-

Posts

340 -

Joined

-

Last visited

-

Days Won

10

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Exposed

-

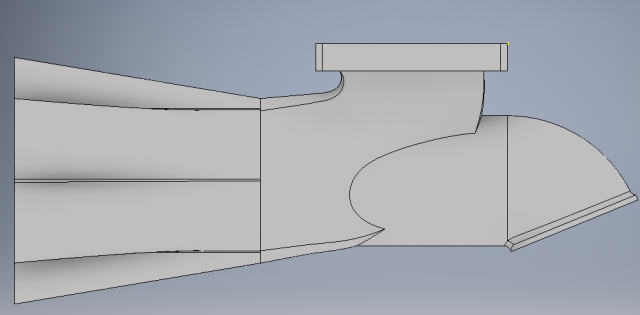

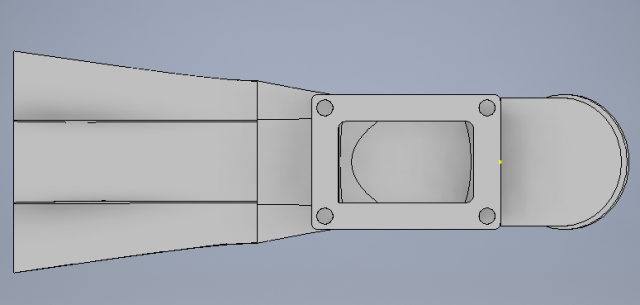

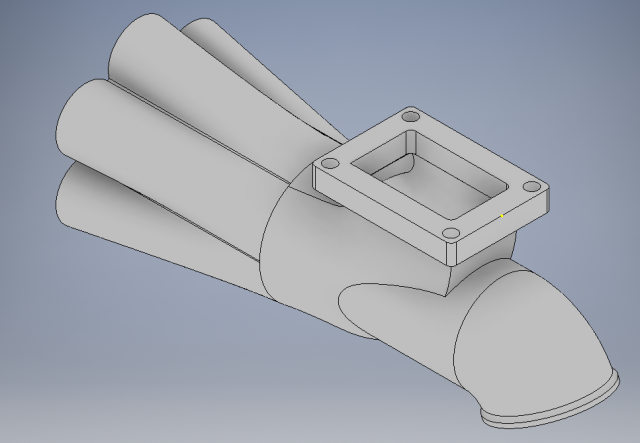

finally found some time to begin working on one of the intercooler end tanks, mocked it up in CAD before starting, then got to work.

-

Need wiring help - 2JZ GTE direct ignition coil packs on GE

Exposed replied to M_Dragan's topic in Toyota L6 Forum

might be different for the 2jz but on my 1jz I still had my soarer igniter when I swapped coils. Everything worked well while I had the stock ECU. Everything remained the same once I swapped out the ecu for an AEM infinity. Hopefully someone with more knowledge is able to chime in. -

any build pictures? Looks like a good looking car.

-

@Zetsaz yup, that's awesome

-

I'm really happy with the way my current build is going, don't think I have a "dream build" though. Everything I've wanted to do I've began or started to brain storm ways to achieve it, the down side to this is the Z is NEVER going to be finished. I guess I just like trying new things and I enjoy seeing a genuine reaction on someones face when they see the car. After this one is "done" i think I'm going to be looking for a Cummins engine out of a dodge ram and possibly tinker with the Idea of AWD. Always thought it would be cool to see a stock looking Z ripping around with a turbo diesel.

-

@HuD 91gt it felt like a life time. Hoping to find some time this weekend to plug away on the end tanks.

-

lol I think it took me 4 hours, that includes farting around on some other stuff. Ended up cutting off the end tanks on the intercooler and started my cardboard template.

-

-

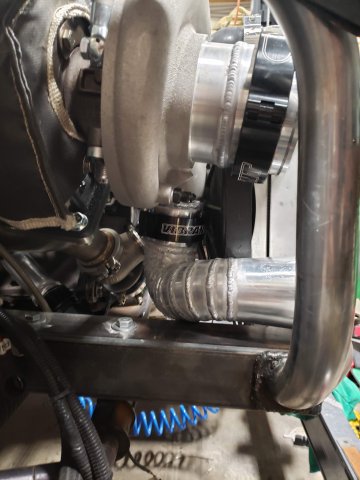

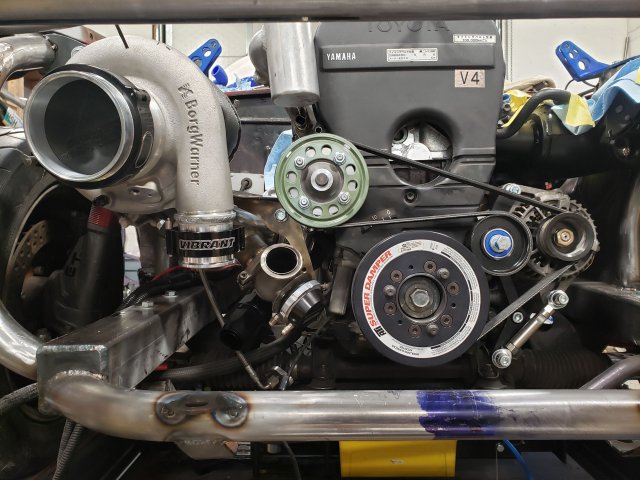

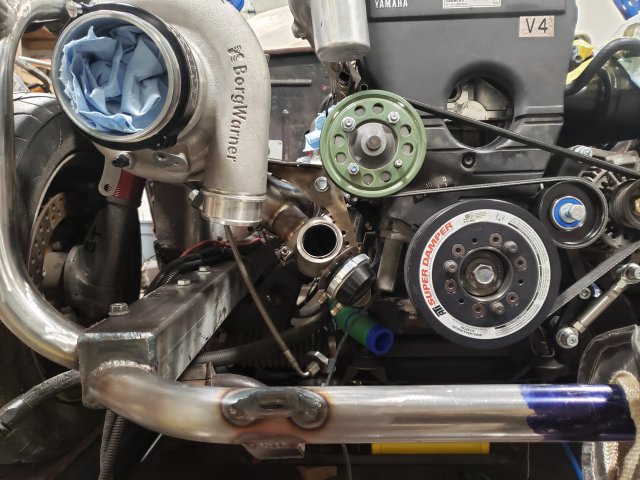

Ended up making a brace to the block that's able to support the weight of the turbo, fingers crossed it doesn't crack on me. Will also be modifying the water neck outlet to pass below the waste gate.

-

great looking car, post a break down!

-

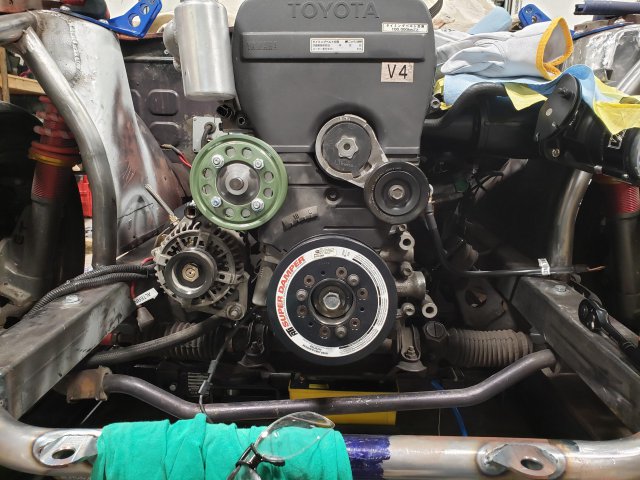

Haven't had to much time to plug away with work being as busy as it is and wrapping up home renovations. On the fence about mounting the turbo and snipping the hood or mounting the turbo lower and leaving the hood as is. I ended up moving the alternator over just incase I want to bring the turbo lower. Next step, modify the lower waterneck outlet and bring it as close to the block as possible. For the guys who upgraded to a single turbo has anyone braced the turbo back to the block or frame of the car?

-

I used the stock one from a 350z, havent had an issue with it.

-

I ended up putting the engine in today. Good news is it clears it by half an inch!

-

@softopz havent tried to put it in the engine bay yet, going to test it this weekend hopefully. Fingers crossed I dont have clearance issues, im not running CX mounts. he's a pic of how the car sits as of monday. Worst case I cut the car apart again and sell it to the scrap yard.....

-

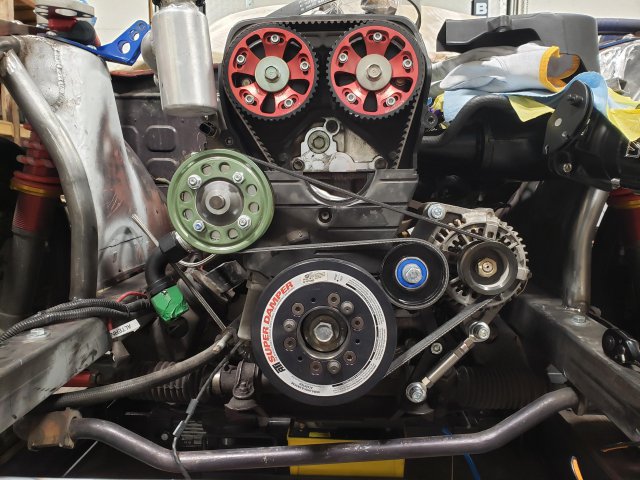

im everywhere with this project really need to focus on one thing. Back from the powder coater, heres a little teaser!

-

printed off some of tubes to do my mock up. The plan is to try and shorten up the tubing as much as possible to try to keep all the tubes even. Also welded in the patch panel

-

@seattlejester I considered just moving it and rewelding it but the shop that did my tuning suggested running a ford iac. After I put the sandwich plate on the oil filter it gave me enough room though so I'll probably just run it like that until it stops working. @Geno750 thanks for the input, great to know its doable. Would you say its worth doing the swap? Looks like it could get costly....then again everything we do to our cars seems to cost an arm and a leg.

-

and last but not least I made two more patch panels. They didnt turn out the best but it looks good enough for me.

-

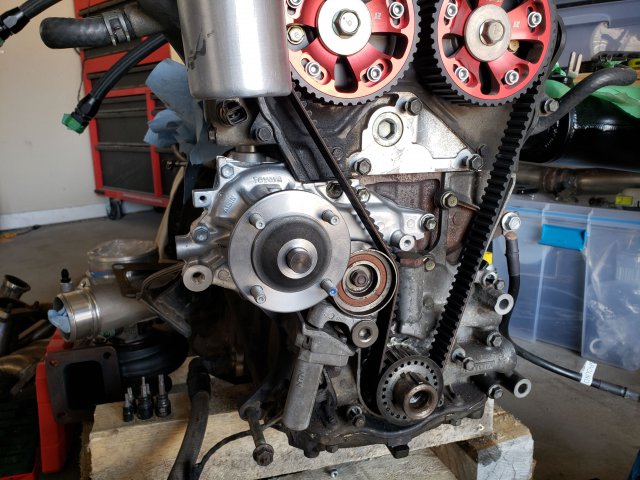

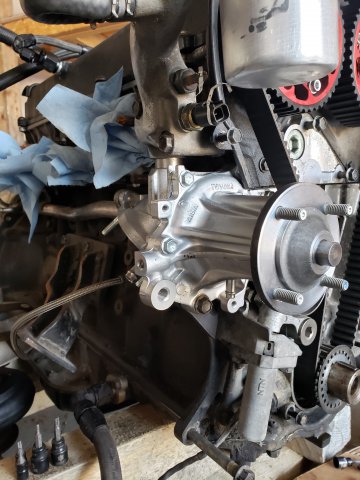

Water pump was swapped out for one of the ones from Driftmotion. One thing that I cannot seem to find an answer to is why is it that the 1jz/ 2jz water pumps are interchangeable but the 1jz/ 2jz waterneck outlet isnt? Am I missing something? I switched out the stock oil cooler for an aftermarket sandwich plate and got that installed. Going to run some -10an lines to the new oil cooler. Fittings on the cooler are -10an x M22 to a 60 degree -10an to hose.

-

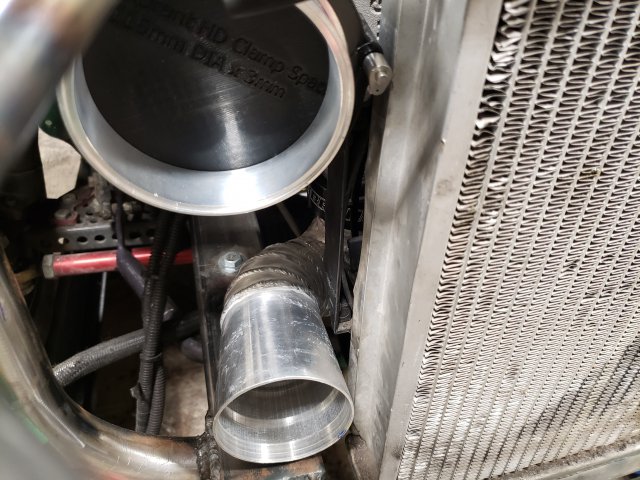

once again thanks to @seattlejester for grabbing me that manifold flange. Shortly after receiving it I started working on 3d printed manifold tubes, similar to whats already being sold. Just need to prints out some 45 and 90 degree pieces. I had purchased an intake plenum about a year back when Otaku Garage first started producing them, assuming they were testing waters at the time because the price of them now is abit higher. With the engine still out of the Z I finally got around to installing it. Fingers crossed that it has good results on the dyno. One thing I dislike right off the bat is the location of the IACV, it comes in contact with the stock oil cool/ filter. From speaking to the guys at Otaku they've since revised its location so its no longer in the way of the stock oil cooler/ filter location. The throttle body the comes with the plenum is a 90mm, I ended up putting a Vibrant HD clamp on the end of it.

-

did you ever finish this 100% sanded, painted, etc? was digging the design, really want to see it finished

-

@M_Dragan Id probably add sleeves as rturbo 930 mentioned. I ended up adding them on my Z as I had a similar issue and upon further inspection it turned out that the rails were rotten. I just recently posted an update on my build thread showing how bad the rails actually were.

-

Thanks for the picture.

-

Thanks, Yes they wanted $350 just for shipping. I've tried looking through ebay and buying from them but its still a ridiculously high price on shipping. If your willing to do that let me know and I'll send you the money and my shipping address right away.

-

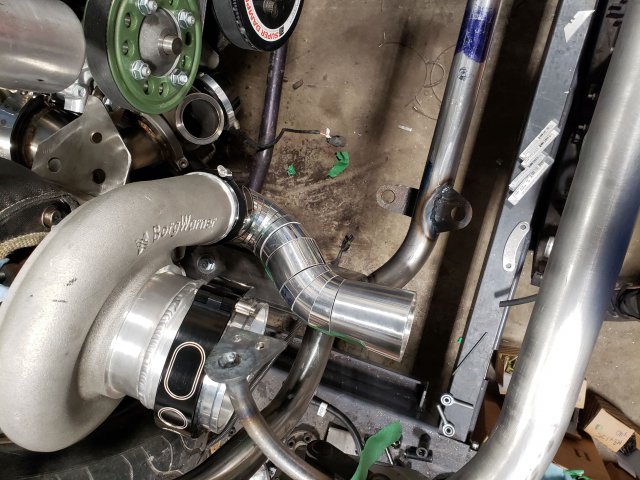

Placed some orders for some misc engine parts and decided I'd start on a new manifold. Found some inspiration online and decided to start plugging away. Tubes were cut, tacked into place and sent off to be welded professionally. The shop recommended I add a flange incase I decided to change anything down the road. They did an amazing job. Anyone know anywhere to get a stainless 1jzgte manifold flange? I was looking at the CX Racing one but they want $350 usd just to ship it up to Canada.

.thumb.jpg.2002d645ec2a0a4f693ae52bf0fe4bcc.jpg)

.thumb.jpg.00606cad8936087fb1b24f403ae7aaac.jpg)