All Activity

- Past hour

-

12-03-2025: Very rarely do I see things for Datsun's that are more than what I expected, particularly with fiberglass parts. Today my roll pan came in from Hot Hod Chop Suey. The pics tell it all. The quality is easily 10 times better than I expected. It was packaged so well it took me quite a while to get it out of all of the wrapping. Ken, the owner, not only made it for me with a special change, .....eliminating the exhaust cutout, but also fitted it to a car he had to make sure it fit correctly. The threads embedded in the fiberglass are clean and everything is just perfect. So, when it comes to Ken at Hot Rod Chop Suey, take it from me, you can buy with confidence.

- Today

-

New All Aluminum Body Panels of Datsun240Z manufactured in Japan

DuffyMahoney replied to toolman's topic in Body Kits & Paint

Thanks for posting, pretty amazing sheet metal work. -

A COMPLETE EARLY MODEL 240Z BODY may be available soon

DuffyMahoney replied to toolman's topic in Body Kits & Paint

They make bronco bodies, and a bunch of people have complained about how crappy they actually are. Fit, overall shape, poor paint etc.. I guess still better then a rusted out junk car. - Yesterday

-

Junbug joined the community

-

Help PCM no ground injectors-LT1

Junbug replied to love-my-V8-280Z's topic in Gen I & II Chevy V8 Tech Board

Hey guys/gals im hvn the same issue with a 95 TA-LT1... no ground signal at injectors. Customer has already changed: optispark,ignition switch,and has a vats bypass module installed. -

Next I need to pull my current engine as I need the oil pan from it along with the new timing chain guilds and oil pump and everything else. Thats new from when i built it a year or so ago. With it being a front sump I'm going to look into adding some oil baffling of some sort. I cant remember if there is any. Need to button up my 4n71b Jatco from the 84 300zx turbo and finish the inner hub for my adjustable cam gear. But I cant finish that till I pull the old trans as I need the bellhousing. Then I go down the rabbit hole of needing a new driveshaft but also wanting to swap in a 8.8 out of an ford explorer... ..

-

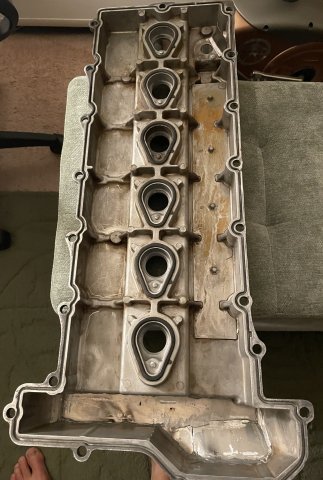

Slowly been chipping away at building this engine. Got all the oil pickup tube mods done. Then used my cnc router to plot out where to drill my block for the cooling mods for JeffP's head gasket. I'm cheap and not using his gasket but modifying a felpro to have all the cooling passages. My router isnt ridged enough to actually machine the holes but it allowed me to do a spot drill for the hole centers. Then came back and use the correct sized drill bits in a hand drill. Then used a die grinder to connect the 2 holes on the oblong holes. Worked well. Some time after that i was working on m wife"s car but wanted to keep going on the engine so I took my heavily carboned up pistons and soaked them in Superclean. DO NOT do this!!!! It eroded my pistons and made them unusable. Talk about a gut punch. The pistons where within spec and perfectly usable. Well I didnt know what I wanted for Christmas But I did after this. My mom and Aunt said they would go in together and get some new ITM's for it and where nice enough to let me have them now. Pressed the old ones off. New ones on. Gapped the rings. And install.

-

The head is an E88 casting which came from a 240z. So, that opening was there for the stock fuel pump already. Though not a desirable head as is, this one has been milled quite a bit to get the combustion chambers to be usable for this engine set up.

-

DJHsuperZ The pics are fantastic of your build. Actually did not take you very long to completion since you purchased the MFactory LSD. The fabrications along the way are really spot on. Great choice on the stubs and axles . Have to say congratulations on a mighty fine build. Enjoy the ride you deserve it. Chip JDMPowerhouse

-

12-01-2025. First day of December. My right side headlight bucket I ordered form Z Car Depot came in, VERY nice part. Also a new set of front and rear side marker lamps. Why restore the old ones when new ones are available and affordable! My new 260Z fender badges should also arrive in the next day or so. Cool stuff.

- Last week

-

A fun z video I just was sent. It has my R35 coil bracket on it and has over a 1/4 million views! How cool is that.

-

Building Another Stroker Engine for the Track

Mitchel0407 replied to inline6's topic in Nissan L6 Forum

I love the look of the spray bar and the use of the stock fuel pump hole! I believe those are blocked from factory for the L28 engines, did you just cut it open? -

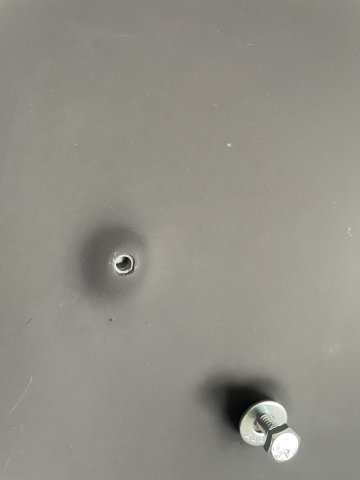

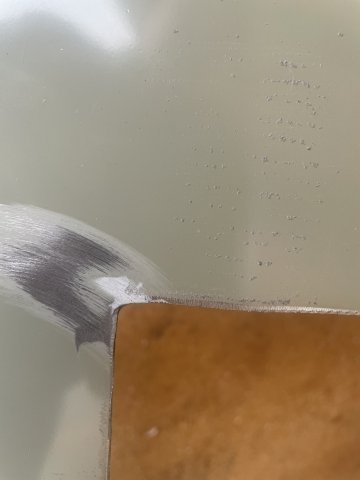

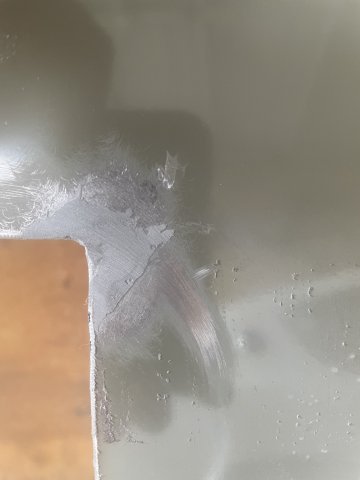

11-30-2025. Weird day for progress. Last day of November and its 15 degrees out . So, it was time to bring stuff inside to work on. My Rage Gold finally showed up, so I can begin the tedious process of making the doors, quarters, roof and tail smooth.....when it gets warmer. A couple corners on the hood had some nicks from cutting it, and I filled them with all metal filler and was able to sand them smooth quickly. All Metal is the only filler that can survive powder coating, so the hood is now ready for its trip to the powder coaters for gloss black just like my new hatch. I brought my valve cover in, as well as my coils, dash vents and dash name plaque. I used my bathtub, and some pine sol, water and an old toothbrush and scrubbed out the valve cover...it was full of dust from the polisher, then scrubbed my coils, fresh air vents from the dash and the dash plaque. 1974.5 is different, the dash vents are very unique, when it became a 280Z the next year the vents have a push pull knob in the center to open close the vent....these are just vents, with no door to open and close them. Since this is a one year car, there can't be many of these setups left........The dash plaque I will attempt to paint the letters etc with a paint pen, but I have no faith at all in my ability to do so. I have shaky hands. Anyway, it was mentioned earlier that the port I added for a catch can wasn't baffled, and that as such, I will just fill my catch can up with oil......so I asked A.I. on Chat GPT about it, and did some thinking, and came up with this.....I cut a piece of sheet metal and bent it and then used some JB weld bonding glue I had in the garage to make a baffle which will allow the pressure out but keep the oil IN. See the pics below. Once dried, it will function fine for keeping my catch can from filling up with liquid, and let the crankcase breathe. PICS:

-

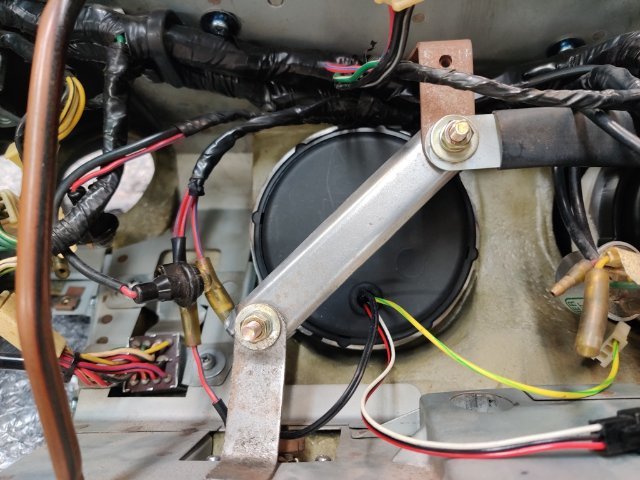

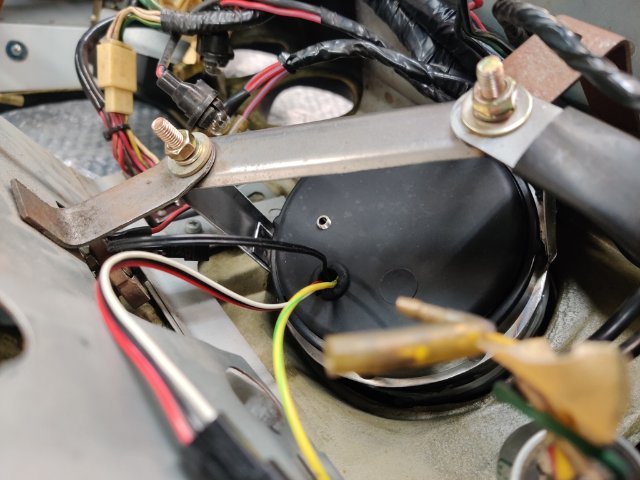

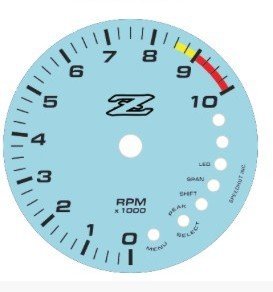

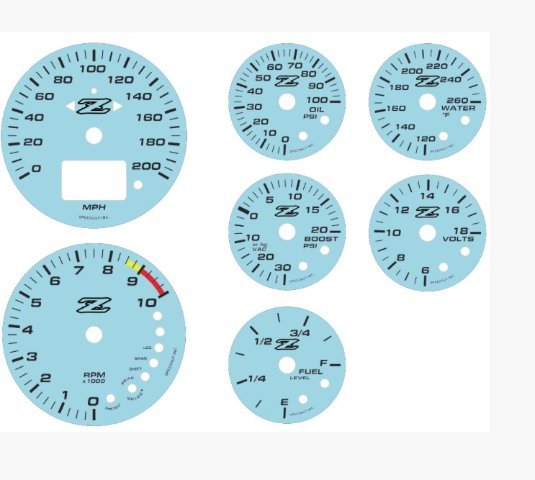

I worked on mounting the gauges a bit more this weekend. Some pics showing what I ended up doing for the tachometer: Basically, I drilled 4 holes through the outside of the modified gauge pod and into a sliver of a pvc pipe end cap. I just cut a section off the cap to make a round ring about 1/4" in thickness. The gauge goes in and seats against the much hacked remainder of the original gauge pod. Then the pvc ring goes in. Then the screws go through the housing into the pvc ring. This locks the gauge in place in the pod. Then the metal frame I made slides on. Then the trim ring that comes with the Speed Hut gauges gets spun on to lock the metal frame in place. I welded some M6 x 1.0 studs onto the metal frames. Backside showing metal frames for the tach and speedometer being secured to the original gauge mounting brackets. I also checked the fitment of the pod gauges. Because the bezels are a little under the size of the dash openings, I decided to buy some 3D printed mounting brackets I found on eBay. They will add a small ring of black trim around the gauge and facilitate a snug fit in the cut outs. They should be here in about a week. For the three center gauges, I chose water temp, oil pressure, and oil temperature, which I will probably install in that order from left to right. I have started looking at the wiring instructions... and comprehending what has to be done to get these functional. That is where I will pick up when I can.

-

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

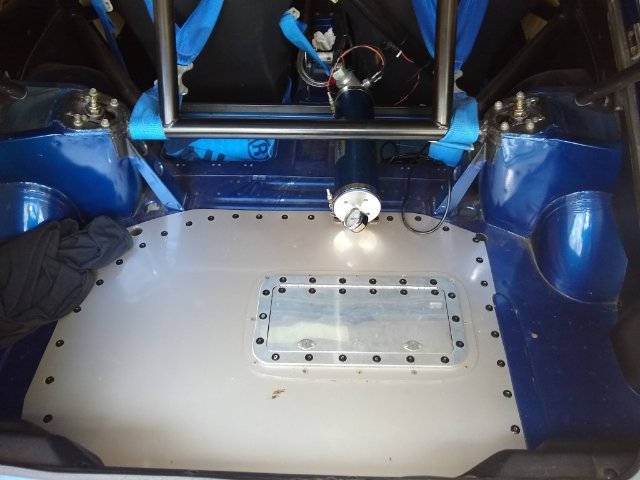

The access panel is to get to the fuel filler neck. I think I got the panel from Allstar Performance. I wish the panel was just a little bigger so that I could remove the filler plate though the opening. The one I have is just a little too small... -

acotyk joined the community

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

I replaced the stock 370Z diff cover with a Nismo one, and got it bolted and torqued to the subframe. -

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

So is the fuel tank recessed below, and that is an access panel for filling? I’ll look into the black box as I’ll be running a fuel return as well. Hadn’t thought of offsetting the tank for balance, thanks. -

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

-

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

I have the ATL 12 gallon cell in mine. I also use the ATL Black Box sump with pump. The fuel return dumps into the top of the Black Box. I can use pretty much every drop of fuel in the cell without fear of starvation. My cell is below the rear deck and offset to the right for weight distribution reasons. You can just see the bottom of the cell in this picture: -

11-28-2025. I started today by sanding out and using some filler glaze on the left headlight bucket, and then sanded down both front fenders. Then I finished scribing out the hole on the hood and cut it. After that, I went ahead and primed and painted the front fenders and the one headlight bucket I currently have. There are 5-6 spots I will have to fix / paint correct, but progress is made. Pics:

-

Area27 in Canada is only 400m above sea level, so I'm not sure that accounts for the lack of nice airflow. I'll def take some stuff off the motor, and see what I can figure out. I'm still very new to the LS platform, so there's lots of learning to be had!

-

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Decided to go with the ATL 12 gallon, just ordered it. It’s 10”. Will need to build a frame for it, should be good little project to practice some more welding. -

Yea Max is still arguing the problems with my doors was due to the amount of bodywork on my car. Yet he always goes silent when I post pictures of the holes being in the wrong place for the latch and pictures of the top ledge being too wide to let the door panel fit over it. Really weird situation but based on how successful his business seems to be doing I would say it's the correct business model to have in these modern times. I'm old and have this quaint idea that you should stand behind your product if you want to have a successful business. He's starting to push back on me posting my well documented problems with his doors and his lack of standing behind his product but based on the fact that the doors are unusable I'm going to get my pound of flesh

-

-

-

I can't tell from the tape what you're doing. Cutting a hole in the center of the hood for clearance? Making the hood into a donut or a U?

-

Who's Online 3 Members, 0 Anonymous, 740 Guests (See full list)