-

Posts

539 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by kj280z

-

auto Climate control effects engine performance

kj280z replied to madkaw's topic in S130 Series - 280ZX

I suspect one of the vacuum pots under the dash or a one of the vacuum lines running to/from them under the dash -

I got the 18 Inch line - seems to be a good length

-

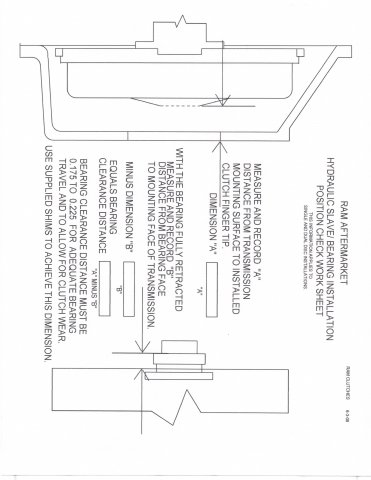

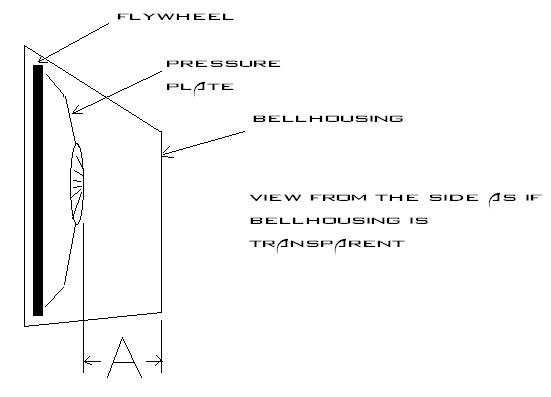

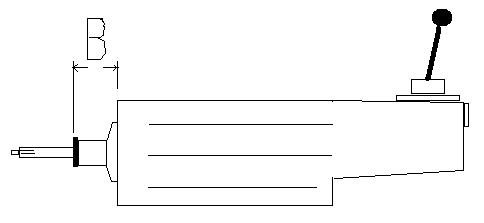

I have had my transmission out 3 times now and I "think" I've finally figured everything out, but I was hoping to verify and pick your brains... pictures are below I have a 2002 LS1/t56 all stock (tranny wise) installed in my 1975 280z. I had the stock flywheel resurfaced - it measures .79 inches front to back (anyone know what the stock unsurfaced measurement should be?). I'm also using a Wilwood Clutch Master cylinder - specs are located here: http://www.wilwood.c...itemno=260-1304 It appears I have 1/16" of an inch between measurement A&B (A being greater than B by 1/16") as per the info at this link: http://www.ls1tech.c...-need-shim.html I'm trying to determine if surfacing the flywheel and using the Wilwood MC will work ok. I want to avoid any clutch engagement issues and also to avoid blowing out the Throw out bearing seal. I purchased the bleeder line and I'm also using a Clutch Masters stage I clutch good to 550 hp (BTW check them out - they have an impeccable reputation and their products are very reasonably priced). My particular clutch is designed to be used with the stock flywheel - they have 2 different versions. For verification purposes, how far into the fingers of the clutch should the TOB ride while the clutch in not engaged? I know that it only takes 1/4" of outward movement to disengage the clutch... I'd like to get a measurement and verify all of these details before putting the tranny back in - for the LAST time! Any insights would be greatly appreciated.... Thanks! I need to verify this measurement but I've included it for informational purposes - maybe it'll help others...

-

280Z stock fuel tank with LS-1 for dummies

kj280z replied to pokypine's topic in Gen III & IV Chevy V8Z Tech Board

Well you have no reason to eliminate it, would be the better way to say it... I thought you were eliminating it for a specific reason which was why I asked. An expansion tank is needed to provide space for the expansion of fuel(and water if there's any in your system) and without it your fuel tank will experience higher pressures, which could impact your fuel pump and other aspects of your fuel system. I'm not sure how critical that is, but I elected to keep mine since there's no harm in keeping it, it's already plumbed and it serves a purpose that the manufacturer felt was important enough to include as part of the system. Maybe others have more feedback on it? -

280Z stock fuel tank with LS-1 for dummies

kj280z replied to pokypine's topic in Gen III & IV Chevy V8Z Tech Board

Why do you want to eliminate the expansion tank?!!! -

Ya know - I was thinking about this, and I wonder if they trimmed down the Passenger side to allow a dual exhaust to exit over there if they could make up the lost fuel capacity by wrapping the tank around the drivers side some more - kind of encapsulating the spare tire well so it didn't have to be eliminated... I'll crawl under mine tomorrow and see if there's enough room Thoughts?

-

I suspect that the better pedal feel is simply due to the replacement of your old unit with a new one?? Is there any data available to review or any folks that have tested them?

-

Hey all I've been searching around and have noticed that there are some of you that have swapped out your stock brake boosters and replaced them with boosters from later years... My question is why? I realize many of you have been chasing the reaction disk problem. I'm just asking because I currently have mine out - and it is the original, but seems to be working fine Are there any advantages to running a booster from other years? Mines a 75 280z which will have a LS1 running in it soon... I can't think of any benefit to running a booster from other years so I thought I'd ask the question... Being that replacing the booster is such a PIA I was thinking about buying a new one just to avoid a potential failure of an old original part later - and it's easier to install a new one with the Dash out...

-

I have my Speedhut GPS Speedometer all installed in the dash and the dash is ready to install. I have the motor out right now while painting the engine compartment. Should be ready to put the motor back in very soon. Then I'll install the dash and give a review... Waiting to install the dash because it's easier to install the Brake Master Vac and clutch master with it out I'm moving along at a good steady pace so I'll have an update soon

-

No search function on mine either - maybe I should download the app? It does look great in Safari on the iPhone and is fast! Would be perfect with the search feature

-

I will not be pulling the tranny to bleed the clutch so that remote bleeder while a nice idea isn't an option. So are you saying the fluid will drain into the socket while it's on the bleeder?

-

I have seen a lot of posts which have talked about issues with bleeding the clutch, but I've looked everywhere and have not found a post specific to the clutch bleeder... I realize I need to get a small 1/4" drive 7/16" socket on the bleeder, but I'm wondering - When you open the bleeder does the fluid spray into the socket or does it exit somewhere else? If it exits somewhere else (or even out the back of the bleeder into the socket), it seems that the fluid will drain into the bell housing... I don't see a way to easily attach a hose to the bleeder either... I've searched but no luck... Lot's of people talk about bleeding the system in the traditional ways, but none of the posts that I found touched on this aspect of it... And yes - since I'm down to bleeding the clutch that DOES mean I'm almost ready to start up and drive my LS1 280z! Finally!

-

just got the racegate, you weren't kidding when you said it was brand new. was missing the 3lb spring but i was just going to throw it out. Thanks

-

Heat from LS1 in S30 engine bay

kj280z replied to RB30X's topic in Gen III & IV Chevy V8Z Tech Board

Hey all, Is there any data on the differences of wrapping the headers versus having them ceramic coated? Is there any benefit to having them ceramic coated AND wrapping them? I have a set of the JTR shorty headers - they're currently painted silver but I'm sure it won't last (I will be starting it up for the first time very shortly) How does the wrapping effect the longevity of the headers? I'm thinking about just painting them real good with a high heat paint and wrapping them unless that's not a good idea... I also want to keep the radiant heat out of the passenger compartment, but if I can save the money on the ceramic coating and still get similar longevity by simply wrapping them that may be an ok trade off -

Bernardd - I challenge you to share the list with us - I don't think you've analyzed it correctly... The pistons are cheaper - and you only need 4 vs 6 for the L Motor parts, same with rods, rings, head gasket, bearings etc etc etc... the list goes on and on... Parts availability and aftermarket parts and support are FAR superior for the KA - face it the L Motor is 30 year old technology If you simply "like" the L motor better than the KA, just say it - you're entitled to your opinion, but the argument you're trying to make doesn't hold any water Plus you can't buy Turbo Headers for the L Motor so you're stuck with the stock turbo L manifold which in many cases requires modification which adds to the cost, also Intake manifold choices available for the KA are pretty impressive with very low cost. Additionally, the KA PCM can be tuned and thus the stock KA harness can be used - this is a huge savings over aftermarket fuel injection required for a proper L Motor turbo setup - yes some folks use the 280zxt ECU but it has its limitations

-

Let's use the manifolds as an example (there are several other examples as well) Do a search on ebay or with google on KA24DE Turbo exhaust manifold or KA24DE Turbo headers or KA24DE Intake manifold - you'll be AMAZED at what's available and the prices are GREAT! Now try to find equivalent parts for the L Motor - good luck! Ain't gonna happen! Then look at all the turn key turbo setups for the KA - again you can't compare - Take a look at some of the huge numbers they're making with a properly built KA - no one has ever gotten close to them with an L Motor due to the head design and several other factors Good headgaskets for a turbo KA - $80 - Good luck finding a 2 mm (or 1mm) metal headgasket that is equivalent for under $200 The list goes on and on Plus when an L Motor breaks - usually it's you who is the only one who has the correct expertise to fix it... The KA is well supported and well known by most shops - when you bring an L Motor to them nowadays they don't wanna deal with them anymore... It's nice to be able to go to any shop and say - "open the hood and pretend it's a 240sx" Just my .02

-

I agree - the KA is a better choice and the turbo parts are MUCH cheaper! Plus, you can get a KA24DE with 5 speed tranny AND the computer and wire harness for $500 all day long you can have the stock computer flashed (RS Enthalpy does it and a few others) - with an upgrade of injectors and a Z32 MAF you're in business for a fraction of the cost of a Turbo L and it'll make GREAT power!

-

adding some neg camber to back end

kj280z replied to janaka's topic in Brakes, Wheels, Suspension and Chassis

You can also notch the bolt holes in the strut tower... I have not had stock insulators in my Z for many years so I'm not sure how much you'd gain but between doing that and the poly bushings it may be a good starting point -

Clive That one looks repairable and if you were lucky enough to get it, I'd fix it and sell it!!

-

Try these guys http://justdashes.com/

-

A KA24DE (twin cam) turbo setup is really sweat if done correctly. It is also much cheaper than the old L Motors and parts are more readily available for the KA

-

280Z stock fuel tank with LS-1 for dummies

kj280z replied to pokypine's topic in Gen III & IV Chevy V8Z Tech Board

I'd like to see a pic of the torque tube tranny mount -

Do you have any pictures of the car completely assembled? I'm thinking about doing the same color on mine and would like to see it at different angles

-

280Z stock fuel tank with LS-1 for dummies

kj280z replied to pokypine's topic in Gen III & IV Chevy V8Z Tech Board

I am finishing up my fuel system today. 3/8" aluminum hard lines replaced the stock hard lines. The hard lines are connected to steel braided lines which connect from the pump to the tank and from the the lines to the FPR and rail Feed line is connected to the right fuel rail Right fuel rail has a line across the front to connect to the left rail Aeromotive FPR is connected directly to the rear of the driver rail Return comes off the FPR and back to the tank I used after-market solid fuel rails (forget the brand) Pump is a Walbro 255 with an inline filter mounted in the rear -

They are skyline GTR tail lights. Had to hand fabricate a custom rear panel. I used small portions of the GTR bezels to make it look like stock . There's at least 40 hours invested in the rear of that car in make all those parts by hand.