tube80z

Super Moderators-

Posts

1401 -

Joined

-

Last visited

-

Days Won

31

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by tube80z

-

510 rear suspention swap

tube80z replied to alexideways's topic in Brakes, Wheels, Suspension and Chassis

Yes, Steve and Al. They have a jig at their shop and have done two or three wagons. That car is by far the fastest 510 I've personally driven. Maybe even the fastest car I've ever driven. That includes Kipperman's Z and a few others. A real beast but not scary. Cary -

510 rear suspention swap

tube80z replied to alexideways's topic in Brakes, Wheels, Suspension and Chassis

A friend of mine created a bolt-in 4 link conversion for a 510 wagon. It was developed for high HP 2-door cars. The difference between the 4-link and the trailing arms is amazing. Unfortunately this isn't offered for sale. It was on a yellow 510 with a turbo KA that was at Shasta a few years back. In case anyone saw it. Cary -

Maybe/Maybe not. A long time ago I measure the CG of a VW supervee (using the flat motor) and a formula ford. The Ford actually had a lower CG by a small amount. If the Subies have the crank about center of the motor and you can get a normal engine lower than this it may be able to have the same/better CG. The engine is pretty light from what I've heard and being short will help the car turn better. For SCCA classes you may be able to use the exhaust clearance loophole to trim the frame rails for this to fit. Then use a cage to put the structure back in. Rear steer and forward mounted TCs would fix the suspension issues assuming you keep it strut based.

-

I'd guess C4 suspension. Benefits would be reduced scrub and better camber control. Downsides could be reduced torsional stiffness in the chassis if this wasn't done right and more than likely the car hasn't been setup. I think there's some gain to be had doing something like this but it needs to be balanced front to rear or in the end you'll end up with a lot of work and not much payoff.

-

510 rear suspention swap

tube80z replied to alexideways's topic in Brakes, Wheels, Suspension and Chassis

Not easily, a few swaps have been done like this over the years. The straight axle is actually better. Check dimequarterly for info. -

Yet another Rear control arm design

tube80z replied to tholt's topic in Brakes, Wheels, Suspension and Chassis

A spherical on the end of the arm could attach to a double eared bracket on the strut. You could do that in such a way that you could use stock or the new option with the same struts. -

Yet another Rear control arm design

tube80z replied to tholt's topic in Brakes, Wheels, Suspension and Chassis

Since that's what most people run on the front for a tie-rod setup I don't see why it wouldn't work on the rear. Cary -

It really depends on the officer. Most harnesses aren't DOT certified/approved and this technically means you aren't wearing and approved belt. It's not a safety thing at all. Here in Oregon I know two people that got seat belt tickets for wearing a harness. If I had to guess they pissed off the officer who pulled them over. I think Schroth and a few others have street harnesses that are certified. I know of no actual race harnesses that are. Cary

-

Yet another Rear control arm design

tube80z replied to tholt's topic in Brakes, Wheels, Suspension and Chassis

So what are you going to do? Something like your diagram? This is a good thread BTW, even if we don't agree -

Yet another Rear control arm design

tube80z replied to tholt's topic in Brakes, Wheels, Suspension and Chassis

CL is center line. Your example is not the same as what we have in the back of our cars. The spindle pin doesn't move up and down more in the front or the back because it is all rigidly connected to the strut. The control arms can be connected anywhere along the spindle pin and it will still move up and down. In order to make the installation stiff you want to have the max distance between these points. In your example arm the toe link is going to be in compression under power. Most race cars I've seen lately put the toe link in tension. And for our cars it would be a simpler design with more distance between the points (on the outer end). Cary -

Yet another Rear control arm design

tube80z replied to tholt's topic in Brakes, Wheels, Suspension and Chassis

Thanks for the detailed reply. I'll file this away for later use when I make my toe-control arms. And this time I'll use double heims. Cary -

Yet another Rear control arm design

tube80z replied to tholt's topic in Brakes, Wheels, Suspension and Chassis

So how does the front not bind solid when you brake and hit a bump? Lower triangles and toe links are used on a number of WRC cars. I figure if it works for the front there's no reason it can't work in back. But I know we've agreed to disagree on this one. Cary -

Yet another Rear control arm design

tube80z replied to tholt's topic in Brakes, Wheels, Suspension and Chassis

No real major concerns but some feedback. If you make the top triangle all from tubing it will be lighter than using the clevice arrangement. It will also be stiffer from a compliance standpoint. The toe link should be cleviced (or better yet fed into a double shear gusset) that is from this triangle. How these are attached to the strut will make a difference in compliance too. If you can I'd mount the swaybar to the strut to reduce friction on the joints and remove a small bending load. I ran a similar set of arms on one of my cars when I was trying to get parts figured out for the tube car. One issue I ran into is that you have to watch for is the halfshaft hinge points. When I ran longer lower control arms there seemed to be some kind of binding when the car was loaded under power. If you look at the stock arms you'll see that these points are very close. CVs may be the answer but I didn't have them at the time to try. If you want to be able to adjust track you might consider changing the inside to sphericals and using shims to adjust them. If you do all the work in the shop then this is quick and easy at the track. For a Z I'd first look at working the front for better grip before playing with the rear. -

Any reviews on AZC "Racing Suspension"

tube80z replied to ZT-R's topic in Brakes, Wheels, Suspension and Chassis

Some additional information we've found out about these is the adjuster changes both compression and rebound. So they are more like an illumina insert. That said they did work reasonably well on a friends car that he was autoxing and hillclimbing. I still don't have a definitive answer to if they can be rebuilt and/or if they must be replaced. I'd want to know that before I bought them. -

Welcome to the big butt club How much of the inner fender did you cut out? On my car it's flat from the center of the inner fender to the outside. Cary

-

Contact patch, weight, and lap times?

tube80z replied to jt1's topic in Brakes, Wheels, Suspension and Chassis

John, Take a look at http://www.jameshakewill.com/tech.htm. This site has a lot of good info on using free tools and low cost options to help you get the most from your data logger. You can see what he did with lapsim to see if it's worth the time to invest in learning it. Cary -

Contact patch, weight, and lap times?

tube80z replied to jt1's topic in Brakes, Wheels, Suspension and Chassis

First a couple of questions. How camber sensitive are these tires? And are you stuck with running radials? If the wider tire is more camber sensitive you'll probably have issues with a stock S30 chassis. While these may work for a BMW our chassis isn't as sophisticated. Have you considered running used bias ply slicks? These are a much better match in my opinion and a lot cheaper than the prices you mention for running the radials (perhaps a class issue). There are three primary factors for cornering speed. Weight, CG height, and track width. Your losing two of those for sure going to the bigger tire combo. If you have some basic data you may want to think about downloading bosch lapsim and trying it out. It may help you make the choice as to which is better. Cary -

Don't you watch Mythbusters!?

-

Brake lines and brakes.

tube80z replied to EMWHYR0HEN's topic in Brakes, Wheels, Suspension and Chassis

And here, in case this is cheaper http://store.fedhillusa.com/cuniferbrakeandhydline.aspx Cary -

Near Zero Front Suspension Droop

tube80z replied to 260DET's topic in Brakes, Wheels, Suspension and Chassis

It's inside front, if it says otherwise that's a mistake on my part. When you droop limit you will have the amount that the spring is pre-loaded. To get the tire off the ground you will need to transfer more than that, which is possible if the car will bicycle. My car won't lift the front tires on acceleration even when I have a true zero-droop setup. I think what you typically see are cars that are fairly soft that allow the chassis to move enough to get a tire off the ground. The weight transfer happens regardless of the roll angle. Movement of the geometric and/or forced based roll center standard in most any suspension. If it helps to think of it how do you calculate the RC in a suspension where one wheel is fixed and can't move. That's what we have here when the limiter tops out. And the change in ride height (net up/down) can be measured with a data logger. I don't know if I'm helping or hurting at this point. All I can tell you is this is a trick I use and it works well for me. It's not something everyone should do without understanding why. I have lots of pics of the people I run with and all the cars running stiffer spring packages keep their tires on the ground. All of the softer cars are running around with tires off the ground and many of them have loads of droop. Cary -

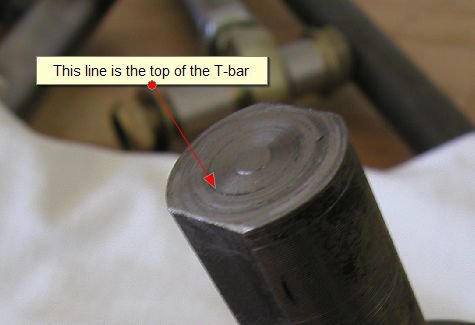

The attached picture shows the outline of the t-bar. The pinion is actually hollow where the u-joint connects and inside this is a torsion spring that is hooked to the servo valve. The top of the pinion is hooked to the t-bar and the bottom to the servo valve. This is what controls the power steering and the feel. If you cut the top down and didn't keep the t-bar pinned you will not be able to have functioning power steering. And if you decide to weld the top of the pinion you need to be very careful because you can damage the t-bar, which happened in Dave's case. The first thing that happens when the t-bar breaks is the steering goes freaky light. If you get the servo valve cocked one way or the other then you have power steering in one direction and get to fight the pump to turn the other way. Cary

-

Near Zero Front Suspension Droop

tube80z replied to 260DET's topic in Brakes, Wheels, Suspension and Chassis

Cables between the strut tower and the lower control arm were used. Adjustments were done via turnbuckles. Very crude but it worked. -

In your first pic is looks like I can see part of the t-bar. Did you pin that before this mod? It's hard to tell from the picture. You need to be very careful with that piece or you'll have steering that will not work correctly. Cary

-

Actually from what I can tell different types of race gas have different specific gravities and need to be tuned for when you have a motor on the edge. Probably not something you'd worry about in a normal auto engine. But something still to think about. Cary

-

widest rims that fit inside YZ rear flares?

tube80z replied to briann510's topic in Brakes, Wheels, Suspension and Chassis

Yokos are slower than the GY radials, even though the GYs are narrower. But if you have access to a bunch that are cheap why not use them. You probably already know this but you need to run stiff springs to really make those tires work. And the setup is going to be different between the GYs and the Yokos since the tire stiffness is different. And to make the rears work you will need to think about droop limiting or you will see high inside tire temps that look like too much camber. It's caused by inside tire roll when you put the power down. Cary