-

Posts

302 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Naptown Dave

-

Autometer Phantom 2s in 5" and 2 5/8". Oil pressure, water temp and fuel level in he center pods and the volt gauge in the drivers side vent. I'm glad I pulled the dash to put them in!

-

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

Chickened out on the widebody (for now) but have been busy... rust repair, mechanical sorting and the while I'm at its New gauges Dynamat Improved stance Led tail lights Bought a d/a sander and started stripping 3 paint jobs... Headed to a project in Florida so the Z is back on the shelf -

ETZ, sent yesterday should see em Saturday or Monday

-

I'm surprised more people haven't chimed in on this one... T56s are out there but usually the seller wants more than most are willing to pay. I happily paid 2k for mine (freshly rebuilt with a new in box LS7 clutch) check out LS1 tech classifieds and scour craigslist in the area you are willing to drive to. Dom has a good question the ones with the LT bellhousing usually cost a little less..

-

T56 shift knob with button

Naptown Dave replied to socorob's topic in Gen III & IV Chevy V8Z Tech Board

I used a $3 rocker switch from radio shack that lights when turned on mounted to the console. Its fairly discrete, cheap and works. -

Payment sent thanks guys

-

Sunroof, should I patch or cut?

Naptown Dave replied to voltron_boi's topic in Fabrication / Welding

I patched mine and it turned out okay, not great. I still have some hammer and dolly work to do but think I will end up with an oilcan problem that may take a stiffener spot welded inside the roof to fix. -

Looking for a decent front LCA for a 75 coupe. Will buy a pair if needed. Thanks

-

I have a fuse box cover from a 75. I don't know if they are the same

-

Time for the 5.3 to get some more power

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

Looking good bro! You should steal that 454 and plug another turbo into that extra tb. Power! Unlimited Power! Muhahaha -

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

Thanks Matt. I wonder if I should trim the new panel down 1/4" or so from the upper body line? That butt weld is gonna really make me commit to this! -

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

Yeah Matt I've been spot welding them with .020" wire. I've been meaning to ask you about tig welding body panels. I have access to a Miller 110v tig machine from work and I am a pretty experienced tig welder, just with process and steam piping, a little different than 20ga sheet. Do you use the minimum amount of amps and filler wire to fuse the pieces for something like this? and then skip around with short welds? I have some worries about warping the areas I can't get a dolly into - a good part of the door, the rocker area and under the quarter window. I am planning to lap joint these not butt weld. Yeah Daz bring it out here to the Midwest! Well see if I can get the passenger side to match the drivers side. -

1973 240z 5.3 / ls1 microsquirt build

Naptown Dave replied to ECUAdam's topic in Gen III & IV Chevy V8Z Tech Board

Alright maybe wise was pushing it -

1973 240z 5.3 / ls1 microsquirt build

Naptown Dave replied to ECUAdam's topic in Gen III & IV Chevy V8Z Tech Board

Tank looks good bro! I built a steel rectangle one and its a little tight on the exhaust. I put some stationary baffles and a 1.75" sump in mine and still get some cavitation at low fuel levels so I'm going to try foam blocks. I have a behind the license plate filler too and I put a flapper check valve in the filler to keep a full tank from puking during take off. Just a couple things to think about. Keep up the work! A wise man told me there is 'nothing to it but to do it!' -

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

A little work on my wide body experiment. I need to adjust the rocker piece to flow with the body line but its not looking too bad. Hopefully I won't need 5gal of filler to smooth this thing! -

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

I shaved my drip rails too so i don't see stepping out into a rainy day on purpose too often! -

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

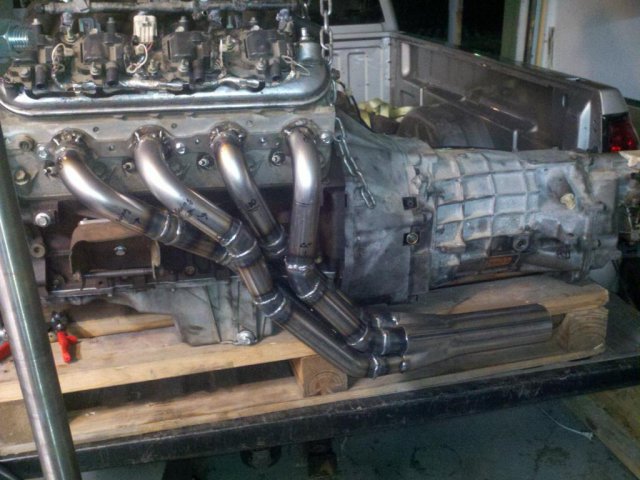

Back on the wrenchin'! Have been doing some misc sorting and details during this wonderful Indiana winter. Removed a nice looking mouse home from my blower motor, anyone have a source for the fan cage in the blower? Replaced the heater core and attempted to repair the cable operated heater valve. Fixed one leak in the valve and created a smaller one, I will probably just pick up an early '70s Bronco heater valve and mod as needed... Pulled the dash to try to repair and to install gauges, that really felt like I was moving backward...I'm not real happy with the tach light color variation, email sent to Autometer.. Knocked out some headers for my buddys 3rd gen Camaro swap Cut out the rust and patched the lower front fender. Someone left me a vintage sunkist can in the cowl area, that 5 cent deposit is going straight back to the car fund! Dropped the front end one inch to get it looking right, the back will follow soon as soon as I get the nerve up to start the steel widebody attempt... -

Time for the 5.3 to get some more power

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

Looking good my friend! Test n tune this spring? -

Time for the 5.3 to get some more power

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

Been in Hawaii, ya miss me? I'm back home for a little bit, pulled my dash for gauges feels like I'm moving backwards on my car. -

Time for the 5.3 to get some more power

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

Looking good bro! Hurry up. -

Finally got started

Naptown Dave replied to Naptown Dave's topic in Gen III & IV Chevy V8Z Tech Board

How did that 2.8 turn out for you Steve? Been back from paradise for a week and haven't turned wrench one but have an order list to get cracking on before I come back for christmas break. Just wanted to drop a pic from last week at the office! -

Yeah you have air in the rear system, again the most likely in the calipers. Your bias is going to change whenever you change brake systems, tire sizes, pad composition, weight distribution etc etc. I pulled my proportioning valve to eliminate the possibly of it giving me problems during my trouble shooting knowing that I would have to add an aftermarket adjustable one later. Oops, double post

- 48 replies

-

- brake bleeding

- bleed

-

(and 2 more)

Tagged with:

-

Yeah I would guess that the rear fluid going down would be an indication of air in the line. Changing the brake setup will change your bias. Tires, pads, weight reduction will also all change the bias. You really just have to try it and adjust as needed.

- 48 replies

-

- brake bleeding

- bleed

-

(and 2 more)

Tagged with:

-

On the master I could open my inspection lid and stand outside the drivers side and pump the brake to see the level go down. I'm still betting on air in the caliper!

- 48 replies

-

- brake bleeding

- bleed

-

(and 2 more)

Tagged with:

-

Time for the 5.3 to get some more power

Naptown Dave replied to mattd428's topic in Gen III & IV Chevy V8Z Tech Board

With the shop you work in you should be able to knock out some nice ones, I was looking at a Cadillac ctsv wagon the other day and thought it had a decent looking flare