-

Posts

637 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by ozconnection

-

Maybe I should throw the cat amoungst the pidgeons and remind them of that electramotive L28 turbo! I've heard and read about the PCV issue, that could well be the problem they're experiencing. Would they know about it? Dunno? I'll suggest it and see who says what. Thanks Tony.

-

There is a thread on an Aussie forum that discusses the fabrication of main cap girdles as a bottom end 'support'. Their arguement is that the guys who are dripping oil from their pans and rear seals are those experiencing block twist. The solution they say is a cap girdle similar to the RB setup. Is this valid or just silly talk Tony?

-

How can you tell? Be wary of the old fallacy "Bigger is always better" (Just ask your ex girlfriend! )

-

Use an L24 gasket, place it on the head, see if anything touches. Put the gasket on the block and see how far recessed the gasket is from the edge of the bore. The rest you can figure out for yourself, surely.

-

Nissan Datsun Automatic Transmission badge emblem

ozconnection replied to zgeezer's topic in Parts Wanted

http://cgi.ebay.com/ebaymotors/Nissan-Datsun-280Z-FULL-AUTOMATIC-Emblem-Badge-NOS-NEW-_W0QQcmdZViewItemQQhashZitem439477e638QQitemZ290253694520QQptZMotorsQ5fCarQ5fTruckQ5fPartsQ5fAccessories -

Seat to seat. Most peoples focus here is on making HP at revs so that kinda means the stock cam is rarely used. Like John said, if a class requires it, then again the search is for power and with such small lifts and durations and with such minor differences, it's not worth too much power worrying about which cam you have. (A or C or whatever) However, in the realm of street use, with low speed torque being the king, there ARE noticable differences in the cam profiles. The amount of cam advance is a tuning tool also and I have found so much of a difference in performance by just doing that, it was like I was installing a different cam each time. My favourite stock grind cam is the "B" profile. It's currently in position "2" which I find a good compromise between off the line acceleration and willingness to rev to the shift point (auto trans). Position "3" is excellent for towing or burnouts! Position "1" doesn't come alive until 3500 rpm and will spin well to the shift point and beyond if held. Great for highway cruising/long interstate trips where the extra bit of power is useful for overtaking.(Position "1" is the factory setting too so I wonder why the factory opted for this when I find I get much more torque on 3 and even 2. Maybe that aspect was left to the diesel Cedrics, the petrol powered ones were the "faster" ones? ) Who wants to design a variable cam drive for the L series....come on, someone's gotta know how to do it/adapt it? What does Tony say "I digress...."? Why don't you play with your cam timing for a bit....get the feel for what I'm saying? I had a boosted L28 at one point.....just didn't know then what I know now!

-

Why did you decide to stay with the Datsun L6 motor?

ozconnection replied to logan1's topic in Nissan L6 Forum

Awesome++++++ -

Not proof of its existance, merely a suggestion. But others know and have seen stuff I don't about so who am I to argue.

-

Why did you decide to stay with the Datsun L6 motor?

ozconnection replied to logan1's topic in Nissan L6 Forum

Nice L Series mate! Your bike reminds me of what the Goose was riding in Mad Max (The first Road Warrior). Awesome!! The "L" has always served me well. And my garage is so full of bits and pieces now, I could be building new engine configrations for years! Stroker, Turbo, Long rod L28 and an L20A cranked L28. AND a 'secret' project using some L20B bits and pieces and a deck plate and... Someone buy me a lottery ticket...I'll share, I promise. But apart from all that, my plain old L28 is a great piece....I love it. -

And mine!

-

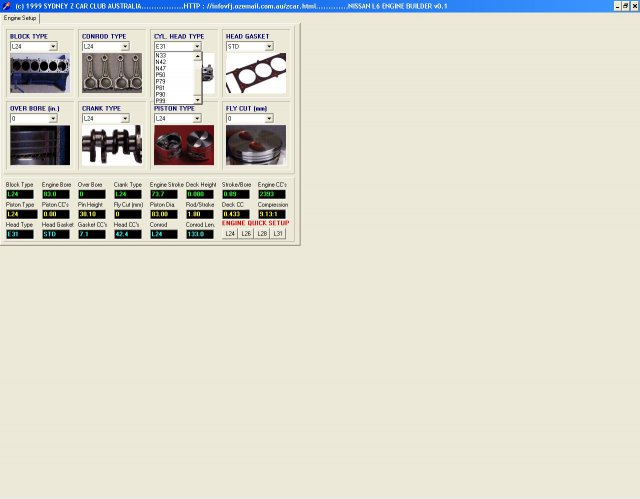

Have you never seen or used the famous "Nissan L6 engine builder v0.1 1999 Sydney Z car club Australia" engine program Tony? The P99 head is listed right there.

-

Nice engine bits and pieces....good luck with the build. Just a observation on that welded thermostat cover. The option of easily changing the restrictor is not there with the restrictor welded in. If there is to be any testing of block coolant pressures after the build and it is determined that the restrictor needs to be larger, then I guess that's not a problem than if the restrictor needs to be made smaller. (This also ties in with coolant temperature, so a balance needs to be found here, harder to achieve with a welded in restrictor.) I would have thought that a machined disc similar to the thermostat itself be used in that original position. A selection of restrictors could be made easily, with a range of hole sizes so that flow, temperature and pressure could be optimised. Another way would be to alter the water pump speed with a variety of water pump pulleys but this would be more work and expensive to set up.

-

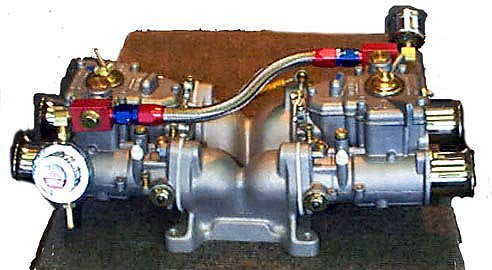

Help identifying 4 barrel conversion manifold

ozconnection replied to beemer's topic in Nissan L6 Forum

Yeah, that's right. Mine has Cartech cast into the manifold without the plenum hump for the water heater passage. I'm going to use an removable aluminium divider plate to divide the plenum into two, creating a dual plane manifold, boosting low to mid range torque. It's an easy tuning option, however recalibration of the carb is essential afterwards. Without the recal (with the plate installed), it'll run pig rich!! Don't be shocked by how many jet sizes you need to go down, especially on the secondaries. Cheers. -

If I may.... I ran a L20A factory turbo grind and the thing was a torque monster in a stock NA L28 with 8.3 comp. Completely out of breath after 4.5k rpms but the torque off the line........ Such a short cam would assist in all things mentioned above, enhancing low rpm torque with only a 7.8 to one factory turbo comp ratio.

-

Yes similar but not the same as the one on the E32 manifold. I looked at those throttle bodies without the fuel injectors. When I found one with injectors in it, I bought it straight away. I wanted to keep the manifold wet flow as locating the injectors close to the head would remove this aspect, along with costing considerably more to set up. I don't mind the idea of throttle body injection at all. Sure it doesn't have the precision or individual cylinder tunability of port injection but its gotta be better than a carb (and it looks different too). Dunno, I could be looking at this all wrong but it was there, so I bought one. I haven't run it yet, so I cant talk about its performance. The car that its bought for is still being built ATM. (Not too long now ) Cheers

-

Yep, I think along the same lines and have gotten a bit further than just thinkin about it...... I have the AZC manifold, a Clifford 6=8 manifold, an E32 factory 4 barrel intake and a modified P53 to suit a 4 barrel and now an adapter to suit the twin su manifold, a Cartech piece They're all different and help change the power and torque curves, exactly like you're theorising I would love to see how the offenhauser dual plane intake would work on the six. Strangely they made one for the 4 bangers, but not for the six. With some adaption, maybe one from a Jeep could work. The manifolds are very close. I have the 4 banger one for analysis purposes, to see exactly how the plenum is structured. Very clever and interesting design!! The weber manifold thingy would work well with the split plenum AZC manifold, I think. Even the huge Clifford could be made to work with the superior atomisation from the injectors.

-

And has taught me something about the 'stock' exhaust manifold. Hmmmmm. Wastegate plumbing.....not finished there by the looks of it. Some more R and D? Oil cooler? Where does that line go to? Mechanical oil pressure guage?

-

Forget wallpaper, gimme a roll of toilet paper! Ditch the shitty hose, use sections of aluminium pipe joined by rubber hose, like intercooler plumbing. "A very expensive engine running a very cheap hose" Boys!!!!

-

I wouldn't sand the headgasket. Maybe use some thinners and a clean rag to smarten up the gasket, head and block surfaces. You might consider using some copper spray on the HG when it's time to instal it. I have one of these gaskets too, anyone else have any suggestions?

-

That's funny! Ok, the next logical question is: Can the standard Nissan connecting rod small end be bored out to fit a VW 22mm gudgeon pin safely? If it can be done, will this be the new "weak link" in the bottom end? What is the 'standard' setup on the VW'? Would it be a press fit jobbie, a full floater or does it matter?

-

It is the festive season after all Nigel Is someone jotting these things down??

-

Mate, you can turbo anything. You could work the P90 to increase chamber size and/or use a thicker headgasket to lower your compression ratio into the eights. Ditch that cam and get something that works properly with turbos. An "A" spec stocker is a good place to start. A low boosted (less than 7 psi) stroker would be a torque monsta Do it, you know you want to

-

Those pics are with flat top pistons I assume. What about those heads with dished pistons? I read what Paul wrote but your drawings don't include that scenario...or do they? Please clarify your information.

-

I run a 280zx distributor in my car. I have a few of these and they all seem to have slightly different advance curves. The one I like the best is the one that has only 12 degrees mechanical advance. I set this on up with 22 degrees static timing at idle and get 34 degrees total advance at 2600 rpm. I don't use any vacuum advance when timed this way. Throttle response (torque) is excellent at lower to mid rpms. Fuel economy is very good with a well set up induction. Sort out your fuel delivery and get good mixtures all round. I see 13 AFR at idle at 800 rpm's, 15AFR's at light cruise and around 12.8 to 13.0 at wot. I use Msd 6 and a Holley 465 cfm 4 barrel and a stock head and cam. This is a street engine and it runs very well. A little cam advance is also good for low to mid range response. Replace the chain when you can. Good luck with it.

-

Do I read this as 'reducing lag'? What are the tips/tricks required to do this? Nice short BTW....keep up the good work!