AydinZ71

Members-

Posts

1073 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by AydinZ71

-

I wonder how the OEM helical (Torsten) Subaru (17’ for example) measures up to another helical unit like qualify. OEM units usually have a good reputation reliability wise. At least now I know a clutched OSGiken unit is king. $1400.

-

@gnosez well you are the right person to speak too! Gosh I may have made different decisions now since I have the diff and the CV’s are in the way 😂 Still, ya live and you learn. i think my background and goals would be helpful. This is a SCCA vintage racing car that had huge amounts of rust, which I discovered post purchase. I was intending for it to first be a hot rod, but I started to appreciate how much effort had gone into making it a race car. So I decided to restore it as the closest thing I feel it would qualify for: EP. I never even considered if I would ever race it myself, but I enjoy the build process as a mechanical engineer and mechanic 🤷🏽♂️ I hope I can make something I can be proud of, even if I won’t be the ultimate driver. The improvement you mentioned with the OS Giken is huge! Maybe il still consider it if I find the funds. Would love to chat with you sometime and get your frank feedback! -Aydin

-

same here. I couldn’t tell if it was my iOS update or the actual page code itself. Getting used to it

-

@gnosez thanks for the feedback! This car is set up for EP at the moment, so I am expecting less than 150ft-lbs RWT. Engine is limited to 2.4L, 12:1 Static CR, and must use SU’s. Wheels are maxed at 15X7”, but can run full race slicks. It’s about a 25lbs savings going from the R200 helical to R180 helical. I hope she holds up! i also hear good things about Fritz’s CV’s, but again time will tell. Since the cheapest adapters for the stock shafts were $500, and Fritz’s CV are integrated with the right bolt pattern for $1,000, it seemed like a reasonable splurge. I like the nord washer & blue locktite combo. You certainly have the experience, so il take anymore advice you got!

-

yep! Got them off with vice grips yesterday and ordered the right studs from zcardepot. Kind of a rip off for 8 bucks a piece, but it will save me time so worth it. They have 1.75mm Pitch thread on one side and 1.25 on the other, so not exactly common. just need to rough-in my fuel lines and il be able to get everything bolted back in.

-

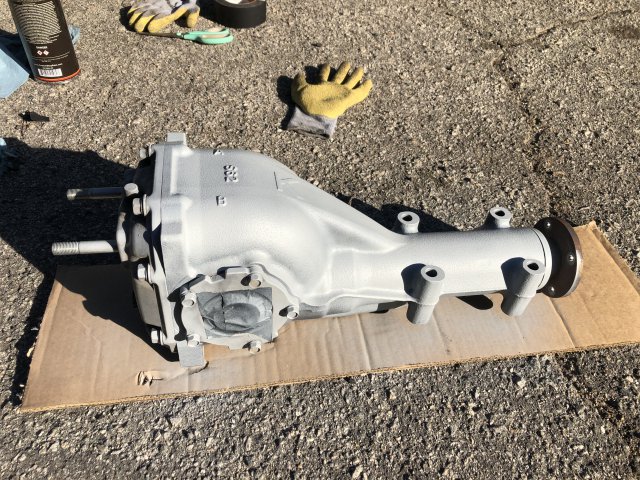

280z R200 3.545 open. Working condition and recently resealed cover after checking ratio. left & right half shafts. I had cleaned them up and painted to re-install but decided to downsize to an R180. also have the OEM diff mount and strap.

-

Got the right yoke. This one is from a OEM 240z R180. It did match-up to the 280z driveshaft I have. Here’s hoping the length works too. Diff is cleaned/painted with black epoxy, and took the opportunity to clean up the tranny tunnel where it meets the diff. Going to let the undercoating cure for a few days then install. New predicament. The diff cover mounting studs are too long on this guy. Looking at photos of alternate covers, it’s seems I should be able to just unscrew the existing studs and replace with shorter units? I had not read this issue on the swap write-ups I had looked at. Ah well Il also see if an M12X1.25 die will work.

-

Cleaning up the Subie R180 with a wire wheel, primed with self etching primer, and followed by single component spray can black epoxy. Here is a pic of it primered. I swapped the yoke with the one from my 280z R200. The diameter of the z Yoke Shaft OD looks like it’s 2-4mm wider. It’s a super snug fit into the front main seal. Hope the extra OD doesn’t ruin the seal. Definitely feel more resistance when I turn the shaft. anyone else experience this? I guess there is only one way to find out if it will work

-

Yep, i was eyeing the G25-550 but i have a smaller power target. Expensive little bugger. Garret I believe the GTX(70?) is about $500 less but also less efficient. Garrett has a program on their website that calculates the most efficient turbo for your application.

-

A musician's therapist (The $300 Z)

AydinZ71 replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

@Zetsaz In my experience the diff mount was the most likely cause of the clunk on/off power. Next was U-joints. Hopefully that will fix it! good luck! at least you are checking off the boxes. -

Racing wheels - complete novice

AydinZ71 replied to AydinZ71's topic in Brakes, Wheels, Suspension and Chassis

I have only cared less about aesthetics with age, haha! I'm glad to hear they will fit the purpose, and appreciate your input! -

Racing wheels - complete novice

AydinZ71 replied to AydinZ71's topic in Brakes, Wheels, Suspension and Chassis

thanks for the tip! I think il get a cheap pair to get used to how slicks handle. She should be back on her feet in a month or two. looks like he only has a pair for sale at 225/50R15. Il save his store so I can check back periodically. -

Racing wheels - complete novice

AydinZ71 replied to AydinZ71's topic in Brakes, Wheels, Suspension and Chassis

hey thanks!! Il reach out to Greg. Would love to get perspective from someone successful in EP. Il hold off on getting tires until I do a little more research. -

Racing wheels - complete novice

AydinZ71 replied to AydinZ71's topic in Brakes, Wheels, Suspension and Chassis

Thanks for the reply! The wheels are actually 16lbs, but it sounds like there is room for improvement. I didn’t want to put on tires if I was starting with a flop. Il go ahead and use them for now. Thank you! -

Hi guys! The racecar I am restoring came with Diamond racing wheels. They are 15"X7", which complies with SCCA production class. Just weighted them and they are 16lbs each. Anyone else have any experience with the manufacturer or the wheels themselves? Would these be considered light weight, or could i do significantly better? I don't even know the difference between a racing wheel and a road wheel, so I will do a little research so I don't waste your time on that. Thank you!

-

A musician's therapist (The $300 Z)

AydinZ71 replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

@Zetsaz forgive my ignorance, as I have not followed your build so far. When I put the L28et in my 71', i wore out the OEM driveshaft u-joints in about 4 weeks. I didn't think anything of it, so i just replaced the driveshaft with another OEM junkyard unit. this time, 3 months later the U-joints went bad again. My front diff mount had gone bad too, so the diff was lifting 1/2" (and made a terrible "thud" noise). I figured the misalignment was what wore out the joint. Replaced AGAIN with another junk yard unit. I finally pieced 2&2 together and realized the additional torque was wearing out the OEM joints. The 4th time I replaced my driveshaft, I went to a local offroad truck shop and said "Make me one that is durable for 300ft-lb of torque". For $300, they made a custom one with spicer u-joints and was 1/2" larger in diameter (this was 2004). I highly recommend if you replace your driveshaft, you get one with replaceable u-joints! Even if you dont run big torque numbers. its a PITA to get back under the car and drain the tranny oil. -

A musician's therapist (The $300 Z)

AydinZ71 replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

@Zetsaz congrats! Good luck with the axles! I have never driven an S30 with CV’s so I’m curious to see if there is any noticeable change at various speeds. I ordered a pair from Fritz for the Subaru R180 Torsen LSD to OEM hubs. -

Adding rigidity while restoring rusted metal

AydinZ71 replied to AydinZ71's topic in Fabrication / Welding

-

@fusion hmm... when you hold it up to the car, does it look like water will not naturally drain out the bottom of the gas filler door? would water stay put in that pocket? Instead of putting a nipple in, id just weld-in a sheet of steel to replace the rusted out piece, but angle it in a way that makes sure water does stay trapped in there. It should drain out the filler door.

-

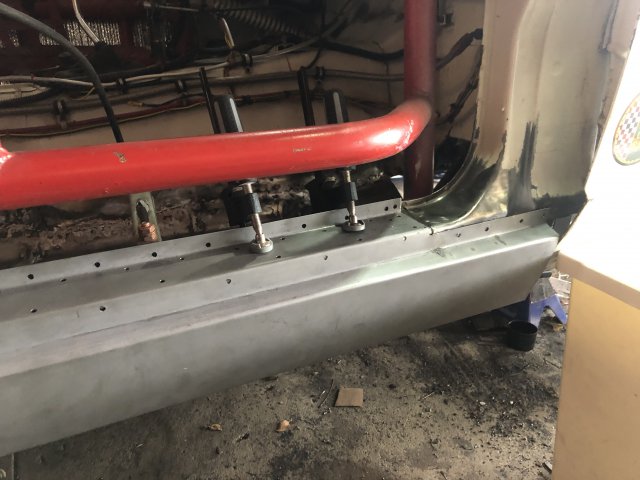

@S30Dave Try https://kfvintagejdm.com/ They make the inner rocker, which most of the other's don't. I have not bought any parts directly from them, but there are several guys on here who have. I can tell you, it seems their die/stamp is closer to OEM from what I can see. For example, their floor pans actually contour to the tranny tunnel, where the others must be cut and hammered into place. You should think about what goals you want for the car. If you want 100% OEM, it is worth the money to just buy all the replacement panels and weld them in. If you plan to race the car or turn it into a hot rod, you might consider just replacing components with various pieces of (much cheaper) steel stock. For example, you could run tube steel through the rocker panel for added rigidity, then just use flat sheets of steel either bent or welded at 90 degrees for that inner rocker. Many options. Just make sure you leave some of the rocker (like the outer) while you replace the inner. If you lift the car and cut the entire rocker, floor pan, etc. at once you may warp the body. I just replaced my rocker as well, including the floor pan and some added structural rigidity in the rocker. If you are interested, you can see the images on IG @240z_restomod

-

@Nelsonian Much respect on chassis reinforcements and welding! having spent months now on metalwork, I certainly recognize the effort. Unlike bolt-on mechanical work, there is an extreme swing in attention to detail and durability/longevity with metalwork. Sealing the seams from future corrosion, minding unnecessary weld material for weight, primer adhesion, sealer coat (epoxy), undercoating. On and on.... How low do you plan to mount your seat? My car now is mounted to the floor. I'm short (5'8"), so I'm thinking of raising it an inch when i replace the driver side floor board. Just cant see all that well that low LOL!

-

@calZ LOL, fair point I have been spending way too much time fabricating rust replacements, replacing roll bar mounts, and reinforcing the chassis. I think I'm getting carried away. I have been cutting quite a bit of weight by removing unnecessary components such as unused brackets and factory unibody-welded nuts. When incorporating monocoque structural components (cells, like tubes), you can reduce quite a bit of weight when compared to the resistance welded stamped steel. I may actually have to add-back weight to meet the 2150 lb spec., but at least then I can replace the weight as low as possible, and move the CG backwards to compensate for the natural understeer of the car. @jhm I think the top mount is brilliant! snapped one up yesterday with no hesitation. Had I known this was available, I would have gotten it years ago for my high-torque Z. I am not running very much torque on this application, but obviously needs to be robust enough for RR. I'm looking forward to it! Funny thing... he/she printed the shipping label within minutes of me making the purchase. I have been posting quite a bit recently. It might be time to just start a dedicated thread for the car.

-

These are a convenient solution, but I think the cross bracing serves an important purpose for body rigidity. If they made them in steel, id get a pair for the bushings, then weld square tube steel between them. Maybe the techno tubing set adds rigidity by some other means. I agree. If I can find the time, I will use the OEM bushing cap as a template to stencil from. Il use 14 gauge to transfer the template to, which will act as the "rib" for the bushing cap. Il find a pipe with a similar radius and hammer 18-gauge steel over it to make the radius. Then il tack the 18 gauge on one side (perpendicular to the 14 gauge ribs) and hammer the finished curvature in place, then weld them up. Once the caps are done, il weld rectangular or square tube steel between the two. Wont need to be that thick. 1.5-2" should do the trick. I just bought a fish-hook type scale so im going to start documenting the weight of some of these components.

-

Hey thanks! honestly, i did not know about this! I don't think it was available in 2003 when I built my 71' L28et. On that car, the torque eventually wore-out the bottom differential mount (thanks to constantly pulling "up" on it). At that time, I was only aware of the solid bottom mount sold by MSA, which is what is still on that car. This is a much better solution since it retains a bushing of some type, and actually resists the upward torque reaction with compressive force, vs. tension. A few questions: 1) You have used only the top mount for 12 years? So, If I understand correctly, you have a small "gap" between the bottom of your diff and the front transverse link (forward control arm crossmember)? 2) when you speak about creating more space for the exhaust, how do you achieve additional clearance? You would still need a cross member to compress the front control arm bushings, and provide bracing across the tunnel. Would this front mount be replaced with a modified one with a taller clearance? I have raw materials for a 2.75: 304SS exhaust, so I'm certainly interested creating more clearance! the most likely place to bottom-out on my car is the exhaust as it passes the bottom of the diff. I have the tools to fabricate this mount. Really appreciate all the input! -Aydin

-

Thanks for the tips! so I expect my 3.545 Torsen r180 to be here next week, and Fritz's CV shafts arriving next month. The head will be out of the shop in 2 more weeks. She should be back on the road by the end of February. Looking forward to taking my lapses! I hope to get my car low enough to limit as much of the axle-cv angle as possible, as you mentioned. I have already eliminated some low points and cut about 1/2" of clearance. Il have to spend some time at the performance alignment shop tinkering with the coil overs to get the right height. I settled on a 10:1 static CR on the head for now. If I run a 1.75-2mm gasket, I drop down to 9.4, which will allow me to run ITS (thanks to your suggestion). With a prepared block in eventual development, I'm considering domed pistons to achieve the 12:1 needed to compete in EP. I'm really enjoying the process of upgrading the vehicles components strategically, even if its not perfect. I am learning so much about how these cars handle and perform again, I can't wait to test her out. I'm really learning quite a bit from the community. I appreciate all the advice.