All Activity

- Today

-

Hello, @nixkarz, it looks like you got it figured out and are good to go. If you are still experiencing any issues/problems, please feel free to shoot me a Message and I'll help you get it sorted. Thanks.

-

I know how to close the ads 😄. And I don't expect entirely ad free. I do as a user don't want 80% ads though. And agreed there is cost involved, not doubting any of that. There is no such thing as a free lunch as they say. Guess we are all constant problem solvers 🤔. My only thought isn't so much from a how do I block ads, but I know hybridz gets referenced all the time on Facebook groups and Reddit. If I was a new user and didn't happen to have adblock setup, I definitely wouldn't sign up because nothing looked legit. My .02, appreciate y'all listening and I'll go back to my own problems 🤣

- Yesterday

-

nixkarz joined the community

-

Hi, my username is nixcars, the email used for this account is nixcars@exemail.com.au but I'm having problems logging in, I tried the "forgot password" link but I'm not getting a reply email to change it... Plz help!

-

Tap the arrow on the drop down ad and it will collapse. Then just scroll down. I too lament how prevalent ads are on the internet these days, but Dan has to pay for the server somehow. I like the membership idea. The merch campaigns always bring in a ton of money, but that takes a lot of work from whoever is organizing it.

-

You might want to add some reinforcement to that trans mount. I know it's thick metal, but all the force is going through the weakest axis of the metal with the way you've got it.

-

john4 joined the community

-

Not a bad idea. The 370Z forum shut down a few months ago, would drum up more traffic here.

-

03-03-2026 ATLAS Z UPDATE: Fuel system. I got 90% of it done. I just need some parts to finish. Evil Energy equipment. I love this stuff.

- Last week

-

I honestly don't know if we've ever tried anything like that; but it certainly sounds worth considering. I'm relatively new to the Admin group, so I'm happy to kick it up the chain of command for their consideration. Thanks for the suggestion! 👍

-

Thanks jhm — appreciate the honest response, and totally understand the bind. Obviously, I'm shooting in the dark here. I don't know the traffic, active users, new users etc. Firstly: you are correct, ad block exists. I could do something like that for mobile too just like desktop versions. Out of curiosity, has there ever been any thought toward a paid ad-free tier? Honestly, if it was under $5-10 a month I'd sign up today, I pay $9 a month to Skooler.com, I've used it once, but have never bothered to cancel the membership. Feels like there might be others who'd rather pay a small amount than fight the ads, not a one time donation, but an a subscription and a badge. Are the ads currently through something like AdSense, or do you have any direct vendor relationships? I can't help but notice a Ford Mustang dealership ad on a 280ZX forum and wonder if there's a more Z-relevant way to fill that space. Not trying to armchair quarterback, just genuinely want to see this place thrive. Self Acknowledgment: these things could have been tried during my time away and that is on me.

-

kenny_b started following Needs 370Z and Nissan Z (current) sections

-

- 1 reply

-

- 1

-

-

Glad to have you back....sorry about the ads. You are correct in your assumption that they're necessary for the revenue they bring in. Member donations have steeply dropped off the last few years; so the forum ads are a necessary evil, but maybe your web browser's inherent capabilities to control/block pop-ups, etc. can help. Best,

-

tfreer85 started following Login Reminder / and Ads

-

Been a member here since 2004. I miss the old days spending hours upon hours here actively reading. Got the email "hey you haven't logged in for a while". Happily reset the password to see what's been going on. Was low-key excited to be back. Immediate disappointment: Most of my screen is ads. Not just static ads, not just ads inline, ads that actively are fighting me using the site. Common bitch? Probably. Way to make money to keep the site alive? Most likely. I get ads are a guarantee these days, but the site is borderline unusable on mobile because of it.

-

Flowmaster "50-series big block" mufflers for quiet exhaust?

Brad-ManQ45 replied to Michael's topic in Exhaust

Unless you are running high compression, I'd look elsewhere. These chambered mufflers rely on pressure waves to cancel sound. Lower compression = less sound cancellation. I had a Flowmaster put on my '83ZXT against my wishes by the local Z shop back in '95 when I had to replace my turbo with a bigger one and had a 3" mandrel bent system with cat put in - because the owner had one in his DYNOED 600 HP 280ZX. I drove it home to try it not expecting much and it DRONED at set speed and was loud. I was back the next day and had them put in a DynoMax Ultra Flo center in/out oval canister muffler. Not only was it a bit quieter, it didn't drone and the car even spooled up quicker. The owner humbly said he'd learned something from a computer nerd. -

-

03-01-2026 ATLAS Z UPDATE: Switched gears a bit, I decided to take a break from the trans tunnel and work on small stuff that has been waiting. I pulled out the 4" X 4" aluminum L backet plate I had, and measured and cut it to fit in front of the radiator, then cut out a portion to keep from inhibiting air flow to the intercooler! After I got that installed, I grabbed all the oil fittings and oil lines, and ran the oil line frm the filter boss to port#4 to help oil the 4,5,6 cylinder main bearings a bit, ran the turbo supply line and turbo drain line and installed everything, about 95% done on that. Then I installed the oil catch can and line and will go back and tie the line up later and finish the loop on the top fitting for that. Yeah I know it's gold....it what he had left....I will probably paint it blue. Before calling it a day, I mounted my electrical panel plate to the passenger floor plate or as Skillard calls it a heel plate. Then I just plain old ran out of daylight. PICS

-

02-28-2026 ATLAS Z UPDATE: I repainted the interior trim that goes behind the headliner with the landau Black SEM interior paint again and it looks like new, then I went around with some Locktite 567 and thread sealed the water, oil and boost sensors and ran them in and tightened them up...wiped off the excess..Then I started on the bracket for my gas pedal. There are 3 bolts above the gas pedal I will use to hold the bracket, and I am using 1/4" thick steel to hold it firm. It will need to be welded. Then the big job of hte day, then the trans tunnel isntall. Several trips of putting it in, deciding what to do, and then cutting strips of 18 ga. sheet metal, drilling holes, and self tapping TEK screwing it together. I have it about 90% done. I did it so that the majority was done before it was permanently installed in the car....that way I could cut off the screws and give it a last touch up of paint. I started running out of equipment and parts and had to do a couple other small things before stopping, taking a shower and running to the hardware store before they closed.... to God willing do more on it tomorrow. PICS:

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Cleaned up the block, got it primed and painted this weekend. Replacing pan and timing over, will paint timing when it gets in. Now I can get new parts on the engine, I’ll start with swapping the cam next weekend. Also ordered the TKX transmission should be here this week. -

For the folks running lower-rpm, higher displacement naturally aspirated engines (say, 400 cubic inch and above), what have been your strategy to get reasonably quiet exhaust that isn't too restrictive? I stumbled across Flowmaster's purportedly quietest series of mufflers: https://www.flowmastermufflers.com/products/exhaust/mufflers/street_chambered_mufflers/50_series_big_block/ . These would, coincidently, go behind a big block (Chevy). Muffler size isn't an issue, since my fuel tank is removed (S30) and there's a fuel cell in the hatchback area. My question is about simultaneously quieting the exhaust and keeping backpressure to a minimum. This would be dual exhaust, of course, with a conventional crossover pipe, and headers (for the moment, block huggers).

-

Greenblurr93 joined the community

-

Bluewhalez joined the community

-

280z 1jz track build from a pile of parts

flatout replied to flatout's topic in S30 Series - 240z, 260z, 280z

I have been way to damn busy last two weeks so haven't gotten much done. I did get to borrow a set of seats I thought I wanted, but they just really don't fit. being a full containment seat they basically stick out the window. I was also pretty disappointed with the quality. My buddy had these for one season in a drift car that lives mostly in a trailer or garage and they were already real faded from the sun and had plenty of little rips and tears after just one season. I ended up buying a set of kirkey intermediate road race seats. I have one of these in my other car and have put 100k street miles on it so figured id be happy with another set. I may add some head support pieces but for now I'm happy with them. Also think I got my wheel picked out. little teaser for now until I can get some tires and sit this thing on the ground -

I just posted this to ZCAR: “Receiving periodic/automatic emails that say: ‘Come back, we’ve missed you!’ Sometimes life gets busy enough that I forget to login. I appreciate getting occasional emails reminding me of this great resource. I also think it helps keep the involvement up in the forum. Excellent idea. Thank you.”

-

Jim James joined the community

-

The wheels I want for my 260Z happen to be 16" x 8" with 225/50-16 tires. I'm told they would fit with the CORRECT offset. Anyone know what that might be? Nick

-

02-26-2026 ATLAS Z UPDATE: Today I got my rollbar and rear strut brace back from the powdercoater as well as the tunnel I dropped off to sandblast. The rubber is still on there, but this yucky sticky layer of honey look goos (glue) is gone. I also picked up my trans mount, he welded it up and added gussets on both sides out of 1/4" plate. I painted the back side quickly before I ran out of paint. Ready for the next day in the garage! P.S. self tapping screws and sheet metal (18 ga) here and ready to built it back, then the welder will stitch weld it and weld the plates over the top and over on both sides to the door jambs. 1/4" thick, 4 inch wide plate. Car will be overbuilt int his area like I did with the radiator support. 350-400 horsepower you really have to, even with the reinforced floor I have.

- Earlier

-

Mitchel0407 started following Exposed's 1jz Build

-

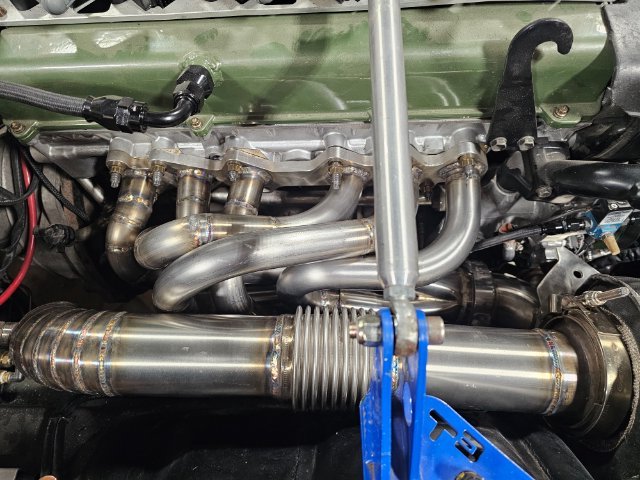

incrdibly nice work. Keep it up! can't see the flange on the turbo header....you hid it!

-

this is very cool, I will be following along. Love the custom work. I am doing a 1jz swap myself at the moment so nice to see another with another person fab ideas

-

-

Who's Online 2 Members, 0 Anonymous, 1282 Guests (See full list)