-

Posts

2366 -

Joined

-

Last visited

-

Days Won

27

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by madkaw

-

So are we saying here that the bigger the better-within reason. Looks like the mikuni manifold is as you say tapped for 1/8 pipe all the way across and one 1/4 pipe. I looked at pipe sizes and there isn't much difference as far as ID with these two sizes. The LOG I am using(basically a fuel rail) is set up for 1/4 pipe on the ends-or basically 1/2" ID. Also-any general rules as far as keeping the vacuum log as short or as long as possible???. Looks like about 20" log would work for me , but someone had commented to keep the vacuum ports on the log close together. One last thing-to make things easier to mount the log, I would be mounting the log a good 6 to 8 inches from the manifold, so the individual hoses will be longer then most set-ups I've seen---any problems with this???

-

Well i posted this on another thread and realized I had started my own---anyway Any opinions on vacuum line size-can it be too big or too small, I have no idea and I am ready to order fittings.

-

I am reviving this thread looking for opinions on vacuum line size on the log . With my set up I could go from 1/8 all the way to 3/8 or better, but not sure if bigger is better or visa-versa?

-

As far as headgasket thickness, when i disassembled my engine to change headgaskets, I meaasured the gasket thickness and it was .047. Unfortunetley I can't tell you what gasket this is, except that it came with a MSA gasket kit(i'm betting Felpro, but maybe original nissan). I ordered a Nismo gasket from nissan and it is advertised as 1.25mm compressed. That would be dam close to what you need as far as numbers. Quench would be around .026 -not sure if you can get closer then that- and would you be absolutely sure of all your measurements? If the gasket compressed anymore then 1.25mm then you have a safety margin.

-

I thought I was the only one that used chewing gum LOL. Actually I was trying to check for minimum piston/valve clearance and I used a stick of UNCHEWED Wrigleys(which measured about .095) and laid it in the piston. I was using a used/compressed head gasket and messing with cam timing and had to take the head off afterwards anyway, so I just laid a piece on the piston and lined it up with the valves. It actually worked because when I got the cam way out of time( wwaaayyyy retarded) the valve left marks on the gum. If someone was slick enough they could probably stick a piece(trimmed down) thru the sparkplug hole on an assembled engine.

-

I have been reading this thread and not sure if you realize the error in your numbers Now I need to think about what to do, I think it will be quickly a matter of cost between new gasket (stock one at 1.25mm (0.060") would be good with quench around 0.7mm - 0.027") or machining cost for pistons isn't 1.25mm actually .049"

-

Rota RB-R 17x8.5 +4 offset. What size tires?

madkaw replied to 1siCk240Z's topic in Brakes, Wheels, Suspension and Chassis

Running 245/45/17's all the way around and the tires do rub on the rear. The tires catch the inner fender just above the fender opening. The fender rubs the tire sidewalls over bigger bumps or hard turns. 235 might clear with no problem. -

I found it very difficult to get my heat shield to go all the way to the head under the intakes. I'm considering some heat wrap material around the individual runners. Any negative results from wrapping the intake runners completely or should I just wrap them half way around the bottom.

-

Ray, in the process of making my CAI and heat sheild. I have been looking at yours and wonder if your accelerator pump linkages hit the pan? My set-up is similiar but I had to punch some holes so the pump linkages would clear for WOT. Nice job getting the pan all the way under the intake. I didn't take mine that far, but will add some double side insulation on top of the pan and run it all the way to the head.

-

Nice flat torque curve. The AFR's really get rich at 3500-do you feel that while driving?

-

Someone talk me out of (or into) this... (F54 combo)

madkaw replied to BrandenZ's topic in Nissan L6 Forum

Don't know if your e-88 is ready to bolt on or not, but you could lay your head gasket on that head and unshroud those valves which would let it breathe and gain some chamber size to a safer CR. -

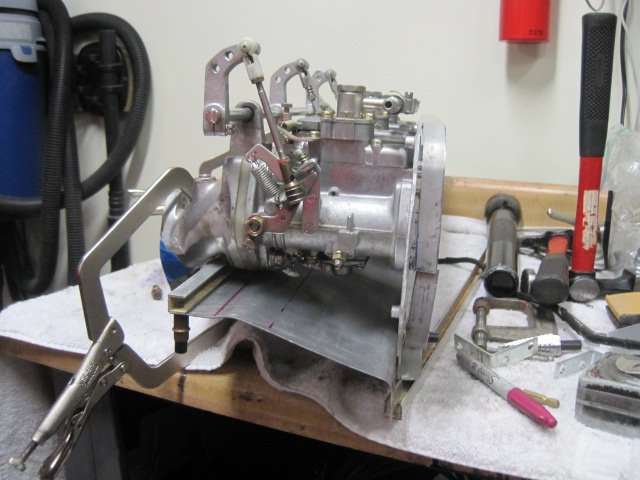

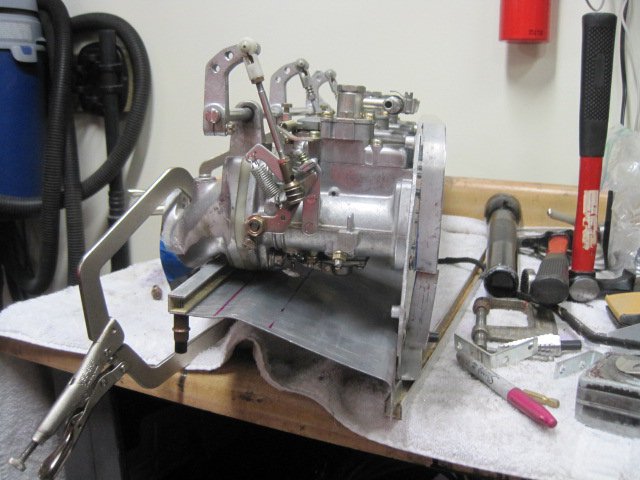

Well this thread went no where So after looking around for while for an air filter system for my Mikunis I have decided to make a cold air intake set-up instead. There seems to be very little choices for CAI for triples-make your own or pay 400$+ for a TMW fiberglass box. Being a cheapskate and a father with bills I have decided to take my time and make my own-with a twist--I'll elaborate later. For now, I have been lurking around and seeing what else has been made by my fellow Z'ers. It seems that SS is the material of choice for a heat shield, I guess because it doesn't transmit heat as much as aluminum. For now I have made mine from aluminum, but plan on using a some kind of heat barrier material on top of the aluminum. I have been suprised to see a lot of set-ups that do NOT use any additional material-just the SS shield. IS that enough? For those of you that have used a heat barrier material-did any of you find some double foil sided stuff. Almost everything I have found has a sticky sided and a foil side. The way I understand it the foil side needs to be on the heat side-which doesn't work for my set up. So I have been looking for double sided that I can fasten down. I have also noticed that a lot of heat shields are installed flat against the carbs-no air gap. Am I just too anal, but it seems to me that you would want a air gap to help with heat reduction. I did find out that Mikuni's have a particular situation issue that you have to work around----Accelerator pumps. They have quite the throw on the linkage. I decided to punch holes thru my shield to allow the rods to go thru. I might put material over the holes with room for the linkage afterwards. Anyway, here are some picks of what I have started with. The great part about this project is that most of material was given to me!! The backing plate your looking at is made from a railroad crossing sign that my motherlaw gave me. As a locomotive engineer my motherlaw thought it would be a cool gift to hang in the garage-all I thought was WOW-that's some nice aluminum, what can I make out of that. Well you can see what I decided on. Hell I have enough to make a couple more. That stuff is thick enough to make a pressurized box

-

NA 3.1L=>head & camshaft questions. No shortcuts, max

madkaw replied to zredbaron's topic in Nissan L6 Forum

THAT SUCKS! Man I am so sorry to hear that news. Hope you get to salvage something from that motor. Try not to get too discouraged, but I know these lessons hurt--bad -

Hopefully as stated above it is an exhaust leak. When I took off my MSA header this last time I think I finally found my ticking noise. There was a divit on the flange and you could see where the exhaust was escaping. I couldn't see it on the car because it was pissing out the bottom right in the middle. The more I read about oil pressures I think I might have too much and that is why it's squezzing by my rear main. The 10psi per 1000 doesn't always hold true for my engine. it seems a lot of these L6's have some kind of 'noise personality', maybe yours a tick-but I know it would drive me nuts too!

-

Pete, for some reason my sprocket didn't come with that chart. Thanks for posting yours as it will add more valuable info to this great thread.

-

I have a really cool Nurburgring shirt that someone gave me and that's as close as I will get to that track-I am also very jealous-congrats!

-

Okay guys-need some more help. My Nismo cam sprocket arrived and I threw it on there since it was easy at this time. I set it up on #2 since that was what the stock was set-up on. The timing came in slightly retarded from where I was. Dialing in #3 puts me too far advance. Not sure where to go from here. I see the letters on there A-D. If I want to advance beyond #2 do I use the letter that falls between the numbers?

-

If it were me, I would do one step at a time. I would bolt on the head with your carbs now-assuming that they are SU's and in good working order. You start changing things around too much at one time and if you have problems it is harder to diagnose.The n42 is a good head, but do you really know if it's ready to go and in running condition. I would just get rid of that lousy e31 head and give it to me-its no good for anything As far as weber stuff, posting the jet sizes would help the members see where you are at with the sizing.

-

Stroke-stroke and 2.6 are a few hints. Lots of info by means of the search button!!

-

I started a thread on this about a manual type sensor based on the human ear used with one of the cheap hearing appliances. Everywhere I read that most detectors are junk and give false indications. Scientific testing is what we need! My l24 sounds like it is detonating but it is really the exhaust. No way to be sure until I had to remove the head as saw no evidence. I am running 38 total with pretty high compression- which if you listen around here- that can't be done( could be cam timing allows this advance). Each engine is different So true evidence and scientific testing is the only way to know

-

There will probably be other folks dealing with what I am now, so I thought I would post up my findings. In the true spirit of Hybrid I have a mixed combo of parts. L24 hooked to a 82/bwt-5 trans running with the dedicated t-5 driveshaft to a r200. If you are running the bwt-5 driveshaft your aware that it had it's own particular driveshaft. So swapping to the STI/r180 from a r200/bwt-5 presents a few issues. No longer can I just swap out the pinion flange on the diffs, because of the difference in pinion diameter. Since I am running the t-5 driveshaft, it's body diameter is larger than a stock driveshaft which makes welding a different end on the driveshaft diificult, at best. So I layed my driveshaft yoke up to the subby pinion flange and realize that there is plenty of meat to redrill this flange. The other very nice thing I notices was that the driveshaft yoke cenetering ring fits perfect into the subby flange. That raised ring on the end of your driveshaft yoke that helps center and keep the shaft centered so the bolts will line up is the same!! In other words, it will be much easier to drill since the parts are concentric to each others pinions. I took the two pinion flanges from the two different diffs to my machinist and he agreed with me that a simple bushing could be made to center the two flanges to each other, than it will just be a matter of tranfering bolt patterns. I like this idea since I am keeping the subby flange with the subby diff. Hope this helps someone.

-

My car being a 9/71 couldn't use the original console. I had to use a later year console where the hole was further foward. If I remember correctly, I had to cut the hole in the tunnel further foward and it didn't line up with the original console. Even with all that the shifter is still located NOT centered in the console. I went with a offset style shifter to keep it away from the heater panel.

-

It was in the last few months. I went on the NASIO site and it was sitting there in the classifieds.I couldn't believe how clean it was-inside and out!~ It was a 3.90 ratio. I didn't care about ratio that much because later on I can just swap out, trade, buy another Subby LSD with a different ration. This is a much better deal than being stuck with 3.7 in the r200. I don't know how to change gearing or install a LSD unit---but I can swap out a diff!!!!

-

I found one on the Subby forums for 350$ with 60K miles(so he said), but it looked new. Maybe I just got lucky.