-

Posts

340 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Exposed

-

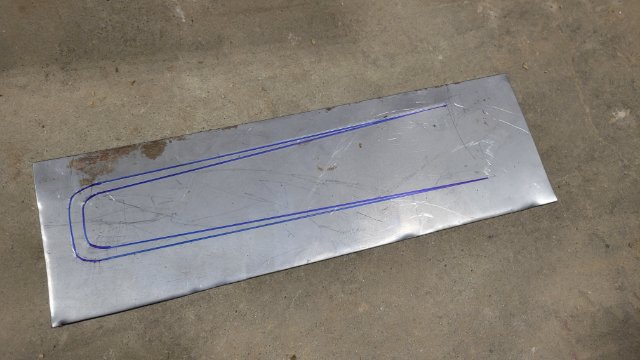

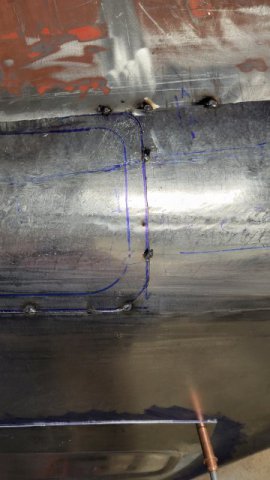

I probably should have posted the process but hes a quick break down. Dont know if this is the correct way of doing this but it seems to work for me. 1 -Identify the area and take measurements so it can be similar to the other side. 2 -mark out your design, try to plan out the steps so you arent remaking a panel because you put an indent on the wrong side. 3 -put the design into the panel using whatever tools you have a your disposal (hammer & dolly, bead roller, resip hammer, etc) 4 -remember you didnt account for the stretching that was going to take place and now you have to hammer and dolly your panel straight again. Some of this hammer and dolly work could have been eliminated if I calculated prestretch required 5 -using your patch panel as a template, scribe around the edges and begin cutting. I try to leave 0.125" from the scribe line and finish it with snips 6 -tack the edges 7 -begin welding. I like to use tig for this and I try to run a bead without stopping. It warps alot. 8 -hammer and dolly or use a planishing hammer to flatten out the welds, go over the entire welded area with a wide faced hammer/ slapper and try to finish the panel as best as you can.

-

-

found an audi at the scrap yard that had most of its fuel door latch intact. Latch system looks . Modified it abit but managed to get opening and closing. Still need to clean up the filler area, gap and reinforce the fuel door.

-

Making the fuel door opening. Will need to place a backer on the door and some type of latching system.

-

@fusion ball peen hammer, chisel, sandbag and dolly

-

-

@Zetsaz @TUME @Dat73z Thanks guys, was thinking of running 5mm @Jboogsthethug Ya I'm liking how its coming out, only thing I dont like is how many peices I made it in. Might redo it one more time and try 2 or 3 sections instead

-

-

@Jboogsthethugim just winging it lol. Longest project ive ever started, couple days a month. fingers crossed im done in 2030

-

-

hopefully I wont need as much filler as the last guys 😅

-

Small update from this weekend. Passenger side is getting welded up. Having some issues with symmetry but think I'm going to just leave it as is and run with it.

-

-

I'm Back, 1971 240Z and Yes, it will be TurboCharged

Exposed replied to 240Z Turbo's topic in S30 Series - 240z, 260z, 280z

Great progress and quality of work. Enjoying the build, keep it up -

are you welding with tig or mig? If you doing a tig weld I'd do what AydinZ71 suggested and run a single pass or as close to one as possible. I have no doubts that it'll warp but just take a dolly and a body hammer to the tig welds and hammer them into themselves. You'll restretch the metal and it'll flatten out again, then you can grind down whats left of the welds.

-

Filler panel for the driver side and remade a wider skin for the rocker panel. Drilled out a couple holes and welded a nut at the front and back of the rocker panel to hold down the new skin. Pretty happy with how its turning out, need to start on the door soon.

-

@JboogsthethugThanks! I know it can be hard to find time. I'm hoping to have it outside of the shop sometime this year, glad its winter here for 8 months, gives me a bit more time to work on it 😅

-

Slowly plugging away. Hopefully this is the last bit of rust left on the car.... A lot still needs to be cut away and remade. The door skin and driver side frame is up next.

-

Heavy Duty frame rails and connectors

Exposed replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

@toolman thinking im going to pick up a shrinker, I've been beating the panels with a hammer but to get on the small edges is a pain. Thanks for the response on that. -

At least I'm not the only one who constantly changes there mind. I definetly wasnt expecting a change like that, looks great!! Cannot wait to see this roughed out panel from the side.

-

Hey! From looking at there site it looks as though they just relabeled there company. If its the same owner as before it was called Retro Spec. From what I've seen in the past 9 out of 10 reviews thats ive seen about retro spec were similar issues to what your dealing with. and 1 of 10 was that they received a product after a long wait and quality was good. There are some reviews on Hybridz about them.

-

@Sanchez I did something similar to my front end when I redid it, I ended up using 2x2 0.125 wall thickness. I havent driven the car yet but looks a lot better than it did. If I was to redo it again I would run the frame rails all the way under the floor pans and brace everything up together.

-

Another long weekend down and a bit more finished on the Z. Passenger side panel remade again... still need to adjust for spacing and give it abit more shape.

-

Heavy Duty frame rails and connectors

Exposed replied to toolman's topic in Gen III & IV Chevy V8Z Tech Board

making some good progress on the car! How do you like the woodward line of tools? Do you have any other? -

@Nelsonian yes that was the idea. Feel as though it isnt flowing well though, might finish the panel then just snip that section out.