-

Posts

154 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by TUME

-

It is bit different to do swap with bolt on-parts. Subframes need lot´s of farbrication and you don´t have anything ready there. Everything must build from nothing. Using R33 subframes, why not. They are just a bit too wide, IMO. Why do I know this shit? Because I´v build R32 rear suspension in my 240Z. You are wery welcome to look my project and after that give you´r honest opinion, did it look easy? By the way, I would´n start to doing this when I was 19.... http://forums.hybridz.org/topic/120418-arttu´s-240z-never-ready/?p=1127575

-

Idea for front knuckles.

TUME replied to AkumaNoZeta's topic in Brakes, Wheels, Suspension and Chassis

http://forums.hybridz.org/topic/120418-arttu%C2%B4s-240z-never-ready/?do=findComment&comment=1127576 Something like that in your mind? My FLCA is about same lenght as S13. This is what get´s you in trouble, KPI increases a lot if you keep strut upper mount in original position. Ackerman related mods are also done, if you scroll down a bit. -

Just checked my calculations about roll-center(s). Seems like in my car r-c is ~65mm front and ~115mm rear. Should be decent compromice. Bit of a job to get those figures, with my "modified" suspension.

-

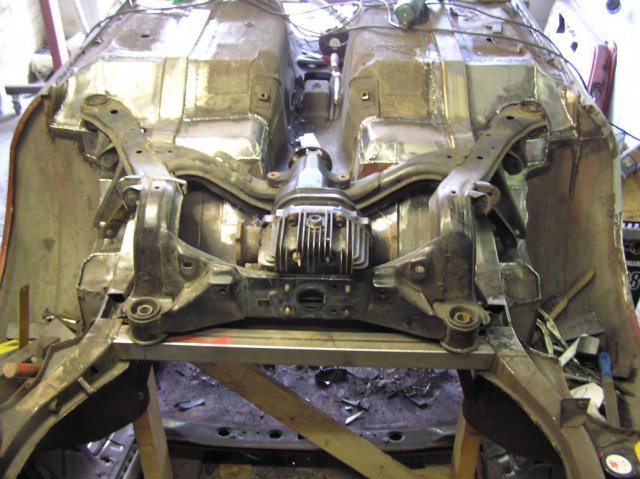

Those drawings seems to be right. Here is pic how much it takes to modify chassis to take S13 subframe. I had to modify little bit of those frame rails, also, to make room for control arm attachments. It´s pretty easy to found right height. Just mount rear mounts to level with rear frame rails and keep upper arm (camber and traction) attachment points to level.

-

It sure is, and, if you look at my pics and those videos you'll notice that i cut floor off much more. IMO those swedish guys ruined suspension geometry by mounting subframe too low. It will work but it's far where it has been origi ally designed.

-

Sure, here is my build topic. http://forums.hybridz.org/topic/120418-arttu%C2%B4s-240z-never-ready/ There are few pics, but i have more and can always go downstairs to my carage It´s R32 subframe but basically same as S13. Little bit modded, though. After i was struggeled this subframe to car, i got an idea of making subframe by myself. Well, maybe that day will come someday. I agreed, if you can do fab work by youself, why not. If you have to do swap in a shop, hefty wallet is needed. It´s not so simple as weld in. Also keep in mind, that track width is increasing, you should do something to front also. I have bit wider track in rear, but i have also rear bias weight ratio. Front heavy car with wider rear track is disaster.

-

-

Addressing firewall flex

TUME replied to grannyknot's topic in Brakes, Wheels, Suspension and Chassis

-

Addressing firewall flex

TUME replied to grannyknot's topic in Brakes, Wheels, Suspension and Chassis

I`m afraid, those does´t help with firewall flexing. Here is my solution, didn´t think firewall when did this but maybe helps a bit with it. -

Universal Anti Roll Sway Hollow Bar Kit

TUME replied to 260DET's topic in Brakes, Wheels, Suspension, and Chassis

I´m planning to use roll bar like this; it has hollow tube and adjustable knifes. Mine is D.I.Y-kit, so it has to cut to proper lenhgt and weld those sleeves into it. Those blades are rotating, so you can adjust their stiffness. -

240sx suspension swap kit interest?

TUME replied to noilan's topic in Brakes, Wheels, Suspension and Chassis

So am I. Not sure who to You answered, but I´m still intrested noilans´s setup with proper coils. Just went to carage and take picture my (cars) ass, and it looked like this. I have ground clearance 13cm i.e 5in. Well it´s S30, but principle is the same. -

240sx suspension swap kit interest?

TUME replied to noilan's topic in Brakes, Wheels, Suspension and Chassis

Pics please, with S14 coils. Also i'm curious what is your ride height with them? -

S13 Rear Subframe upgrade for 260z

TUME replied to grayson260z's topic in Brakes, Wheels, Suspension and Chassis

Agreed, go with S14´s. MIne is S13´s and I had to cut down strut tower. Also made new hat on it, so i get those S13´s upper mounts to suite. It´s worth to ask, if they (BC) swap upper mount´s. I get mine with Z32 bottom mount by just asking. -

Got this on wheels recently, and that´s about it. Some struggling with alignment and finishing, but nothing major. Also tried steering with seat and noticed china boss and quick release was too much. So i ordered NRG short hub and will try with it. Need some motivation, anybody got some extra?

-

Yes and yes. They will attached like original struts, but i had to do some modifications. Strut tower had to cut down about 10cm, and weld in a new hat.

-

Almost there, still middle with fabricating ball joint pins. Pity they don´t sell these solo, i really don´t want to buy whole control arm for just a pin. Front ones will fit nicely, and bump-steer seems quite nice. Need to fab threads when i get back to lathe. Rear pins are still inside of the rod, i need to dig them out too....

-

Have you thought supporting those engine mounts to frame rails? If you leave them like that i`m afraid they will twist your front beam (subframe)

-

Control arms almost done. Did some turnbuckles from aluminium hexa-bar. Little paint on surface and good to go. These will be assembled and mounted in end of week...

-

Chance of plan. I noticed how easy is to paint while car is in the rotisserie. Sanded to bare metal and some basecoat. Looks instantly much tidier.

-

Underbody is now done. I sprayed stoneguard in wheelwells and here and there uder the floor. Top of that, black urethane paint. Also painted subframe and front beam. Grey, for a some color under the car... Bolted them in too, with polyurethane bushes of course. Next I must fabricate some little parts in suspension and get this thing on wheels. After that, some bodywork. Rest of the body ready for paint.

-

So you´re going to hide gas filler under licence plate? I thought that too, but not decided yet. What kind of hinge you have in mind for licence plate?

-

That's the plan. I've sprayed underbody also couple a days ago. There will added some stoneguard and other layer of paint on some day. Propably black, despite that light color looks quite nice too....

-

Got the car sandblasted, underneath, engine bay and inside. I think i gonna clean rest of the body with sandpaper. Don't need any strecthed bodywork. Funny how much little bit of paint change looks. Sprayed with polyurethane paint, witch should be decent primer.

-

Let´s get this up for a long time. Lately I´v been working with the engine. Made oil grooves to main bearing saddles, to use Gti-R-version bearings. Also conrod bearing are from Gti-R, because they are wider than rwd-bearings. Honed cylinders and smoothed deck, thats about it. Pistons got ceramic heat barrier on top and solid lubrication on skirts.