Noddle

Members-

Posts

572 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Noddle

-

The fuel regulator regulate the pressure, as long as the pump can supply it, and the return large enough as not to be overwhelmed. (I don't know what minimum size is needed) I have a question about the use of copper pipe, will this cause a issue years down the track with it going hard (flexing over a long period), and cracking ? Nigel

-

the High Flow should have a "H4" on it. http://forums.hybridz.org/index.php/topic/79476-high-flow-oil-pump/ I did the search for you. only because I have been looking into this. Nigel

-

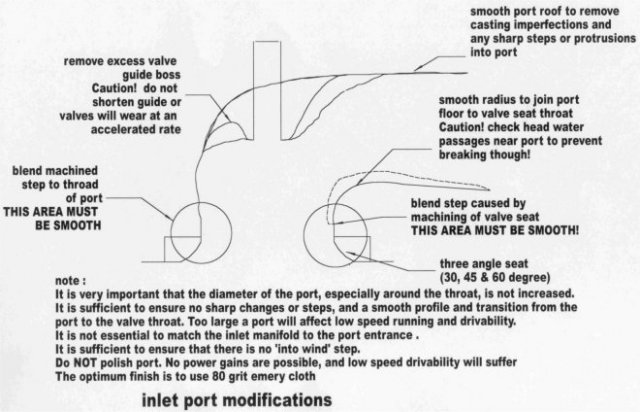

During my internet searching, I came across this page http://alfaboxertuning.fws1.com/ it not directly related to the 'L' engine but has some nice information about porting in general, I liked the pictures regarding the "inlet / exhaust port mods" as seen in this picture Nigel

-

I was using the distributor, and taking the RPM signal from the coil, later I moved to EDIS. I don't use MAF, I use throttle position and MAP you can see what I done here noddle.110mb.com Nigel

-

MS II was my first real project that I built, and yes there was a big learning curve involved in the building and wiring of my system, and a lot of reading on forums But for me it worked out fine, the use of the stimulator helped me in understanding how it all fitted together, besides the testing of the hardware, If I was going to do another fuel injected car, I would do MS II again. If this is you primary transport to work, then I probably would not do it, since it took me a couple of weeks to build, install, figure out what I was doing, and tune it, to be drivable. Nigel

-

Possible fire issues with CBFC 210 Blower?

Noddle replied to FricFrac's topic in Turbo / Supercharger

Is this anything to do with your sheep ? -

Tony, I found this while doing some searching, I assume it has not moved on, from been a good ides ? http://forums.hybridz.org/index.php/topic/79968-euro-manifold-in-ss-316l/page__view__findpost__p__761294 I did some measurement today on the thickness of my manifold, where the runners squeezes together, its about 4mm thick, so I wont be doing anything like JeffP did. Nigel

-

http://www.angelfire.com/extreme/280zxt/page11.html

-

I assume a 3 inch mandrel bend exhaust with no cat, and a free flowing muffler should make it breath easier, this is what I have been been running since I started playing with my turbo charger and EFI ( MSII ), talk about a steep learning curve. What can be done to a standard turbo manifold to make it flow better ?, I've been working on mine, mainly on the area inside the mouth of the runners, removing the rough casting, and opening it a little. Nigel

-

Hi, I been reading some post where TonyD and other are talking about not needing to run higher turbo boost pressures, but to allow the head to breath more. But I have not heard anything about spark advanced verses boost pressure, for example, lets say I'm running 20psi, but I can only run 10 degrees max at high RPM, would this give more power than say running 12 psi running 35-38 degree at the same RPM. Nigel

-

for the price USD$ 410.00, you could buy a MS II unit and use spark only..

-

I had this laser cut for me this week for $10 Aus dollars, about $8 US. I made this so it fits better on the manifold where I needs to weld it ( it only fits one way ) Rename "Weld Flange.dwg.zip" to "Weld Flange.dwg" , it wouldn't allow me to upload with a .dwg file name for some reason. It's 12mm thick. Nigel Weld Flange.dwg.zip

-

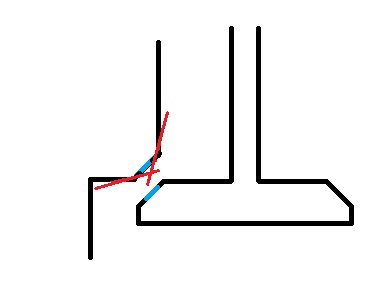

I would have thought, on the exhaust valve anyway, that you would want to have 45 degree cut on the seat and the valve, to have a larger contact area to help remove the heat from the valve ? see picture Nigel

-

Thank you for this, I have access to a old valve grinder at work, that I have used before, I'll look at doing this when I do my MN47 head, Nigel

-

Hi, I was reading a thread here, (it in the shed now), but BRAAP mentioned "stock valves that have been given a 30 degree back cut." since the search engine here freaks out with search terms less that 3 characters, I was wondering if anyone had some picture they could share showing this, and explain how it's done. Is this a easy DIY thing to do on standard Nissan valves ? Nigel

-

You want something like this, the only problem I found, is I'm running two gaskets, and the inside one leaked on me, so I'm going to weld it to the manifold Nigel

-

Use Teflon buttons ?

-

Hi, Hopefully sometime soon I will be building a L28 to replace my Turboed N/A L24 my issue is that I have 3 heads to choose from, a E30, a N47 (MN47), and a N42 I don't have a lot of money to spend, so replacing the valves in the head is not a option for me at the moment. The E30 has very small valves which i assume would be a negative point. The N47 I believe has slightly smaller vales than the N42, but it has the closed chamber design (like a P90) The N42 has the larger valves, but has a open chamber design. What I was planing, unless some one has a good reason why not to, is run a L28, with dished piston, with a standard N47 head with some minor head work, this would include some work on the intake port to remove the casting marks, blend the port onto the valve seats and un-shroud the valves. i would be running a N/A "A" Cam as I am now with my L24 Engine management will be, Megasquirt II, ( msextra ) EDIS, 440cc injectors, standard headgasket, arp head bolts and arp rod bolts, 3 inch exhaust, Intercooler T3/4 Turbo, the same as what on my L24, fuel will be E10 ( 95ish octane ) Can anyone see why this would not work with good results ? thanks for any input Nigel

-

Hi, I just got my new laser cut spacer flange for my mainifold, and I have some questions about welding it to my manifold, 1, I assume mild steel rods will work Ok, since the manifold is cast steel, not cast iron, 2 How hot should I pre-heat it before I weld it to the manifold, warm, finger burning hot, glowing red hot ? 3 do I need to de-stress the weld (with center punch punches) ? 4, using a stick welder, what sort of amperage should I be using, 90 - 100 ish ? I'll also be doing my external waste gate, looks like I will use a 90 degree bend to a flange. thanks for any help Nigel

-

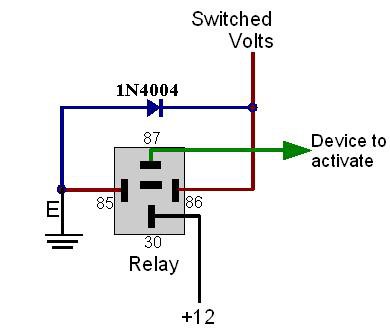

Hi, I'm in the process of re-wiring my MS II system, including my fuse / relay box, and I'm wondering if I should uses 1N4004 diodes to enable flyback on the relays I'm using, or am I'm been to paranoid about it. Nigel

-

Silly question, you have your coil hooked up to the fuel + on the pump, doesn't MS prime the pump and turn it off until the engine fires ? just had another look, MS earths the pump (relay) to fire it up.. my Bad. Nigel

-

Stupid question, can't you just block it off ?, cut, crimp, bend, bronze Nigel

-

Thicker Head Gasket Recommendations Please

Noddle replied to WindyCityZnut's topic in Nissan L6 Forum

How much taller is the L20B cover ?, I assume you could run very high boost with a thick head shim and the L20B cover to drop the compression. or am I barking up the wrong tree ? -

Ask here http://www.skylinesaustralia.com/forums/Classic-Skylines-f77.html Nigel