-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

The HKS 2mm head gasket is alo going to lower compression. Stock Nissan gasket is 1.25 mm ( installed thickness ) if memory serves me correct ( OZ dat shows 1.25mm for calculation ) With the HKS 2.0mm head gasket ( installed height I'm assuming ) Oz dat calculates 7.9 CR with Flat Top Pistons and Zero deck height. I calculate with pistons .020" ( .450mm ) above deck height ( figure shown in calculation is -.020" or -0.450mm to show piston above deck height ) , as that I believe that OZ Dat has the piston pin height wrong for the NA Flat Tops. Using the latter figure, that gives a CR of 8.3 to 1 with FT and P90 head. Not a lot of CR.... but good for Turbo charging Stock Turbo CR with dished pistons sitting .020" below deck is a rather anemic 7.35 to 1.

- 31 replies

-

- fml

- more z car torture

-

(and 1 more)

Tagged with:

-

^ That makes a huge difference. Engine must be to full operating temp and Throttle Blade held wide open when cranking. I'll add to it. Battery should be fully charged ( and on a Charger ) , all plugs removed, Injection disabled and starter must be in good condition. Cranking RPM makes a huge difference. The old direct drive starters did not spin the engines over very fast, even when new. The gear reduction starters are much stronger. Camshaft duration also makes a big difference. More duration effectively lowers cranking CR. The fact that all the cylinders are the same is a good sign. Specs are within 15 psi of each other. If it's not burning oil... I wouldn't worry about it too much.

- 31 replies

-

- fml

- more z car torture

-

(and 1 more)

Tagged with:

-

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

Actually I was thinking of the Walpro 255 figures. A 044 will push a bit more . This is taken from real life testing on Big Turbo Audi's and VW's. You never want to push a fuel pump to 100% , particularly in Road Racing. The testing done above does not take into account performance loss by pump electrical heating, fuel heating, and line loss ( through bends and fittings ) . That all adds up and takes a toll on efficiency in the real world. Pumps also get weaker with age. Particularly when you drive them near 100%. And while mathematical calculations look great on paper, real world seldom ( at the Amature and DIY level ) approaches the efficiency levels tested in theory. It's always smart to leave an overhead for variables. One variable is the AFR. A lot of Big Boost Turbo guys would get very nervous at a 12.0 to 1 AFR ratio. Depending on the engine you often see 11.5 or 11.0 for AFR. Again especially in Road Racing ( Which is my background ). You get much more heat build up in a Road Race engine or Hillclimb engine than a Drag car. AN-6 is getting a bit small in the 450HP to 500 range IMHO. It should be noted that the Audi's I mentioned are all 4 bangers and in the 2.0 liter range. Those would be working a lot harder to make 450 HP to 500 HP than an L28. No replacement for displacement. I tend to be conservative when estimating values or fuel systems. That's just me... YMMV -

A 2nd Gen RX7 gauge Pod fits pretty darned close. Similar to the Miata Pod. A friend of mine installed the RX7 pod and it fits slick with just a bit of edge trimming and shaping with a Heat gun. Autometer Part # 20670. Fits 1986 - 1989 RX7.

-

L28 Build Thread 75 280z (N/A to Turbo Conversion)*UPDATED

Chickenman replied to RefreshRate's topic in Nissan L6 Forum

Double Post -

L28 Build Thread 75 280z (N/A to Turbo Conversion)*UPDATED

Chickenman replied to RefreshRate's topic in Nissan L6 Forum

Had a look at the Fast system. As soon as I saw it had a " Pocket Programmer " I lost all interest. I've worked with Pocket Programmers before and they are a royal PITA compared to a proper Laptop. Some are better than others ( SDS is pathetic... stuck in the 1980's ) but all have less functionality than a Laptop software. Edit: If you don't mind using a Pocket Programmer, then the Fast system is a very good Option.... for a NA engine. Edit 2: Apparently it is not suitable for Turbo's. That limits it's appeal a lot. -

L28 Build Thread 75 280z (N/A to Turbo Conversion)*UPDATED

Chickenman replied to RefreshRate's topic in Nissan L6 Forum

Problem with the 4 Barrel setups is that you are running a " Wet " manifold and the fuel distribution not as good as Port Injection. End cylinder tend to run lean and middle cylinders a bit rich. This is the same problem that Chevies and Dodge inline six engines had back in the 60's with Holley 4 barrel carbs on an inline 6. These modern 4 Barrel EFI systems are nothing but an electronic carburetor. TBI is not as efficient as Ports injection. MS can be a HUGE learning curve and most people new to EFI are over whelmed by it. If you do go MS, I would highly suggest a 3.57 pre-assembled board and I would recommend the MS3. The MS1 is a dinosaur and the MS2 is nearing end of development. Edit: Apparently the Fast System is not for Turbo engines according to their information sheet posted. Although that seems a bit weird. Last sentence is confusing. In one sentence they say it will support up to 650 HP... and then they end it with ( Not for Turbo cars ) A bit confusing. -

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

If this is the engine that I think it is, Don is running a GT3076 Turbo with 550cc injectors So the single Bosch 044 is definitely NOT overkill for his project. And they are only good for about 450 HP on a single pump on Petrol. If he goes E85 later he will have to go to an even bigger pump or dual pumps. Don give me an E-mail. I've recently updated some of the AE tables. Would like some feed back on how the Tune is working if possible. -

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

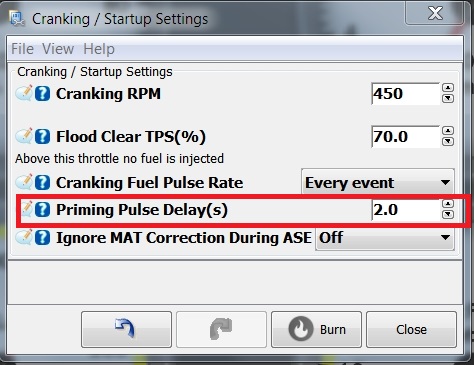

Don, it is very common for aftermarket Fuel Pumps and particularly Aftermarket FPR's to lose rail pressure after sitting for some time period, as others have mentioned. Perfectly normal. The stock FPR controls most of the pressure loss. Aftermarket FPR's due to the nature of their design are less concerned with Rail leak down than OEM designs. There is a setting in MS to Prime the fuel lines before cranking the engine. By default this is off. Set it to 1.5 or 2.0 seconds. Then you can turn the key to " On " the fuel pump will run for the set time to pressurise the fuel rail. Then you can crank the engine. the Fuel pump will " Turn Off " after the time period is exceeded if the Ignition switch is left in the " On " or Run position ( Safety feature ). Picture attached with setting to change circled in Red: -

Megasquirt Relay Board with Bosch 044 fuse blowing

Chickenman replied to dpuma8's topic in MegaSquirt

Don. I've seen several comments from experienced builders that don't like the Relay boards. For High amperage draws they simply can't flow enough current. Connectors and PCB traces are simply too small for big amperage electric pumps and even some cooling fans. Moat builders with high amp draw pumps and things like Nitrous solenoids build their own Relay boards with appropriately sized Relays and wiring. . 12 Gauge is the recommended minimum size for any High Performance Fuel pump. Do not run the Main pump and scavenge pump off the same circuit. Each electric fuel pump should have it's own relay ( 30 or 40 AMP continuous duty for the Bosch 044. 30 Amp for the Carter scavenge pump ) and separate +12v feed. So it looks like you are headed down the correct path with the modifications you are planning. Dual HD relays and separate 10 or 12 gauge wiring feeds to each pump is a good idea. I'd even go 10 gauge to the 044 pump. It's a long run. -

Could be that the Shneider grinds are symmetrical. Often cam grinders use a " Profile " from a different engine and juts grind it down till the lift number matches what they want. Saves them monet on developing Master Cam Lobes. It's not the correct way though for Datsun cams. Talked to Barry at Shadbolt many, many years ago ( Late 70's ) and he explained why the L-series needed an asymmetrical profile. I think he said even the stock camshafts were asymmetrical.... but don't hold me to that. It was a long time ago. All the L-series Race cams that I have seen from the original Nissan Comp catalogs and Electromotive were asymmetrical. As were the Racer Brown and Malvern Racing cams ( I believe )

-

Go by the Cam sheet. In this case the LSA is 107.6 which makes sense. The Intake and Exhausts LCA's are set 4 degrees advanced. Definitely not a Turbo Cam. Too much overlap. and too Narrow of an LSA as Colten mentioned.

-

Shadbolt grinds, and therefore Colt grinds were asymmetrical. . In fact most of the " good " performance L-series grinds are . It has to do with the weird changing rocker arm ratio as the Cam slides across the rocker pad.

-

This is what you need. Just picked up one of these for my Oil pressure gauge. Proper BPT Male and female threads for block and Nissan sensing unit and then your choice of 1 or 2 female NPT ports on side. Nice part. http://prlmotorsports.com/oilfeedblockbspnpt-bsp-npt.aspx#.WfdVbVtSypo

-

Wilwood Prop Valve Adapters

Chickenman replied to KevvinG's topic in Brakes, Wheels, Suspension and Chassis

1/8 " 27 NPT Male to M10 x 1.0 Inverted Flare Female adapter: http://www.lowrangeoffroad.com/1-8-npt-male-to-m10-1-0-female-inverted-flare-adapter-fitting-diy-a-1-8npt-m10.html Edit: Fying Miata has them as well. But they are $15.99 each. Brass though. https://www.flyinmiata.com/npt-to-metric-flare-adapter.html -

Wilwood Prop Valve Adapters

Chickenman replied to KevvinG's topic in Brakes, Wheels, Suspension and Chassis

WilWood specs say the 260-8419 has 1/8" NPT ports. http://www.wilwood.com/PDF/DataSheets/ds488.pdf -

Wilwood Prop Valve Adapters

Chickenman replied to KevvinG's topic in Brakes, Wheels, Suspension and Chassis

Double post -

Wilwood Prop Valve Adapters

Chickenman replied to KevvinG's topic in Brakes, Wheels, Suspension and Chassis

Good catch. I think you are right on that. I may be getting the Z car and my Audi mixed up. Kevvin, make sure you double check flare!! -

Wilwood Prop Valve Adapters

Chickenman replied to KevvinG's topic in Brakes, Wheels, Suspension and Chassis

If you have the 1/8 27 NPT threads in the Prop valve, then this company has what you want. 1/8 NPT ( Male ) to M10 x 1.0 Female Metric Bubble flare. Part number CNC896 = $9.00 each. http://www.pacificcustoms.com/mm5/merchant.mvc?Screen=PROD&Store_Code=PC&Product_Code=cnc896&Category_Code=brass-adapter-fittings Edit: If you have the 3/8 24 NF straight threads in the Prop Valve then you want adapter CNC897 = $12.00 each http://www.pacificcustoms.com/mm5/merchant.mvc?Screen=PROD&Store_Code=PC&Product_Code=cnc897&Category_Code=brass-adapter-fittings -

Wilwood Prop Valve Adapters

Chickenman replied to KevvinG's topic in Brakes, Wheels, Suspension and Chassis

What Part # of P/V. WilWood has them available in 1/8 27 NPT ports and 3/8 24 National Fine straight thread. Once you find that out, search Earl's, Russel, McMaster Car. There are adapters to go straight from the SAE thread to the 10mm x 1.0 Bubble flare. Juts have to Google a bit more. The other Option is to buy Universal brake adapter lines. These have Metric Bubble flare on one end and SAE on the other. Since the WilWood kit includes SAE inverted adapters with the Prop Valve this may be the way to go. Then you can bend your lines to fit. Any decent Automotive Parts store can get these. If they can't find them, get a Parts guy with an IQ bigger than a Peanut. Hint... search out the grumpy old fart types ... like me . They usually know their isht. -

Wheee...my Lord that is a beautiful looking Chassis. Well done sir

-

You could get some 4 wire shielded wire for the IAC Valve ten. Audio quality Microphone cable with twisted wires and shielding would work. Ot put the external sleeve shielding around the IAC wires. You can always. double up on shielding. And it looks cooler than Tin Foil. Military, Aerospace, Audio Recording and Scientific Lab equipment is often double shielded.

-

If you can find a Dyno Plot on a Colt Cams C542S, that is the exact same grind as the M445. Very good grind, easy on the valve train.. When Shadbolt was sold years ago to an off shore company that was only interested in doing Industrial grinds, Geoff Bardahl ( who worked at ShadBolt ) stated his own company Colt Cams and and continued with the performance grinds. Datsun L-series C542 = 224 degrees at .050", 280 advertised duration, .510" valve lift and 108 LSA. http://www.coltcams.com/html/camshaft/index.cfm

-

I don't think you'll have much issue with EMI from the IAC. ( Sounds like a Michael Jackson song... LOL ). just don't run them the IAC and Trigger wires zipped tied t together or running Parallel for any appreciable length. 2" to 3" separation should be enough. WireCare.com makes products for just about everything.. Put their Flex Shield braided sleeving around you trigger wires and that should be more than sufficient for EMI shielding. https://www.wirecare.com/category/braided-sleeving/metal-shielding

-

1980 280zx vs 1983 280zx rear brakes

Chickenman replied to turbogrill's topic in Brakes, Wheels, Suspension and Chassis

Actually I wasn't sure if I was losing my mind... When you get older you lose all sorts of things...keys, pants, mind...