turbogrill

Members-

Posts

350 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by turbogrill

-

Where did you find that? 1. So no, since 43.5psi minus boost_psi will be your max fuel pressure. If you want to run 10psi boost your fuel pressure will have to be set at 32psi. Probably not enough with your performance goal. (maybe ~250hp)

-

1. Doubt it. Have no clue, maybe at 40ish psi. 2. Most injectors are rated at 43.5 psi. So if you use that it makes it easy for you, if you use 80psi your 440cc/min injectors flows ~600cc/min. 440cc (43.5psi) into this (http://www.witchhunter.com/injectorcalc1.php) calculator seems to give a max HP of about 330hp crank (bsfc 0.65 ). 600cc (80psi) into this (http://www.witchhunter.com/injectorcalc1.php) calculator seems to give a max HP of about 420hp crank. Why not run as high as possible? I guess it's just put's extra load on pump, fittings and FPR. Not sure how much pressure stock system can take (hoses, filter etc). The fuel pressure is set by wit a knob on the FPR 3. Aeromotive are popular

-

Block heater core - add pressure sensor?

turbogrill replied to turbogrill's topic in Nissan L6 Forum

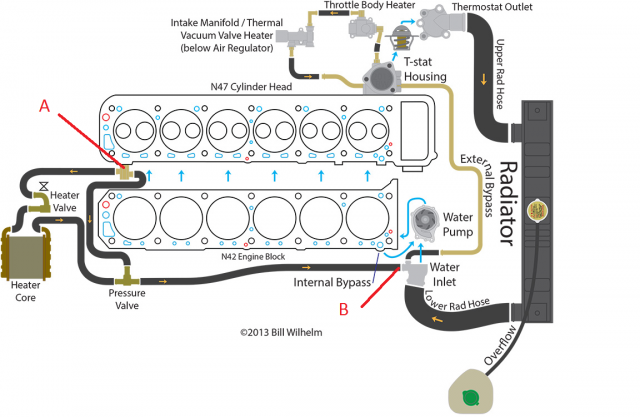

Thanks I think I got it now! Whatever I do I will make sure the pump always have somewhere to pump water. Reason I want to remove most stuff is to remove failure points. No thermostat means no thermostat that can fail, no heater hoses means no heater hose that can fail etc. I haven't raced the 200hp engine yet so I don't know if there is any cooling issues. With our 140hp engine we had ZERO cooling issues in Texas heat enduro racing, we where almost running a little cold we thought. I am mostly worried about pinging, but seems like there are plenty running my setup without issues. (n47 flattop, M445 cam, megasquirt, nice head) I like your suggestion for pressure sensor location, will check it out. I might keep the internal bypass, that way I don't have to mess around with the block and screw something up. -

Hi, I don't have a heater in my race car but I do want to monitor the coolant pressure so that a the driver can stop if there is loss of coolant. I have a N47/F54 combo. 1. Would the heater outlet in the head be a good place to put a pressure sensor (location A) ? Or would it be better to put it in the pump housing (location B)? 2. Plugging the heater core have no negative impact on the system? Infact it might have a slight positive impact since there is no reflow back to the pump? 3. If I can remove the thermostat would it be beneficial to remove the bypass altogether? Car is a ~200hp NA build if it's matter for Endurance racing.

-

Race car: P79 + flat tops for turbo engine? (Moderate boost)

turbogrill replied to turbogrill's topic in Nissan L6 Forum

What is this head cooling mod? -

Race car: P79 + flat tops for turbo engine? (Moderate boost)

turbogrill replied to turbogrill's topic in Nissan L6 Forum

That is a very good point, while I am sure the EFI was spectacular in the 70s it's very ancient. So intercooler will reduce the temps and therefor reduce the possibility of knocking. I terms of engine management what is important from a knocking perspective, is it make sure that AFR is what it's supposed to be and timing is being where it so supposed to be? -

Hi Is it possible to build a turbo engine using the flat top pistons with any head/gasket combo? Or will compression be too high? Would be looking at <300hp. According to the calculator the P79 and flat tops gives 1:8.63 with Fel pro gasket. My NA N47+flattop build has everything that I need for turbo except turbo parts. (fresh rebuild, ARP head+rod bolts, megasquirt, pallnet w/ supra injector, large pump, loud exhuast) When I get tired of this engine I might try the turbo route, would be nice if all I needed is a P79 head and the turbo gizmos.... This would be in an enduro race car in Texas, so plenty of heat and abuse.

-

Downside with a big cam isthat you might have to do modifications to the valve train, new springs, lash pads and so on. Your stage2 might be a "bolt in". Something like Isky L-480 maybe? Not sure if it works with your carbs ( I am EFI). I would call Isky or Rebello and ask. Sites to google: Schneider Cams Isky cam shafs Rebello Racing Colt Cams It's a jungle...

-

L28 Build Thread 75 280z (N/A to Turbo Conversion)*UPDATED

turbogrill replied to RefreshRate's topic in Nissan L6 Forum

300hp is a lot for a light car as that. Great that the suspension has been upgraded! It would be undrivable with those power levels and shitty old suspenion. What wheels are you running? 15x8? I would get sporty tires, like Direzza or Ventus RS-4. Depends on if you like to go around corners fast or just floor it at red lights. You technically don't need the actual gauge but you do need the wideband controller for megasquirt tuning. The gauge cost nothing, it's the sensor/controller board that cost. I would recommend getting the gauge as well for back up during tuning. Just zip-tie it initially and then remove it after your tune is steady. As for fuel pump, not sure if the stock fuel pump can handle your power levels. Are you planning on running stock fuel pressure or higher? Depends on your injectors flow rate. I would just get a Bosch pump, old pumps can fail. Will you be controlling timing as well with Megasquirt? I think turbos like that. -

L28 Build Thread 75 280z (N/A to Turbo Conversion)*UPDATED

turbogrill replied to RefreshRate's topic in Nissan L6 Forum

Cool with the turbo swap. Good luck! As you might know there is a guide here on the forum. Also join the Datsun facebook pages, sometime they sell turbo parts if you need. I can recommend buying injectors from motorman, it's a little more pricey than ebay but you know it's all good. Can be hard to diagnose a faulty injector when you have so many new things going on. As for FPR I have the Aeromotive 13105, works well and no to pricey, however make sure that whatever FPR you get has the right connections (ORB, AN or hose). Also I didn't see a wideband on the list, you really need one. -

Not sure I follow, are you asking if you should use the F54 or the 2.4L block for your build? I would guess the F54 block? I think the cam is the bottleneck here, that stage 2 looks very mild. Compare with this thread: There is a few people there with cams similar to Schnieder stage3 cams and they seem to make about 170hp to the wheels. So maybe ~150hp is reasonable with stage2 if everything else is tiptop? I would get a much bigger cam...

-

Stage 2 cam is schneider stage 2 or Isky/rebello stage 2?

-

L28 Build Thread 75 280z (N/A to Turbo Conversion)*UPDATED

turbogrill replied to RefreshRate's topic in Nissan L6 Forum

Bottom end seems to survive a little over 300hp as long as you stay under 6500 rpm. Over 300hp and I think forged pistons are in needed, not sure when you need forged internals but seems like there is plenty of 400hp builds here. However do a leakdown/compression test, it might show that 2 or so cylinders are low on compression. Who knows, maybe the trip meter wrapped around, maybe there was a coolant leak at some point. Having that said due to lazyness I have driven my stockish L28 based race car with a very worn engine for a total of 32hours racing, only issue has been maybe 10% loss of power. -

L28 Build Thread 75 280z (N/A to Turbo Conversion)*UPDATED

turbogrill replied to RefreshRate's topic in Nissan L6 Forum

Great! There is something called Microsquirt, it's a durable version of Megasquirt 2. It has some limitations but nothing that matters on our cars. I can recommend that since it's nice price and good fit for our car. But requires a slightly different harness, I am sure softopz has something to say about that. Regarding cam, not sure what your intention is with the valve train but some cams works with stock valve trains and some needs an upgrade. Are you having a professional fiddling with your head or are you confident in messing with it yourself? And I know, getting cam is a jungle. Google and forums are your friend. -

L28 Build Thread 75 280z (N/A to Turbo Conversion)*UPDATED

turbogrill replied to RefreshRate's topic in Nissan L6 Forum

Hi and welcome! Looks like this is going the be fantastic. Do you have any emission requirements where you live or are you exempt due to the cars age? (as in Texas) I have done MS2 and I really like it but I am computer and electrical skilled, I can see how it's a challenge if you are not! Do what ever makes you complete the project even if MS2/MS3 with after market fuel rail is best from a cost and performance perspective. Regarding the cam, I have spend many many hours googling cam and the general consensus is go big! (as someone said). But pick something where RPMs will be below 6500. Maybe ISKY 480 is a good option but requires new springs I think. Colt Cams C.542.s might be good since it doesn't require significant upgrade to the valve train. -

Ok. Using either centerline or LSA from camsheet gives me correct LSA/Centerlines. Curious about the reasoning with longer intake duration? Maybe this has something to do with the asymetrical lobes causes "slower"opening in the opening. This is just pure gibberish speculations btw... My spreadsheet seem to work well for Schneider cams Maybe they don't have asymmetrical lobes... All valve events are relative ATDC (I find ABDC, BBDC just confusing) Overlap = ExhaustClose - IntakeOpen DurationI = IntakeClose - IntakeOpen DurationE = 720 - ExhaustOpen + ExhaustClose IntakeCenterLine = DurationI/2 - IntakeOpen ExahustCenterLine = DurationE/2 - ExhaustOpen LSA = ( IntakeCenterLine + ExhaustCenterLine) / 2

-

So with IVO you got the same AFR for some operating point with 7% less fuel? Does this translate to 7% better BSFC? Very cool stuff!

-

The centerline and LSA numbers doesn't make sense to me, using my homemade spreadsheet I get: LSA: 110 Intake centerline: 119 Exhasut centerline: 102 Anyone else want to have a go? One explanation would be if the lobes are asymmetrical (as in one side steeper than the other). It also has a higher duration on intake than on exhaust? Makes me think is a Turbo cam shaft, NA usually has it other way around. Also most 290 duration NA cams seem to have over 70 degree overlap, again maybe it's a turbo grind. But 65 degree overlap seems a lite much for turbo cam... So not sure

-

If you can have someone do the harness for you then great, otherwise there will be a lot of crimping and it sucks after a while You might also want to start with fuel only. Essentially start with having the old computer and harness inplace and only add what you need for fuel. Once you get that working you can start remove stuff. Also you don't need TPS and all the fancy feature to get going. This is a project where incremental changes will save you a lot of time. And finally do timing. This is how I did it on my L28. If you just start with 10000 things then you don't know what's wrong. To clarify, don't reuse the old existing hardnes..

-

1980 280zx vs 1983 280zx rear brakes

turbogrill replied to turbogrill's topic in Brakes, Wheels, Suspension and Chassis

Yes and even facebook. Seems like Wilwood is the way to go! Was hoping that the 83 rear calipers would be magic... Thanks -

Hi, I am using Supra 7GME hi-z injectors that I drive directly from microsquirt, seems to work well. I bought the M445 cam from a Canadian I haven't seen any dyno plots from the cam on a L28 (only on l20) so I cam curious about it.

-

Hi I guess what I am wondering is how people find their AFR targets? Start with guidelines and then trial and error?

-

Hi I have a MS2 converted stockish L28 that I very much enjoy tunung. I run a mix of autotune and manual tune. But currently building a new engine. My problem is how do i know what my AFR targets should be for my L28 build? As of now I have tunerstudio calculate it for me based on some generic formula. Works OK but probably not optimal for our engines. So how do I find the best afr targets? 1. Trial and error at Dyno? 2. Find a rebello engine with similar specs and copy theirs? Currently stock but planning on 200whp target. N47 with Flattops, decent port, mild street) M455 cam (280 advanced duration). Thanks

-

1980 280zx vs 1983 280zx rear brakes

turbogrill replied to turbogrill's topic in Brakes, Wheels, Suspension and Chassis

I am curious if the 1983 brakes are better than the 1980 brakes for my race car. It's a 1980 280zx chumpcar race car running on non slicks, stockish engine and stiffer suspension (cut springs, swaybar, camber, strut bar,roll cage).