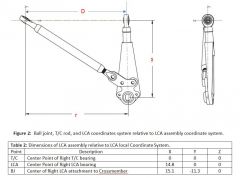

Lower Control Arm Assembly The lower control arm assembly consists of the lower control arm, the tension/compression (T/C) rod, and the rod ends that connect this assembly to the chassis. On my car the control arm is stock, but the inner bushing has been replaced by a spherical bearing. The T/C rod is a welded tube with a rod end that attaches to the T/C bracket on the frame and a clevis that attaches to the dog-bone on the lower control arm as shown in Figure 2. Table 2 gives the coordinates of the T/C rod attach center, LCA attach center, and Ball Joint Center relative to a local coordinate system attached to the LCA assembly and constructed such that the X axis connects the centers of the T/C and LCA spherical bearings, the Z axis is normal to the plane defined by the three center points (T/C, LCA, and BJ), and the Y axis completes an orthogonal right hand coordinates system. -

Front Suspension Kinematics

74_5.0L_Z replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

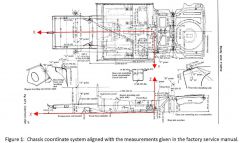

For analysis of my car I set up a coordinate system that is consistent with the Datsun Chassis drawing in the factory service manual as shown in Figure 1. The X axis is along the centerline of the chassis with the origin aligned with Point C. The Y axis is directed to the left, and the Z axis is upward. This is the base reference system to which all other points will be related. Now that a base coordinate system has been defined, the coordinates of various points of interest can be defined. Based on the coordinate system established above, the chassis attach points of my right front suspension and the stock front suspension are as shown in Table 1. Table 1: Position of Suspension Attach Points relative to Base Coordinate System. My Suspension Stock Suspension Point Description X Y Z X Y Z CPR Center Point of Right Front Camber Plate 75.13 -18.00 23.1 75.4 -17.9 23.1 TCR Center of Right TC Bracket 62.4 -12.00 3.0 62.4 -11.75 2.17 LCAR Center of Right LCA attachment to Cross-member 77.2 -12.13 2.12 TBD TBD TBD To perform a kinematic analysis it is necessary to know the following information in addition to the chassis data given above: Length of the lower control arm, length of steering arm, geometry of the strut assembly, and the location and length of steering rack. Unfortunately, Nissan did not provide much regarding useful dimensions. So, to perform an analysis of the S30 suspension it was necessary to measure the suspension components and do a little reverse engineering. What follows next is a compilation of measurements taken from various 240Z and 260Z parts. Wherever possible the measurements were made using factory components, but in some instances the only parts available had been previously modified. -

This is the start of an analysis of the front suspension on my car. It has been modified several times, so most of the dimension are different than those of a stock S30. However, as part of this discussion I want to establish the geometry of the factory suspension so that we can compare various modifications and determine whether an improvement exists. During this discussion, I plan to present the geometry of my suspension and discuss how I arrived at those published dimensions. I also plan to discuss the mathematical model of the suspension, and finally to make the model available to those who need it. All I ask is that people refrain from posting until I have finished the initial part of the discussion. I will post several installments before I open the floor for discussion. Until that time, feel free to PM me with questions / comments.