AydinZ71

Members-

Posts

1073 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by AydinZ71

-

With the VQ37, you will be running what? Near 300ft-lbs of torque? You should make getting an LSD a priority. With that much torque you will just be spinning one wheel. Even with an LSD, keeping traction will be a struggle. You can swap the open diff spider gear with an LSD assembly from MFactory, Kaaz, quaif etc. I believe top-of-the-line is adjustable clutch OS Giken, but I think they are near $2,000. if you want to swap it out entirely and go with something bulletproof, look into “invincible extremes”. He sells parts for swapping in a mustang GT diff, axles, and hubs.

-

Using 5/8 bolt in place of spindle pin

AydinZ71 replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

speaking of stress on the control arms, my transvers link mount (I think that’s what it’s called?) had a cracks diagonal along the curved surface that is in contact with the bushing. Anyone else experience this? I welded it up and ground it flush. The car already had a racing history before I got it. I also had the control arms sandblasted, stitch welded, primed and coated, but I found a pair of apex ones used for a good deal so now they are paperweights. -

Using 5/8 bolt in place of spindle pin

AydinZ71 replied to fusion's topic in Brakes, Wheels, Suspension and Chassis

Yeah I didn’t quite understand the purpose of the spindle lock pin either. I mean, you have bushings in either side. Why can’t the spindle rotate about its axis? Or not rotate. If the ends have locking nuts, what’s gonna happen 🤷🏽♂️ as long as there isn’t play, the control control arm can still rotate bout the spindle, and the thing doesn’t come undone... what can go wrong -

Engine and chassis swap datsun 260z

AydinZ71 replied to jos260z's topic in S30 Series - 240z, 260z, 280z

My next S30 is going to be an all tube frame chassis. I am lucky in that southern California has plenty of donor vehicles for the skin material. I have done so much rust replacement, chassis reinforcement and reconstruction that I'm stuck wondering "what have I not replaced?" There are some talented shops that can make you the tube frame with some key dimensions from a template S30. I plan to design mine on CAD, and construct it myself. I would still consider myself very much a novice amateur, but I am making mistakes and learning everyday! its fun making stuff from scratch. -

Ditching the distributor. Racing application.

AydinZ71 replied to AydinZ71's topic in Ignition and Electrical

I do like how the megajolt uses OEM auxiliary components. That’s a cost saver for sure. I will compare cost with electromotive. Heard of them, but never had direct experience. I used the SDS system for years on the L28et, and really enjoyed how simple it was to tune. An expensive system though, and overkill for a carb only application (as you eluded to). The hall-effect sensor worked flawlessly though, and I installed the magnets in an hour with a drill press and calipers. looks like I’m leaning towards the megajolt so far, with the TPS. According to their literature, My 320 duration will not be stable enough at low RPM for a MAP sensor to advance timing as effectively. thanks for the thoughts! -

Ditching the distributor. Racing application.

AydinZ71 replied to AydinZ71's topic in Ignition and Electrical

I looked into the kameari, but one drawback is the need for a very specific pump/diff shaft. It’s also quite pricey. Il take a look at the microsquirt! Thanks for the feedback! -

I did a bunch of research on this. You made all good points. SCCA does not consider the Braille AGM battery as a “wet cell”, and therefore does not require the non-conductive marine type enclosure when inside the passenger compartment. Braille also describes the battery as being capable of being mounted on its side, so we are good there. I think I am OK, but we’ll see. Appreciate the feedback though!

-

Ditching the distributor. Racing application.

AydinZ71 replied to AydinZ71's topic in Ignition and Electrical

Hey this is interesting! looks like it does what I need it to. It says it needs the ford EDIS module. Can you help explain that a bit for me? Also looks like its intended to receive inputs from separate crank trigger and output to separate coil packs. Any reference which make/model is should look into? -

I highly recommend beehive springs guys. I was able to drop a huge amount of mass per valve, and you can have a smaller diameter & thicker retainer which can remain steel, given how much weight you have saved in the springs. im not sure if anyone makes them off-the-shelf for L-series, but there are several machine shops that can make them custom for you (and retainers). I used Steve’s machine shop in Azusa, CA. while you are there, look into replacing the typical rubber valve seals with one made from better material (Viton, for example). Besides ring wear, these seals are the most likely oil burn source. They will last much longer. speaking with Greg Ira yesterday, he is running beehives as well.

-

Ditching the distributor. Racing application.

AydinZ71 replied to AydinZ71's topic in Ignition and Electrical

your response is appreciated yeah I can add magnets to the dampener (drill press) or a trigger wheel. I doubt the wheel adds enough weight to throw it off-balance. I’m pretty handy, as long as it doesn’t need to be precision machined. I see several on the market, but thought I’d start here and get some feedback from folks with first hand knowledge. I have used the SDS Hall effect sensor for many years on another application, but that is a more sophisticated system than I need just for ignition trigger only (with carbs). -

woops! I said crank when I meant RWHP. 160 at the crank may be possible with bolt-ons alone

-

pretty cool!! I kinda want to be wrong on this 😂. I mean how cool would it be if we could get F20C flow efficiency out of an L24! I don’t even want to ask how much it would cost! 😂😂😂 very impressive though! I will be happy to get a piddly 160 crank HP out of my 10:1CR, .500 lift, 320 duration L24! I will know in a few months still looking for a tuning guru once she is running. So many of the people/shops I knew as a kid are gone...

-

gosh that just boggles the mind! I’m struggling on how an L24 can get much past 250hp NA, and without an oxidizer. I mean, the volumetric efficiency just doesn’t add up. Coupled with the poor flow characteristics of the L-series heads, being a non cross-flow and only 12 valves... are we talking high octane gasoline only, or nitromethane? Methanol? I don’t mean to dispute the claim. I don’t have concrete evidence to say it’s not possible. I would just really like to understand how, since I have never seen a dyno sheet get anywhere close.

-

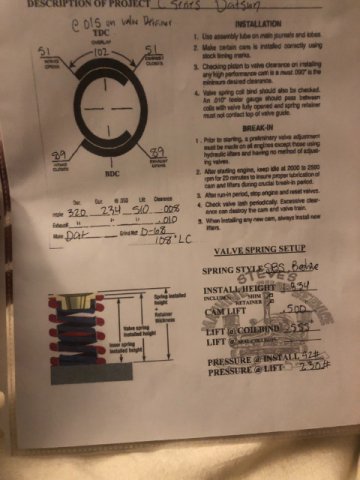

Hey all. I have my head back from the machine shop, and now looking into alternative ignition systems. SCCA is only prohibiting magneto ignition systems for my application, so I would like to ditch my distributor and look into a system utilizing a crank sensor. Hall effect or optical, I’m open. I would like to be able to adjust ignition timing as well. this is for a racing application, and I’m looking to rev around 8000rpm with the head mods I have made: .500 lift, 320 duration, 109 overlap, Same for i & E, bee-give springs and custom retainers. I like the reliability and resolution of distributor-less electronic ignition at the higher RPM’s. any suggestions?

-

Suspension Setup Gurus....help...

AydinZ71 replied to Ironhead's topic in Brakes, Wheels, Suspension and Chassis

+1 on not mixing metals on rotating parts, unless one is intended to be a wear surface (like a bearing), or it’s an activity oiled bearing like the forged cam in the aluminum tower in your head. ME here, but I don’t work in rotating equipment. Mostly process design (oil, gas, and alt. Energy). -

Adding rigidity while restoring rusted metal

AydinZ71 replied to AydinZ71's topic in Fabrication / Welding

Replacing passenger toe panel. Needed to reinforce the area just ahead of the passenger front vertical door Pilar, so I can cut out my rusted frame rail and tie rod box. I’m happy with the results needed this done so I can confidently finish the brake line and fuel line in the tunnel, since it passes the frame rail. Anyone else feel like one thing lead to another... to another... and soon enough it’s 6 months? IMG_5520.MOV -

curious to know what are the best L Series Transmission options now?

AydinZ71 replied to primaz's topic in Drivetrain

I just purchased one of Derek’s CD00A bellhousings through Godzilla Raceworks last week. Going onto an L28et. Hoping they have one in stock. Looking forward to it! -

2+2 Chassis Reinforcement

AydinZ71 replied to Twisted46's topic in Brakes, Wheels, Suspension and Chassis

Some work I did yesterday: IMG_5494.MOV IMG_5493.MOV -

Digital fish scale. 600lbs capacity. Assume +-5% error or to within nearest pound, whichever is greater. R200 open diff, no oil, with cover, no stub axles, including front yoke: 70 R180 from Subaru STI w/ helical LSD, no oil or stub axles, with cover and front yoke: 56 280z halfshafts (drive axles), with diff stub axles attached, left and right: 31 280z front diff mount: 3.1

-

Various weights for S30 OEM and A/M parts

AydinZ71 replied to AydinZ71's topic in Brakes, Wheels, Suspension and Chassis

Oops! Will do now. Admin is invited to delete post. -

Just got My head back from Steve’s Machine Shop in Azusa, CA. Here are some pictures and specs. Looking forward to getting her on and running. - N42 head as a core - exhaust valve and seats fabricated to 35mm to meet OEM L24 diameter (race spec limited ). N42 came with 38mm exhaust valves - chambers debured, ground and polished - valve seats deshrouded and some clearance added to exhaust valve seat. - ports ground to 1” into runner, and port matched to manifold (race spec limited) - deck machined to a volume of 38.5cc - with gasket volume and a piton-deck clearance of -0.35mm, yields a static CR of 10:1. - bee hive springs and custom retainers. - viton valve seals Race cam lift .500 (race spec limited) Specifics in attached photo. excited to get the car put together and break her in.

-

If you are a technical junkie like I am, you will always be gathering specs on various parts and options. I thought I would get a thread going with my own first-hand measurements as I go along. I bought a 600lb fish scale for this purpose. For the sake of argument, let’s say it is accurate to the nearest pound or 5%, whichever is greater. Weights are in pounds (Lbs) R200 open diff, no oil, with cover, no stub axles, including front yoke: 70 R180 from Subaru STI w/ helical LSD, no oil or stub axles, with cover and front yoke: 56 280z halfshafts (drive axles), with diff stub axles attached, left and right: 31lbs 280z front diff mount: 3.1 I will continue to add more to this thread as I gather. -Aydin

-

N42/P90 Head Wanted (Or Running L28et/RB/JZ) **Full Ls Swap Trade**

AydinZ71 replied to OldZNewLife's topic in Parts Wanted

I will have an P90a head in great shape (with hydraulic lifters) available for purchase in April. Off of a running L28et. Might consider new valve oil seals, but otherwise does not require any work. -

sorry friend. 250hp on an NA L24E will cost you $10-15k and will not be enjoyable to drive on the street. 300 is impossible NA without NOS. Adapting a turbo will cost you the same on an L24 as it will on an L28. If you really want those power numbers, consider a modern engine swap, an L28et from a 280zx with bolt-on mods and tuning $4000, or throw $5000 at an NA 280z and turbo it.

.jpg.bfc62d5ebe5c23dfe6f9371e803fa454.jpg)

.jpg.43a83f92a7f4b212cade4bf3047b41a7.jpg)