-

Posts

877 -

Joined

-

Last visited

-

Days Won

47

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by clarkspeed

-

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Well then go for it. It should be a nice car when complete. And dont worry too much about the rules as long as you can reverse things. My tube car is kind of dual purpose in that respect. It could convert to scca gt3 if desired. And I usually tidy things up before I sell because it is worth more if it can be raced in many organizations. Cool, do your enging tuning on the street if able. That can save a lot of time. Of I were starting from 0, I would go ahead and do a race school. One where they provide the car. It's not cheap, but you will learn more in 3 days than any other way. Most likely you will come away motivated, committed, and understand how a good car should feel. Then you will want to do some hot lapping on a track to sort the car out. Plus you can run with open groups since you had the school. Get some help from an expert on setup if you want to speed that up.. At that point you should have a good idea on what you want to do next to support your new addiction. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

That is why you don't see aluminum tube frame cars or nothing even close. Aluminum space frame with rivets was popular and aluminum honeycomb, and even aluminum adhesive was popular in the 70's into the 80's. Before carbon fiber took it all over. It is very malable and doesn't like point loads. That is when aircraft switch over to titanium. Still a little cost prohibitive for racing except for F1. Plus steel can still get you under most weight limitations up through Trans Am. -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Greg is the Zen master if you want to interpret EP rules. He has been to the tech shed many times. I have personally been there.. Vintage is a little looser for sure. But again there is a gold medallion level and acceptance to Rollex historic in Laguna at the other end. I have seen newer built cars accepted there, but they must be correct. Perhaps a question again, are you going to sell it or race the shit out of it? -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Rule of thumb is use aluminum thickness little less than 2x steel. So equivalent aluminum structure is not so light. But when you are not super critical of structure, like secondary structure, then it becomes super attractive. I can tig steel with my welder but not aluminum. Hopefully upgrade someday. -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

For vintage you want to end up in CP (2.4) Or BP (2.8). 0.40 over max.. That is where they ran back in the day. Many organizations use 1972 scca rules. SVRA has one of the most complete rule books. Engines are fairly unlimited. An EP air dam would not be allowed. Rules enforcement depend on the org. Some are happy to have a lot of cars on track and no one complains, others want parity, and many complain. And even they are welcoming as long as you are not podium. Some will do a displacement check. When I run with SVRA they are critical of obvious things like big brakes and super wide wheels. But I usually run around mid pack. I've even run EFI with no problems. Some groups will let you run with no points, some will bump up a class if you are way outside the rules. Greg's latest car it built to win in that 2.4 CP class I believe. So he is ready for any scrutiny. Vintage is full of cars running much faster than they ever ran in the 70's. I ran against a Jag with twin plug head and 400+ hp. And not unusual to to see 40k Porsche engines with titanium rods and more. And V8 stuff forget about it. Some swap tires before every race.. I think the best answer don't worry until you are running top 5. Then if you want to run at the sharp end, tighten it up. I am usually around top 10 and have a hell of a lot of fun. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

So I decided to re-do the rear suspension again. I am confident the Delrin bearings would be fine, but started thinking they do deteriorate over time. So when I got my little homemade mill running I thought about a simple solution I could replace them with using oillite bearings. I have used these in the past with great results. Slightly more weight, but probably less than 1 lb overall. So I milled out some ears that could be welded to DOM tubing with both a top and bottom weld. Slipped in the 1" ID flanged bearings and done. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

That is interesting. In my old car I had a cage build out of aluminum angle iron. I had a dude where I used to work tig it all up. It was beautiful, strong, and light and dropped right off with 4 bolts. I don't have the luxury of a full weld/fab/machine shop anymore. So steel for now, fast and easy. I may regret it later. -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

That header is gorgeous! I think you would have a hard time doing 2 v-bands with it because of clearance. I think slip on collector with v-band downstream. Plus the collector needs to be a certain distance from the valves for max extraction, which is probably just after the 2 pipes terminate. You can search for it. The stroker for vintage depends on the rules which you will probably break with that crank. If you race as an IMSA GTU, no problem, 3.0 is allowed. Otherwise, you will want an org that does not care about such trivial things. -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Yes all Jon said above. I normally use black button head Allen screws with lock nuts and washer under nut. 10-32 I think or 8's I can't remember. Whatever you do don't tighten too much. Just snug. -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

I just looked for a local plastic and composite retailer. 4x4 will not work, must be 4x8 for the front. Most people that sell that kind of stuff can order any thickness. Start with little oversize on the cut out and slowly work your way down by fitting and sharpie marks. You can trim with a sander, die grinder, or skill saw or all 3. Once you work with it you will want to use the stuff everywhere. Trick with windshield is try to get perfectly smooth transition to metal for least wind resistance. -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Yea, weight is a struggle for me as well. It's hard to tell what is added vs. Subtracted on my hack job. My shell with cage weighed 500lb before I started. When I take it off the stand I will weigh again. I can comment on the Lexan. I always do mine myself. I buy 1/8 generic polycarbonate, I think SCCA requires thicker. Cut it to a pattern little oversize of an old windshield makes it little easier. I trim the edges down until the face is just flush with metal. Spray paint a 2" flat black ring around the inside perimeter. My new process is to drill the mount screws and mount with a little spacer out of vacuum hose to get the right height. Use lock nuts.. Tape up the outside very well to seal to the window frame and tape 3 or 4 inches on the inside. Spray foam insulation around the inside. Trim it along with the inside tape. 1/4 to 1/2 turn on the screws to lock solid. If done correct you can't see anything from outside and about a 1/2 foam filled gap on inside. Polycarbonate is very easy to work with, you can't crack it. I don't think mine has any fancy coatings. As long as you are careful cleaning it with right products and don't get any chemicals on ti, it will last a long time. Not like you are dirt track racing or something. And if you need to bend it 45 or 90 degrees just heat it up carefully. Too hot and it will bubble. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

The radiator will have a serious slant forward. So it looks like the shroud will not be very large. I thought aluminum but it is still open for now. It has to slot into the opening in the Gnose. I gotta get it off the rotisserie and fit the nose to figure it out. I am more worried about getting engine air and oil cooler air. Each side of the shroud I hope? -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

The G-nose came with this crazy body kit I bought. It is exactly 4" wider than stock to match the 2" extended fenders. I decided to do the dam in glass to match what everyone was running back in the day. Like the BSR cars and Frisselle. It needed a few curves here and there that I could not get with pure aluminum fab. And if you have ever seen aluminum air dams, they look little getto. Funny that a lot of people did that back in the day too. My overall idea was to incorporate a lexan lower strip on the bottom that I could adjust up or down to achieve the lowest possible clearance. Lexan is the perfect material for the bottom of an air dam. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

These are some pics on progress with the air dam. I kept looking at this wide body G-Nose trying to figure out a way to create a mold. Then I realized it is a fairly simple shape and if I took a sheet of thin aluminum I could hand roll it to get the correct contour. And even better, it would be a nice smooth finish to pull the final part without much correction. I ended up using 2 sheets riveted together so there is a small crease in the middle. I am smoothing the crease with body filler and rounding the corners so there is a nice smooth transition when I lay the cloth. As you can see I laid a ton of glass for this mold and added big cardboard ribs to make it rigid. I figure I will pull 2 or 3 air dams to start but it will always be available to pull more. I have been working on it on the side while I am trying to finish up other stuff. Dirty work. -

I agree, mechanically, most of the parts last an exceptionally long time, even when abused. L6 engine with efi and all other. But it is a really old car now. Electrical things deteriorate over time. Electro-mechanical wear is an issue and unless preserved in a low humidity environment, corrosion at every connection. 98% of the time it is something simple to fix by troubleshooting with FSM, but sometimes, it will be very difficult to diagnose.

-

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

I laid out the entire electrical system in PowerPoint and put together a bill of material. I will purchase most from Waytek. I highly recommend. But I had a few surplus spare parts I loaded it with for the photo. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

I loaded the switch panel with switches that light whan energized and circuit breakers. -

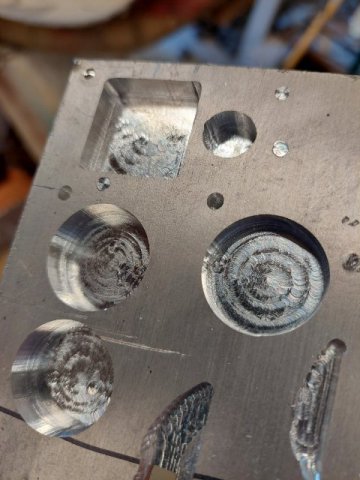

Here are some shots of my test parts. It looks like most of my tolerances are around 0.010". I am starting an upgrade to hopefully bring that in. My goal is at least center drill hole locations within a few thousands. Surface finish can be as good as you want . The pics all all rough cuts without a finishing pass.

-

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Another post. Getting much closer to my current state on the car. These photos show the electrical panel I 3d printed, tabs everywhere to secure wiring, window supports, panel to mount all the electrical components, and a pic of my messy shop. -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Tell me about it. For my build I am trying to do all the work ahead of the spend. I only purchase parts that I need to weld around. My goal is to get to a completion state where I only need to final assemble and wire it up. I have this huge list of parts I will pull the trigger on as soon as I sell my other car. Most of that is shocks, wheels, tires, and gauges. But I am trying not to sell it so I can still race until this one is finished. That cross over point is getting closer. I am still not sure what I am going to do with the motor yet, but I have a few options. -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Yea, I could see 320 duration as giving some vacuum issues. Then again, take my TPS values, they should get you close. Much of the low RPM, Iow load stuff is just to get it cranked easy. I recently purchased a 14point7 system to tie in with my data logger. I have not used it yet, but it was recommended to me buy a reputable tuner. The Innovate stuff is good too, but as in previous posts, goes back to how much data you want to collect and what do you want to collect it with. -

back from the the dead 7/78 s130 ISMA Race car build

clarkspeed replied to frank280zx's topic in S130 Series - 280ZX

Hell yes! -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

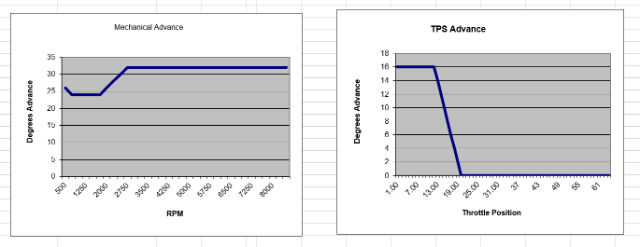

My 2 cents. You will probably learn just as much on the Megasquirt site as any book will give you. It is very extensive. I'm not sure you really need a TPS for ignition, most racers just run RPM (mechanical) advance. But I always liked adding some load advance because it does make things a little smoother on throttle transition and makes it "snappy" at throttle tip in. I would think you generate plenty of vacuum with SU's so a MAP sensor may be better than TPS for load? I don't know. I don't have any vacuum so I must use TPS for load. I run a curve similar to below with my EFI system. Pretty standard stuff, 32 degrees all in a 2750. I played with timing on the dyno and didn't get any real gains. More benefits playing with cam timing. You can convert my tps numbers to a % if you want. Should get you in ball park. Theoretically 12.5:1 is air/fuel for most power. I have always found 12.7-12.8 to work best and that is what I shoot for. Dial it in for full throttle at the dyno, but get a data logging O2 system so you can continue to fine tune it at events. I gradually fine tune low rpm and part throttle stuff over time or if you feel a stumble somewhere. Maybe you will get some better answers than mine. May need to post in L6 forum. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Here are some pics of the fuel cell area. The boxed in rear section was already in the car so I just made the panels to finish it out. I also fabricated a cage that will bolt from the bottom and has a removable top section. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Here are some photos of the body panels as I did a wheel check. These are 15x8 wheels with a 235-50-15 tire. I am planning on running 15x10 so it will be close. I really like this body kit, it is basically stock fenders extended out 2". It came with a cowl induction hood, G-nose, and a whale tail. I will run the G-nose with a custom air dam. I will probably sell the cowl hood. And I may consider the whale tail later.