-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

You can PM me with your E-Mail and I have a decent baseline tune for a VG30 Turbo and L28 Turbo stock engines I can send you. Safe tune, conservative values. You will have to tailor to your particular setup. That is why I will not Post them up to the general public. seems to work well on Bagged Goods engine from his reports back to me. I can also generate a base Tune for NA engines. Include all specifications for engine and any modifications such as different sized injectors and any other mods. Tell me what you are running for an ignition system a well. Use only as a baseline and at your own risk. Everything is based on default MS 3.42 Firmware. You should be running the same firmware to prevent errors. Also update your TS to latest version. May as well buy the Paid version. You will need the Auto Tune function and VE Analyzer which are only included in the Paid version.

-

A few things I have learned. 1: Req_Fuel is just a multiplier for the cells in the VE table. The default values are artificially high. It also supposedly incorporate WUE and Start enrichment. Req_Fuel can be a wildly inaccuarte calculation. Bets to use and online PW calculator to calculate more accurate features. Bear in mind that this figure is simply a multiplier. Don't get married to the number it indicates. Most experienced Tuners recommend adjusting Req_fuel to a level that will scale the idle cells to a number in the 30's and 40's. 2: VE table. It is not an actual Volumetric Efficiency table as used by Motec and others , which calculate actual pumping volume of engine. Motec and other high end VE generators can be very accurate. Tuner Studio is not It's a very rough calculation at best. 3: Req-Fuel works with the VE table to adjust Cell resolution. If you find that the generated VE table values around idle are too low, decrease the Req_Fuel by a set percentage and re-scale the VE table upwards by the same amount. Very low numbers near idle are not good. IE: If you have a "10 " in the cell at at 800, rpm and 35Kpa and you reduce it by 1 unit, that is a very course adjustment. 10% change. If you have a 20 in the same Cell ( by rescaling the VE Table ) a single digit change will only be 5%. Ideally you want idle cell ranges to be in the 30 to 40's. 4: VE Table cell numbers are NOT percentages. They are just base numbers or units. A 100 does not = 100%. It is just a number influenced by many factors. One of them being the required Fuel factor. ( Which really should be called something else ) . With a Normally aspirated engine it is common, and often desirable to have the Maximum VE cells numbers ( supposedly calculated at 100% Engine VE ) well above 100. Turbo engines will often be above 200 units. That is just fine. It is the idle cell numbers that you want big enough. Those are controlled by the Req_Fuel Multiplier and by re-scaling the VE table. Maximum limit on Cell numbers should stay beloe 250 though... as calculations go really whacky at figures higher than that. 5: The generated VE table numbers in the Paid version can be wildly inaccurate. MS says that over and over again in their documentation. You can not guess at the input numbers. This is particularly true with forced induction engines. So that means if you have a heavily boosted Turbo engine you have to have accurate Dyno data, before you can start Tuning. Does any one see the problem in that? Best way I've found is to look at the factory data for HP and Torque. Enter those figures for a stock engine. Generate your table and export it to Desktop. Then go to required Fuel and enter the overall Master PW that you have calculated with a proper online PW calculator. Save the tune. Then Import your original table back to your saved Tune. It " should" automatically recalculate the Cells to reflect the re-calculated Req-Fuel. If it doesn't then you will have to re-scale all of the Cells manually. I'll include a link on how to do this later. Whew.... you getting all this?? Oh yeah. I take screenshots of every single VE, AFR, and Timing Table. Print them out so you can compare the before and afters. The VE generated tables and Req_Fuel should only be regarded as a SUGGESTION. A general starting point. That sucks, but TS is built as a learning tool only. It will always need adjustment. Sometimes a little, sometimes a lot. All part of the adventure... Attached is the PW generator developed an experienced HalTech Tuner. This seems pretty accurate and has been well proven in the field . It is what I like to use. There are others online, but their results jive with this and this one is easy to use. Note. This PW calculator is designed for Sequential injection. For inlet temperature enter a default value of 20 Celcius as a baseline. For Batch fire or Semi-Sequential, enter 35C as a correction value. Good Luck PW Calculator version 2.0.zip

-

I should say that Tuner Studio is good for what it is. A learning tool for tuning home built ECU's. Biggest disappointment is the VE generator. At $60 for the paid version, I would expect it to be a bit more accurate. The free version is worth the money though.....

-

^ I agree 100% The best thing about MS is that you can build it yourself. The worst thing about MS is that you can build it yourself People vastly over estimate their ability to assemble electronic components. A complex project like an ECU is not the place to be learning precision electronics soldering skills and small component assembly. Cold engine issue seems to have developed recently, because when I first started helping Morgen, it would get up to around 160 to 170. But engine was so bloody rich that didn't really matter. AFR's were constantly in the 7.8 to 7.9 range. Even with WUE turned off. At least now the plugs aren't coming out like wet lumps of coal. It has been a struggle.....

-

Been working with Morgen on this via remote tuning. Been making some progress. Have sorted out a lot of hardware and software issues. Aeromotive FPR fixed the excessive fuel pressure issue. Stock FPR and $15 E-Bay POS FPR could not handle pressure and volume from a Walpro 255 F/pump. Fuel pressure with Aeromotive #13129 unitis now at 37 psi with FPR hose disconnected and 26-27 psi with hose connected. Bang on factory specs. 1 issue solved.... 27 to go... Timing is now sorted. Good spark apparently. Idling decent, but with a lot of work Base Req-fuel has to be set extremely low. Blowing fuses was due to the dropping resistors had been removed and Low -Z injectors were pulling big amperage at a full 12 volts. PWM current limiting was not originally enabled. PWM current settings have now been enabled, tested and those are now set correctly. No longer any fuse blowing problems. MS Req-Fuel calculation is purposely set way rich by Tuner Studio. Unfortunately they don't make that information easy to find. VE table generator is next to useless. Req-Fuel can be out as much as 50%.. Recommended Req-Fuel was 12.0 ms at 100% VE, 14.7 stoich and zero boost. That's way to high . Excel PW calculators show it should be between 8.1 to 9.1.That is just simple Math. Apparently Tuner Studio does some sort of " Modern Math " where 2+ 2 = 9. Go figure. All mute, as Req-Fuel is just a multiplier for the VE table. You change the numbers to get a reasonable scale and injector PW. So basically it's like throwing Cow S**t at a barn door. Wing it and see what sticks. Very poorly written software... but that's what you get when Tuning software covers so many different ECU versions and firmware. There are still some issues. Engine won't warm up properly. Won't get past 145 F. Either thermostat is stuck open or GM temp sensor for ECU was installed in wrong port. It could be contacting the thermostat spring and jamming the stat open. I've had to lower the Auto Tune low coolant filter to 140F or Auto Tune won't even run. Not a big deal as I can manually tune VE table. But still an issue to be corrected. I've got it to idle fairly smoothly now. I can get it around 12.8 AFR at idle with a Vacuum reading of 19.5 in/hg. Batch fire usually likes around 13.5 at idle. So a tad rich, but I can't cut back down fueling any more. Req_Fuel is now down to 4.5 from a initial recommendation of 12.ms . And we still get an injector PW that is too low.... under 1.0ms Injector Pulse Width is at absolute minimum. Around .95 ms. Can't go any lower as injectors then go into non-linear mode and AFR goes unstable. PW should be at a minimum of 1.5 to 1.7 ms with the stock injectors ( yes they have been checked by Part numbers and are 260cc Turbo injectors ). So minimum injector PW and minimum fueling, and it;s still too bloody rich. ASE and WUE have been scaled down and are confirmed as switching off. BTW, brand spanking new O2 sensor, properly calibrated. And I can tell it's rich by Tuning for Rich Best idle and Lean best idle with the PW reading, Idle speed and Vacuum readings. Engine wants less fuel at idle... but ECU won't co-operate. With PW current limiting the Dead time has to be decrease compared to dropping resistors. .7ms with PWM current limit is just right any higher or lower and injectors become unstable. Have tested the other settings under PWM as well, and the base settings are optimized. Morgen is going to re-install the dropping resistors and install a new thermostat. I don't think that will solve the issue. I have used this same basic Tune with a 9.5 ms Req-Fuel and appropriate VE tables on BaggedGoods car. Same injectors, Same PWM current limiting but larger Dead Time of 1.2ms. It' seems to be running fine with only minor tweaking to idle cell values. Cruise values are 14.5 AFR and car is running good. Why is Derek's car running fine at 9.5 Req-Fuel... A reasonable number and yet Morgen's car is at 4.5 ms Req_fuel and still rich? Derek's car also is running at higher PW's . Waiting for the final number when he send his Data Logs to me. But I think it was around 1.3 to 1.5ms. Right in the ballpark. Edit: Morgen's car goes absolutely PIG Rich at 1.2ms Dead Time and with PWM enabled. ... somewhere in this area is where I believe the real problem lays. Garbage in = Garbage out. I've come to two possible conclusions with Morgen's car. 1: Stock injectors 260 cc Turbo injectors have been been modified and are flowing way higher than they should be. Like 400+ cc Unlikley but possible. Part numbers on injector are A46-00 which equals 260cc Turbo injectors. 2: There is a build mistake somewhere in the board. It's a Version 3.0 assemble it by yourself board. Could be as simple as a cold solder joint or a wrong value resistor. Who knows. Certainly not me from 3,000 miles away. . . This seems to be the logical conclusion. Ultimately, I believe that the board is going to have to go back to DIY and have them go over it mm by mm. There is some inherent error in what the ECU is measuring and outputting on the Fuel side.... 3: This ECU doesn't like us... Need to get VooDoo doctor... Really a tough Nut to crack..

-

Yeah... and that particular link is old info and misleading. Newer 3.0 boards come with PWM current limiting. With older 3.0 boards was an Option. And 2.2 boards had to have the Flyback module be added on. It's really like a DIY electronics science project. With remote tuning, I've found you are never really sure what's on the other end. The build it yourself boards vary greatly in build quality. It's all up to the skill set of the builder. All it takes is one cold solder joint, or one resistor in the wrong spot and you are banging your head against the wall. . Electronics soldering is totally different from Automotive soldering. A lot of people do not understand that. Electronics soldering has to be 100% perfect. Most people can't even assemble Ikea furniture properly.... Better to pay a little extra and get the 3.57 pre-assembled boards. At least they have some rudimentary testing and you have a fighting chance that it is assembled correctly. At one time I was thinking of buying an MS-2 or MS-3 ECU ( pre-assembled ) but now I wouldn't touch them with a 10 foot pole.... just my .02c

-

What about heat soak from the Intake manifold? Warned from several sources not to do that. ( HP Academy, Guild of EFI Tuners )

-

Question is... why would you want to use the factory cold start valve? All start and warm up enrichment's are handled by MegaSquirt through the regular port injectors. Course you could put a NOZ nozzle in there...

-

I have the 1987 Toyota Supra NA 295 to- 310cc ( specs seem to vary ) Low-Z injectors. Injectorman says the 23250-70040's ( 7M-GR Yellow ) are 310cc Just an FYI. Borrowed this from a Toyota Supra site:

-

Damn... you're right about the connectors. I've had the Pallnet rail and Supra injectors sitting here for months. Even mocked them up. Didn't think to test fit the connectors though. The Supra ones are not standard EV1. SOB!! Wish Injectorman had warned me about that. Off to find Toyota Supra connectors. Oh they are 11 mm O-rings. Those I did test fit. Another local Z member club member is using the Supra 310cc injectors but he didn't mention the changed connectors. Oh well...not a biggy for me. I can pick up the proper Nippon Denso injector terminals from Injector-Rehab. http://injector-rehab.com/shop/Nippon-Denso-Type-Connector.html

-

Compression of an L28 with Flat Tops and stock P79 head is approx 8.8 to 1 . 9.0 to 9.5 is more than enough on Pump gas 91 Octane for the street IMHO. I'd shave the P79 no more than 020" to .040" and save yourself some aggravation. No good having a high compression ratio if you have to take ignition timing out of curve to prevent detonation.

-

These are all basic questions that are in the MSExtra manuals. Check the Hardware, Software and Tuning manuals. http://www.msextra.com/manuals/ MSExtra has a ton of information on their site. Unfortunately it can be somewhat hard to find what you are after, due to the large amount of information. But it's all there. TPS terminals are usually left un-terminated as there are so many different types of TPS that can be used. Google the year and model of your TPS switch. IE: GM TPS connector. Or Ford TPS terminal. 240SX TPS connector. DIY Autotune carries some of the more popular types.

-

Broken Extended Wheel Studs

Chickenman replied to Bartman's topic in Brakes, Wheels, Suspension and Chassis

My Audi uses 14mm wheel bolts. Factory specs are 90 ft lbs. Bought some aftermarket extended bolts ( Ceco brand ) for wheels with a thicker flange. Only about 20mm longer than stock to fit wheel flange flange. After 4 years I noticed the aftermarket bolts were getting " Stretchy". Was only Torquing to factory spec of 90 ft/lbs. Obviously, the metallurgy in these left something to be desired. Bolts were on the edge of failure. Fortunately I caught it in time. Binned them all and replaced with a different brand. But I only Torque these to 80 ft lbs. 80 ft/lbs on a 14mm fastner will still tension the fastner enough to keep it tight. But shouldn't stretch them beyond there yield stentgh. -

Broken Extended Wheel Studs

Chickenman replied to Bartman's topic in Brakes, Wheels, Suspension and Chassis

Wheel size should have no affect on stud torquing values. A fastener is designed to be torqued to a specific tension so it doesn't come loose. It doesn't get " stronger " with more torque. Quite the opposite. Over Torque a fastener and it will fail. Some will stretch ( low to medium strength fasteners ) but high strength fasteners may simply shear. It all depends on the material used. Bottom line. Don't over toque, and if you put huge wide sticky tires on... install a larger diameter fastener that can handle more load. There's a reason why Autocross and Road racing guys upgrade to a minimum of a 1/2 inch high grade fastener. Nascar uses 5/8". That tells you something. ARP is high grade. Not sure about Ichiban?? Isn't that a noodle?? -

Broken Extended Wheel Studs

Chickenman replied to Bartman's topic in Brakes, Wheels, Suspension and Chassis

That metallurgy looks very sandy and grainy. That's a sign of poor heat treating or bad materials . Toss them all. Buy ARP studs. Broke some Moroso 1/2 studs years ago on my Autocross car. Was surprised at that, but again, poor heat treating. Grain structure was all sandy which is really bad. ARP or factory studs are all I trust now. Don't ever let anyone install wheels with an Air gun. Make them write it on the shop order!! Bust their chops if they even think of it. -

Well.. we've found that the Tuner Studio VE Generator is buggy as hell. Most tuners recommend not to use it. Might be that Tuner Studio's PWM current limiting is buggy as well. Couldn't hurt to put the resistors back in and disable the PWM current limiting. Do post your .msq file though.

-

You still have to have the correct Dead Time for either Low-z or High-z injectors. Having the correct Dead Time is the most important of all. Dropping resistors with Low-z injectors is actually a bit easier than getting rid of the dropping resistors. You don't have to mess with the PWM Current Limiting settings. High -Z injectors eliminate that step of course, but so does keeping the dropping resistors with Low- z injectors. My Haltech has automatic current limitation calculation built in. You ohm test the resistors and select the corresponding range. It does all the rest.

-

Fuel Injector man has reman Supra injectors for $150 a set ( 6 ). Not the cheapest, but you get what you pay for. These will fit the stock 280Z/ZX intake manifold and use 11mm top O-rings ( Pallnet Rail ). 310cc http://www.ebay.com/itm/Remanufactured-Denso-Fuel-Injector-set-6-1986-1988-Toyota-Supra-3-0L-Non-Turbo-/291075192985?hash=item43c56ef899:g:OC4AAOSwv0tU9jcD&vxp=mtr Or did I suggest these before?

-

It's a freakin' nightmare. Worst thing about MS is all the different software versions.

-

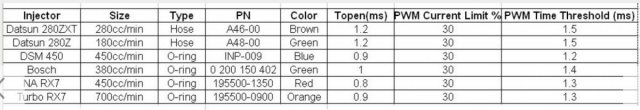

E-Mail me at the address I gave you in my PM and I have what should be a nice starting base for you. I've corrected all the WUE and ASE tables as well. I think the VE generators in Tuner Studio are not all that accurate, but this should be a pretty good start point. My AFR table should be spot on , so IF you O2 sensor is accurate and properly calibrated then you can use " Incorporate AFR Target ". However, if your O2 sensor has been Fuel soaked due to rich running or overheated ( Innovate specs WB O2 sensor 12" away from Turbo ) . Then it may be advisable to turn that Option off. Note the factory bung in a ZX Turbo downpipe is for a Narrow Band O2 sensor. They can withstand a lot more heat transfer to the O2 sensor body than WB sensors. It's far too close to the Turbo for a WB sensor, unless you use one of those fancy O2 sensor extensions with a built in Heat sink. I won't post up Tunes on Forums any more, because they really have to be made for each specific acr. BTW, finally found a definitive answer for the Dead Time for Z injectors. Also if you are not using dropping resister, the PWM Current limitation settings. Strangely enogh, it was all on Hybrid Z.... from 10 years ago. http://forums.hybridz.org/topic/55910-injector-opening-times-spread-sheet/ Screenshot below. Click to expand: Thanks to Morgen Kirby ( MerloZ ) for digging this Gem of an article up from the graveyard.

- 25 replies

-

- 300zx

- megasquirt

-

(and 2 more)

Tagged with:

-

Actually, with the ZX dizzy being an LED Optical sensor. There " shouldn't " be any need to go through a VR conditioner... with the proper software and hardware. The main advantage to using an Optical sensor is that it puts out a very clean Square Wave signal that requires much less signal conditioning than a Magnetic sensor ( VR or Hall ) Here's a good read on the basic differences and the Pro's and Cons of VR ( magnetic ), Halla and Optical sensors: http://www.breakerless.com/igntionfacts.htm#Magnetic Triggering

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

I wonder why they would do that? Run Digital signals through a VR circuit which is analog? Seems a step backwards?? Do you have a link to that documentation? Might be some of the old " archived " or outdated info. I find that frustrating on the MSExtra Manuals site, Been tripped up by outdated info at DIY and MSExtra forums a couple of times already....

- 73 replies

-

- megasquirt

- vg30et

-

(and 1 more)

Tagged with:

-

I don't think anyone gets annoyed at reasonably intelligent questions. Unless it's like on VW/Vortex where you get something like... What spark gap should I run? When there is an extensive FAQ and the question has been already answered a thousand times over. That clearly indicates a lack of effort in using the " Search " button. However, something like tuning a standalone ECU is an entirely different animal. It's a pretty difficult task. MSExtra forums and MSEXTRA Manuals have a wealth of information. They have a very knowledgeable staff of people including the developers of the software.However, particularly with the Manuals, There is such a wealth of information, that the particular issue you wish to address can sometime be hard to find. Some of the navigation links also lead to old information out-dated information. This can lead you on a bit of a wild Goose chase. But the people there will generally chime in with corrections. Because MS is a DIY build, that in itself can cause confusion because boards can have optional ways of building them. What does annoy people, is that if specific instructions or procedures are given, and then those instructions are not followed, that can be frustrating from a Tuners or helping persons perspective. Garbage In = Garbage Out.... and it literally just becomes a waste of time. Just my .02c.

- 25 replies

-

- 300zx

- megasquirt

-

(and 2 more)

Tagged with:

-

When you get home a picture is worth a thousand words.

- 25 replies

-

- 300zx

- megasquirt

-

(and 2 more)

Tagged with:

-

BTW, those recommendations in the drop down menu's are " Condensed " versions. They are only " Tips " and should not be taken as Gospel. If you read the actual MSEXTRA manuals, in the TS tuner settings manual they mention that Low-z injectors are commonly .7ms to 1.0ms ( if memory serves me correct.... I've had a lot of late nights and doing a lot of remote tuning lately ) . And some injectors are more laggy than others. Age plays a factor too. I've also found that a lot of those " drop down tips " are not always updated. I've found some that refer to settings on much older board versions. Always have a look at the MSExtra Manuals for the latest updates. The best thing about MS is that they have a lot of information. The worst thing about MS is that they have a lot of information. I've found that there Navigation of information can be quite scattered. It's all over the place with a lot of references to older versions of hardware and software that can be conflicting. You also have to be careful with links from Google. I've found that these often refer to archived information for older board builds and software. Most have a warning about being archived information... but it is not consistent.

- 25 replies

-

- 300zx

- megasquirt

-

(and 2 more)

Tagged with: