-

Posts

877 -

Joined

-

Last visited

-

Days Won

47

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by clarkspeed

-

AME complete chassis '77 280Z

clarkspeed replied to lifeprojectZ's topic in S30 Series - 240z, 260z, 280z

Hub centric most likely means then bored the hub true to the lug/wheel diameter. Sometimes custom wheel manufacturers don't take the time to do this. Without the true hub, you need an adapter that bolts up to do the spin balance. -

AME complete chassis '77 280Z

clarkspeed replied to lifeprojectZ's topic in S30 Series - 240z, 260z, 280z

Sorry I did misread your post (with history). I would assume the wheels are still lug centric. -

Shoutout to Z and Universal part vendors!

clarkspeed posted a topic in S30 Series - 240z, 260z, 280z

I'm in the middle of logistical nightmares trying to assemble my race car. Trying not to order too soon so I am wasting capital sitting on the shelf, or ordering too late where I am caught up in a global supply chain freeze up. Shout out to the following suppliers who are solid as a rock. Jdm-car-parts, just ordered a stack of Kameari parts and they arrived quicker than my orders from Summit. Packaged great. Summit, always there, not always cheapest, but always honest on what is in stock and multiple national warehouses. Summit Brand parts usually decent also. Coleman Racing. Easy to work with on custom orders. Amazing customer service and dirt cheap on Americam made race parts. Motorsport Auto, always there for Z community and massive inventory. And last Speedway Motors. My choice for the cheapest race parts when I want the cheapest race part. But I have to be careful with them. The cheapest race part may not be the best choice, eapecially when they brand it. Found that out with 1/4 fasteners and a few others. But pleasantly surprised by some also. There are many others, but these are recent buys that I can attest to. I am not going to go through my most hated list right now. That will be another post. My career is in manufacturing and quality and a general statement that I stand by: Country of origin has no significance. Only the specification it is manufactured to and quality control standards imposed. So thinking about who controls those those parameters goes a long way toward satisfaction. -

Yes weld it unless you have some rule book preventing you from doing so. Then forget about any fatigue issues.

-

AME complete chassis '77 280Z

clarkspeed replied to lifeprojectZ's topic in S30 Series - 240z, 260z, 280z

Hopefully i understand the question correctly. I think you will be fine. The wheels should be self centering with tapered lugs so they only need enough clearance in the middle. It is more important that rear rotor hats (if running them) have a nice spigot fit over the hub centers. Just like the stock drums do. Which is next question, what are you running for rear brakes? Depending on what you slide over the rear hub, you wheel interference may go away. And Forgeline is A1 Top Notch wheel. -

Wheel/tire discussion (carry-over)

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Yes the alternate parts on same line are accepted with no penalty. I did not think he runs a wilwood caliper on EP car that I can remember. It looked like a Maxima setup. EP allows alot of mods, dog ring box, brake upgrades, and EFI. But you have to pay it back in weight. Greg has optimized each of these with the stock parts. And even tested against the upgrades to verify his stock based parts are best. For example, he runs a stock 4 speed because he proved to himself that even the additional weight from a 5speed was not worth it and engine torque curve beat out better ratios. Think about that for a minute. It's funny I can talk about Greg's car freely without giving away any secrets. I've been all over it throughly, and there are none. Just 20 years of development, attention to detail, solid chassis and a damn good driver. If there is a secret, it's his constant experimentation, he is always testing new ideas. So yes your thought process is good. You could even start with stock soild front rotors to get going. And drums with good shoes are fabulous. Just a little more difficult to keep adjusted. Again, put race tires on a car and it becomes a race car with corresponding G forces. -

Wheel/tire discussion (carry-over)

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Oh hell, I have not been on their website in a couple years. Check out DP Racing. They are the only company offering a "small" big brake kit that I know of. They have the right idea. But you can go even beyond this if desired. -

Wheel/tire discussion (carry-over)

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

So I am looking at the GCR production class. If I am reading this correctly, you can substitute brakes for a 2% or 43lb weight penalty. Measured with driver coming off track. If substituted: 1. No more than 4 piston 2. Aluminum caliper 3. Unrestricted rotors as long as they fit inside wheels 4. 2pc hat allowed 5. Rear rotor no larger than front 6. Rear must be solid rotor. Hmmmm. I know Greg would say it is not worth the penalty. But he only runs his car in pursuit of Runoffs trophy and intends to win every race. No regional races. And he can extract the last couple of 10th's out of a lap better than most of us. Something to think about. Would cost alot more up front. Might be able to save a little overall weight. As stated before, probably not stop 1 inch shorter, but could add a ton of consistency. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Here is a shot of the front brakes (For Aydin). Custom hat from Coleman, wide 5 floating adapter, floating T-nuts, and 11.75x0.810 rotor. This will be combined with raidial mount 6 piston Wilwood SL calipers. -

Wheel/tire discussion (carry-over)

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Oh your gonna need to throw everything you can at those EP brakes. Again, best to ask Greg what he runs. I know he struggled for years with pedal feel before he got it right. I would copy his pads and fluid if possible. And make sure you have very good cooling air up front, if pulling from buckets that sould be good, but make sure it exits efficiently. Again you are going to need a very good race pad for "small" EP brakes. Street pads will cook immediately. With those big brake kits, you have alot more options to control the heat. I never put any extra money in the stock based hardware, and I don't think Greg does either. Greg's car did 155 at Daytona and is usually 10mph faster max on every track than my vintage cars. But Greg is a relatively light on brakes. So cheap calipers and rotors on Rock Auto unless he does something I dont know about. Start by Putting the money in the consummables fluid and pads. Weather you autox, track day, race, or endurance race, brakes are just one of those things you should upgrade to the level you need, no more or you are either wasting money ot taking a weight penalty (outside of cooling air, gotta max that first). I know many that run track days in a Z and have to bleed between sessions. As long as they don't go beyond 20 min, no problem. But that is right on the edge, but then again, brake fluid is cheap! If they wanted to upgrade, I would evaluate their system and go just 1 step more. And 1st thing I would check is if cooling air can be improved. Hope this helps, and if something is off, hope someone else will chime in. -

Wheel/tire discussion (carry-over)

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Just my opinion, and you can get many, but the 12.19 x 1.25 rotors (or bigger!) whick is what most big kits go with, are way overkill. My car did 135 to 145 max on track, weighed 2350 total, and I brake really hard. I could not understand why I had such a crappy pedal feel after trying a few different pads. We put temp paint on the rotors and found they never got hot enough for the race pads. Ended up going to a performance street pad which felt much better. The pads lasted forever. The rotors never show any wear but eventually heat crack after too many cycles. All this combined with their huge weight convinced me I had to downsize. Unless you really want your brakes to last over multiple weekends, it's not worth the weight penalty. After driving multiple "vintage" setups I mentioned before, I am convinced I don't want much more for my unlimited car. The weight savings is a noticiable performance improvement. Hell the circle track guys only run 11.75x1.25 rotors and they weigh 3000+. Brakes are really about heat management and pedal feel. It's the sticky tires that stop you. With that said, the IT guys always ran to totally stock set up with drums. If everything is fresh and adjusted correctly, they will pull your eyeballs out, but they need lots of cooling, maintenance, and may only last 1 weekend. They will start boiling fluid when the pads reach 20% wear. PITA. So it's your decision. You might consider running same as the EP car. You may get some quantity breaks, can swap stuff around, and will always have some spares. If you want to go down a different path, I can make some recommendations. And fabbing your own setup is roughly similar in cost as the big kits. Or you could upgrade with Bremo or AP if you really want to go big time. -

Wheel/tire discussion (carry-over)

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

How much do you want to spend? I'm not a fan of the big brake kits, they are way overkill. And depending on organization, the will get you bumped a class. Check the vintage rules, many also require a cast iron caliper. In front I prefer the stock solid rotors with Toyota 12+8 caliper. You can adapt 2nd gen RX7 pads which opens up a cornucopia of choices at a fair price. Cheap pads, calipers, and rotors that work with proper cooling and fluid. The rear you have about the same options as EP including drums. On the rear of the car I just sold, I adapted stock front calipers to the rear using a SAAB solid rotor. They worked great, SUPER cheap, and within the "spirit" of the rules. Calipers are wide so you have to run wheel spacers to keep them out of the wheels. I don't have any restrictions on the tube car other than they fit in the wheels. That is why designed my own setup based on floating 11.75 x 0.810 vented rotors in front. 2 options for rear I have not finalized yet. I have all the measurements and can adapt just about any race rotor/caliper combination if you have something else in mind. Floating rotor mounts, radial mount calipers, etc. I have an old Arizona kit I will probably sell once I prove out my newest design. -

Wheel/tire discussion (carry-over)

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Brakes are a challenge, but those cantilever slicks are the bomb. Roughly 9.5 tread width on a a 7" wide rim. There is nothing else like that. I may end up with them if I can't beat it. But surprising enough, a 245 Hoosier R7 generates very similar lateral g's but with more weight to carry. Greg runs a fairly simple brake setup. He uses the vented disks up front and a Maxima setup in the rear if I am not mistaken. I don't think he does anything special to the rotors, just cheap off the shelf. He does use a VERY high quality pad which is also off the shelf. I think you are only limited by rotor diameter in EP. I may go back and take a look at the rules to see if there are some better options like Cary mentioned. Greg also runs very high quality wheels. Volk or Jongbloed Not sure how much that factors into his success. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Let's get a update in. I had a damn sinus infection which slowed me down for a couple weeks, but I'm still chugging along. After the rear alignment I dropped it off the rotisserie onto jackstands. Spent a couple hours planning out the final welding push up front. I've got to mount a radiator, oil cooler, along with G-nose braces and air dam braces. Along with shroud for radiator and pulling cool air for the engine and brakes. Quite a bit of packaging. The good news is I got the front sway bar all worked out. It was a leap of faith that everything would clear. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Now you tell me!. Just kidding. I have been running this design for years and never noticed it before, but yes adjusters are super sensitive. A full turn is probably over 1" of toe change or more. If I ever make some more rear arms, I will definitely address this. This exercise has been very beneficial so far. I found I had the wrong springs installed, interference with the helper springs, and L/R cambers uneven due to stack height of the hats/bearings. All corrected yesterday. In the end, I have exactly 1mm wider track on passenger side than driver's side, but stub axles are not fully torqued down and that is location of the error. Rear set to 0 camber, 0 toe nominally to start and "centered" to chassis. I am satisfied with the rear. I have another idea that has been baking in my head for a couple years. I want to fab a hub mounted alignment system that also incorporates scales for corner weighting. I don't know why no one had done this before. Heavy duty inline load cells are $50-100 and a digital read out/load cell amplifier/programmer is less than $10. It would need to have a leveling mechanism (laser reference) and ablity to slide a little so camber can be adjusted. Lasers are also super cheap. -

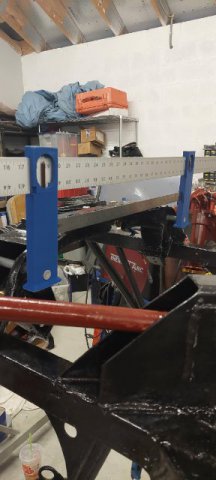

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

I am quite proud of this little tool. I did a dry run tonight and it looks like it works. The 3d printed brackets have pins that slide into the front control arm holes. The 24x1" scale is really just there to keep everything square. The 60x2" scale slides through the brackets and is aligned to center of chassis by the marker pins in the bracket. 23.5 between holes. I installed cast iron rotors on the rear and measure to the rear control arm bolt to adjust control arm length even on both sides with zero camber. Then will use a line laser to the the front scale to set rear toe to zero and verify the left and right CA lengths are the same. That should ensure rear is aligned with chassis and later, much later, I can thrust align front to rear. I'm not sure all this is necessary, but with double adjustable control arms Front and rear, it sure seems easy to get the track and toe uneven left to right and have the chassis tracking sideways. I ran these rear control arms on another car and first thing I found were the lengths were different even though the rod end stick out looked the same. -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

I am dying to know what you are going to do on exterior. But I will patiently wait. -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

Congrats. Spraying the interior of a race car with full cage is extreemly difficult. Nothing like an exterior body panel. Thats why many powder coat whole chassis now. I remember changing my safety glasses multiple times from the blow back. And no matter how careful you are, you will always pass the gun over a surface that is 12" too close and generate a run. The cool thing is, if you have full coverage, none of your mistakes will be noticable. Complex surfaces mean mistakes will blend into the background. And it will look spectacular once loaded with equipment. The only thing that makes me crazy on my previous cars was finding a small section of cage or whatever that i missed. Thats an interesting 2 tone split. Dont think i have seen that before. Keep in mind all of those bars near the driver will need padding so it might throw off your feng shui a little. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

No comments on my color choices? Step by step. I have designed a measuring tool that fits to the front crossmember control arm holes. It will allow me to thrust align the rear wheels to the chassis. Then at a later date I will align front with rear and set toe. I spent many a nights thinking about this and studying alignment methods and machines. If both front and rear control arms have adjustable toe and adjustable length, and you want symetric, then there is no fixed reference other than suspension pick up points. I will post pics when available. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Yes, you are correct. There is friction present. It takes maybe 3-4 oz pull to make them move in my estimation. I could measure but it will not help me. I think over time it will be less. But main thing is there is no change with velocity. It took a lot of pumping to get all the oil out. I made a design for a bearing loaded strut tube with a HD strut shaft (low friction). I would cost maybe $100/corner. I decided I would postpone because this is cheaper and I need to proove the concept. -

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

Slow progress. Close to finishing up the rear suspension. I keep finding things I need to clean and paint. But it is getting there. I suppose its time for the big reveal. Based on Cary's sugggestion, I am going with an external shock. Not sure I can get away with it, but its easily reversable. It was surprisingly easy to do. I used adjustable shock brackets from AA Manufacturing with a some angle iron for strength. Even easier in the front to connect to tubing. I used 1/2 threaded rod with rod ends to mock it up. I 3d printed a shock body to make sure there was clearance. I took a set of cheap Toyota MR2 struts and drilled a little hole in the bottom to drain out the oil. They are loaded in the strut tubes just for keeping geometry, no friction. The only tricky part is the motion ratio is different than the strut. Right now I am thinking Penske 7500's for the shock. They are reasonably priced, come custom valved to my parameters, have multiple lengths, and are double adjustable. -

AME complete chassis '77 280Z

clarkspeed replied to lifeprojectZ's topic in S30 Series - 240z, 260z, 280z

With those giant rotors, you will not generate very much heat into the pad (relative of course). The Wilwood pads are surprisingly excellent for that application in street or track duty. -

240z SCCA vintage race car, restoration

clarkspeed replied to AydinZ71's topic in S30 Series - 240z, 260z, 280z

That's a creative idea for the windshield. I always cut oversize to a template I have and then work it back down with a sander. If I ever mess that up, I will copy you for sure. If there is 1 thing I learned building the tube car, it's adapting what you have to what you need. Try your best to mount it flush with surrounding metal. Which it looks like you side panels do that. If you can, try to get the window to have a smooth transition onto the roof. Depending on what you end up with, maybe some caulk or rtv to smooth it. -

I try to keep up with damper technology as it has been developing rapidly over the last 10 years or so. Basically what was F1 technology 10 years ago is now available to the public. Most high end dampers still rely on some way of controlling a fluid with valves, orifices, tubes or sleeves with special features to control extreme forces. The highest end are infinitely adjustable, consistent, and repeatable over long distances. Active and semi-active systems are often banned in motorsports and are just now becoming more popular. Most modern sports cars have semi-active dampers that can be programmed for various effects and conditions. Corvettes have a very highly developed version of this. A suspension "master" spends countless hours developing the few programs that end up in the production version, up to and including sending test teams with 100's of tires to the Nuremberg Ring each year. Now that technology is available to the aftermarket. There are a few providers out there but I was really intrigued with these guys in Netherlands. https://tractivesuspension.com/ They sell a fully programmable stand alone strut with g force sensors that can be adapted to many platforms. What really shocked me was the price. $6-7000 for a full package. I know that seems expensive, but compared to high end struts (check out Motion Control strut prices) this is a total bargain. They can be programmed to fully control stiffness, roll, dive, and squat so no roll bars needed. Imagine 30+ year old car that is fully comfortable on the street, yet capable of setting lap records with a program change. Pretty much like a new Porsche or Corvette.

-

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

It's funny when you talk about painting a car, most everyone thinks about the physical act of spraying it. When it comes to bodywork, spraying is equivalent to the last 5 minutes in the history of the universe.