All Activity

- Today

-

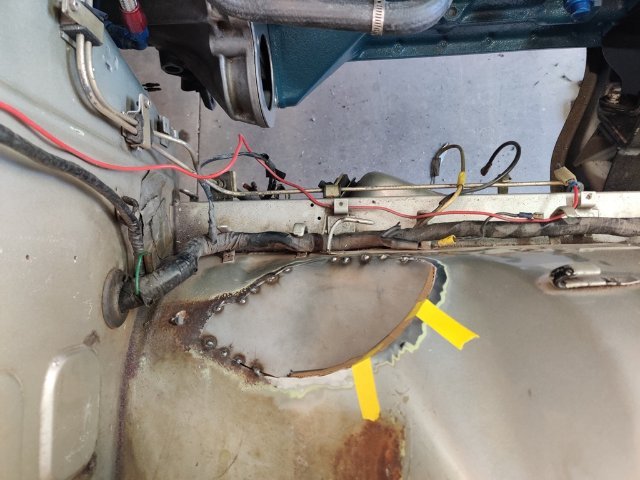

10-15-2025. Busy morning in the garage. My 260Z gave up its engine and trans to make way for a future ATLAS install. And yes, it fought me A LOT. My new Harbor Freight hoist gave out midway through, but I got it to limp along with 2 floor jacks and a neighbor guy to basically wrestle it out. From now on, engine only....no more transmission attached for me. Yep....I cut the firewall bracing. It was my plan to do so anyway, and to reinforce and make it removable. I measured before cutting it and sure enough it widened 1/4 inch after cut. After I have made the brackets for re-installing the piece, I will simply use a ratchet strap to pull it back to the correct distance and bolt it in with grade 8 bolts. All nice and pretty. reinforced with thick plate steel. Inside the tubing I will put a spacer for the bolt to go through so when tightened it will keep the tubing from buckling. We move forward!

-

Thanks jhm. Probably get a lot of mean looks taking such a clean shell and making a hot rod out of it.

-

Nice find! I really lucked out with my late-model 260 as well (similar vintage and condition as yours), and was super happy with the condition of the shell. My current car (early-model 260)....not so much. 🤣 Looking forward to seeing your progress -- best of luck with the build!! 👍👍

-

jhm started following 1974.5 260Z ATLAS build

- Yesterday

-

That's Merle. He still has it. He got it running, and all is well. In the 6 cylinder portion of this webpage is the build of my 4.2. got a good start on the header wrap for the 4200 today. ran out so waiting for more.

-

-

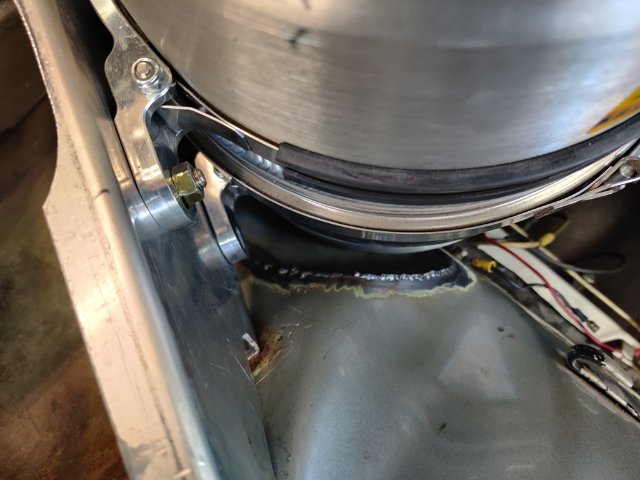

This past weekend I made some more progress. I worked on cutting the right inner wheel house, made two new panels, and welded them into place. I used thin cardboard to make templates for the two replacement panels. After tack welding the lower panel in place, I made the second, upper panel. I checked tire clearance, and then finished welding them in. I think my welding regulator is inaccurate. I was getting some contaminated welds until I bumped the gauge up to 27 psi (I have always used 20). Once I bumped the pressure up, the welds got a lot better. Metal fabrication like this always takes me a long time to do. I am glad this part of the work behind me now. I ordered a remote filter assembly and mount, and a breather tank this week end. They should be here in a few days. Then I should be able to finish up my order for XRP fittings for the entire oil system. I plan to buy the fittings and install them all so I can check/set orientation. Then I will buy some corrugated pool hose for the purposes of mocking up the lines. I will cut it to fit for each hose assembly, and then mark the hose and fittings to "clock" them in the correct orientation. Finally, I will box all of them up and ship them off to have an XRP distributor install Pro Plus Xtreme hoses with crimp on fittings.

- Last week

-

I've been considering the 4200 as well. I'm glad to see another build. I youtuber got all the way to tuning his but gave up after he couldn't get it to idle. It looked sweet though.

-

Ls1 swapped 280zx exhaust issues

nismoluv replied to bajajoas's topic in Gen III & IV Chevy V8Z Tech Board

Today I made more progress. To improve the angle I had to chop off more than I wanted too, and remove the rag joint to get that extra inch. Here is a photo of the unfinished angles. -

-

I have been building my ATLAS 4.2 for a little while now, and I have an AR5 transmission from a 2WD Chevy Colorado truck for it. I found a good deal on this Z car online. 1974.5 260Z. The "Big Bumper" 260Z car. Build date of 10/74.....so it's really a 280Z to me as the drivetrain is going away pronto. I love that it has the thicker sheet metal in the subframe and all those extra bends in the floor, that is more rigidity, and it already has the R200 rear end with the 3:54 gears I wanted to offset my transmission gears and work better with my engines power band. Yesterday I took the front panels off of it, looked the whole car over and I am amazed. No rust in rails, no rust in doors, no rust in fenders, no rust in rear hatch panel. 5 rust locations and somehow the hatch itself on one side is completely missing from rust. I ordered the patch panels needed from KF Vintage JDM except the under battery tray rounded piece, which I got form Z Car Depot. Also ordered a new hatch from Resurrected Classics. So soon, the shell will be completely done. This is a long term project, but at least I have a home for the ATLAS, and finding this Z so rust free has made it an absolute keeper. I am thinking about the Rocket Bunny knockoff kit. 1400 bucks delivered is a good deal. Opinions on that? here are a few pics:

-

This week, I feel like I didn't get nearly as much done is I wanted. I went to a local shop and got an alignment done. I built some low profile ramps to make jacking up the car easier, and it is 100% better. I also gave the car a wash because it was filthy from sitting in the garage for so long. I also drilled out the rusted bolts from the skid plate. I removed the skid plate a couple years ago to fix an oil leak. All the bolts were rusted, so I cut the heads off the bolts just to get the skid plate off. I regret that now, because it was a pain in the butt to drill out all the bolts. Now, I need to go back and tap the holes for some new hardware. I also found some more rust. Both sides of the frame rails where the sway bar attach are pretty bad. I don't remember them being this bad when I first did rust repair. I upgraded to a beefier sway bar about 1,000 miles ago. I also have driven the car pretty hard through corners and turn since upgrading the suspension. I wonder if the new bar and hard driving could have brought some rust I missed to the fore front. I'm not an amazing welder, but I'm also not awful. If I was doing this correctly, I should have removed the sway bar to get more access, but I feel like it's good enough for my standards. I also started soaking the exhaust bolts/nuts in PB blaster because that has to come off next so I can fix the leak. The goal this week is to: finish the exhaust, install the skid plate, more rust repair, and adjust the front suspension to sit better (it is a little high for me right now.)

-

IMSA GTU vintage racer build

clarkspeed replied to clarkspeed's topic in S30 Series - 240z, 260z, 280z

It is just insane how many hours I have put into mounting the hatch. The simple things always take the longest. And I already had brackets fasteners from previous install. Had to fab up my own support strut setup. And I am still fine adjusting the entire thing so someone can remove and install quickly. -

Anyone running a Schneider 270-60F-14? Questions about idle

juggernautjoee replied to juggernautjoee's topic in MegaSquirt

They never gave me an answer to exactly what idle vacuum I should be getting. Just a suggestion to open the lash a bit. I do not have any EGR remnants. I've sealed off the EGR plate and the bottom is plugged. I've bumped up my advance to 25 degrees in the idle range and can get a steady 16in of vacuum now at the same RPM. But obviously that doesn't leave a lot of room for me to advance the ignition through the load ranges. I've got a set of home-made detcans that I've been using to detect pinging/detonation. I advanced the ignition at idle up from 25 and didn't notice any difference of vacuum, but did notice some stumbling around 30 degrees. I can live with the 16in of vacuum at idle if -

Tach is struggling below 2,000rpm

BoostLee replied to Luzifer's topic in S30 Series - 240z, 260z, 280z

I had a lazy tach, and taking it out and disassembling it and cleaning it helped. -

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Will do. I’m going to go with some wide wheels and tires up front, somewhere between 305s up to 325s. With all that rubber the power steering will be a huge help. -

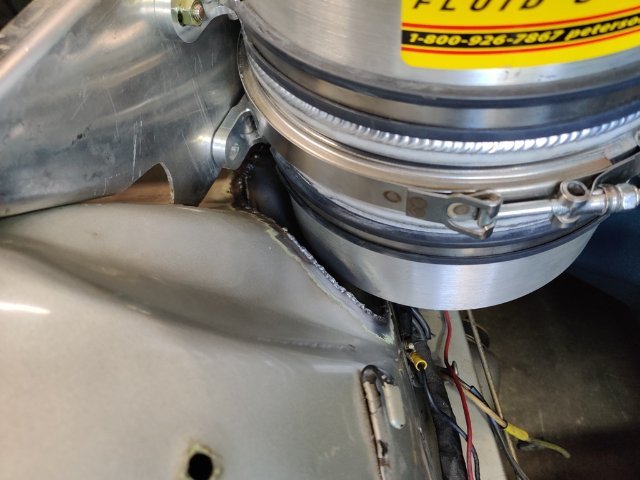

10-09-2025, This morning I trial fitted the tight 90 turndown on the turbo, clearanced the boss on the head that was touching the turbo compressor housing, and then masked and painted the engine. Once dry I can then mask and paint the crank pulley. See pics:

- Earlier

-

-

4200 Progress, 10-08-2025: Finished the cleaning of the engine today, using a can of gas (not recommended) and an old toothbrush and a shop cloth to wipe it up, razor blade on gasketing surfaces and other spots as needed.......then I mocked up the turbo header and turbo.....yep, my turbo is a bit bigger than what was expected I guess. I can get some space with another flange stacked up with the aluminum plate gasket for the second one, will probably need to put a wrap of header tape just in that spot as well. Also have a small boss sticking out on the head touching the compressor housing. I can just carefully grind it down a tad for clearance. Big T-76 turbo sticks up there huh? Good thing I will run an intercooler huh?

-

Working on PCV again, I am going to try for the exhaust. My basic plan is, valve cover to stock pcv valve, to a catch can, then block to the catch can, catch can to the exhaust.

-

jeffer949 started following L28 Front sump conversion

-

Im building a l28et and im converting it to front sump. I've already drilled everything and I know what im doing there. Wanted to run how im sealing the oil galley off. I the picture you can see my new pickup hole and dipstick hole. I have already put a Welch plug to the left of the small hole and plugged the old pickup. Next im going to put the aluminum plug i made that has a npt plug inside of it between the new pickup and dipstick hole. When I tighten down the npt plug it will spread the outer wall of the aluminum plug and seal it off. I will theb back that up with another Welch plug. Im almost sure it will work but I wanted to get some more eyes on it to make aure. Because if it doesnt work. Ill suck air and take out the bearings. Any recommendations on a sealer I should use if any?

-

Today was a cold snap, but I managed to get a job done I have not been enthusiastic about doing..... removing the oil screw in plugs from the block. Metal plugs in an aluminum block and have been in there for 19 years. I had to use a pipe wrench, hammer, hex wrench, PB Blaster, a MAPP gas torch, and a cold chisel. I found that the cold chisel is the most effective at getting them loose and off, but it will take several cycles of PB blaster , spraying it where the bolt face touches the block and letting it seep in, and then MAPP gas (2000 degree F or close to it, maybe more) held around the bolt to heat up the aluminum and get it to expand, then hitting the head of the bolt a few times hard with the hammer, and then putting the chisel on an angle and beating on it with a hammer to shock it loose and turn it. These bolts are M16X1.5 thread, with the exception of the bolt facing the side at the oil filter. The bolt facing straight ahead is the same size, M16X1.5 but the one to the side where the sensor normally is..... is a coarse thread bolt, M16X2.0 thread. I have ordered brass plugs from Auto Meter to install into each port that are drilled and tapped with a 1/8 NPT center. I will put brass plugs in #1-3, #4 is for the oiling system re-route from the front facing port at the oil filter, number #5, the last port on the block at the very end is for Turbo oiling feed. The side port at the oil filter, the bolt will be drilled out in the center and tapped to 1/8 NPT so I can use it for an oil psi gauge. Sure feels good to have this done. In the pics you can see how the factory really gooped up the threads when they installed them. Pics follow. Cheers!

-

Fast Floridian's 240Z Track Build

Mitchel0407 replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

I’m curious as to how the electric steering kit will hold up and what you think of it. No power steering isn’t that bad but it might be a nice upgrade down the line. Please keep us up to date once you have the car driving. -

Fast Floridian's 240Z Track Build

FastFloridian replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

You are 100% correct, thanks for pointing that out. You don’t know what you don’t know. The new steering kit lets you attach the u-joint in any configuration, I wasn’t even thinking there was a right and wrong way to install them. Quick google search and see what you mean and how to align them properly. Glad to be able to fix now, rather than find out later, love everyone’s help on this forum. -

Fast Floridian's 240Z Track Build

74_5.0L_Z replied to FastFloridian's topic in S30 Series - 240z, 260z, 280z

Just looking at the picture that you posted of your steering shaft, it looks like the u-joints aren't phased correctly. It may be an optical illusion from the angle of the picture.

-

Who's Online 1 Member, 0 Anonymous, 803 Guests (See full list)