-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

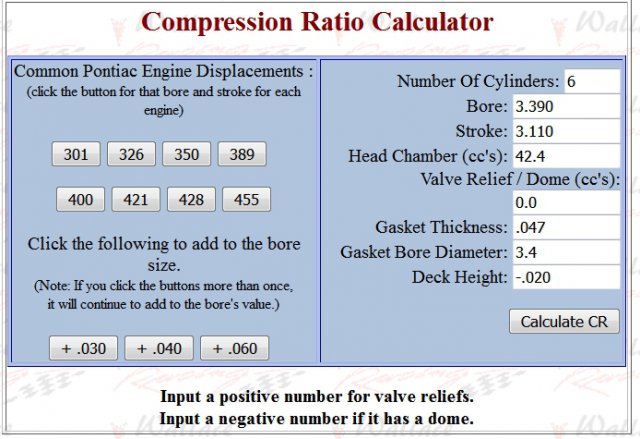

Just an FYI. OzDat calculator seems to have the wrong deck height in their database for the L28 FT pistons. According to real world measurements, which give stock L28 FT a negative deck height of approximately .020" ( plus or minus .005" for stack dimensions ). IE: FT pistons sit above deck approximately .020" That reduces the OZDAT compression ratio calculation substantially. Other data bases and other calculators show an L28 with FT and stock Nissan head gasket of having a CR of around 10.8 to 1. Thin Nismo .6mm head gasket would put you well over 11 to 1 CR I do believe. http://www.viczcar.com/forum/topic/4286-overview-of-l6-engine-heads/ Here is a site that I use for engine calculations. Has a massive amount of calculators: http://www.wallaceracing.com/Calculators.htm Here is the CR calculator: http://www.wallaceracing.com/cr_test2.php Edit: I used the Wallace calculator inputting a std bore L28 with Flat-top pistons ( -.020" deck height ) and E31head with stock head gasket thickness ( .047" or 1.2mm compressed ). CR came out as 10.9 to 1... which seems to jive with what other sites say. Here are my figures:

-

Silver Mine just sent me a notification about a new product. An electric PS kit for the S30. This is one of the most complete kits I have ever seen and the price point is pretty good as well. $900 and it's literally a bolt in kit. Everything is included and fabricated. No cutting or welding involved. http://www.silverminemotors.com/featured/electric-power-steering-kit-for-240z-260z-280z-datsun-1970-1978-s30

-

Not safely. You'll be really pushing stock injectors at max rate to get that. Always better to keep the Injector Duty cycle around 80% max if you can. 250 HP on stock injectors is going to be really pushing them. Always good to have a little extra over head. Modern injectors have much better spray patterns than old injectors. You can get injectors these days larger than 1,000 cc's that idle just fine at 750 rpm. ( Genesis and Genesis II injectors by USRT for one example ) And the stock injectors are calculated to run Batch or Multi Port fired which is un-timed. If you switch to a standalone system and want to use Sequential fire, then you have to up the injector size as it is a timed system and the injectors have much less time to inject the same amount of fuel. Edit: 280ZX Turbo injectors are 265cc. You'd be pushing stock 280ZX Turbo injectors to 100% IDC at 3 bar ( 43.5 psi ) to achieve 250 hp. You need at least 330cc at 80% IDC to achieve 250HP safely. Note BSFC entered as .60 which is reasonable for a Turbo car. 80% IDC. 43.5 psi ( 3 BAR ) fuel pressure = 328cc. If you calculate .65 as a BSFC ( rich safe mixture for a Turbo ) you will need 355 cc injectors to safely achieve 250HP. Here's a link to a good site that allows you to accurately calculate injector sizes required for HP levels in NA, Turbo and Supercharged cars. http://www.fuelinjector.citymaker.com/Fuel_Injector_Flow_Rates.html Even at 4.0 BAR fuel pressure ( 58.0 psi ) the stock injectors only flow 305cc. That's not enough. Not saying that some people haven't achieved 250 hp on stock 280ZX injectors. It's just that they are really, really on the ragged edge.... just my .02c.

-

shaved intake 280zx, now won't start

Chickenman replied to Mobious5's topic in Trouble Shooting / General Engine

Not Paul, but on EFI if you are using an AFM ( flappy doodle ) or MAF ( Mass Air Flow ), ALL of the air that is ingested by the engine has to be maesured by the AFM or MAF. The PCV system is a loop system. Fresh air is drawn through the Valve Cover ( and naturally needs to have some form of Air Filter ) into the crankcase ( big freaking hole though timing cover to oil pan ) and then extracted through a breather port in the block and then finally drawn into the inlet manifold through the PCV valve. The PCV Valve is nothing but a metering valve. Now the crankcase fumes ( mainly ring blow-by ) are somewhat combustible and the outside air flowing through the system has to be accounted for by the ECU on a AFM or MAF EFI system. Otherwise the will be thrown out of whack. Early L-Jetronic EFI systems have no feed back loop ( O2 sensor ) to self correct the mixture. So you must make sure that the PCV system is properly routed and the Intake air is drawn through the AFM. One exception is if you are using a Speed Density EFI system. Speed density does not use any type of Air Flow measurement device. Only a MAP or Manifold Absolute Pressure sensor . Then you can use a K&N style filter on the Valce Cover vent. There is no advantage to doing that, other than esthetics. The other exception is carburation. Carburated cars are already calibrated for the bypassed air used by the PCV. The vent line goes from the valve cover to the inside lid of the air cleaner to draw in fresh air. You can use a K&N style filter on the Valve Cover of carbed cars as well. It will make no difference to the closed loop function of the PCV system nor the fueling calibration. Hope this helps. And BTW... you ALWAYS want to run a PCV system on a Daily Driver. The Positive Crankcase Ventilation systems main job is to remove contaminants and acids in the engine oil caused by ring blow by. Secondary action is that it provides a negative crankcase pressure under most operating conditions that improves Piston ring seals and also reduces oil leaks from crank shaft seals and engine gaskets. The seal lips are designed to operate normally with a Negative crankcase pressure, not a positive crankcase pressure. Race cars can get away with Vent To Atmosphere oil breathers and catch tanks. They change oil often ( gets rid of contaminated oil ) and run Dry Sumps or Vacuum pumps that create negative crankcase pressure ( for improved piston ring seal ) But VTA is not a good idea on a street car, IMHO. -

Yes it is always a good idea to run an oil cooler on a Turbo engine. Turbo's heat the oil like crazy, even stock Turbo's at boosts under 10 lbs. You will never find a factory Turbo car without an oil cooler. Turbo's heat the bloody snot out of oil... even at low boost levels ( 5 psi ). Run an oil cooler....period. Tip for engine oil. Use the best Synthetic oil you can. The best synthetics are full Ester oils, like Amsoil, Redline Motul, Joe Gibbs ( Driven oils ). They cost more but they stand up to higher oil temperatures better. The point of highest oil temperature is at the Turbo oil journal. HTSP ( high temperature shear point ) is very important in a Turbo motor. A good 10w-40 weight synthetic in the above mentioned brands will suit your engine just fine. Regarding the Automatic crankshaft. I think the only other thing you have to remember is to install a pilot bushing for the transmission input shaft. Crank should already be drilled to proper size from factory.

-

L28ET not reliable as a endurance track car

Chickenman replied to turbogrill's topic in Nissan L6 Forum

As mentioned above, cooling is going to be your biggest concern, As well as running a GOOD oil cooler ( Setrab and Earls make some fine units ). Edit: Use a decent quality Intercooler, but be careful to not go too big as you don't want to radiator air flow. Low pressure drop as well. Some other points to consider: 1: Get a custom aluminium radiator with a thicker core. You can't have to much cooling on a track car. Add ducting in front of the radiator to force all inlet air through the core. Use Water Wetter by Redline ( it really works ) or DEI's product. You don't really need a fan, but you may want to run an electric puller fan for keeping engine cool in pits when tuning etc. 2: Exhaust heat control. Ceramic coat the exhasut manifold on the outside. Ceramic coat the outside of the exhasut Turbine housing and/or run a Turbo blanket around the Turbo exhasut housing. Ceramic coat the inside and outside of the down pipe. I do not like heat wrap as it causes fairly rapid deterioration of the exhasut piping due to heat retention. Ceramic coatings ( particularly on the inside of the down pipe ) are a much better solution. Some guys like to Ceramic coat the inside of the exhaust manifold and exhasut Turbine housing. This can be very tricky with the exhasut manifold, as it can be hard to properly clean and prepare all the crevices and corners in the manifold. Any bit of coating that comes loose can damage the Turbine exhasut impeller. I prefer to use ceramic coating on the inside of the exhaust system ONLY post-Turbo 3: Pay particular attention to insulating all of the brake lines and wiring on the Turbo side of the engine. Make sure that ALL brake and clutch piping is insulated with a goof quality heat reflective wrapping. 4: Make sure that the brake master cylinder has a good heat shield. The 280ZX has a factory shield and I would consider upgrading that. Some gold leaf reflective foil on the outside of the factory shield, or a custom made shield, would be a good start. Consider putting a Naca duct in the Access panel for the Master Cylinder. This will draw cooling air from the outside and allow it to flow over the Brake and Clutch master cylinder. You need some airflow in that area to cool things off. 5: Water/Methanol injection is always a good idea. Even with fairly low boost pressures. Detonation is your enemy in any Turbo engine, and the Piston ring lands are the weakest point. 6: Forged pistons designed for a Turbo engine are always a good call. They are much stronger than cast pistons overall, and particularly in the ring land area. Custom Turbo pistons will have the ring lands moved down from the combustion chambers to reduce some of the thermal shock loads and will have thicker ring lands to make them stronger. The piston crowns are also made thicker to better handle thermal loads and shock loads ( detonation ) If the budget and rules allow it, get some proper forged pistons from Ross, Wiseco, CP etc. If you decide to stay with the factory Turbo cast pistons...go conservative with Boost and Ignition advance. Detonation MUST be avoided with cast pistons. If re-using the old pistons. Get them professionally claened, measured and crack checked. Again, the ring land areas are the places that get pounded out of spec and subject to cracking. 7: Keep the revs down. Turbo cars don't need a lot of RPM's to make power. I'd consider a shift point of 6,000 to 6,500 RPM MAX... if using stock bottom end components. Use new ARP hardware for Rod Bolts ( preferred ) or new factory 9MM bolts. NEVER re-use the stock rod bolts in a Race engine. Hope some this helps and gets you some trophies. GL !! -

^ Great find. Thanks for sharing

-

Not a silly question at all. In fact a very good question that requires some hard thinking. IMHO, Altitude should not make any difference in choosing carburetor BORE sizing. Remember it is the pressure differential between the bore sizes of the main venturi and the main bore that creates Booster signal and regulates the air/fuel curve. The total amount of air ( dependant on air density ) does not affect Booster flow curve all that much. As far as carburation is concerned, all that you may want to do is perhaps run the main jet a size smaller if the altitude change exceeds 5,000 feet. . But carburators are self compensating to an cetain extent. 4,000 feet in elevation change can easily be handled by a well tuned carb. Even a stock carburator. The air/fuel ratio will get a bit richer... but the actual air/fuel curve should remain the same. Racers running Pikes Peak still run as big a carburetor as possible. You still have to get as much air to the engine as possible. It becomes even more critical as air density increases. " Choking" down a carb or running a smaller carb is the last thing you want to do. What they will do is build extra compression into the motor. It is not uncommon for Pikes Peak motors to be built with 15 to 1 or higher compression ratios. Pikes Peak start line is at mile & and is at 4,720 ft above Sea level. The top of the course finishes at 14,110 feet. Jack Roush built some hillclimb motors in the 1990's that could not be run at Sea level because the CR was so high. They had to be started at elevations higher than 4,000 feet or thye would detonate themselves to pieces. If you live in a high altitude area, such as Denver, consider building an engine with a higher CR. of course that means that you will have issues with detonation if you travel to Sea level . It's all a good excuse to build a nice Turbo engine....

-

Agree with JM. If you read Passini's books on Weber Tuning you find that the ideal Main Venturi size is 80 to 85% of the main bore size. For all out track racing you can go to 90%, but at a big loss in drive-ability. 80% is what most street cars and Autocross cars should be aiming for and in fact what most " universal " DCOE's come equipped with . Same for Mikuni's and Dellorto's. This assumes a cylinder size of 350 to 400cc. It's all about Booster signal strength and Booster signal depends on the pressure drop created by the air speeding up to pass through the smaller venturi. The carbs are engineered around the 80 to 85% Venturi to Main bore sizing. 40 mm bore size x 80% = 32 mm 45 mm bore size x 80% = 36 mm A lot of guys start with a 40 mm Bore carb. Find it's weak on the top end, so they install larger Venturi's such as 36's and the carb turns into a sloppy mess on the bottom end. The reason is that they've gone out of the recommended ranges of Bore size to Venturi size. However, if you started out with a 45 DCOE equipped with 36mm Venturi's you are smack in the design range of the carb to bore size. You woul have better top end and lose minimal if any driveabilty over a 40 DCOE with 32 venturi's. The important thing is the PERCENTAGE of pressure differential created by air passing through the Venturi in relation to main Bore size. That creates a strong and stable Booster signal. On an L-24 I would consider nothing smaller than Triple 42's. L-26 and larger, 45 DCOE or 44 Mikuni's all the way.

-

This fast enough spool for you? AWD Rabbit with 2.0 L VW 16 valve Turbo engine. GT2871R ( Ball Bearing Turbo ) around 18 lbs boost. Virtually no lag. Josh Autocrossed this car as well. Would work well on an L24 and give you more than enough power. https://www.youtube.com/watch?v=fiYg9okV-ME

-

I'd definitely be looking at a good set of Forged pistons at anything over 10 lbs of boost. I see you're in California? What are you planning to run for fuel. If 91 pump gas, you're going to have to keep the CR down to around 9.0, unless you run a lot of H20/Meth injection ( Well recommended ) . We have some high CR Turbo cars running locally in the PNW . Keth L run 10.1+ CR on his stroker L20B ( 2.3 L ) . 16 lbs boost, with big intercooler ,Water/Meth and C16 fuel!! But he pushes 300 RWHP out of that 4 banger all the time. ( No E85 up here to speak of ) . Can you get E85 in California? Go for it if you can. A good EFI system will help keep things alive. The AEM Infinity series have gotten a lot of good reviews ( although they do have a recall on now for early models with a weak Internal Power relay ). Audi/VW guys are really liking them. Haltech is also really, really good but $$$. Whatever you decide to use, I would definitely set it up with twin Bosch WB Knock sensors on a Forced Induction motor. Modern EFI systems have all the tuning and Data logging tables to make adjustment of modern WB Knock sensors relatively easy.

-

Yes. I agree with NZ. Some of the dimensions in those " Hot Rod " books are not the same as the FSM and Machinist spec tables. There seems to be a fair amount of conflicting information, particularly involving Piston Pin heights. Machinist tables on the other hand are constantly updated and checked for accuracy. Measure twice.. cut once.

-

List of Options for Crank and Cam Position Sensors

Chickenman replied to cockerstar's topic in MegaSquirt

Rock Auto has A1 Cardone remanufactured 1983 Turbo ZX distributors #311003 for $166.79 out right. Does not include Cap and rotor, but these are also available from Rock Auto. I picked up one of these distributors for my Haltech conversion and it seems well made. ( Conversion was only tested due to time an health issues ) Note I did have to do a bit of fine tuning to th CAS trigger setup. Out of the box, the CAS assembly was rubbing on the trigger wheel. Taking it apart I found that a couple of plastic " Nubs " on the bottom of the CAS assembly were preventing it from sitting flush. Five minutes with a file and a careful alignment on re-assembly and it was Golden. I think the issue is because A1-Cardone uses a Maxima CAS assembly instead of the original 280ZXT CAS. The locating nubs are slightly different . I also had to drill out the threaded mounting holes in the Dizzy body. The 280ZXT CAS has non threaded mounting holes and the screws slip though the CAS assembly and thread into the Dizzy body, which is threaded. The Maxima CAS is the opposite, and has the threaded holes in the CAS and the Maxima Dizzy body has un-threaded holes. So the screws go in from the bottom of the Dizzy body and thread into the CAS assembly. As A1-Cardone had it setup, both the Maxima CAS body and the 280ZXT Dizzy body had threaded holes and they just ran the screws down from the top though both sets of threads. Unfortunately this allowed no " wiggle room " for alignment of the CAS to trigger wheel and you got some very slight rubbing. Drilling out the threads from the 280ZXT bodyand inserting the screws from the bottom up allows for slight alignment changes to be made. YMMV. -

A lot of the 510 guys around here like to idle at 900 to 1,000 rpm as they have big cams ( over .500" lift, 290 to 300 degrees duration ) and the extra RPM ensures more oiling to the cam at idle. It's a bit of an insurance policy. Valve spring pressures are pretty high. These are on 2.1 to 2.4 Liter strokers that still twist to 7,500 to 8,000 rpm.

-

List of Options for Crank and Cam Position Sensors

Chickenman replied to cockerstar's topic in MegaSquirt

Yep. Crank oil worm gear. 15043-21000 Approx $60 USD. Available from Nissan dealers or online stires such as Courtesy parts. http://www.courtesyparts.com/oe-nissan/1504321000 Turbo oil spindle . 15040-P8000 Approx $95 USD. ( Sometimes us Canadians get a deal. I paid $75 CDN from my dealer. Ordered part direct from Japan. ) http://www.courtesyparts.com/oe-nissan/15040p8000 -

List of Options for Crank and Cam Position Sensors

Chickenman replied to cockerstar's topic in MegaSquirt

You don't have to pull the Timing Cover when you change the OP spindle shaft. Just remove the oil pump. The spindle shaft will drop down when you remove the pump. Spindle shaft has special splined drive to eliminate slop on Dizzy end. Gear slop is not a big concern if new gears are installed. -

Thanks for the info. One more thing to do in the Spring!!

-

Recalculated from the above site using a head gasket diameter of 3.5" and a crush thickness of .047" ( 1.2mm ) which seems to be a common figure for Nissan factory head gaskets. CR came out to 10.35... which sound more in line with other forums such as the link below. Your thoughts? http://www.viczcar.com/forum/topic/4286-overview-of-l6-engine-heads/

-

I used this online CR calculator which seemed to give calculations more in line with what some Forums post up for L28 with FT pistons and N47 heads. Note: Measurements have to be entered in Inches and to get a positive Deck height ( Piston above deck ) add a minus sign to Deck Height figure. http://www.wallaceracing.com/cr_test2.php Calculation of the following figures gives this result. Seems a bit high, but head gasket diameter and thickness I inputted may be a bit low. Your displacement is 167.93 CID The Compression Ratio is: 10.61

-

That's the best way. I wish my engine had a bit less compression. It's a bit touchy on fuel. Pretty sure I'd have an issue in California. I'd have to dial the timing back a bit.

-

Can't like your Post 'cause I exceeded my Like quota?? Anyhoo you are correct. I'm just going by what I've measured and others have posted previously. I think Brap was one who head a threda about the L28 Flat Tops being around .024" out of the block. Main point was that some online calculators are incorrect. OZ Data being one of them. If you configure with their piston deck height specs, it calculates that L28 Flatops are .020" below deck height... which is wrong. You have to manually over ride their " calculated " data. Best to measure everything yourself. That's what " Blueprinting " is all about

-

Steel hose barb to AN fitting

Chickenman replied to grannyknot's topic in Trouble Shooting / General Engine

You can get high Quality fuel hose from XRP, Goodridge and Earls. Should not have any issues with modern fuel or alcohols. It's the cheap brands from offshore brands that have issues. ( Personally I don't like Russel products ). You don't really need PTFE lined hoses for modern pump fuels ( including E85 ) with quality hoses.... IMHO. CPE lined Nitrile fuel hose should not have any permeability issues. ( Synthetic CPE can handle Methanol and Nitromethane...so Ethanol E85 and modern pump fuels should be no issue ) With that in mind you could go to something like XRP's crimp lock CPE hoses. Would push over your stock fuel nipples, secure with fully banded SS worm clamp or crimp clamps. Makes life a lot easier. http://www.xrp.com/wp-content/uploads/2013/12/XRP-new-Product-Catalog.pdf Even Earl's cheaper line of Super Stock hose has been reformulated to handle modern fuels including E85. https://www.holley.com/brands/earls/products/plumbing_an_fittings_and_hose/hose/ Goodridge hose lineup. Type 200 with synthetic CPE is good for Methanol and Nitro Methane. http://goodridge.brakes-hoses-fittings.co.uk/goodridge-hose-types.php -

It is the Holiday season. He may be away for a bit???

-

1: All of the above and make sure that you didn't leave a Timing cover bolt or two loose. Oil passages from oil pump go through TC and loose bolts ( or bad gasket ) will cause oil pump to such air and not prime. Long shot... but it happened to a buddy. You can also prime the oil galleries through the oil sending fitting. Juts get a Mechanics pump can for oil ( remove the sending unit ) and hand prime through oil sending port. If oil galleries are dry, they can take a long time to fill by cranking. Not good for bearings. 2: Pull the oil pimp regulator threaded plug out and make sure that the pressure relief valve is free and not sticking. Some oil pumps can have a bit of machining " swarf " left in the passage and the relief valve can stick open. That or a " burr " in the bore. Best to pull the pump and check it thoroughly. I usually disassemble new oil pumps and give them a thorough cleaning before I install. And prime them as well.