-

Posts

3202 -

Joined

-

Last visited

-

Days Won

18

Gollum last won the day on June 2 2025

Gollum had the most liked content!

About Gollum

- Birthday 07/07/1987

Contact Methods

-

AIM

gollumthesage

Profile Information

-

Gender

Male

-

Location

New Boston, NH

Recent Profile Visitors

17741 profile views

Gollum's Achievements

-

No doubt it will fit, but feels like a huge milestone. Still posting on youtube weekly and hope to get to installing this driveshaft asap. I was very concerned about the cost of a shaft with a splined mid section, but came out to a very reasonable $647.02. Granted, I guess when you only paid $800 for the engine and $800 for the transmission, that seems like a lot. But this is also one of the main custom pieces not off the shelf available nor that I can make, so I'm happy it wasn't more than $1k.

-

My K swap isn't done yet, but under 4k isn't impossible if you score the right deals. Done with a "lazy wallet" 6k is overspending but not impossible. Go price out JUST a TR6060 locally, or a new T56 Magnum + flywheel, clutch, etc. Doing a RWD K swap is definitely more work than a LS swap, even if you had off the shelf mounts. Tuning the ECU isn't open source/cheap like it can be with the GM stuff. You have to do something about the intake manifold which can cascade into other choices. There's less documentation about exhaust manifolds/headers that fit. By contrast, you can buy a truck LS for $800-1200 depending on what gen you want, and toss an auto box behind it, and have a whole swap done for under $3k if you're pinching pennies, and most of the parts "just work" or at least are known quantities. Much less time fiddling solutions together. But you want a manual transmission, right? The only budget LS option is Muncie 4 speed, which I'd argue isn't a terrible idea. When I pulled the trigger on doing K24, the cheapest TR6060 within a day's drive of me was over 3k. The cheapest T56's in "ran good in my 250k mile F body" that have been passed around like a peace pipe, was still over $2500. I've seen some deals since, but I was hunting for 4 months with NOTHING interesting enough in price to jump on. By contrast there's SEVERAL AP1 transmissions I've seen go for under $1k. The AP2 transmissions are going for more, but there's little documented about them that's definitely better/stronger, and the ratios aren't much different if I'm honest. The transmission is really what kills the LS as a comparable swap to proper "budget" swaps. If you're fine with a 4 speed, sure it's a great budget option. But realistically I think I'd rather have a VQ35DE with CD009 than a LS3 with a Muncie, and I don't love the VQ. Now as for power. It depends on what you want to do. A K series should be nearly 200whp stock if we assuming you've got a decent base tune with basic bolt-ons (needed as part of the swap anyway). Even if we under rate that and say 180whp... that's still what a stock L28ET puts out, and that's a fun car still. By contrast, a LS3 or similar Gen4 6.2 LSx with JUST A CAM, is going to be potentially a 450+whp car. The stickiest tires that fit under a stock fender well are still going to be easy to overpower at will. So unless you do a bit of work with throttle tuning and/or enjoy babying the throttle, you're going to find yourself eating through tires, and depending on experience maybe investing in diapers. The latter is what leads many to the escalation path of upsizing tires and adding flares. Well now with a 315+ rear tire you're bound to start breaking driveline parts (like stub axles). So now you're looking at rear end swaps with beefier axle options. But of course it's going to understeer like a pig, so you also have to start working on the front. And will all this escalation you're going to add bigger brakes right? Before you know it, you've got a 2800+lb Z car, and yes, it's FAST. But is that what you were setting out to build? For me, that's not what I'm after. Before K swapping, my L28ET powered 280Z was at 2280lbs, and I hope to get as close to 2k as I can eventually. I want as raw and connected of a street driving experience as I can get. I don't want/need the ability to do burnouts in 3rd gear. I want the limit of my vehicle to remain attainable and the overall street driving manners to be fun, not terrifying. Once could always add a turbo to the K series though. No reason an unopened K24 don't do 450whp same as a NA LS...

-

Gollum started following Manimal's Honda K24 Swap 260z

-

A musician's therapist (The $300 Z)

Gollum replied to Zetsaz's topic in S30 Series - 240z, 260z, 280z

If I was going to buy an off the shelf kit, that's what I'd get. And as most spec miata guys will tell you, compound matters far more than just about anything. And for autox (read: not long periods of repeating heat ups back to back), thermal mass is almost irrelevant. Most people's perceived "weak braking" is lack of pressure at the pad and/or poor bad choice. And in that regard, the Micro BBK gives you in practice more than double the usable thermal mass, and also much better pad options. All in all I'll be waiting to hear your thoughts once some miles are put on them. -

Just updating for others, I reached out and Tom said it's sold.

-

In case anyone's not paying attention, I'm up to Episode 5 published now. And in the backlog to be released weekly, the engine mounts are done, and I'm working on the transmission mount. I've got my digital whiteboard forming and will transfer to a common cardboard punch list soon. Definitely making progress!

-

The plan is to gusset the 1.5" tube on multiple planes so that the plate isn't supporting the weight just around the diameter of the tube. Depending on how I feel about it I might do more to reinforce it, even maybe boxing sections in.

-

Not the most impressive thing. But officially marks being further along than I was with the Ford. Somehow that marker makes this feel far more "real" of a swap now. Like, I can get any engine and just put it into the engine bay. But actually having a mount made? That's something. Also, I'll be posted progress as I go on Youtube. Not trying to make some huge successful channel, just attempting to catalog what I'm doing and share some of the info and kinds of info I wished I could find more easily in the past. Sections of the swap and work on the car will be broken down into sections with their own playlist and grouping of episodes.

-

No pictures, but got the driver's side plate made for the engine mounts. Kind of "fun" since each bolt is on a different plane, but just takes some fiddling around. I ended up moving the engine towards the drivers side to generate more clearance for the exhaust. This whole powertrain is so much more lithe than the Ford engine it's comical, so it appears as though I should be able to keep the engine/trans parallel to the diff even with the offset. And since there's only the intake on the driver's side, clearance on that side so far looks great. I'm not even close to anything touching the steering.

-

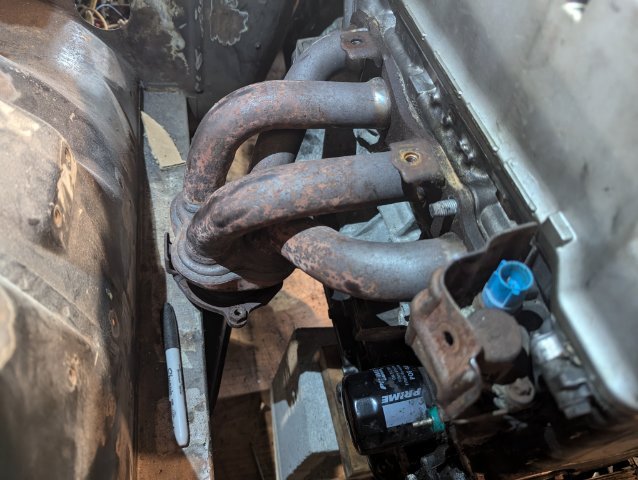

Well it's far from exactly where it needs to be, but getting a picture for how it will fit and come together. SEMA ready! But in all seriousness, plenty of room for the rear sensors and water neck + cap Hood should clear by a mile in this position (since the center sits fairly proud of the inner fender seam). I think this would leave enough space for pulling the pan without pulling the engine as well as plenty of space for getting belts on. I thought for sure this would sit further forward leaving so much room behind the engine at the firewall. So, that leads us to the real challenge, making the OEM exhaust manifold fit: Now, I already planned on putting a v-band on that so the OEM bracket can come off anyway. So I'll need to take some measurements of the ID/OD at various points, and see if I'd have to put on a 4" v-band then maybe transition to a neck down to a 3" to get it cut far enough up to work. Alternatively I could cut the runners up by the head and add some angle up there (could just cut them 90% through, close the gap and weld them easily enough). This would definitely tuck the manifold in closer to the block, though either way there's still the planned cutting at the other end for a v-band. Just might give me more room and options. And in all that, I need to also figure out fitting the mounts around the manifolds. The intake side should be "easy" because the manifold doesn't want to occupy the same space as the mount, but the steering shaft does. So there's that. I might mock up the intake manifold this weekend simply for some aesthetic motivation. Edit: Oh, and the oil pan is sitting about 3/4" below the cross member. Still well above where the floors sit, but I have the space. Might be worth it raising the whole thing up that much since I have that clearance (and more) above the transmission currently. Won't entirely solve the exhaust manifold fitment, but might make it a touch better.

-

Engine + Transmission Also added from the previous minimum weight of the engine is an aftermarket aluminum rear coolant housing. Edit: Also includes adding the starter back in since it helps hold the adapter plate on. Not including: - Flywheel - Clutch - Intake Manifold - Exhaust Manifold - Alternator - PS/AC

-

No updates, sorry y'all. Dealt with the passing of my father (unexpected) this June. So spent a month away which as many might know doesn't just kill momentum but also motivation. I'll be back at it eventually, but might not get back in the garage until later this autumn.

-

Got my AP1 trans on the scale. Didn't zero tare weight but that's sub 0.5lb from my previous measurements. Weight is wet, with shifter. 104.87 or call it 104 if you want to over-weigh the strap. These only take a very small amount of fluid, so very similar dry vs wet weight (1.4qt iirc off the top of my head)

-

Another reference. This took me a while as two of my flex plate bolts weren't happy to be removed from their home.

-

This is fantastic information. I also need to get some dowels but I have that information assuming it's correct: Dowel Pins 4x 15.25mm (Length) x 12.70mm (Diameter) And yeah, I ordered the upper coolant housing version that had the fill neck. I don't have a hood latch, so I wasn't worried about colliding there. As far as mounts, my factory perches are already cut off anyway. And I also already have metal materials and bushings from the Ford swap attempt that I plan to reuse. Luckily mounting is a small piece of the time pie, so it's not a huge expenditure. I wasn't sure yet on a swivel neck housing for the t-stat, and I wasn't sure I liked the idea of tossing parts at something when the OEM parts might work. And yeah, I'm definitely keeping the internal tstat bypass. I'm aware of how bad that would be to entirely eliminate for the pump life, though my research suggests it's probably better to cap off my heater line (since I won't be running a heater) versus routing that in as a second internal bypass. I'm also not adverse to hammering/cutting the transmission tunnel. I already have the reinforcement box that the stock ears are welded to. I'm also not adverse to having the oil pan a touch under the stock L series location, as the stock L series pan actually sits ABOVE the bottom of the floor pan and the lowest point of the radiator from factory. I don't plan to drag the oil pan, but I do plan to eventually build a belly pan and expect to run my engine as low as I can realistically get to that pan. Sounds like your clutch setup will be pretty trick and I'm sure it'll be wonderful. I'm rolling the dice, and going with the ebay xtd option. It might be crap. We'll see. In other news, some goodies have arrived: The MAP sensor on the TB was damaged in shipping, but not a huge deal since I wasn't planning on using it anyway. Intake came with K2F intake adapter and hardware and all looks to be in good shape. Now to just get my two stuck flex plate bolts out (it's been fun). Then I can get manifolds attached and lay the engine in for initial look of how things will lay out. Then onto transmission fitting and planning out the engine mounts.

-

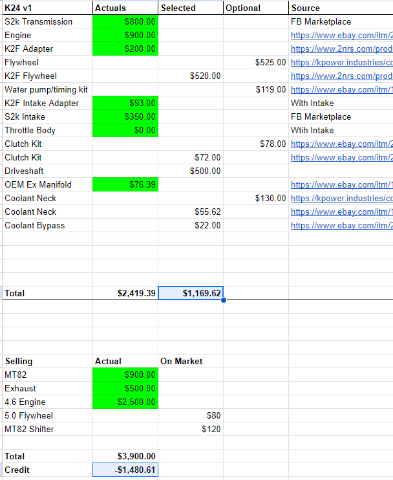

Also just for openness, this is my current budget states. Intake an exhaust manifolds are en route. A had a lofty soft goal of doing the swap for $4k or less. Still unlikely. But not impossible.