-

Posts

154 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by TUME

-

Let's talk brake system design

TUME replied to 280Z-LS3's topic in Brakes, Wheels, Suspension and Chassis

http://www.jakelatham.com/radical/info/brake_calculators.shtml#MaxGBraking I used calculator above with my setup. -

Bit bodywork on the rear end. Installed new fuel cap behind licence plate to hide it. Almost started to fab chevy-style plate flipper, but maybe be happy with some magnets to keep it close. Also replaced rusted hatch lip with aluminium one. Installed with glue and couple of rivets. Those water rails on hatch surroundings get more length to avoid water problems in future. Some problems occured with front fenders, driver side is ~1/4" longer than other. Is this common?

-

Roll bar connected at strut are not creating upward stress to balljoint. It only reduce downward force. It`s not lifting wheel of the road isn`t it?

-

Parts source isn´t the issue here, i think. You can use any car parts here, if they fit. I´ve noticed that here in Finland car guys are more creative and everything don´t have to be bolt-on.😜 I wouldn´t stress about forces to the ball joint or things like that. Especially if you use ligther sway bar. Attaching pickup point to the strut would cause much more stiffer sway bar. It´s all about suspension arm motion ratio. Same effect for the springs here-> https://www.hypercoils.com/spring-rate-calculator/

-

If it's genuine OMP, i don't think so. There are big differences between aluminium and aluminium. I had Biltema rally wheel in 90' and current Nardi is bit stiffer...

-

There is not so much forces that will bend control arm. Most of the vertical forces are directing to the strut. Control arms get involved mainly lateral forces. So i think those arms are just fine. Btw. is this same car that is some vids from kalajoki @youtube many years ago?

-

1970 240Z Race Car Front Suspension Issue

TUME replied to Gmagno's topic in Brakes, Wheels, Suspension and Chassis

Are those square frame tubes same width than originally? If so, i bet you have wider inner lca pick-up points than originally. Are you done that frame by yourself? Why fabricate tube frame and maintain original geometry? I would add caster atleast because you can with than kind of modding. -

Question about dual master cylinders...

TUME replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Longer brake line makes chance that you have air in line, more bigger. Line lenght and shapes do not affect brake pressure, that for sure. Corner weights can also affect, even rear corners. Weight moves to front when braking... -

Front Suspension Swap? Anybody done one

TUME replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

Thanks for comments. Do you mean S13 control arms/TC rods. I can't see why they won't work, of course it is possible they need some modifications but nothing major. Of course left side arms goes to right, with S13 spindle and wise versa. Also because longer arms, there will be enormous KPI angle which affects camber behaviour when turning wheel. Thats why i modified shock upper mount in my car. Btw, those ultimate bolt-on set doesn't ring my bells... -

Structural Reinforcement to Handle 500rwhp

TUME replied to luke87gt's topic in S30 Series - 240z, 260z, 280z

For $8700? 🤣 -

Structural Reinforcement to Handle 500rwhp

TUME replied to luke87gt's topic in S30 Series - 240z, 260z, 280z

Looks fancy, but I wouldn´t hold my breath with benefit´s. Silly bolt on system, imo. -

Structural Reinforcement to Handle 500rwhp

TUME replied to luke87gt's topic in S30 Series - 240z, 260z, 280z

-

S14 front spindles hubs and brakes on a S30

TUME replied to Jethoncho's topic in Brakes, Wheels, Suspension and Chassis

Yep, it was whole afternoon trial and error fun. Just cut loose steering arm and tacked it in various angles. Then measured wheel turning angle vs. steering rack movement. Both ways ofc. When found best possible spot just weld couple of tacks more and moved to welding table. Then i was welded couple of bolts to table and attach spindle with them. Welding itself was pretty easy with tig. Just noticed that i don´t have any pics about this whole job...😲 -

S14 front spindles hubs and brakes on a S30

TUME replied to Jethoncho's topic in Brakes, Wheels, Suspension and Chassis

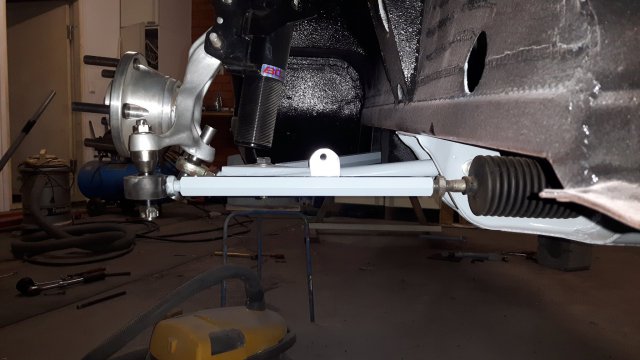

Yes they are custom and lca's are bit longer than originals. You can find more on my build topic. -

So I finally got my exhaust manifold into shape. There will be lots of welding ahead, but it´s an easy part. I have to see, if I can shorten that collector a bit.

-

Front Suspension Swap? Anybody done one

TUME replied to rabrooks's topic in Brakes, Wheels, Suspension and Chassis

With S13 spindles (and others, i believe) and longer LCA:s is possible to achieve near zero scrub. At least not so wide wheels. I´v got 8" rim and scrub max. 10mm. You should keep about 50% ratio between caster and KPI. My car has 13-14 degrees KPI and ~7 dergees caster. Shock upper mount is moved outwards aswell... -

I did mine out of hockey puck. Quite cost effective.

- 3 replies

-

- 1

-

-

- 280zx

- steering coupler

-

(and 1 more)

Tagged with:

-

Cut & Shorten 240Z Steering Column in Race Car

TUME replied to Gmagno's topic in Brakes, Wheels, Suspension and Chassis

I just turned upper mount other way around. It's not symmetrical. And yes spline shaft can/have be shorten. I did't because my cross member is bit further. I only did shorter bush to connect shafts. Out of icehockey puck🤣 -

Cut & Shorten 240Z Steering Column in Race Car

TUME replied to Gmagno's topic in Brakes, Wheels, Suspension and Chassis

-

S14 front spindles hubs and brakes on a S30

TUME replied to Jethoncho's topic in Brakes, Wheels, Suspension and Chassis

Here is mine solution, S13 spindles and R33 brakes. You do know that swapping spindles side to side, you messed up ackerman steering. Or not, depends how you look at thing. Just swapping spindles you get negative ackerman, which is used F1 cars today. Not very useful on road. So I cut and welded that steering knuckle in different position. Made also longer lca to get close to zero scrub radius. Those hubs are custom made aluminium 5-lug for S13. -

-

I did tech line cbx ceramic coatings for my engine. Piston tops and combustion, including valves for heat resistant and insulating surface. It´s very thin, you can see piston markings through it. So, if its cracking pieces will be very thin and small. Also i think that mostly problems are occured when surface is not treated properly. It need quite rough surface to bite in. Also did some kind of ceramic lubrication for piston skirts and camshafts. My motor is, of course turbocharged (SR20) and here is big gains archived especially turbomotors. Not so sure advantages on NA engines.

-

Thanks for that. I haven't done almost nothing in past year, because depression. But, i have a feeling that maybe something is coming next winter....