-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

MS extra forums are the best place to find info like that. The MS2 Hardware manual will have what you want. http://www.msextra.com/manuals/ms2manuals/ And just to reiterate, the MobyTheVan articles are really ancient history. Much better ways to do things now.

-

There's been considerable changes to the Installation procedures since the MobyTheVan article. For instance, the development of the DIY L28 Trigger wheel. This is much more up to date. https://www.diyautotune.com/support/tech/hardware/nissan-trigger-disc/

-

280zx ignition module with Megasquirt - is it necessary?

Chickenman replied to supernova_6969's topic in Nissan L6 Forum

I would use the BIP 373 drivers in the MS. Switch to a crank fire trigger wheel or install the 82-83 280ZX Turbo distributor with Optical CAS trigger. With the Turbo CAS distributor you will have to purchase the DIY Custom trigger wheel for the L27ET engine. The advantage of using a Crank Wheel or CAS distributor is that now you will have fully programmable ignition timing. With three BIP373 coil drivers you can run Waste-spark spark ( 3 x twin tower coil packs.) and Batcfh fire injection on an MS2 If you add in an MS3X expansion daughter board, you can have full sequential fuel injection and 6 individual COP ignition coils on an MS2. Look on our Vendors forum. Softopz is a MS distributor and he can either build you a new ECU or repair/update the ECU you have. He also makes excellent Plug and Play custom harnesses. http://forums.hybridz.org/topic/128308-megasquirt-plug-and-play-harness-and-pre-configured-ecus/ It may be a good idea to send the MS2 ECU to him and check it for any hardware issues. MS units can be built many different ways. And the build quality of course depends on the skill of the builder. used units can be a crap shoot. If you need Tuning, I can help you with that. I Remote Tune MS1, MS2 and MS3 ECU's. primarily for the Datsun L-serie's. You can PM me for more info.- 30 replies

-

- megasquirt

- ignition module

-

(and 1 more)

Tagged with:

-

When you re-ring it, use regular Cast Iron rings... not Moly. Cast Iron rings with bed in nicely on a hand hone. Moly rings require a very fine and precise finish that cannot be duplicated with a hand honing tool. My L28 was hand honed and assemble with Cast Iron rings and it has virtually zero oil consumption.

-

Need a quick brain refresh on this. Hectic day so don't have time to research. L24 crank pulleys and L28 crank pulleys have their respective TDC marks in different locations correct? As I recall the L24 Ignition timing tab was on the drivers side ( Distributor ) side. L28 has timing tab or Arrow on Passenger side. Alternator side correct? ( Because of AC on 280Z and ZX. ) Person has put a L24 crank pulley on an L28. Timing Tab is just an arrow mounted on Passenger ( alternator ) side. That would put the timing marks out around 120 degrees? Correct?

-

I've been in contact with Shane. He apparently got it fixed. It was those darned resistor jumper leads. He went back and re-did them with shrink tube, touched up a few solder joints and I think reloaded his Firmware. Anyhoo.. it goes Sparky, Sparky properly now. Shane and I are scheduled for a Remote Tuning session Sunday morning. D14 out seems to be one of those quirks in Tuner Studio that has never been updated. Older Instructions used D14 but it's been JS10 for a long time now. Used MS ECU's are " Like a box of chocolates. You never know what you are going to get "

-

Scroll down to the Vendors Forum: http://forums.hybridz.org/topic/99098-pallnet-fuel-rails/

-

Now you tell me!!! LOL.

- 10 replies

-

- injector clips

- 440cc injectors

-

(and 1 more)

Tagged with:

-

This may be the conversion harness I saw the other day. I'd E-mail them and ask if the Denso end is universal. IE: For both High and Low side tabs. https://fuelinjectorconnection.com/products/denso-to-ev1

- 10 replies

-

- injector clips

- 440cc injectors

-

(and 1 more)

Tagged with:

-

There are universal Nippon Denso connectors that fit both the high and low tab style of Toyota injector terminals. You can get them on E-Bay, but I saw a Vendor on Church of L series that specialises in conversion harnesses the other day. I'll see if I can find the link. I made the same mistake the first time I ordered EV1 to Nippon Denso conversion harnesses. I finally found the correct ones. I'll look for that as well. Was a while ago. Edit: Here are the correct Toyota connectors that fit both the high and low side tabs on Toyota https://www.ebay.com/itm/6x-Female-Fuel-Injector-Connector-Electrical-Plug-Adapter-For-Kia-Nissan-Toyota/291929715010?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2060353.m1438.l2649

- 10 replies

-

- injector clips

- 440cc injectors

-

(and 1 more)

Tagged with:

-

^ That looks like a pretty stout beginning for a Baseline Tune. Looks to be well sorted already. Would have been nice to see AFR's.

-

You should be able to " Free Rev " the engine a few times and build up the Vacuum in the Booster. On the " Over run " Vacuum will build higher in the Booster. Wing it hard to about 4,000 a few times. Let it return all the way to idle. Repeat about 3 or 4 times. Then press brake pedal. If brake pedal is easier to press, then you know the issue is just low idle Vacuum. If the pedal is still Rock Hard then you may have a problem with the Booster check valve ( Backwards or leaking ) or the reaction disc fell out when you changed the Brake M/Cyl

-

Do you always degree your aftermarket cam?

Chickenman replied to turbogrill's topic in Nissan L6 Forum

Isky's ( and other MFG's ) recommendation is for the good Ol' Boy push rod Cheby's and Ford's. They don't have over head cams and don't have the unique issues that OHC motors do. That being said, I have to admit I've assembled some of my own street Datsun ( A-series push rod ) and SBC engines without ever going near a degree wheel. Never had any issues. -

You didn't mention what Generation of LT1 you have. Early style Gen 1 (1970- 1972 ) or late style Gen 2 ( 1992 - 1997 ) or Gen V ( 2013 - Current ) . The later style have smaller combustion chambers and require a bit less initial ( mechanical ) timing than the Gen 1. Fuel quality also plays a part of course. So you do have to experiment a bit.

-

9in/hg is probably too low. You need about 12 in/hg minimum. A larger Booster or an Auxiliary Brake Booster Tank will help. You can also increase Idle Manifold vacuum, significantly by Increasing timing advance at idle. Cams with more overlap require more ignition advance at idle. Are you carburated or Fuel injection. You need to run a digressive Vacuum advance curve ( Carb ) or Load curve ( EFI ). With a carb you need a Vacuum advance that has adjustable spring tension and curve . You set the spring tension very weak, mso that full Vacuum advance is all in by 8 to 10 in/hg. Set the stroke length to give you about 10 degrees of total Vacuum advance. Then connect the Vacuum pot to Manifold Vacuum, so you have full Vacuum at idle. Set your initial timing to about 14 to 16 degrees BTDC at 700 rpm, with the Vacuum advance hose disconnected. Then connect the Vacuum advance hose to give a total of 24 to 26 degrees . Then adjust idle to about 1,000 RPM. You should find that this gives a considerable increase in idle Vacuum over Ported Vacuum, or no Vacuum advance at all. The only difference between Ported Vacuum and Manifold Vacuum, is that Ported source does not pull any Vacuum at idle. Manifold sourced vacuum does. As soon as you open the throttle Blade slightly, they both behave the same. But the extra 10 degrees of Timing with the Manifold Vacuum really helps cammed engines idle better, use less throttle blade opening to achieve a set idle speed and thus pull more Vacuum at idle. Stand alone EFI is a bit easier to do. You just play with keystrokes and builds the extra timing in by a Programmable curve instead of messing with Vacuum pot spring tensions and stop limiters. Note. It is very important when using a regular distributor with Mechanical weights, that your advance curve does not start too low. I always set mine so it started around 1,200 rpm with an idle speed of 900 to 1,000 RPM. Having too weak of advance springs will cause the timing to " bounce " at idle. Will cause erratic idle and erratic Vacuum readings.

-

Proper ECU Grounding to the Cylinder head or Intake manifold is clearly recommended by MS as well. Have a look at section 3.2 " Grounding Schemes " of the MS3 Hardware Manual. Page 13 and 14. In fact, download and read the whole Hardware manual. The Hardware manuals provide the most accurate information for installation, setup and various Option for MS models. http://www.msextra.com/doc/pdf/html/MS3XV30_Hardware-1.4.pdf/MS3XV30_Hardware-1.4.html

-

One other thing. Check the Trigger wiring to your CAS. On the Factory ECU wiring diagram you can see that all 4 leads for your Trigger wires are shielded. On some of the early MS3 builds, they have the Crank and Trigger wires as a separate 2 x 2 bundle. The Crank signal wires are shielded , but the Cam signal wires are just unshielded twisted pair. They should be shielded as well. All depend on how it was built... but it is something to check.

-

Looked at your .MSQ. It would definitely help to Enable " Noise Filtering " under Ignition Settings. Enable both Primary Tach ( Crank ) and Secondary Tach ( Cam ) as you are using both of the Trigger sensors on the CAS. Use the default settings. Right now you have all noise filtering turned off.... not a good idea. Edit: Tuner Studio gives unconventional names to things sometimes ( actually, quite often ) And it can confuse people. I Have no Idea why they call these a " Tach " circuit. People immediately think of Tachometer and leave the setting off. What it should be called, and is called by other manufacturers is: Crank RPM signal ( or Trigger ) and Cam RPM signal ( or Trigger ) . Makes more sense to me at least....

-

The ECU main ground should never be mounted anywhere near the starter nor to the Negative battery circuit. The starter motor draws huge current, and is extremely noisy electrically. It creates large Eddy currents in the engine block and strong Magnetic fields around it when cranking. This can induce a voltage impedance in ground circuits. Things like lights, solenoids, DC motor aren't affected by this slight voltage impedance in the ground circuit. But the ECU, which has components that operate on Millivolts, can certainly be adversely affected if the ECU ground is connected to the Negative battery cable or any where in close proximity to the starter motor. The Magnetic fields, Eddy currents and Voltage impedance diminish within a certain radius of the starter motor and it's ground wire.

-

That method of grounding can introduce a s**tload of electrical noise into your ECU. Which is exactly what your Datalog is showing. ( I had a quick look at it. ) You have trigger drop outs all over the place. Run ALL of your sensor grounds back to the sensor ground on your MS ECU. Then run the MS ECU ground back to the Intake manifold just like it was done at the factory. The ECU ground MUST not share grounds with any other circuit. Especially DC motors such as Fuel Pumps, Cooling Fans , Defroster motors. DC motors create a ton of electrical noise. That is part of the reason why the ECU is grounded to the Intake Manifold and DC motors are grounded to the Chassis. You want the shortest ground loop possible for the ECU to eliminate electrical noise. Bus bar grounds are fine for use as a common ground for things like Lights and Motors, but NEVER connect an ECU to one. It's an excellent way to inject a whole lot of noise into the ECU circuit. One sensor grounded to the wrong place, is all it takes to Inject noise into the whole ECU. This was the Mazda Miata screw-up that Andy Wyatt mentioned. The Early Miata's had a Engine coolant temp sensor that was grounded to the chassis. Instead of through the ECU sensor grounds as it should have been. Caused a lot of erratic ECU problems. The paper gasket under the distributor mount has zero effect. The bolts threading into the Timing cover complete the secondary CAS ground circuit nicely. As do all bolt threads. FSM with wiring diagrams is available for download at: http://www.xenonzcar.com/s130/fsm.html

-

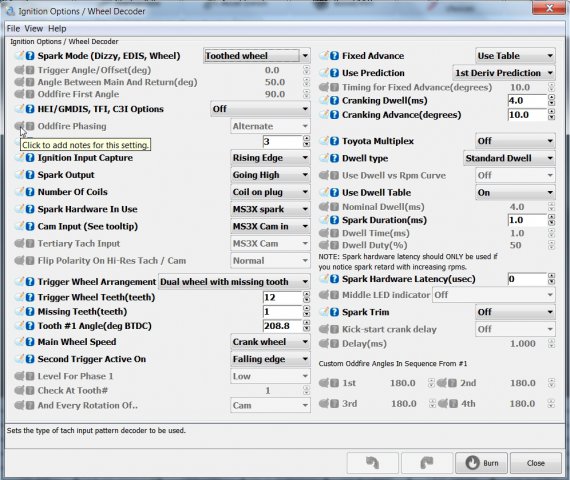

I juts did a remote tuning session with Bryan R on his son's L28 Turbo He has an MS3 with MS3X Full sequential fuel and individual COP ( LS2 coils ) Here are the trigger settings we used. Fired right up and ran beautiful

-

To change to WasteSpark instead of COP, under Ignition settings Change Number of Coils to " Wastespark ". . I haven't read the whole thread, so what coils setup do you have. individual COP ( LS style ) or three two coil wasted spark? Edit: I just went back and loaded your Current Tune from Post #5. In that you were running Wasted COP. Wasted COP, COP and Watespark are three different setups. Please tell us your Exact ignition setup. With number of coils, or number of Wastespark Coil packs and number of Coil drivers in the MS3X expansion board. . Not very often will anyone run Wasted COP. It's a weird Option only used in special cases. IE: Six individual coils ( For an L-6 ) , but only 3 Ignition coil drivers. Coils would be wired in matching pairs and fired twice per 720 degrees of crank rotation.

-

I see two " possible " problems right off the bat. Second Trigger Active On is set to " Rising Edge " . Although DIY recommends " Poll Level " with MS3 and MS3X, some people on the MSExtra Forums report that doesn't work well. You may want to try Falling edge. You may have to re-sync your #1 Tooth Angle. DIY Auto Tuning instructions leave something to be desired. Use Prediction is set to " No Prediction ". It should be set to " 1st Deriv Prediction " Update your MS3 firmware as well. You're running an outdated format of 0435 .13. Latest Firmware is 1.51 with Signature format 0566.05

-

Question about dual master cylinders...

Chickenman replied to JMortensen's topic in Brakes, Wheels, Suspension and Chassis

Delete Post. -

Small diameter heat shrink tubing makes a nice insulating sleeve for resistor leads. Much easier to install than tape as well. If you need tuning help, give me a PM. I do remote Tuning and can set you up with a good Baseline Tune.