-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

1980 280zx vs 1983 280zx rear brakes

Chickenman replied to turbogrill's topic in Brakes, Wheels, Suspension and Chassis

Didn't we discuss this on another Forum and I suggested going with WilWood Superlites on the rear with the smallest Piston diameter they had? Or was that someone else. It was an Enduro car and they kept seizing the rear ZX Calipers. Had a number of suggestions and reasons why. I'll try and find the link later... -

Still have to find the article that shows the changes in DT between using Resistors and using PWCL. It's about .1ms to .2ms less than resistors if I recall correctly.

-

Here is one of the articles I found In Mega Manual to Tune PWCL : http://www.megamanual.com/ms2/tune.htm

-

One thing that will really affect your fueling Tables is if you are using the stock Low-Z injectors and PW Current limiting instead of the factory dropping resistors. The Default TS values ( 30, 1.0,66 ) do not seem to work well with the stock Nissan 188cc and 260cc injectors. These settings seem to be fine on other injectors though. Unfortunately it's not a " one size fits all " situation and finding the sweet spot for our injectors is tricky. MS1 and MS-2 can be problematic using PWCL and stock Nissan injectors. The MS-3 units seem to be OK. Mind you MS-3 uses a completely revised Firmware model over MS-2and MS-1. Seems to be a lot better in many aspects. For MS-1 and MS-2 I would highly suggest using the factory dropping resistors ( or something similar ) or using HI-Z injectors. The difference in the Fueling curve can be quite dramatic. with no dropping resistors. The same Tune that runs perfect on dropping resistors ( stock injectors ) will turn Pig Rich on a vehicle with out dropping resistor. Using the recommended TS settings for PWCL. There is little information on how to properly tune PWCL. Nothing on the MSextra and TS sites worthwhile that I can find. And of course it's all about finding that sweet spot for the PWCL settings. However, I did find an older article in the Mega Manul archives that explains how to actually adjust the settings and what should happen. I'll post up this up a little later. Right now I'm up to my neck in Alligators. One of the interesting things in the article is how DT settings are affected by PWCL. I always knew this was probably affected and PWCL requires less DT than dropping resistors. This article explains how much you have to change ( decrease ) the DT settings. compared to using resistors.

-

M455 Cam in Texas. man those Shadbolt cams get around. Still one of the best grinds to this day.. I think Steve is running a Baseline Table that I sent him. He may have tweaked it to further enhance. I'll let him respond, but I have some tables that should work pretty good.

-

You don't " really " need that left headlight do you... LOL

-

PS. I'd relocate that CAI. Do you have room in front of your Inter-cooler?

-

Good stuff!!! How much does the Nistune mod cost? I really like the new Haltech 750. Purpose built for 6 cylinder engines with 6 injector drivers and 6 coil drivers.

-

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

This is a very good article on how to adjust VE Tables manually: http://stinger-performance.proboards.com/thread/1002/megasquirt-tuning-basics-initial-startup -

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

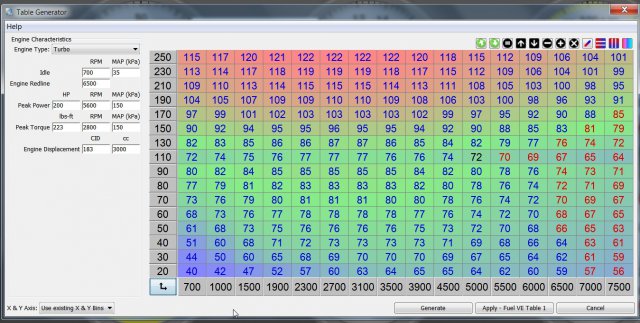

Tuner Studio' VE table generator doesn't always. handle high horsepower numbers well. It's not a true VE calculator. It can sometimes calculate some truly bizarre VE Tables when large HP and Torque numbers are added. If you use the MS-2 VE Table as generated by TS, it always seems to make the non-boosted area overly rich ( Too high of cell numbers ) . Particularly if you don't have accurate Dyno figures. Of course how do you get accurate Dyno figures if you haven't gotten the engine running properly yet? Catch 22. As a result I find it more accurate to enter the stock HP and Torque figures and generate a table. That is normally pretty close up to 100 Kpa and at least makes the non-boosted area driveable. In boost I'll add an Extra 10 to 20% increase to the rows in ascending order. Just to be sure it's Rich enough. Always better to pull fuel out under Boost than to have to add it in. Auto-Tune is not fast enough to correct a Lean condition under WOT Boost. Actually, I want to double check that 4.8ms Tune that I posted. That came off a " problem child " car and I really had to pull the Req-Fuel down to get the VE Table even remotely accurate and with some resolution. As TS originally calculated it we were down in the 12 range at idle... which is not good. As mentioned though. The Req-Fuel calculation is just a number in an equation. Reduce it to get more resolution in the VE cells at the low end. Leave it alone if the resolution is OK. -

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

I meant reduce spark table 3 degrees overall when Boosting IE: over 100Kpa. "Under Boost " meant when ON Boost. I used a PW calculator developed for Haltech. It's very good. Numerous other online calculators and they all come up with the same answers. I enter the figures to get a Master PW and then add about 1ms to take care of the additional enrichment values. 4.8ms was a figure I had derived from a L28 Turbo with 440cc injectors. Another 200cc in your engine won't make a lot of difference in the Req-Fuel calculation . The tables I posted were for 440cc injectors. Here is the Injector Calculator I use, Note : For Sequential injection use an ambient temperature figure of 25c. For Batch Fire use 35c Injection Time Calculator V2.0.xls -

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

I think your Spark Table is also a bit too aggressive for a Baseline Tune. Knock about 3 degrees off everywhere under Boost to start off with. The last thing you want to have happen is to be Lean on Boost and have too much ignition advance. Auto-Tune does not react fast enough under Boost to correct a Lean condition. It's always better to start of too Rich under Boost ( or even at 100Kpa ) and then let Auto-Tune pull the fuel out. In fact, I would take the above table that I posted and multiply everything above 2,700 RPM and 110 Kpa by a factor of 1.2 just to be safe. Always better to pull fuel out than to be too Lean. After re-scale: -

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

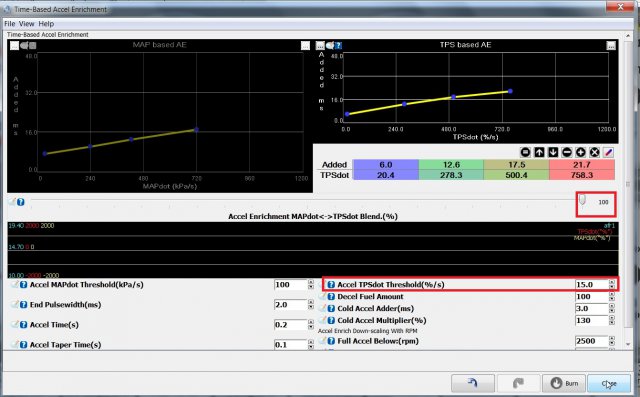

Change the first value to at least double your idle PW value. After you have loaded up the new Req-Fuel Values and re-scaled your VE table as per post above. Once you get the Tune dialed in and Auto-Tuned so that it's not running overly Rich every where, you will probably find that you have to raise the Slope angle of the TpsDot curve. Engiens don't need much AE when they are running extra Rich. Make sure that you change the TpsDot threshold down to about 20. -

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

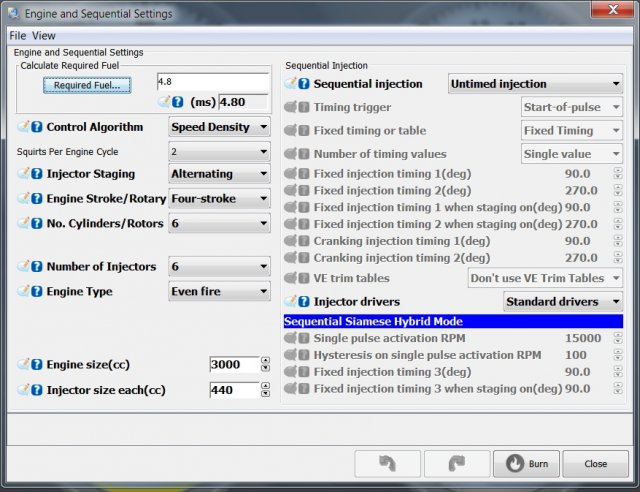

40cc injectors with Batch fire? . Try 4.8 ms Req-Fuel. Set to Injector scaling to alternating ( Smooths fuel rail pulsations ) and squirts to 2. alternating Re-scale VE table via generating a new VE Table. Set parameters as per attached picture. I think this will be a good starting point. You will of course have to retune idle and Auto-Tune. -

The factory 260cc Fuel injectors are rated at 260cc at 36.5 pSI ( FPR vacuum hose disconnected and engine idling ). The Supra injectors are rated at 310cc at 43.5 PSI ( FPR vacuum reference hose disconnected and engine idling ). If ECU was calibrated for those injectors, you may need to raise you Fuel Pressure some more. IE: 43.5 psi at idle with Vacuum reference hose disconnected and plugged.

-

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

Here's a quote from a long time Tuner at MSExtra Forums taht maybe explains the Req-Fuel scenario better than I have. -

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

One of the strange things about Tuner Studio is how they used Req-Fuel. Required fuel in most other systems is a calculation for the Master Pulse Width. That is a multiplier factor. Then other enrichments such as AE and WUE are calculated separately as Additive factors. Tuner Studio has combined both the PW multiplier and Additive enrichment factors in the Req-Fuel calculation. This is a bit of a programming shortcut, but it does have one undesirable effect. Often the Req-Fuel calculation is too large, especially with larger injectors. What this does is to create low RPM and Load Cells with very low values. This affects your resolution.in Tuning ability. IE; Go from a 10 to a 9 in an idle Cell, and that is a 10% change. Go from a 50 to 49 and that is only a 2% change. The VE cell values are just Hexadecimal numbers in Tuner Studio. They do not really represent a VE scale. They can be any where from 0 to 255. In fact it is desirable to have larger numbers to increase Cell resolution. To do that, some Tuners reduce the Req-Fuel Calculation by a percentage and recalculate using the VE generator ( Or manually increase the whole VE Table by the same amount the Req-Fuel calculation was reduced ). This has the desirable effect of increasing the low RPM VE cell values to a higher value that gives better resolution when adjusting up and down. The overall fuel end value doesn't change, it's just how the tables are altered. It's all just numbers in an equation. 50 x10 = 500 is the same as 25 x 20 = 500. The problem with how Tuner Studio has done things is that they have thrown the PW calculators ( Multipliers ) and the Enrichment values ( Additives ) all into the same equation. Change the Req-Fuel to a lower value, because you've installed larger Injectors, and it also changes most of the enrichment calculations. That's why other manufacturers keep the two calculations separate. Now, you could just lower the whole VE Table by a set percentage... but then you may run into the Low Cell resolution at low RPM problem again. Because Enrichment values are included in the Req-Fuel calculation it makes comparing enrichment curves ( and tunes in general ) very difficult. Lower Req-Fuel values mean higher enrichment values to get the same end result compared to a Tune with a Higher Req-Fuel amount. It's all a matter of Table scaling, but it's a PITA that Tuner Studio did it this way..... IMHO -

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

Brian. Which engine is that . The 2JZ I'm assuming by size. 3.0L Generated VE table can be crap as Steve mentioned. . Very dependant on inputted values, and even when those are correct it can be as much as 20% lean on the Top end and 20 % rich on the bottom end. It is very much an approximation... Setting Idle AFR manually is necessary om most cars, especially ones with a larger camshaft. I don't allow Auto Tune to touch the idle setting as it usually screws it up. I usually set Minimum VEAL RPM at 200 RPM above idle. Same with EGO control. This is absolutely necessary with bigger cams. The reason this Tune has minimal AE, is that I have a feeling that it is running very rich at idle and just off idle. Probably 12.5 to 12.0 or richer. Common with big injectors. It can be hard to get the Pulse Width down low enough to get a good idle AFR ( more difficult with Batch Fire ) . Which should be usually end up at 13.6 to 14.0 with Batch fire and a stock cam. 13.8 is a good starting point. Big cams like the 13.0 to 13.5 AFR at idle range. 1st step off idle to 1,500 rpm should be very close to the idle calibration. This will smooth Tip in response from a stop and at cruise. If the main Fuel Table is rich all over... you don't even need AE and the car may run surprisingly smoothly. It will be swilling fuel though and money will be flowing out the Tailpipe. Once you get an ideal AFR ratio dialed in... and that means Cruise AFR's of 15.0 to 15.5 ( or higher with CDI Ignition ), THEN you need more AE. He is also running a TON of ignition advance down very early. Turbo cars like to do this to build boost quickly and to combat low CR, but in this case I think it may be excessive. Again, I'm thinking this car is running really rich down low and that is preventing low rpm detonation. But done improperly, it can also make the Turbo lazy. Once you lean it out a bit, you can back off the amount of low end advance. If you don't, the engine will be fighting itself one you get above the 1,500 rpm range because the flame front will burn quicker when closer to Stoich. Flame propagation speed is affected ( slowed ) by excessively Rich and Lean mixtures. I'd like to see some datalogs of idle and cruise if possible.... -

I'd have a look at your Acceleration Enrichment curve. The low rpm and Map thresh holds may be too low. Edit: Your AFR reading also appears to be far too Lean at idle. Should be in the 13.6 to 13.8 range with Batch Fire. However, I also hear what appears to be an exhaust leak. Have you checked for any exhaust leaks ahead of the WB O2 sensor? Those are an absolute NO NO and will give issues such as this.

-

Drag racing suspension

Chickenman replied to walkerbk's topic in Brakes, Wheels, Suspension and Chassis

Longg time Road Racer Auto crosser and Hillclimber. And the problem is mainly your tires. Tires built for Autocross do NOT launch well at all at a Drag Strip.. The sidewalls are way to stiff for Drag style launches. Get some dedicated Drag tires and save the Autocross tires for when you run Autocross. I've Hillclimbed a lot and believe me, you can easily lose a second on a run with Autocross tires. It's usually a slow roll on with lots of clutch slip that works well. Start to spin an Autocross tire and they just go up in smoke. Some are much worse than others. Hoosier DOT Autocross tires don't like being spun up at all. Difficult to get them to bite again when they spin up. And put a Posi in that diff. While IRS does not have the same inside wheel unloading issues that a beam axle has, it's not ideal at a Drag Strip. And it will help immensely at Autocross. I don't think the extra complexity and particularly the extra weight of the Torque arm setup on an IRS is going to help that much. Biggest change will be getting dedicated Drag slicks. Eventually you may have to decide what you want to do with this car. Autocross and Drag Racing are two diametrically opposed Chassis setups. Nether is really compatible with the other. You will always be in a compromise situation until you decide which way to go. That being said. I have seen IRS suspension cars launching VERY hard ( Wheels up hard ) at Drag Strips with Stock IRS suspension. No torque arm Wizardry used. However, that was on proper Drag Slicks and with a Posi. You could weld the diff. But it's not an ideal solution. Can be wicked evil nasty on the street if it rains. Be fore warned. Been there done that!! -

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

Juts remember to leave the AE and EGO control enabled. It's a myth that you have to turn them off when running Auto-Tune. Old wives tales back from the days of the original B&G MegaTune. Since Tuner Studio has taken over tuning development, there are Automatic filters in place to compensate for the AE and EGO controls. I like to make the VE Cells in the high boost areas about 10 to 20 % richer over what the MS VE Table generator calculates. Auto-Tune cannot compensate fast enough to correct a lean condition at WOT and high boost. Melty, melty. Where-as if you set the High Load areas purposely rich, Auto-Tune can pull the values down at it's leisure. No harm no foul. GL with your Project. -

I've tuned a couple of local SDS systems. They are 1980's technology and archaic. The Tuning on that single line programming pad is a nightmare, as nothing is user friendly. Very few people will Tune SDS anymore. Not trying to be a Smart Arse.. but ditch the thing or sell it on E-Bay. Take that money and put it towards a proper ECU such as a Haltech Elite 750 ( purpose built for 6 cylinder engines with 6 Universal injector drivers and 6 coil drivers ) . The Elite 750 is a bargain for 6 cylinder engines and it just WORKS. Straight out of the box. Other good options are : Adaptronic, Link, Holley Dominator, AEM Infinity. You pay more...but the ease of installation, setup and tuning is well worth every single penny IMHO.

-

You posted a question about MS Maps in the FAQ Forum. You will not get any replies to thta thread as it is a LOCKED Forum. People cannot reply to that Forum.

Delete that thread and re-post in EMS> Megasquirt Forum. BTW, check your messages. I sent you a PM.

-

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

Every engine is different of course. A lot of variables. But think of the TpsDot as the accelerator pump shot on a carburetor. Now, in general, Datsun L series are a lot like SBC in accel pump shot. Thye like a quick fat shot of fuel. So start the left side of the graph at about 15 -20 TPsDot and then adjust the slope angle . Should be fairly steep. BTW, that graph shown is fairly steep. Due to a bug in the code. The Y Axis will not scale lower than 48. Even though it will prompt you for a number between 0 and 25.5 if you try and set the minimum value. You can monitor the TpsDot figure at idle. It should be fairly close to zero. That is the only sensitivity level you should be concerned abou. Do NOT worry about the AE ( TpsDot or Map Dot ) coming in at cruise. It is supposed to. Think about a Holley accelerator Pump cam system. There is absolutely no delay at cruise when pump shot AE comes in. Any slight " Tickle of " the throttle will initiate some AE enrichment. And that is how it should be. Tip in at Cruise is often the hardest part for people to understand. You have to have IMMEDIATE AE, because you are already running lean mixtures and a low throttle angle. So any slight opening of the throttle " Or Tickle " will require an immediate increase in AE. I had a perfect example the other day when I installed a new Tune on a local car. Car was originally Pig rich, idle was near 10.0 AFR and cruise was in the 12.0 AFR range. After loading a " proper " tune engine idled smooth as silk at 13.8 AFR ( mild cam ) and cruise was dead smooth at 15.0 AFR. On problem was a stumble at Cruise Tip in and just off idle. This wa due to the TpsDot Thresh hold being to high. Customer mentioned that it never did this on the old Tune. Reason was he was running so Pig rich that ZERO AE was needed at any speed. When you lean things out to get efficiency and fuel economy, AE " Tip in" plays a big part in obtaining smooth driveability. Full throttle AE is dead easy to set up. It's subtle little roll on or " Tickle " of throttle that is hard to get right. That you just have to play with, on the left side of the scale. The area between idle and 1,500 RPM is alo very important as a " Tip In" transition zone. Don't get it too lean. Should be under 14.0 to one with a stock engine. Around 13.5 to 13.8 with any decent Camshaft. BTW, 25.5 ms of extra fuel is the Maximum value that you can add. As stated in the Scott Clarke video. Your first value should be a minimum of double the idle pulse with. A big camshaft will want more. As will a bigger TB. Send me you Current Tune.msq and I'll have a look at it for you. -

Time based access TPSdot and ms pulse width

Chickenman replied to seattlejester's topic in MegaSquirt

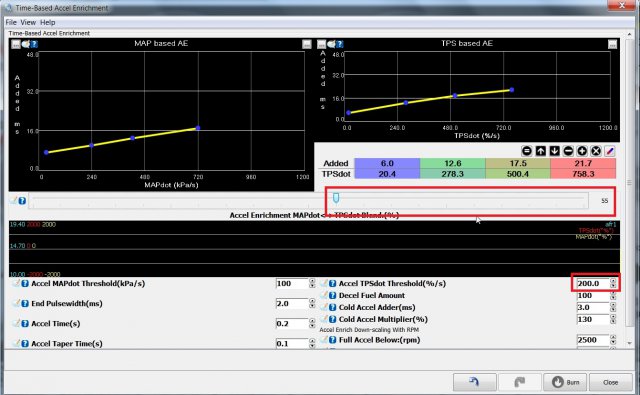

The TPS Threshold Box is the key to getting AE working correctly.. The Default figure of 200 is way too high. Try 10 to 20. Even though you can have the graph line set very low, If you don't change the Thresh hold value, all areas below the Thresh hold point ( Default = 200 ) will be ignored. First picture is of some Default settings. Second picture is what works to get rid of that " Tip In " stumble. Some engines also like a blend of MapDot... so you have to lower the default setting of 100 to about 20 as well. Default TpsDot Thresh Hold at 200. Even though graph line goes down to 20.4..all of that will be ignored till TpsDoy gets above 200. Rather silly programming od software if you ask me. Two values to change when one would do. TpsDot thresh hold configured to 15.0. Now the low end of the Graph is not ignored and Tip In stumble magically disappears. Note that Slider is all the way to the right to use TpsDot only. As mentioned. Some cars like a bit of MapDot blend as in the upper picture. But the MapDot thresh hold ( Not circled ) would have to be lowered as well. I just Luv default values that don't even come remotely close to what real world engines require Grrrrr.