-

Posts

314 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by jpndave

-

You can get faces/needles that are very similar. Even with black bezels they will still show so not an exact match if you really want a "restored" look. That said short of a full restoration, which should be OEM and not at all what this forum is about, this is by far the best option. I've had Autometer, VDO, and multiple other instruments including some high end race pieces. These are by far the best way to go for a Z IMO and for sure what my car will get. We purchased a set from ihiryu for my son's Jeep CJ project (and these are the lower line) his service, prices and the quality of the gauges were outstanding. I'd have already purchased mine but I'm not at that point in the project yet and they may have new features or updates between here and there so I am waiting until I need them for that buy, with any luck maybe this year's Black Friday sale.

-

Very nice work on the exhaust. While a single can certainly give the output if sized correctly - especially torque. Duals are what I'll be using, easier to route the smaller pipes and the look as well as sound out the back are more what I want. Trying to get a 3-1/2" (that's the equivalent size to 2-1/2 duals) single pipe down the middle of the car with a T56 Magnum and all the rear components sounds pretty daunting to me. looking at the photos of alainburon's car, I don't see a 3-1/2 pipe going down there without a pretty good clearance compromise. My LS3 (now a cammed 6.8L) runs nicely on dual 2-1/2 into single 3-1/2 and sounds good - in the Jeep as more a truck type application. I'll take the duals in my Z.

-

Nice write-up. Where are you in Saskatchewan? I spent some time up there years ago. Interesting how much different the Mod motor is to the Voodoo/Coyote. Your thread gives me some hope.

-

Heavy Duty frame rails and connectors

jpndave replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

Nice work! Great idea on the spray can. How did the pickup tube affect things as you were spraying inverted? Did you just use the full cans for that part? FYI Eastwood makes a paint for inside frame rails. Haven't used it but plan to on both my projects. https://www.eastwood.com/eastwood-internal-frame-coating-14oz-aerosol.html -

I did a quick check on ECU compatibility and the earliest Mustang I can flash is 99 - later on other models. You can see the list here. https://www.hptuners.com/vehicles/ I'd be happy to flash one for you if it's possible and you cover costs (credits and shipping). I'm not sure of workarounds and VATS on the earlier models, if other programmers will do it or if you could retofit a newer harness and ECU. It might get more complicated than its worth.

-

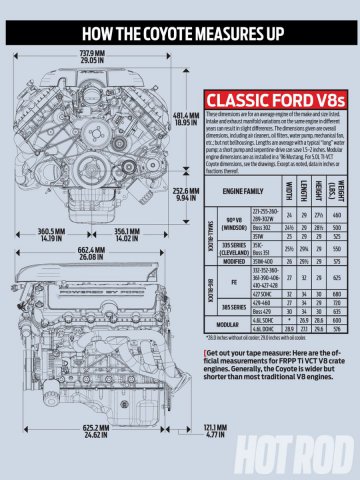

I'm planning a Voodoo in my project (though it may get a Coyote temporarily as I can source one cheaper and have the parts to upgrade the truck engine to Mustang specs which would actually make money when it came out.) All the Ford DOHC and to some degree the modulars are similar as I understand it though I'm most familiar with Voodoo and Coyote. There simply isn't much support out there, all but the Voodoo are heavier than an LS, they are tall and wide. Lots of reasons not to go that route. Personally I'd be better off with an LS as I've done them multiple times before and it's just a better fitting, more cost effective and supported package in many ways. And, just because you have it doesn't mean it's a good idea. Ok, that's the realistic approach and what you are going to run into here for the most part. There is a reason that most of the swaps are LS based. That said... I think it is doable if you are OK reinventing the wheel and fabricating your own parts. I'm running the Voodoo because I want the free and high revving engine with a more linear power delivery and the sound, well it simply doesn't compare. LS torque hits like a truck down low unless you cam it insane then no smooth low RPM cruise which is great for my JK Jeep (it has a VVT cammed as hot as I can and still keep a smooth bottom end ~600hp 4" stroke LS3 6.8L) but not what I'm looking for in the 240Z. Coyote would be ok but doesn't have the insane sound and high rpm. Coyote is down a little on peak hp and rpm but better torque. In a heavier Mustang, the Coyote is quicker quarter mile but Voodoo goes through the traps higher speed. That might be different with a 2500lb car. The DOHC and VVT give you best of both worlds, you can have top end and still keep a stable bottom. Voodoo just has the sound and insane top end from the flat plane. 4.6L is more or less just heavier and less Coyote (I'm simplifying here). As far as fit, the Coyote is too tall and really close width at the heads. You've got 1" clearance on either side of the the strut tower by my measurements. Down lower on the engine should be clear. There is a low profile race oil pan that should solve height. Bellhousing on the mod motors I think is the same and I have one for my T56 Magnum. LMK if you need that application to source one. Accessory brackets might need moved depending on what you get. Depending on how far back you go electrical is likely the least of your worries. I think my HPTuners will probably flash it. For sure the Coyote and Voodoo. Otherwise, electrical is just pull the schematic and rewire, not too difficult. The older Z is simple enough I'm planning on just running one new fuse box for engine and car rather than two parallel. Fasteners and wiring on the old girl are severely lacking and I'd rather not have a fire... Good luck if you choose to go that route, HTH some. Dave

-

A musician's therapist (The $300 Z)

jpndave replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Nice Omar! -

Dual Ball Joint Strut Modification

jpndave replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I'll have to go through Staniforth's book again with a fresh set of eyes. In his defense it was one of my last reads and after Adam's Basics and multiple Smith advanced books much seemed redundant. I'll review the link thanks for posting it up.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

A musician's therapist (The $300 Z)

jpndave replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

Nice work Omar! Things are really looking good. -

Dual Ball Joint Strut Modification

jpndave replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Ackerman itself is pretty simple to sort. The other thread had some good posts and "Chassis Engineering" has a great write up on it as well as the rest of the chassis. I have and have read a bunch of them and Herb Adam's is hands down the best for basics. Carroll Smith's series is next on the list for advanced stuff. All the rest are a few good points here and there all IMO as a disclaimer. I'll see if I can get a chance to post some of that basic information. I highly recommend Adam's book as a must have for basic understanding from this stuff to cage design and chassis stiffness. Not a how-to but all the sound basic theory to get you there. You'll have to watch as steering points get moved for ideal Ackerman to not upset bump steer. Up and down doesn't really matter on the Ackerman just getting it right in relation to the kingpin pivot line relative to the center of the hypothetical rear axle. So a line from outer steering joint through kingpin pivot ideally lands at the center of the rear differential (if it's centered) outboard is less that ideal past center is more. Slow speeds I think "perfect/ideal" is the goal. Other applications might mess with it to band-aid issues. I wiil design for center of rear or ideal which minimizes scrubbing any tire for turning a different radius as both front tires are now turning the same angle as vehicle travel. If you start to push, get loose or drift that is no longer true since the car isn't turning the same as steering. If the car is going to spend a lot of time with one of those conditions setting Ackerman to match conditions is possibly a better option. If I can time to get that program loaded up entering the points would be simple enough. I'd probably start with the lower arm coordinates then move to the arm location to optimized Ackerman and steering. Hopefully the program will show any dynamic changes. Steering effort issue will likely be try and see but with the power rack will probably be a non-issue for you. I'm not planning on a power rack so it could be a problem for me.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

jpndave replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Very nicely done! I really like the sway bar implementation and will "borrow" that idea if I can make it happen. Clean quality work. I'll enjoy following your build TUME.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

jpndave replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

While I believe your are right in the "ideal" setup and intend to go that route on my car (it's a mess up there from multiple impacts and rust plus the engine swap so all the structure is getting replaced anyway.) For that to really work correctly wheels large enough to hold the whole outer end would be needed and a full inner structure with all new arms, rack, knuckles, coilovers, etc. Would be necessary. A build like this where the existing setup is already there and very sound - tearing the whole front end apart for a complete redesign is probably not worth the effort. At best the entire upper structure has to be redone most likely lowers and rack too. Longer lower arms should help but bring all the same issues and more. This double joint idea is simply a long virtual arm. Advantage would be getting the effective long arm without messing with crazy brake/hub/knuckle offsets or maybe impossible parts. Potential disadvantages I see are extra leverage on the steering to move the compounded outer end and not sure what the thing would be like dynamically. Just thinking out loud here, hopefully the discussion helps anyone considering this myself included.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Dual Ball Joint Strut Modification

jpndave replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I think the added width is tires and wheel offset which brings with it a horrible scrub, hence the thread looking for solutions which the dual ball joint potentially offers. If it works, tie rod outer points and their attachment at the knuckles would need to be located correctly to allow proper Ackerman and zero or minimize bump steer (assuming things are correct on the inner points to start with). Caster shouldn't really be affected. Dynamic camber probably would at least a little but maybe not enough to cause issues. I'm intrigued by the possibilities. Advantages to SLA or strut would be similar.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Those look better than the other add on flares I've seen. Not as traditional but that's not necessarily a bad thing. Does the lip roll over or just metal edge on the outer? How does that stagger work in handling? I'm starting to worry I may have too much and the car will push in the front. Planning a little narrower than you list here but similar 40mm difference.

-

The Z interior is pretty small for just inside no way it goes over 4 gallons. We can always lay it on a little thicker with multiple coats to get a bit better sound/heat control. It's not that expensive and super lightweight.

-

A musician's therapist (The $300 Z)

jpndave replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

They turned out really nice with that paint. Nice quality product and the ER80 filler and the welds Colton layed down with my 350P are not letting go! -

Dual Ball Joint Strut Modification

jpndave replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

I ordered up the Susprog3d which allows 2 computers to be used so JD @69Honda and I can use it to coordinate our suspension. We're close enough on builds that combining efforts really makes sense. I'll definitely look into the double joint lower at least in the front. Not sure if we'll need it but it might buy that extra little bit of distance to zero out the scrub should that be a problem.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

Oh, there are cheaper places to get the Lizard Skin. I'll look up my sources. I think I used like 12 gallons in that Jeep. I bought the additional 4 for the hardtop which I sold because they came out with a soft top that had glass windows, defrost and wiper.

-

I'll second that comment on the Lizard Skin being a superior product. Even though the sound control is heavier than the regular ceramic version, it's MUCH lighter than any applied mat. My Jeep has 8 layers in the tub, 2 Sound Control and 2 ceramic on each side. Pretty much no sound and minimal heat through the body most everything comes in around and through windows, etc. Doors though fairly "tinny" stock now "thud" like a luxury car when closed and might be 1lb. heavier. My Z will only get the ceramic because it's light as a feather while still providing a great deal of sound and all of the heat insulation. But I'm being overly cautious on weight with it. If you can handle a few lbs, the SC does help out more in that department. Not bad to install and I have the gun so you can just do it here and save that cost. Pretty Sure I have 4 gallons of the ceramic that should be good, need to check that out today. Nice seeing you yesterday. Glad those coilover turned out so nice.

-

A musician's therapist (The $300 Z)

jpndave replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

We'll get the coilovers tomorrow, well, actually today. We should see if my tank is in any better shape if it's still floating around here. -

Dual Ball Joint Strut Modification

jpndave replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Any suggestions for the "good program" anyone - particularly one that would allow the double joint lower? I've played with the cardstock models that the suspension design references suggest and they help to get an idea of 2 dimensional dinamics but 3d is lacking and changes to pickup points and lengths are tedious. I'd rather not drop thousands on a single car design but would certainly pay a resonable amount.- 38 replies

-

- dual ball joint

- scrub radius

- (and 7 more)

-

BTW, I think the high feature V6 could be made to fit. Possibly open up the hood or carefully fab an oil pan or maybe one of the applications now has a low profile version. Mine was out of a 2008 CTS RWD manual for what it's worth. Impossible is like that best word and shouldn't usually be used. Depends on how bad you want it.

-

In talking about "putting the power to the ground" I am referring to the torque from an LS. Ask any of the guys here with big power LS engines how they launch or road manners, just as likely to put it around a pole. A friend told me about his "it makes me a more religeous person to drive it. Scares the heck out of me...prayer in your heart..." I think the power delivery from the other engines is going to be more manageable as it builds more progressively. The easiest, most economical hp per dollar will be the LS - hands down no question. There is a reason it's so popular. From a practical standpoint I should be going that route. I've done it a bunch, have parts and a 6.8L (4" stroke VVT 6.2 LS) going back in my Jeep replacing a 6.2. They are relatively inexpensive, package well, aluminum block versions are lightweight, big power per dollar, arguably best parts support, and the list goes on. But dealbreaker for me is RPM and delivery. You can't have it both ways with an LS either it revs and open up your wallet with the 8200rpm a crazy high goal and completely give up any hope of a low RPM cruise (cam will lope down low). Or you can have than insane torque delivery I love in the Jeep but more truck/big block delivery which is hard to put down in a 2500lb car even with the VVT which I have and goodbye revs (power is still there and likely even higher just not stratosphere RPM). The VQ37VHR would be cool. It should fit well but I haven't been down that road so not sure what obstacles might be there. It's a Nissan so "in the family" if that's important to you. Power is going to be a little lacking compared to the other choices unless you boost it. Cost will be higher. Transmission will likely need to be stock 370Z for better or worse. Sound will be cool, power deliver will be progressive, should be pretty lightweight and it should rev - all mportant factors to me in a sports car. HPTuners now supports the Nissans so that fixes one major obstacle. 69Honda is using a built Nissan V8/T56 but I forget which version. Otherwise our cars are pretty similar and we're working together on a lot of the parts including the Super 8.8 rear and T56. The Nissan V8 is going to be crazy fast. Voodoo/Coyote is a tight fit both height and width - width is 2" less than the towers at the heads and that race pan will be a must have. T56 is a pretty easy bolt up and I have a wide ratio Magnum along with the aluminum bellhousing ready and waiting. Flywheel and clutch might be a challenge on the Voodoo (stock is dual mass unique design) but easy on the Coyote. Voodoo a little lighter than LS3 and Coyote a little heavier but we're talking 10-15lbs ish either way. Both have more progressive power delivery and naturally higher RPM because of DOHC and true dual VVT again Voodoo more extreme both ways. Sound is a bit subjective but I don't know how anyone can argue with the flat plane crank "brap", it's just insane. But a properly exhausted Coyote, maybe a bit cammed with some compression sounds downright mean. The new GT Coyote engine makes more torque and in a Mustang is quicker 60ft and quarter. Voodoo goes through the quarter traps higher mph with a slower time - can't get the heavy Mustang moving but catches it and surpasses after that initial takeoff but not enough to pass in 1/4. That might change less 1500lbs in the Z but maybe not as properly setup you might get the Coyote torque to the ground and if you do Coyote will be the faster car. Coyote will be half the price and not even close easier to find. Parts much more available (though not as easy as the LS) with some crossover but not all. Both are really unique installs in the Z. I know of one Coyote and mine will be the first Voodoo unless someone else beats me to it which is possible as my project is moving SLOOOW. For me the Voodoo is "best". You'll have to answer that question for you. If you want unique or some of the other "advantages" by all means pursue different. But, if you're not up for all the extra hurdles, money, and time, put an LS in there! You'll likely be fabricating pretty much everything on the unique swaps where the LS has kits available and more support if you have questions or WHEN you hit snags. There's a reason they are the most popular and generally "best" swap. There, used the b-word several times in there - hopefully with enough qualifications to get away with it.

-

So, critical go/no go is height - if you start with a manual trans package assuming you want a manual. Solve that and you have to decide if it's what you want. The SIDI makes good bottom end torque from the high comoression. I drove an LLT Camaro and it felt like V8 car. Take 1500lbs off that and it will be impressive. Supercar power? - NO. No way that engine runs with my Voodoo or any of the higher output LS or equivalent cars. Fun to drive, high reving, potentially great handling, powerful car with great economy? - yes. Boils down to what you want. Like seattlejester and others mentioned it's not wise to use "best" anywhere at least in a general perspective. Might be the best choice for your goals - certainly not for mine. It will have an advantage again IMO in that the power delivery is more progressive which is one of the reasons I chose the Voodoo. That along with unique sound and high revving. VVT allows best of both worlds with high horsepower/RPM but still can cruise just off idle and not be loping.The LS family are awesome engines with massive torque down low - my Jeep feels like a big block on the bottom which is great for that application. Getting it to the ground in a 2500lb Z is another matter.

-

From a post I made years ago on this thread http://www.fullthrottlev6.com/forums/showthread.php?50690-LLT-swap-into-a-4th-gen-f-body/page7 "Ok, these are rough numbers taken with a tape measure.Overall height from bottom of pan to top of the bump on the intake manifold: 30"Width at heads: 23" Width at stock exhaust manifolds: 25"Length from transmission mating flange to front of balancer: 20.5"These are at the widest points." Same problem with height on the Voodoo/Coyote - too tall to clear the hood and it starts an inch shorter (maybe a little bit shorter less the covers). Stock form would nearly have the oil pan on the ground. Luckily there is a race pan available that gives the necessary clearance. Also, for what it's worth heads clear by 1" each side if centered. So the V6 will be golden that way.