-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

If you originally installed the BIP373 with no Mica insulator ( you seen to infer that you added the Mica insulator later on ) then you may have burnt it out. Get another one and install with Mica insulator. They're cheap enough.

-

Quite simply if your TPS is reading like that then you have it wired wrong. You just can't swap the wires around willy nilly, because if you swap them wrong you can actually end up with the same output from the TPS with wires in different positions. Most TPS sensor are 3 wire and they have a 5 Volt reference, a sensor ground ( back to the ECU ) and a variable TPS output. There are several combinations of wiring that won't work. properly, but only one way of wiring that will work. TPS wiring also varies by clockwise or counter clockwise rotation. GM and Ford sensors have both rotations and they have different wiring at the connecting plug. Find a schematic for your particular make and model of TPS sensor. Creative use of Google should find that answer in under 5 minutes.

-

Travis, I've sent you an E-mail with some info on pre-filters. You can still use that Wix 33281 as a canister style filter post pump before the injectors if you like. You still need a fine filter ( 10-20 Microns ) ahead of the injectors, but after the fuel pump. Once we get the Fuel Pump starvation problem fixed, it should be smooth sailing.... BTW, any one using those Fram G-3 filters as a pre-pump EFI filter ( As suggested in AZ Car articles ) should throw them out. They are a 15 to 20 microns and will strangle the high pressure EFI fuel pump. You should be using a coarse 100 -120 Micron Stainless Steel filter as a fuel pump pre-filter

-

With injectors a couple of notes. Assuming staying Normally aspirated. 1: Stock non- Turbo 188CC injectors will support up to 200 HP easily. L28 Turbo injectors ( 265 cc ) will support up to 250hp. 300cc ( 30lb/hr ) will support 310 bhp at the crank at 90% IDC. 350cc will support 360BHP at the crank at 90% IDC. http://fuelinjectorclinic.com/hp-calculator 2: I would strongly recommend either buying new or reman injectors. Or sending your present injectors out to a company like Injector Re-Hab to have them cleaned and flowed. http://injector-rehab.com/shop/home.php Motorman is a good place to buy re-man injectors http://www.fuelinjector.citymaker.com/web_page.html 3: Injector impedance is very important. MS can run either, but it does have some quirks. If Low -Impedance injectors are used, I would advise keeping the stock dropping resistors. MS PWM current control limiting can be a PITA to configure with some injectors. The stock Nissan JEC's injectors are one of those brands that are " finicky ". The factory dropping resistors with Low-Z injectors and MS1/2 are much less troublesome. MS3 also has better Low-z driver software. The other solution is to use Hi-Z injectors. This is what most modern cars use these days. May be a better choice if you plan on changing injectors and installing a Pallnet fuel rail. Will give you more selection in Injectors and Hi-Impedance injectors do not need dropping resistors nor PWM current limiting. If changing injectors and going non-barb hose style I would recommend getting Hi- Impedance with 14 mm Top and bottom O-Rings. This will give you a wide range of choice and you can use Bosch injectors that come with the Nissan style EV1 connector. Get a single spray pattern such as used on Ford Mustangs etc. Dirt cheap from Motorman. 4: Downloading a Tune off the Internet is not a good idea. Even MSExtra Forums warns against this. Every engine is different and even a slight difference in engine specs can cause issues and even engine Damage. Especially on Turbo motors. If you need tuning help, I custom make MS Baseline Tunes from scratch and also supply remote tuning help. I do charge a reasonable fee for Remote Tuning and have helps several members here and at other forums. You can PM me for more info. 5: SoftoZpz ( Hussein ) on the Vendors forum makes custom harnesses and can pre-build MS ECU units for you. He also is a distributor for 14point7 WB controllers ( Very good product. ) and IDash. Richard

-

Thank's Stephen. Give me a shout after Christmas if you want to try some things on the IAC.

-

Can't seem to send you a PM. Can you send me a PM for contact info?

-

Good thing you checked. Tune is VERY rough. Your Spark Timing Table is dangerously high under boost, just for one example. I do remote tuning sessions. I've helped several members here get a " safe " baseline tune going. I do charge for remote tuning, but I think you will find that my rates are very reasonable and you will learn at TON of information. I'll send you a PM. In the meantime, don't run that Tune under boost for any reason. Firmware for ECU needs to be updated to latest version. You are currently running very old Firmware. With ECU connected to your laptop and Laptop connected to Internet, simply Auto Update the ECU Firmware . Go to the Menu Bar and choose Tools> Update/Install firmware. The Wizard will do the rest. Note: Firmware for ECU is different from Tuner Studio software. Alos need to know if injectors are Hi Impedance or Low Impedance. If Low impedance, are you using the factory dropping resistors.

-

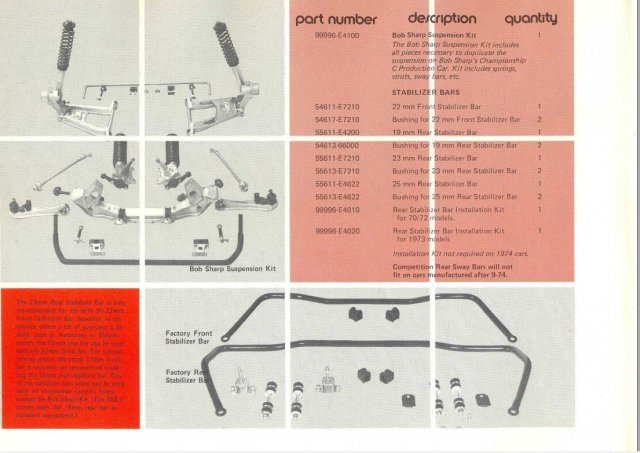

22mm front sway bar

Chickenman replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

-

22mm front sway bar

Chickenman replied to 74_5.0L_Z's topic in Brakes, Wheels, Suspension and Chassis

Readily available... I don't know. But back in the mid 70's Nissan Comp did make an Autocross combo with a 22mm front bar and a 23mm rear bar. Worked very nice on Goodyear slicks with the Nissan Comp Race struts and springs. -

Adaptronic Grounding Tips link; Note section ( about halfway down ) that explains why engines with a Nissan Optical CAS require that the ECU be grounded to the engine. Not to the Chassis or Negative battery terminal. Nissan CAS has two ground. Black wire is Trigger ground that must be grounded through ECU sensor ground. But the Nissan Optical CAS also has a secondary main 12 Volt ground, that grounds through the dizzy metal body and then to the engine. This requires that the ECU be grounded to the Intake or cylinder head. Failure to do so ( chassis ground ) can create a large " Ground Loop " that introduces electrical noise to the Trigger system. http://www.adaptronic.com.au/ecu-grounding-tips/ AS noted in Adaptronic article, ECU's should NEVER be grounded directly to the negative Battery Terminal. Starter can pull over 150 amps when cranking, and this can induce a feedback voltage in the ECU ground circuit ( if connected to Neg Batt terminal ). That is enough to damage sensitive Micro processors and semiconductors in the ECU

-

Revised post Here is the standard Nissan Wiring. Note that the DIY Trigger wheel flips the usage of the Inner and Outer rings. This picture shows factory wiring setup. This picture is for a Haltech ECU, which does NOT flip the usage of the Inner and Outer rings. As does the DIY wheel. Outer Ring = Green Wire ( Cam signal for DIY Wheel ) Inner Ring = White Wire ( Crank Signal for DIY Wheel ) +12v = Red Wire Trigger ground = Black wire ( Must connect to MS ECU sensor ground )

-

Note that there are revised instructions for the DIT Trigger wheel installation, setup and wiring. Effective Jan,31,2017 https://www.diyautotune.com/support/tech/hardware/nissan-trigger-disc/

-

Davek. Please note that I just edited my above Post and deleted the message. My image of the wiring is for a Haltech ECU. That uses the standard Nissan wiring. The DIY Trigger wheel has the Triggers flipped, as the Outer ring is now Cam signal ( 1 window ) and the inner Ring is now the Crank signal ( 24 - 2 ) . But only for the DIY Custom trigger wheel. ( DIY use some funky programming for their wheel to get around Processor limitations on the MS1 and MS2 ) . Grounding info still stands if you read it. The image I posted matches with my AEM wheel, which has the Crank on the outer ring ( 24 holes ) and the Cam Trigger ( 1 hole ) on the inner . Same orientation as OEM Nissan trigger wheel,but opposite from DIY Caution L28T trigger wheel. I have my Dizzy setup for a Haltech as well. Which uses standard Nissan wheel orientation. Sorry for the confusion....

-

Delete Post. Wrong Image posted.

-

I have a Re-man 280ZX Turbo dizzy from A1-Cardone. Purchased from Rock Auto. I can confirm that it uses the Maxima Z31 CAS Module. It's a bit different than the original 280ZXT CAS in appearance. All the components are encapsulated in a smaller base. So no resistors and such visible like in your picture. A couple of notes on the A1-Cardone product. As received, the trigger wheel disc was rubbing on the Optical LED. This was caused by the mounting of the Maxima Z31 module. 1: The Maxima module has two locating " Tits" on the bottom of the plastic base. These have to be cut off with an Exacto knife or filed down. Other wise the base will not sit flat and that is what caused the interference between the Trigger Wheel and the Optical LED. 5 minute fix. 2: The original 280ZX Turbo CAS used 3 screws that installed form the top and screwed into threads in the distributor body. There were no threads in the original 280ZXT CAS housing. Only non-threaded holes. However, the Maxima distributor has holes in the distributor body ( but no threads ), the mounting screws go from the bottom up and screw into the CAS module, which does have threaded Brass mounting inserts. So the mounting methods are opposite. A1-Cardone uses a mix of 280ZXT dizzy body and Maxima CAS. A1 Cardone installed the screws from the top. This meant that the screws went through both the threaded bars inserts in the CAS body and then into the threaded holes in the 280ZXT Distributor body. This can cause alignment problems. What I did was to take a 1/8" ( might have been 5/32" . I can't remember ) and drilled out the threads form the bottom of the distributor body. Just large enough so that the screws would slip through. Now the screws installed from the bottom of the dizzy housing ( no threads now ) and then screwed into the threaded bosses on the Maxima CAS body. Result. Flat and proper mounting of CAS Module 10 minute fix. Bottom line. If you order a new CAS ( be it 280ZXT or Maxima Z31 ) check how the mounting of the CAS is made. It may be slightly different than how the original 280ZXT CAS was mounted. I think there is a fair amount of parts swapping going on in the aftermarket. So it may be hit and miss on what you receive. GL.

-

Your Trigger wheel settings are configured using an using an MS3X Expansion board. Double check the wiring for the expansion board. Also noted you are using really old Firmware on your MS3 ECU 1.34 with a signature version of version 0435.16. MS3 is now on Firmware 1.51 with a signature version 565.00. You should update your Firmware on the ECU.

-

Which vac hose to tap for boost gauge? (with pics)

Chickenman replied to AlbatrossCafe's topic in Turbo / Supercharger

That's an interesting gauge mount. Where did you get it? -

Del-A-Lum LCA bushings

Chickenman replied to Chickenman's topic in Brakes, Wheels, Suspension and Chassis

Just a bad design and were a bad idea for a single LCA design with Mac Strut. . The Herb Adams Del-Alum bushings for Upper and Lower controls rams Use a hardened aluminium outer casing, very thick with a thin Delrin Liner and a hardened inner steel sleeve. They are greasable. All the movement is between the Liner and the greased inner steel sleeve. The Delrin liner does not move in relation to the outer shell. The Zerk fitting pins the two together. Well engineered and they last darned near forever. -

Glass pack is the problem. They will burn out with Turbo heat and aren't very good mufflers to begin with. You needs a tuned chamber muffler with a tuned chamber resonator. A chambered Magnaflow as a muffler is very good. You may want to add a second Magnaflow in the middle as a resonator. A couple of Magna Flow Ultra Flows are not going to cause a restriction. 3 " exhausts tend to drone worse than a 2.5" ( and 2.25 " ) Most guys make the mistake of not making the resonator big enough. Don't use a round resonator. Use an oval one. More area to absorb sound . Stealth is good... and lets you here things like DETONATION!! Very important on Turbo cars with no knock sensors. Make sure GF knows that you are making the extra effort for her. She will appreciate it. You may not be there yet, but..... a happy Wife makes a Happy Life. Applies to GF's as well. To a certain point... buy now we're discussing things that no man has ever truly figured out. Men's Brains vs Women's Brains

-

Pallnet Fuel Rail N47 Intake Megasquirt Fuel Injector help

Chickenman replied to RefreshRate's topic in Fuel Delivery

You can readily find plug and play adapters on E-Bay. Just be advised that Denso plugs have a couple of different configurations. Difference is location of side tabs. High or Low. You can get universal Denso adapters that will fir both styles. Ask me how I know.... DOH!!! -

Pallnet Fuel Rail N47 Intake Megasquirt Fuel Injector help

Chickenman replied to RefreshRate's topic in Fuel Delivery

Can you go 440cc or 550cc? Those are more common sizes. You can also bump the FP on 440's a bit to get the equivalent of 480's. 52 psi at idle instead of 43.5 would do it. Actually, 500cc or 550cc with pressure lowered a bit may be better. BTW... you can run bigger injectors than necessary. Just less maximum duty cycle. Guys are running 2,000cc Hi-Z injectors on Petrol just fine. Modern technology. Have you contacted MotorMan yet? They should be able to make a recommendation. They do know L28 engines and what injectors fit. Just tell them you have a 280ZXT Turbo motor and want to upgrade to Hi-Z, 480cc EV1 style injector with 14mm top o/ring and 14mm bottom O/ring. Ask for single spray pattern http://www.fuelinjector.citymaker.com/web_page.html A Pallnet rail 14mm for top and bottom actually gives a bit more selection, especially in Bosch I made the same mistake and am now kicking myself. 1989-1991 Mazda RX7 injectors may be close. They are 460cc. You have to be careful when ordering though as you can get them in both High or Low impedance. The Hi-Z ones are part number 195500-2010. Double check that of course, and you are likely going to have to use a connector adapter plug. I don't know the O-ring size, but I'm sure Motorman has that info. 195500-1350 also comes in a 460CC and it looks like it has an EV1 connector. But you have to be careful with these. They come in Hi and Low impedance versions and Mazda used the same part number for both styles. This thread at MiataTurbo.net may clarify some of the RX7 injector issues. https://www.miataturbo.net/diy-turbo-discussion-14/rx-7-injectors-again-5627/ -

Oil starvation ever an issue on L28 during racing?

Chickenman replied to turbogrill's topic in Nissan L6 Forum

Logging OP is a very good idea. We used to rely on a Hobb's switch set to 15 or 20 psi and big red light. That's not a bad Idea as well. Soft race slicks definitely create more grip than " DOT " R compound tires. Gotta love the grip of soft compound Goodyear cantilers . On a light car, you could often lift both inside wheels on a hard transition. I don't remember any of the other D-Production cars having amy oiling issues with the stock oil pan. But again it was a long time ago and it depends on the track. -

Silly Question about Incorporate AFR Table and the VE table

Chickenman replied to LiquidCMR's topic in MegaSquirt

You have to be careful comparing AFR Tables ( and Spark Timing Tables ) between two engines. Unless they are identical. You need more info on the engine. Things like Cam duration, CR , is an Intercooler used, Fuel Octane, Meth Injection etc. Then you can make an educated estimate . In general, your table looks OK. I would be be a bit concerned about your AFR above 160 KPA. For a baseline Tune I like to see them a bit richer. IE in the 11.5 to 11.0 range as boost climbs. Being too rich won't burn holes in pistons. Being too lean will. Auto-Tune is quite slow. It cannot correct a Lean condition under Full Boost fast enough to prevent detonation from happening. So you always want to set your baseline Tune a bit Rich under high Loads. Then let Auto-Tune lean it down slowly. This is how you Tune on a Dyno. Start off with conservative Fuel and Timing curves. Them ramp them up as you get the Tune dialed in to build HP. But always start off a bit rich under High Loads and RPM's and always keep the Spark Timing conservative. I really don't like to post up pictures of AFR and Spark Tables, because one size does NOT fit all. But if you PM me and give me all your engine details I'm sure I have something that will gain you a bit of fuel economy and be a bit safer at higher boost. -

Silly Question about Incorporate AFR Table and the VE table

Chickenman replied to LiquidCMR's topic in MegaSquirt

The Requested ( Target ) AFR Table VE table and Auto-Tune all work together to generate the Injector Pulse width required. You should always have the Incorporate AFR Table enabled. Disabling it will require a whole new Tune as Tuner Studio uses a completely different algorithm to calculate the Fuel curve. You can not switch back and forth between the two. The AFR table is a Target AFR . Think of it as " Requested AFR " . The figures are entered by the person Tuning the engine and some knowledge of ICE fuel requirements is needed. The VE Table calculates how much air volume the engine should be requiring. The Tuning program then uses various algorithms that combine the VE Table and the Requested AFR ( and other parameters ) to generate an injector Pulse Width appropriate for the exact conditions at a particular Load and RPM. Definitely making manual or Automatic changes to the VE Table will work with Incorporate AFR enabled. It is the basis for all of the Tuning steps. The VE table is a ROUGH calculation of how much air the engine consumes. It can be quite accurate... or out miles. Depends on Data entered. But the Target AFR table is the main controller. Even if the VE Table is totally out to lunch, using Auto Tune will eventually correct the injector PW to try and match the Requested AFR at a particular RPM and Load. The more accurate the original VE Table that is generated, the less work Auto -Tune has to do. Manual tuning comes into play to " Help " Auto-Tune speed up the process. Or when an experienced Tuner uses a Load Cell dyno to Tune the car. The more you use Auto-Tune, the better it will get things adjusted. But initially your fuel curves may be pretty far out of whack. You can see this in the 3D view of the VE table after running Auto-Tune. You will start to see sharp Peaks and Valleys in the 3D Table. This is due to Auto-Tune correcting some values, but missing others ( for numerous reasons ). That is where manual " smoothing " or " Interpolation " is used. -

Silly Question about Incorporate AFR Table and the VE table

Chickenman replied to LiquidCMR's topic in MegaSquirt

BTW, the reason why you select a " Block " of cells around your idle RPM, is that Tuner Studio ( regardless of weather Auto Tune or O2 correction is enabled ) is always weighing the Cell values AROUND the selected cell to calculate the current injector PW timing. This is called weighting and must be taken into consideration.