-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

Fresh motor rebuild falls of a cliff at 5500rpm

Chickenman replied to Kirkster's topic in Nissan L6 Forum

Just thinking out loud... so bear with me. A few things that can cause Ignition issues. Are the D581's genuine GM/AC Delco coils or aftermarket brands? Some of the aftermarket brands are of poor quality and tend to Auto-Dischrage. This usually happens if Dweel settings are pushed too high and/or Plug gaps are too large. What is important to realize is that once coils have Auto-Discharged, they are usually hooped. Internal circuitry gets damaged. It's a steady spiral downhill after that... Dwell should be limited to no more than 4.5ms and Spark plug gap should be no more than .045". Running more than those figures over heats the coils and slowly fries them. You cannot run a straight 4.5ms all the time. There is a Dwell Table for GM Coils that utilities the MAP signal to cool the coils when the engine is not under high load. You need a clean and strong signal from your Crank sensor at high RPM's. Tuner Pro can help you monitor that. If you're using a Crank Trigger wheel check your air gap. Or are you using the Z31 CAS? What Trigger wheel in that if you are? Crank and Cam Trigger lead wire must be shielded and routed well away from Spark Plugs leads and should also be not be run parallel to any 12V leads. I don't know if the MS3 Pro wiring harness actually uses shielded Trigger wires. They may only be twisted pair. Motec and Haltec always use twisted pair wires inside of a shielded casing. That's the best way to do it. MSD makes shielded Trigger wiring harnesses in various lengths. Plug leads are very important. You must use a good quality Spiral wound leads for the coils. MSD or Magnacore are very good. Beware of Taylor and Accell house brands. There lower cost items are junk. Note. You cannot run Solid Copper leads or Graphite leads with stand alone ECU's. These generate too much EMI, even with short plug leads. Resistor plugs should be used as well. -

First of all never run the car with the Battery disconnected. That's a good way to blow the alternator. For the rest I'll have to think about it, but is this a Stock system or have you altered anything?

-

Fresh motor rebuild falls of a cliff at 5500rpm

Chickenman replied to Kirkster's topic in Nissan L6 Forum

What is the HP doing at High RPM's ? Torque and HP cross at 5,250 RPM after that Torque will decrease in reason to RPM. It is normal for Torque to fall off at high RPM's, particularly with a stock camshaft. How much things drop off is a mater of interpretation... it may be perfectly normal, or it may be a problem. If the Dyno operator is not familiar with Datsun motors, he may not have a a good idea what is Normal. Do you have a Dyno pull on the engine previous to this where the power, did not drop off as drastically? Stock cam is pretty mellow, and a stock L28 does tend to go flat after 5,500. Posting your present and previous Dyno charts would help. Should be from the same Dyno to make any real intelligent..... but any Data is helpful You mention you had the valve springs replaced? That raises a flag. What brand were they and what rate? Did you replace both inners and outers? Some aftermarket replacements are way below the Nissan OEM spec. Just poor quality..... What was the AFR curve reading at the top end. Your Dyno operator should have been measuring that. BTW, wording like " it crapped out again above 5,500 rpm " is not very helpful. Did it start to misfire? Did it start to run rough? What did the AFR do? Was the Trigger signal monitored to see if it was breaking up or getting mis-counts? All of this should be monitored on the Dyno when you do your pulls. You should be logging the MS 3 Pro with Tuner Studio the whole time. What Ignition timing where you using. ( Total mechanical )? What Octane and Brand fuel? Plugs and Heat range? Detonation will cause Torque and HP to plummet... just one of several things that could be wrong. But you must have the data to analyze..... and your Dyno operator has to know how to interpret that Data. -

Comparison different valves quality

Chickenman replied to Ssaga's topic in S30 Series - 240z, 260z, 280z

I think I just found the same link. NOS Fugi 280Z Intake valves ( Set of 6 ) $30 + $10 for Expedited shipping!! -

The finger in the hole method is only to indicate whether the piston is on Compression or Exhaust stroke. Final step with the finger in the hole method is to stick a long thin screwdriver in the plug hole, and then slowly rotate the crank pulley by hand, until you feel the piston come all the way to TDC and then pause before heading back down. You can get it pretty dead nuts accurate like that. If mark on pulley is still out, then it's possible that the dampner rubber ring has slipped or someone has put the wrong pulley on.

-

Excerpt from the article above. This is some very good info IMHO:

-

A picture of the Bob's fan setup would be nice. One thing that is very important is to use a full coverage fan shroud, just like the stock setup. The full back face of the radiator should be enclosed in a shroud. The idea is to pull air through all of the radiator fins. In the Desert you can never have too much Airflow. Especially if you have AC. IMHO I'd go for the highest CFM combo that you can afford. The Taurus fans are reputedly around 2,700 CFM on low speed and 3,800 CFM on high speed. Another very good option is Volvo 2 speed fans. https://www.youtube.com/watch?v=-954_wpRWsQ Interesting thing about Electric Fans. General rule of thumb is that they pull approx 10 amps per 1,000 CFM ( Source Spal ) . So a Taurus fan on Hi Speed pulls a good 38 amps continuous. A stock 60 Amp alternator ain't gonna cut the Mustard with the Electric fans and AC on at idle. Hot Rod actually had a very good article addressing the issues of running Electric fans on Vintage cars. Good info from Spal on current draws of fans, CFM ratings and how they vary, use of Full shrouds and why a 60 or 70 Amp alternator may not be enough. Full article at: http://www.hotrod.com/how-to/engine/ccrp-0707-high-performance-cooling-system/

-

One thing to remember about mechanical fans. There is a reason why they can cost you 5 HP or so at High RPM. They are moving a S**T load of air. Mechanical fans can be much larger and have more aggressive profiles than electric fans, and in general will pull a LOT more CFM than an equivalent sized electric fan. Pitch on mechanical fan blades can be steeper and blades can be wider because they are driven by the engine. This equals more airflow, at the cost of a bit of power and MPG. Stock 280Z fan blades are eight blades and thye have a very steep pitch and are wide. They are also noisy when the thermo-clutch kicks in.... but they do move a Ton of air. One reason why manufacturers went to electric fans was to increase fuel mileage. CAFE numbers are really, really important when you sell millions of vehicles a year. The other reason was Transverse engines in FWD cars. Just my .02c...

-

If you choose Spal check out their home site carefully to get specs. The 30101522 Spal is a 12" Medium duty fan. It only pulls 1,328CFM. That may not cut it in Vegas with AC on. The IX-30102049 pulls 2,048 CFM in comparison. Note the curved " S " blades. Most High Performance fans use " S " blades to increase surface area and allow more CFM to be pulled or pushed. Following is link to Summit... but you may find them cheaper on E-Bay; http://www.summitracing.com/int/parts/spu-ix-30102049/overview/

-

More pictures of the Altima twin fans.

-

For where you live... where it's over 100 F fairly often I'd say go back to the stock clutch driven fan with a shroud. I encountered the same problem when trying to run electric fans on my 1971 Camaro. One trick that does work is to use Redline Water Wetter. I've used this product for many, many years on my Hill climb cars and it pulls overall temps down by at least 10 degrees. Most of my competitors also use it or a similar product. It works amazingly well. We even used it on some British Double Decker Buses when I was in the Tourism business. They had up-rated Radiators, up-rated transmission and oil coolers, but still boiled over when they had to climb a particular long grade, fully loaded. The Redline Water Wetter dropped the temps just enough to stop the Boil Over when they stopped at a View point at the top of the hill. It is designed to be used with antifreeze. Now, if your set on using electric fans. Get a single BIG Arse fan... with a shroud. I've heard that Ford Taurus fan (from a 1990-1995 with 3.8L engine) works well. But I don't know if Vegas might be too much for them. Guys from the SR20 DE Turbo forums also like the Altima Twin fans with shrouds. Nissan Altima Fans are very large twin fans. The Spal 16" diameter fans may do the trick as well.. but $$$ Here's a thread on the Altima fans. http://www.sr20forum.com/240sx-s13-s14-rwd/169960-altima-fans-vs-taurus-fan-comparison.html Altima Twin Fans: Ford Taurus fan on a Champion Radiator. :

-

Verify that you don't have the dizzy installed 180 degrees out. It's really easy to make this mistake when you're tired or in a rush. It's one of the first thing I do when a new engine refuses to start. Note: A Timing light will fire at the indicated timing mark with the Dizzy 180 degrees out... engine just won't run of course because it's on exhaust stroke instead of compression stroke. . Disable injectors and ignition through Tuner Studio. Remove #1 plug. Stick your finger over the hole and bump the engine over till #1 comes up on Compression stroke. Manually rotate crank ( or carefully bump over ) so that Timing Mark is at TDC or very close to it. Pop dizzy cap off and confirm that the rotor is pointing at #1 Spark lead terminal.

-

Back in the early days of Analog non feedback ( O2 soreness ) ECU's the really good tuners would modify the ECU;s with different resistor values or adjustable Pots. Pots were the easiest. Lot's and lots of Dyno time and soldering skills in those days. Todays Digital, Wide Band ECU';s with self tuning features make EFI tuning a " piece of cake " compared to what we did in the late 70's and through the mid 80's.

-

I have a similar setup on my 1976 L28 with Stock FI. OEM Analog ECU and AFM ( Vane style ) does a surprisingly decent job at fuel management on a mildly modified ( 10 to 1 CR, headers, 270-280 degree cam ) L28 engine when everything is running correctly.... up to where the AFM maxes out, which is around 4,000 to 4,500 RPM depending on the VE of the engine. Generally, you will hit a lean spot between 4,000 to 5,000 ( Peak Torque ) as the AFM maxes out due to airflow and then ECU relies solely on an RPM and WOT TPS controlled Fuel Mapping Table. After 5,000 rpm the factory WOT Fuel Map tends to go on the rich side as a safety feature ( Common Japanese ECU strategy in the day ) and this can sometimes put you in a safe AFR reading with a mildly modified engine. Laen at Paek Torque is the worst thing for an engine... so keep the mechanical advance on the conservative side. However, you really need top throw it on a chassis Dyno with a WB Air Fuel Meter to see what it's doing. These old ECU's are Analog ( not Digital ) and they can drift all over the place. Sometimes you can get lucky and they drift into a sweet spot. Sometimes thye go the wrong way. It's all dependant on the condition of the 40 year old capacitors and resistors in the ECU. Once you have your Dyno figures, you have a baseline on what you can do. Best way... Complete standalone ECU and $$$$ or switch to Triple carbs $$$. Poor mans way. Aeromotive adjustable EFI fuel pressure regulator. The 13129 can be found for around $129 at Summit and Jegs. It's a compact unit so easy to fit. On the Dyno, raise the Fuel pressure till your WOT AFR's are in a safe range. This will compromise partial throttle AFR's somewhat ( they will go rich ) but it's an Analog ECU and you'll just have to live with it. If you have to go over 45 to 50 PSI ( 37.5 is stock pressure ) consider slightly larger injectors. Don't go too big as you have limited fuel compensation with the Analog ECU . Stock injectors are rated at 188cc at 3 Bar ( 43 psi ) . ZX Turbo injectors ( 295cc ) at 3 Bar " may " work with the NA ECU... but I'm not sure if that will throw the stock NA ECU calibration out too far. Perhaps others can chime in with more info. After getting the WOT AFR's corrected. You should be able to trim the part throttle AFR values by tightening the AFM Vane " clock spring " a few clicks. Go easy and make sure you mark the original setting. Read up on the old " flappy doodle " Vane style AFM's if you're not familiar with them, and remember you are dealing with Dinosaur Technology. There is limited adaptability.. but some mild tweaks can be done. Bear in mind that everything is going to be a compromise. Biggest challenge will be avoiding Detonation in the critical 4,000 to 5,500 RPM range. What cylinder heads and pistons are you running? Some combo's are better/worse than others. The N47 and N42 heads ( what do you have ) are more detonation prone than the P90 heads. With 10 to 1 CR, be conservative with mechanical ignition timing and use the best fuel available. 94 or 94+ Octane preferred. If you can only get 91 Octane in your state, be REALLY conservative on ignition timing. I'd say no more than 30 to 32 degrees total until you get the AFR's corrected. The last thing you want is too much ignition timing and a lean out at Peak Torque or High RPM.

-

280Z Kick panel speaker pods in development. with content!

Chickenman replied to Derek's topic in Interior

New pictures in Post #16 -

280Z Kick panel speaker pods in development. with content!

Chickenman replied to Derek's topic in Interior

Every 240,260 and 280Z owner should gets these. Awesome products. Check for updates of install and pictures in my posts #14, #15 and #16 -

If Stock ECU, adjust your Fuel pressure to achieve desired AFR at WOT. Let cruise AFR fall where it may. Rule #1 on all Turbo cars with non programmable ECU's. You want WOT AFR ratio around 11.0 to 11.5 on Turbo cars to be safe. Keep Boost and Timing conservative and AFR a bit rich until you dial it in. How much boost are you planning on running and what CR does the engine have and what fuel are you running? Stock ECU has limited ability to adjust. Don't go crazy with boost on stock injectors. You really need a standalone ECU that can be programmed with a Laptop to optimize everything 2,000 rpm free revving in neutral would be around 14.0 to 14.7 with stock camshaft. No boost and minimum load at that RPM equals Stoich ( 14.7-1 ) or close to it with a good tune. . Edit: Simple Digital Systems has some very good Tech articles on Turbo's and EFI. A good read: http://www.sdsefi.com/tech.html

-

"fuel injection dropping resistor," clicking

Chickenman replied to Please work's topic in Trouble Shooting / General Engine

The injector dropping resistors are not located in the passenger foot-well. They are in the engine compartment on the drivers side, hidden behind the W/Washer bottle and snuggled up against the firewall. They have nothing in them that will " Click" and they rarely fail. Remove the relay that is sporadically clicking and have a close look at it. There should be a 10 digit Nissan part number on it. Post up the part number, then we can cross reference it and tell you what it is. -

Aeromotive 13129 EFI regulator is a good bargain. I picked up one for my Haltech conversion on my 1976 280Z. Several of our members on " The510realm " are using them on Turbo EFI conversions and are very pleased with them. Compact size makes them easy to fit in tight spaces. $128.97 at Summit: http://www.summitracing.com/int/parts/aei-13129/overview/

-

The Aeromotive 13222 non-return regulator is vastly superior to the typical Holley regulators, which is a cheap " Made in China " part for the masses. . The 13222 is a purpose built racing regulator with no cut corners and you get what you pay for..... Typical Holley 12-803 FPR for carburators ( 4.5 to 9.5 psi ) = $29.67 at Summit Aeromotive 13222 non return low pressure regulator regulator ( 1.0 to 5.5 psi ) = $185 at Summit Aeromotive 13205 non return FPR ( 5 to 12 psi ) = $102 at Summit Still a bypass system is preferred over a Static system in just about every situation... and that's on advice from Aeromotive. BTW, Aeromotive does make a Universal Bypass regulator that come with two springs. A low pressure spring for Carbs that regulates from 3 to 20 psi and a high pressure spring for EFI that regulates from 20 to 65 ps. Aeromotive Part # 13301. $142.97 from Summit: http://www.summitracing.com/int/parts/aei-13301/overview/

-

A 1/4" return line is not big enough for a Bypass system. On carburated engines it should be equal to the pressure line size, and a minimum of AN 6. EFI engines " can " get by with a return line one size smaller than the pressure side due to higher pressures involved. Edit: I'll have a look at my stock feed and return lines on my 76 280Z. Main feed is 3/8" ( AN 6 ) I believe and return is either 3/8" or 5/16". I'll confirm later... Aeromotive has some very good articles on designing fuel systems for both Carburated and FI engines. Here is one article that explains the basics. In particular, read the info on feed and return line sizes and also static and bypass regulator systems. Bypass regulators are superior to dead head systems in all Racing and Hi Performance applications. They have many more articles available, but I don't have time to dig them out of my Archives. http://www.superchevy.com/how-to/engines-drivetrain/0906chp-aeromotive-fuel-systems-insight/ Acceleration forces when Drag Racing or running Track forces have a big effect on both Fuel Pressure and particularly Volume. Too small of fuel supply lines and return lines make the supply of adequate volume even more difficult. Hillclimbs, are the worst case scenario for fuel systems. Here you have essentially an uphill Drag Race. You have both acceleration forces and gravitational forces working against the flow of fuel to the engine. You have to have a really stout fuel system to handle the stresses of Fuel Delivery in Hillclimbs.

-

^ That's good. Just listing all the things I could think of...

-

Hmmm... those Holley non-Bypass regulators are suspect. Lots of issues, especially when set up as a dead head. Not very accurate, slow to respond and when they limit pressure, they restrict the output flow which reduces volume. Monitor it on the the Dyno if you're testing again. Bypass style FP regulators do not restrict volume to carbs or injectors when they bleed off rail pressure. Electric fuel pumps should be mounted as close to fuel tank as possible and as low as possible. ( Stock 2080Z EFI position is fine ) Must be mounted as a pusher pump, not puller. When you go FI you must run a pre-filter before the FI Hi pressure pump. Fram G3 is fine. New style pumps use Ceramic Turbine vanes and they can't handle minute dirt particles as well as the old Roller vane pumps ( Original Nissan Style ). However, the Turbine style pumps are are quieter, more efficient and will pump a lot more pressure and volume than the old style Nissan Roller pumps. Carb or Fuel Injection, one other thing to check is the voltage drop to the electric fuel pump. A 1 volt drop can affect pump volume dramatically. Can reduce volume by up to 15% A relay system should be used with a 40 amp Bosch continuous duty relay. Run at least 12 gauge wire back to the fuel pump, with the main +12v for the FP relay, connected directly the battery terminal. 10 gauge is even better if you have a long run. Do not go through the factory fuse box. An ATO inline fuse holder with a 20 Amp should be wired in at the battery or use an Auxiliary fuse block. ( You'll probably want one of those when you go Fuel Injection ) CE Auto Electric Supply makes some nice auxiliary fuse blocks and other electrical goodies: http://www.ceautoelectricsupply.com/fuseholders.html .

-

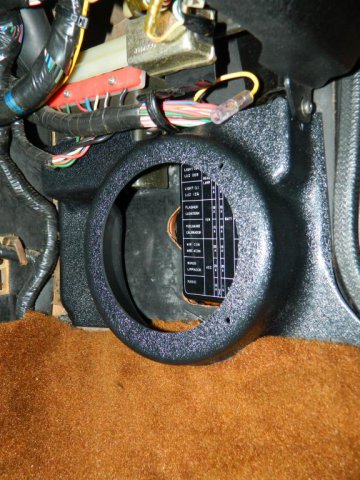

280Z Kick panel speaker pods in development. with content!

Chickenman replied to Derek's topic in Interior

Sorry for the delay, but I've been having some back issues lately and I can't get under the Dash for very long. Here are a few more pictures and some notes. 1: Driver side fits much easier with small notch I made at the bottom slot. Derek will likely modify production models based on this feed back. 2: I have included some pictures with my size 12, D width running shoes on. These are the bulkiest shoes I own ( with a big flare on side of soles ) and as you can see, there is lots of space. I have a lot more room with my dress shoes or driving shoes. Access to clutch pedal is a none issue. Access to dead pedal is fine. You just learn to slip your foot back and under. People without size 12 feet would have even more clearance. I'll update later with speakers in place. Top fits perfect: Lots of room under dead pedal Clutch access is perfect... even with " Clown shoes " Hard to see from this angle, but dead pedal still has a fair bit of room. Lots of clearance between my toe and speaker panel. -

280Z Kick panel speaker pods in development. with content!

Chickenman replied to Derek's topic in Interior

Some more pictures of passenger side fitment. Tomorrow I'll fit speakers and run wiring. Edit: Note my passenger side is sitting a bit lower than normal because I've removed the carpet escutcheon plate for refinishing. With plate in place speaker panel will move upwards a little bit. Should be perfect...or even more perfect than it is. Click for large image: