AydinZ71

Members-

Posts

1073 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by AydinZ71

-

Plates around bell-housing - racing application

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

While we are on the topic, any recommendations on lightened flywheels for L-series on the market? Fidanza is thicker AL, and I believe others are selling thinner steel units. -

Plates around bell-housing - racing application

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Russ_at_steves is the IG name. Steve’s machine shop. Guys, I may have totally read it wrong LOL. @JMortensen you may be totally right about losing 5lbs, not ending up with 5lbs. I attached a screen shot. That’s what happens when you jump to conclusions. It does seem illogical to cut 75% (vs 25%) of the weight just from turning. -

Plates around bell-housing - racing application

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Speaking of flywheels, my local engine shop turns down L-series flywheels to nearly 5lbs! I am tempted since it would be much cheaper than buying new, but honestly I am not confident they have done the engineering or testing to confirm it will hold-up. I saw three leaving their shop on Instagram. Might be OK for the street, but who knows if anyone has ever put one through its paces. it would be quite dramatic if it failed. -

Plates around bell-housing - racing application

AydinZ71 replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

hey thanks a bunch! Il just get rid of them then. The engine mounting points are OEM. Appreciate it!! -

Absolutely agree with @Mike Mileski. A lot can go wrong and you need to have everything disassembled and on a bench. Suspension is a bad place to cut corners and save some time. I’m not familiar with the BC kit, but most kits out there require very close attention to measurements, alignment, etc. my approach required sectioning my struts which has many pitfalls if rushed. good luck!

-

A musician's therapist (The $300 Z)

AydinZ71 replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

it does add stiffness. Whether it is necessary is the big grey area. The RT mount is really beefy up top (with the vertical flange, but the mounting point is cantilevered and can flex. I had to hit mine with a 2lb sledge a few times to move the tabs in on my car. given the relatively light weight of the crossmember, I plan to use it again with my mount. If I had the time, it would certainly be lighter in tube steel. It’s experiencing mostly tension and compression. Not much bending since the ends are bolted down. A thin-wall tube could do the trick. -

Thanks! Yeah I was a little anxious about the CR and cam timing but it looks like he was going for huge numbers. If I bought it, it would be as an investment as I don’t have a chassis for it at the moment. I would take it to a machine shop to have it looked over (check tolerances). The prices are going crazy and it seems like a good deal.

-

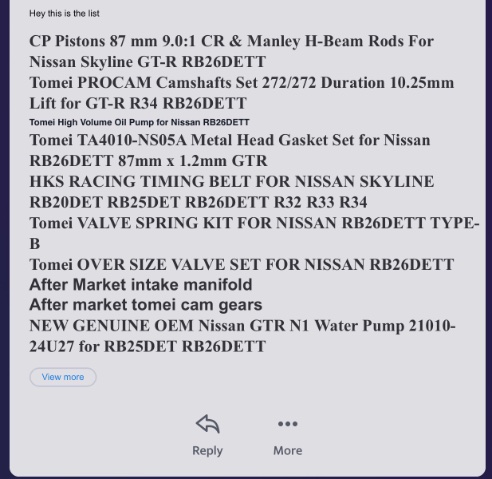

Hi all! Got a line on an RB26 for a future build. Guy went to the nines in parts, but changed his plan. Comes with fuel rail and 1000CC injectors. Complete rebuild with these parts (pic) but never ran. not included in the exhaust manifold. if you were in the market, what would you spend on it? im guessing $8,500?

-

ANOTHER Datsun Z/LS3/T56 Swap Thread

AydinZ71 replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

oh I meant if a muffler and resonator were used in combination. Some websites indicated this was the best overall solution. I can see using a resonator as a muffler in the rear. There aren’t any other recessed areas I can see that could accept the resonator if you already have a muffler in the traditional location. several folks seem to like the resonator as a muffler solution. if used in combination with a performance muffler, that’s probably best-case for noise suppression and performance. -

ANOTHER Datsun Z/LS3/T56 Swap Thread

AydinZ71 replied to Ironhead's topic in S30 Series - 240z, 260z, 280z

im with you! I have been searching and searching for the quietest performance muffler/resonator I can. The best I have done is find some comparison data online. According to one website and a few forums, the Borla XS straight-through mufflers are the best, although 110db at WOT is still pretty damn loud. If you can pair it with a resonator, even better. As was mentioned though, there just isn’t much room under a Z to put both without limiting ride height. -

Adding rigidity while restoring rusted metal

AydinZ71 replied to AydinZ71's topic in Fabrication / Welding

I want to start putting stuff back on the car (finally), starting with the fuel cell. To do that I needed to brace the rear skirt, and add some diffuser mounting tabs when I was at it. The fuel cell is much smaller than the Original gas tank and spare tire well. There is a s lots of room for a tremendous Eddy current to be generated behind the skirt, causing it to flap in the wind and act like a wind catch. IMG_5660.MP4 -

I have a line on a modified, rebuilt Rb26 for about 9k. Just the long block and manifolds, no turbos. I’m seriously considering buying it strictly as an investment 😂 I don’t even have a car for it at the moment.

-

Adding rigidity while restoring rusted metal

AydinZ71 replied to AydinZ71's topic in Fabrication / Welding

Passenger strut tower brace. The other side is mounted to a firewall flange, where the roll cage termites. IMG_5639.MOV -

My machinist strongly suggested the Honda K-series (K24?) for a light weight, reliable, well designed engine for an S30 swap. I’m looking into it... I used to look at larger engines than an L-series. These days I’m looking for smaller engines to compliment other weight reductions.

-

ahhh if the 73 had a pump near the tank, then I was just unaware. I still think you should run a new relay and wire since you don’t know what that amperage that wire was originally designed for. You could try, but you may heat up the wire or burn out the terminal/switch. I found the wiring diagrams from Haynes to be pretty accurate, so you could use that as a reference. Might give you the color of the conductor, and which wires it will be traveling with.

-

Adding rigidity while restoring rusted metal

AydinZ71 replied to AydinZ71's topic in Fabrication / Welding

I used 14 gauge for the bottom flange since it is often used as a lift point. In addition to welding all four sides, I included plug welds along the length so it is attached to the tube as well. one disadvantage of the OEM resistance spot welding is that inaccessible steel surfaces can not be tied together. You end up with a handful of layers laying on top of each other, with only the edges fused. By tying each surface that is nearby, it will act as one ridged body with much less flex -

no. 240z’s utilized a mechanical pump. You will need to install a relay. The trigger signal for the relay needs to come from the “on” signs of your harness. Check the amperage of your fuel pump so you can match it to the relay rating. There are 2 types of fuel pumps for cars: high pressure for EFI (30-60psi), and low pressure for carbs (0-5psi). You want the latter.

-

curious to know what are the best L Series Transmission options now?

AydinZ71 replied to primaz's topic in Drivetrain

🤷🏽♂️ Meh... good point, but if I break the CD00A, I can always get a spare from a junkyard. Plus the L28et I’m running is already so old school, it makes the tranny feel like an iPhone. Are you familiar with a DCT conversion for an L-series motor? -

Adding rigidity while restoring rusted metal

AydinZ71 replied to AydinZ71's topic in Fabrication / Welding

Hey thanks man! I really appreciated. I just picked up welding 6 months ago so I’m glad to see improvement. -

Looking for an L28 block to use as a core. Don’t need the pistons or rods, but crank needs to be in decent shape. I live in Southern California, so something in driving distance preferred. Thank you!

-

Using 5/8 bolt in place of spindle pin

AydinZ71 replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

This makes quite a bit of sense for a racing application. I think even worse is a big differential between the static and dynamic friction. If it takes a lot of force to “break loose” the PU bushing, it will resist suspension travel at low force inputs. Of course, I may be over analyzing this, and suspension forces may dramatically outshine bushing friction. For racing, why not go with bearing brass while you are at it! The surface will harden and self-polish with friction. You can use lithium or graphite lube between the steel bolt/spindle and bearing sleeve. If you really are committed to low friction, you could go with needle bearings, but you would need to watch the maximum tangential pressure. McMaster Carr anyone? -

Using 5/8 bolt in place of spindle pin

AydinZ71 replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

The resistance provided by either case: rubber torsional resistance for OEM & friction resistance from PU bushing riding against the steel sleeve they provide. Do you all think this resistance is necessary/important? Not arguing a point, more out of a curiosity. The resistance will act as a bit of a damper to high frequency vibration, and add a bit of static resistance to suspension travel. -Aydin -

Vors wheels (specifically TR3): opinions?

AydinZ71 replied to Michael's topic in Brakes, Wheels, Suspension and Chassis

Thanks. The Rotas the previous owner purchased for the car is on my street 71', so will not be raced. I'm reassured that they are decent though. I had not even heard of them until this year. I'm looking to use the Diamond Racing wheels that came with my race car for the racing application. The painted finish is failing, but structurally they seem fine.