-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

Silly Question about Incorporate AFR Table and the VE table

Chickenman replied to LiquidCMR's topic in MegaSquirt

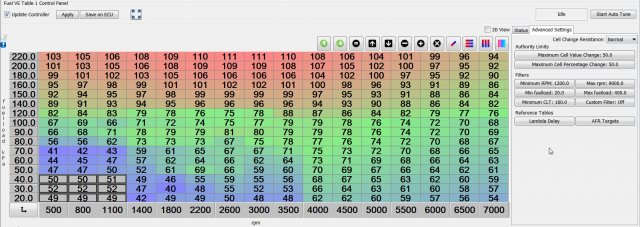

Here is a screen shot of the settings in the Auto Tune VE Table. Take note of the Gray " "Locked out " idle settings and the minimum RPM settings. Effectively this set-up is redundant. Either using Minimum RPM of 1,300 or Cell Lock out would work. I tune idle by the old school, highest RPM and Vacuum reading at idle method. That will always give you the most stable idle on any engine. -

Silly Question about Incorporate AFR Table and the VE table

Chickenman replied to LiquidCMR's topic in MegaSquirt

Auto Tune does not always work particularly well at idle. Especially with larger camshafts. Same with EGO control. You want to Manually control your Idle settings in most cases. So you want to run idle in Open Loop. Set your EGO control to minimum RPM of about 1300. Set your Auto Tune to a minimum RPM of 1300. Now O2 control and Auto Tune will leave your idle cells alone. You can also " Lock Out " Auto Tune at idle ( and any other area ) by opening Auto Tune section and right clicking the VE Cells in a particular area. I usually lock out Auto Tune at Idle . There is a selection to lock the Cells. You have to select a " Block " of cells about 3 x3 all around your idle RPM. Richr Click. Lock the Cells. They should change to Gray in color when you save the changes. Now Auto Tune will leave those Cell areas alone, but you can still change them manually in the Main VE table. BTW, if you are running Batch fire 14.5 is too lean at idle. Aim for around 13.8. . Keep your AFR's at 13.8 just off idle to about 2,500. That will aid in light throttle transition. -

Oil starvation ever an issue on L28 during racing?

Chickenman replied to turbogrill's topic in Nissan L6 Forum

I ran an Aviad 7 qt Road Racing pan on our D - Production 240Z back in the 70's. We ran on Goodyear slicks and never had an issue. Running oil level higher can be tricky. The last thing you want the oil to do is contact the crank throws. That causes oil foaming which is very bad.. Air is a surprisingly bad lubricant. I've also run an Autocross Z on Goodyear Cantilever slicks with the stock oil pan. It was OK, but Autocross has short G-Loadings and no elevation changes. Road Racing with long sweeping turns, Positive and negative banking and elevation changes are a lot more challenging. Only thing more challenging for Wet Sumps is Hillclimbs. The steep inclines push all of the oil to the back of the pan. It's a really problem if you have a front sump oil pan. I think I would talk to someone like Canton on building a Custom Road Race pan. Canton oil sumps are very, very good. You send them your core and they add on the winged pans, dog door baffling and a proper windage tray. You should run a windage tray on any oil pan. I have an Arizona Z car aluminium sump on my DD. It's not bad and would be OK for Autocross and the occasional Track Days. But I'm not sure how much I would trust it during an Enduro. Particularly if you run slicks. -

We have a simple spray pattern, we don't have to worry about siamesed ports or Triple Ports such as on Audi/VW 5 valve per cylinder motors. I'd go for some Bosch single spray pattern. Fords tend to use these a lot. 440cc Green Giants aren't a bad choice at all. Can't remember if they are High Impedance or not. I'd give MotorMan fuel Injection a call and see what they have in a Bosch EV1 High Impedance. Very good company to deal with. http://www.fuelinjector.citymaker.com/web_page.html

-

Any one use an AEM Engine Position Module (EPM)

Chickenman replied to redfogo's topic in Nissan L6 Forum

-

Any one use an AEM Engine Position Module (EPM)

Chickenman replied to redfogo's topic in Nissan L6 Forum

Might be easier just to get an L28 Turbo billet dizzy cover. There's a few guys making them.This is for an RB30, but I'bve seen them for L28ET's as well. You shorten the rotor collar or machine a new one. -

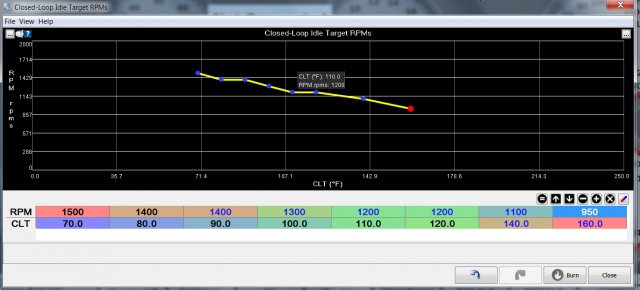

I was actually half kidding about reverting to the AAR dinosaur... but sometimes simple is better LOL. If you don't need any Idle Kick for AC or something, the good old AAR works good enough. Certainly less of a PITA to setup. You could even install the original ThermoTime Switch... but that would be too funny You can also use Ignition Timing Idle advance to give a few more degrees of advance when the engine is cold. The Federal model 280Z engines did this. They had Dual VR sensors in the dizzy. One was advanced ( Phased ) about 6 degrees from normal, and only operated while the engine was cold. MS has a programmable cold advance idle curve that you can do the same thing with. Advances low RPM range a set number of degrees over base timing table until engine wrams up. Works quite well and is simple.

-

Wish I had a garage like you!!

-

The old Datsun AAR valve isn't looking so bad now is it.... LOL Ironically... you could use one and control it very easily with the MS. I use a later Z31 AAR valve on my 280Z. 22660-30P10. You can take this one apart and clean the oily gunk out.

-

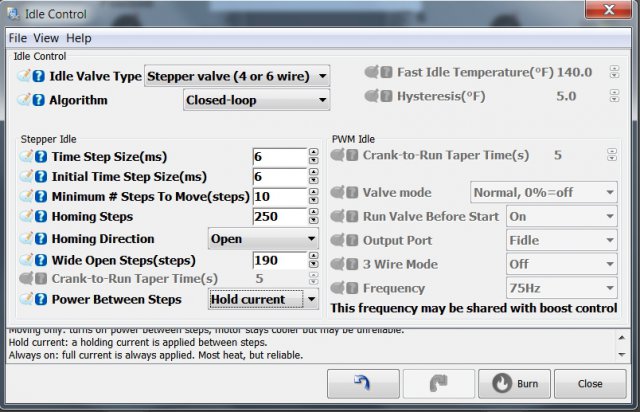

Yeah... I wasn't 100% sure on that Mode ( Always On etc ). But it's nice you can flip the Direction in the Software instead of having to re-wire. Frackin' MS help files sure are nicely organised and easy to understand.... NOT!!! Biggest weak point of the whole product IMHO.

-

Edited my post from Friday. So my WAG ( Switch Homing direction from Closed to Open ) was correct !!!

-

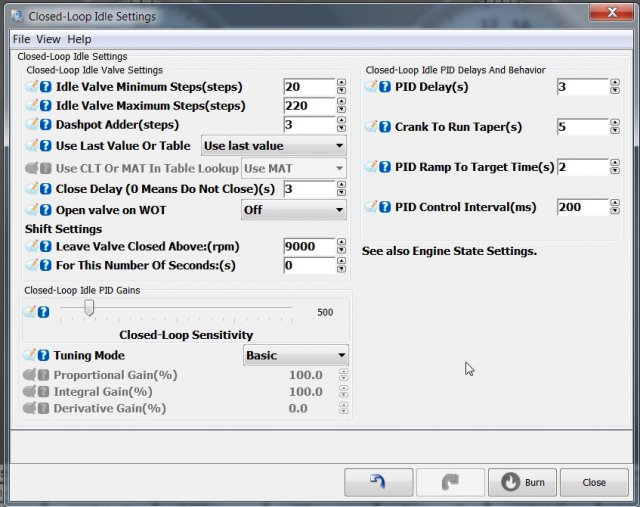

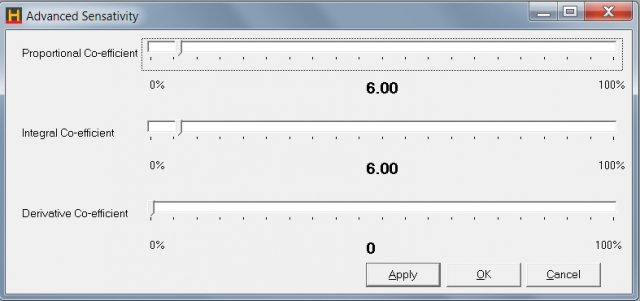

You can also change the PID values by changing Closed Loop Sensitivity to Advanced Mode

-

BTW, I wouldn't put too much faith in just cycling the ignition on and off. The ECU stepper control needs RPM signals to return to the proper " Home " position. Turning Ignition On and Off repeatably may not be a useful test.

-

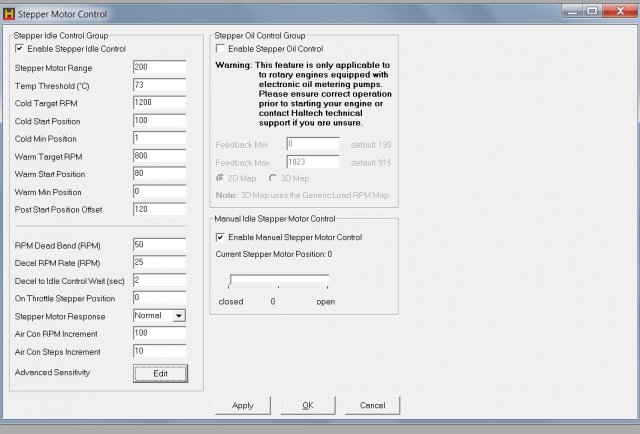

Steve. I think you have some Basic settings wrong. You want Closed Loop and you need to change some of the other settings. When you go to Closed Loop, the Menu Bat Options will change. Try these for a start and LMK what happens:

-

Just for comparison, this is the Help file that pops up on my old Haltech E11 when I'm in the Idle Control panel. Some of these explanations may help in setting up your MS3???

-

If the above setting change doesn't work, double check the IAC wiring. Quote from the Mega Manual IAC article:

-

Just a WAG. But try flipping the Homing Direction from " Closed " to " Open ". Edit: Apparently that's exactly what you do.

-

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

^ It's a very well proven design by Integrated Engineering. No reported issues that I have ever read from BT Audi/VW forums. -

10 year old plug wires are not new. Especially carbon core wires. Wires can deteriorate just sitting. Ozone can crack and split boots. Then you can get arc over to engine. Corona discharge around plugs is also a problem with old leads. Plug leads should be checked with an Ohm meter. Just looking at them is not good enough. Pull your plugs and take some High Resolution close up pictures. use a good digital camera or a good Smart Phone camera. We need sharp clear pictures. Turn the flash off. It will skew the plug coloring. Try to get some good side on shots of the center ceramic and the full view of the side electrode. A Top angled view is best. How old are the plugs? Plug reading will tell you a lot about the engine running condition. I noticed the smoke. Sounds like you have an exhaust leak. Wouldn't surprise me if you have a leak at the exhaust manifold. Check for loose or broken exhaust studs. Also any evidence of soot around exhaust manifold or cracks in exhaust manifold. Engine sounds noisy. probably needs a valve adjustment . If that has recently been done, then it could indicate that rocker arms are worn. They will wear with a horizontal line across the wiping face. If you can feel the line with a finger nail dragged across the surface, then the rocker needs re-surfacing or replacement. No amount of adjustment will get rid of rocker noise when they get that worn. But, I don't think that's your issue though. It's really hard to tell how an engine runs in a video. But in general, I think your car just needs a bit of a sharp Tuneup. It doesn't sound all that bad. But loaded up on the road could be a different matter. Carb adjustment, carb balancing can work wonders on these engines. Also the distributor advance mechanism tends to seize up on these motors. Both mechanical and vacuum sides must be checked for free operation. The rotor should fit snug on the shaft. I've seen after market rotors that fit very loosely on the shaft. That's no good. You should be able to take the rotor and twist it about 20 degrees in the direction of rotation. Then quickly release it and it should " Snap " back to resting position. If it is hard to rotate or slowly returns or doesn't return all the way, time to take the dizzy apart and service it. You will have to clean and lubricate the mechanical Cam and governor weight system. Use a Vacuum pump to check Vacuum advance. Get the FSM specs and test it. Movement should be smooth. Hold vacuum and freely return when the vacuum release. The breaker plates have tiny ball bearing in them, and these ball bearing often rust or even fall out. Jason Grey's distributor page has a wealth of info: http://newprotest.org/projects/510/jasonGrayDistributor.pl Here are specs for popular Z car dizzys in Excel format: Distributor advance curves.xls

- 31 replies

-

- fml

- more z car torture

-

(and 1 more)

Tagged with:

-

The instructions for your plug gapper are are wrong. That's way too much of a gap. Period... end of story. Been using these things for over 40 years. That is a FRACKING strong spark!!! Both appearance and noise show that secondary side is working damned good. It only appears intermittent because the spark has found an easier path to follow than through the HUGE gap of your spark tester combined with the gap from the plug. You are using the Tool wrong, and may have damaged other components ( such as inside of Dizzy cap and rotor ) by running such a huge gap when testing. BTW, have you checked your HT leads with an Ohm meter yet? . Those leads look like old style OEM carbon core. They deteriorate with age. Upgrade to some good quality spiral core wires such as NGK. Edit: Here is a video from Mac Tool showing the proper way to use a spark tester and the proper gap settings. Note that he mentions that the printed numbers on the tool basically mean dick squat. This is the same Mac Tools spark Tester that I use. Also note that the maximum gap setting that the Technician opens it up to is about one third of what is shown in your video. https://www.youtube.com/watch?v=YNIIllZRNRw

- 31 replies

-

- fml

- more z car torture

-

(and 1 more)

Tagged with:

-

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

Holy Hanna... I finally found some specs on Fram G3 filters. They are rated at 5 Microns. That's far too small to be used as a pre-filter for ANY EFI pump. Let alone a high volume pump such as a Bosch 044. Get rid of the G3 and put in a recommended Aeromotive pr pump filter which are 100 Microns in size. Fine filters should only be installed post pump. Thanks Atlantic Z for perpetuating this incorrect information. I was wondering about this ever since I installed a Fram G3 before my Airtex 8312 EFI pump based on the Atlantic Z article.. It's a Ceramic turbine pump, so it does need a pre-filter according to Airtex. In Tank pumps have a sock to catch the coarse stuff, but an inline pump doesn't. Would have been nice if Airtex had recommended a proper inline Pre-filter... but they don't. My pump had been getting growly and noisy during hot weather. Worse when fuel tank was below 1/2. Mkaes sense now as this is a Textbook case of a restrictive fuel filter being installed before the pump ( Fram G3 ) . G3 is going bye bye and I'm ordering a proper Aeromotive 100 Micron SS filter from Summit ASAP!!! -

Deleted. Wrong thread.

-

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

Further reading on Fuel Pump Cavitation and starvation caused by restrictive Pre-Pump filters. http://aeromotiveinc.com/wp-content/uploads/2014/12/TB_101_InletFilter02.pdf http://aeromotiveinc.com/wp-content/uploads/2014/12/TB_802_Tanks_Sumps_Stealth_02.pdf Aeromotive has some excellent Tech Articles. Well worth reading them all. https://www.aeromotiveinc.com/tech-help/tech-bulletins/ -

Aeromotive 13129 EFI regulator will also work just fine, is a quality part and has a reasonable price. https://www.summitracing.com/int/parts/aei-13129/overview/ The stock FPR simply cannot handle the Bypass return volume that a High Volume pump provides at idle and low RPM's. Internal orifice is simply too small. At idle, with bigger injectors and a high volume pump you can be Bypassing 80 percent of the fuel volume back to the Tank. FPR has to be designed internally to handle this amount of flow and maintain a steady pressure. Many new cars use a PWM Fuel pump that reduces flow at low loads to aid in maintaining a properly regulated rail pressure.