-

Posts

820 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by zcarnut

-

280ZX brake options.

zcarnut replied to z_cars_rule's topic in Brakes, Wheels, Suspension and Chassis

YES! The Z31-to-280ZX rear stub axle swap only works on the late (1982-83) ZX's because of the different rear caliper mounting ears on the lower control arm. -

Another way to use Toyota 4x4 calipers?

zcarnut replied to Zmanco's topic in Brakes, Wheels, Suspension and Chassis

-

Frnt Diff. Mount Counterweight???

zcarnut replied to sstallings's topic in S30 Series - 240z, 260z, 280z

Nissan TSB # TS75-068A, Sept 3, 1975 “Countermeasures for S30 R180 Differential Noise†To reduce internal noise in the S30 differential a differential noise damper kit is now available as a service part. Differential noise is caused by the tooth meshing action of the ring and pinion gears, amplified by structural vibration of the vehicle body. The noise damper kit contains a 10 lb mass damper weight which attaches to the differential housing to absorb structural vibration and the necessary attachment hardware. The kit can be also be applied on the 1970-74 S30, R180 differentials only. This kit should not be used on any 2+2 vehicle due to possible interference with the rear seat belt attachment bolts. Kit Part Number: 99991-2000 Since the only 280Z’s that had a R180 were automatics, one might be inclined to think that only automatics had the differential noise damper kit installed. However, I recall that my four-speed 260Z had the damper weight when I purchased it back in the mid 1980’s. -

Yes. However, with your total cost of over $275 you may want to consider getting a re-man rack: http://www.autopartswarehouse.com/details/QQNissanQQ280ZQQA1_CardoneQQRack_And_Pinion_AssemblyQQ19751978QQA1242603.html Just make sure the re-man rack comes with the inner tie rods! Some do not. You can get outer tie rods from several aftermarket vendors.

-

The reason that there is a difference in the left side tie rod (both inner and outer) is because one side had right-handed threads and the other side has left-hand threads (between the inner and outer tie rod). This is just tradition. It just makes for a convenient method of adjustment. Most (if not all) American cars built before 1980 had opposite threads on their tie rods. Hence, Nissan just copied this configuration. However, with its metric threads, the left-hand threaded inner tie rod was only sourced by one aftermarket vendor, Moog. When their stock ran out in the mid 1990’s, your only choice was Nissan, and it sounds like their supply is gone as well. The solution is easy: Just use a right-hand threaded inner (and outer) tie rod on both sides. The treads where the inner tie rod screws on to the rack are the same on either side. Even Nissan themselves stopped using different threaded tie rods on the 280ZX's with rack and pinion, i.e., both the left and right sides of the ZX use right-handed threads.

-

over run problem mn47 head

zcarnut replied to datsun 1/2 dozen SD's topic in Trouble Shooting / General Engine

Just use the L-series engine utility at: Engine Design Utility You will have to add/modify the data appropriately. For example, they do not list the MN47 head which has a combustion chamber volume of around 39.5cc. -

over run problem mn47 head

zcarnut replied to datsun 1/2 dozen SD's topic in Trouble Shooting / General Engine

“Dieseling†is when a gasoline engine continues to run (albeit coughing and sputtering) even after the ignition has been turned off. This is also known as “run-onâ€. Dieseling only occurs on engines with carburetors, because fuel injection systems shut off the injectors when the ignition is switched off. Dieseling is caused by a combination of factors: low octane fuel, high engine operating temperatures, and a high compression ratio. Additional factors include possible carbon deposits in the combustion chamber (which will glow white hot), and using gasoline that contains some alcohol content. The effect is created by fuel in the engine cylinders being compressed and becoming hot enough to self ignite without the aid of a spark plug. This is similar to how a diesel engine works, so it sounds similar and hence the name. As long as the engine is turning over and drawing air through a carburetor, the carburetor will continue to deliver fuel. It is not possible for ignition timing to cause dieseling directly. With the key turned off all power to the ignition system (and sparkplugs) is disabled and there is no spark. Thus you might conclude that the ignition timing is irrelevant. However, since ignition timing has a noticeable effect on the combustion chamber pressure and therefore its temperature when the engine is running, ignition timing has an indirect effect on dieseling. So, now that we know the cause, how do we fix the problem? Well, there are several ways to combat the problem. Roughly, in order of complexity, you can try: 1. Use the highest octane fuel you can find. Also add a can of octane booster. But, you stated you are already doing this, so I will mention this just for the sake of “completenessâ€. Also, avoid using gasoline that contains any alcohol (methanol). The alcohol vaporizes at a much lower temperature than the rest of the fuel and the result is alcohol vapor in the combustion chamber. 2. Reduce the air flow through the carburetors at turn off. Back in the 1970’s (when dieseling was a big problem) carburetors had an “anti-dieseling†dashpot which was a solenoid that completely closed the throttle blade at engine turn off. With no air flow through the carburetor throat, then no fuel flow into the engine. Since the SU’s do not have a dashpot your recourse is to reduce the engine idle speed as low as possible. You should be able to idle at 600rpm unless you have an aftermarket cam with a lot of valve overlap. You can also play around with the SU choke lever. The SU chokes have a “fast idle†position at about ¼ of their operating range before the fuel enrichment comes in. You can adjust the choke lever into this fast idle region and then set the engine idle speed. Then at engine turn off you fully move the choke lever to its off position which will reduce the idle speed. 3. Reduce the fuel flow at turn off. Although dashpots worked, they were not completely effective because there were other (minor) air paths into the intake manifold. So, in the 1980’s automakers began using “fuel shut-off solenoids†in their carburetors. This was basically a needle valve that blocked fuel flow out of the float bowel at engine turn off. Again, since the SU’s do not have this feature you will have to resort to leaning out the air-fuel idle mixture. However, on the SU’s when you lean the idle mixture you also are leaning out the mixture across the whole range of engine speeds. This can result in increased combustion chamber temperatures. So, do not get carried away with the mixture adjustment. A little bit (1/8 turn) goes along way. What you really want are SU needles with a different taper. 4. Reduce the engine operating temperature. Although L-series engines prefer to run around 185 degrees, you can get 180, 170 and even 160 degree thermostats. 5. Reduce the engine combustion chamber temperature. Spark timing that is too far advanced will increase combustion chamber temperatures as will not having enough EGR flow. Too lean of a mixture will also raise combustion temperatures. 6. Reduce combustion chamber “hot spotsâ€. Again, I do not think this is a concern for you, but high mileage engines tend to have carbon build up in the combustion chamber which retains heat and the extremely hot bits of carbon can ignite the fuel after shutdown. In addition, such deposits will increase the compression ratio of the engine. There are additives you can both pour into the engine and put into the gas tank to dissolve carbon, but for heavy deposits the only solution is removal of the cylinder head and scraping away the deposits. Sharp edges in the combustion chamber can get red hot while the engine is running. The hot edges can also ignite the fuel after shutdown. The cure for this is the physical removal of the sharp edges bits with a hand grinder. Sharp edges can occur on the valves, especially if they have just been re-ground. Even spark plugs of the wrong heat range can run hot enough at the tip to cause dieseling. This can also lead to premature failure of the ceramic insulator near the tip of the plug. Always use the coldest plus you can that don’t misfire (due to carbon build up). 7. Reduce the compression ratio. This is probably the major cause of your dieseling. The MN47 head has only a 39cc combustion chamber volume. If you combine this with a L28 block that has flat-top pistons, then the (static) compression ratio is almost 11:1. Using “dished†(by 10cc) pistons would reduce that to around 9:1, which is much more practical ratio with 91 octane gas. Another option is to use a thicker (2mm) head gasket or perhaps to use two stock gaskets stacked, but I have seen this setup fail before. However, using dished pistons or a thicker head gasket reduces the desired “quelch†effects of the MN-47 head. 8. Switch over to fuel injection (join the rest of us living in the 1980’s!). Seriously, this is the preferred solution to dieseling. It just costs more than carburetors and the complexity of the fuel system increases. 9. Add a “gulp†valve. A gulp valve is a solenoid controlled valve that allows outside air to flow into the intake manifold at engine turn off. This induced air bypasses the carburetors and leans out the intake mixture. To be effective, the vent line and valve diameter should be fairly large, at least 10mm. 10. Increase the engine loading at shut off. Turn on the ac compressor (if you have one). Do not “dump the clutch†while holding the brakes on. Unless you have an automatic transmission, this creates severe loading on the driveline parts and you will eventually break something (usually the U-joints). Some people insist that turning on your lights will help, but the electrical loads are supplied first by the battery and not the alternator. -

Seeking NEW wiring harness 1973 240-Z

zcarnut replied to Tengu3's topic in S30 Series - 240z, 260z, 280z

Ever heard of eBay? Datsun 240Z Engine Harness 1973 Restored AS NEW http://cgi.ebay.com/ebaymotors/Datsun-240Z-Engine-Harness-1973-Restored-AS-NEW_W0QQcmdZViewItemQQcategoryZ46098QQihZ019QQitemZ290245556329QQrdZ1QQsspagenameZWDVW Expensive, but I’ve personally seen his harnesses and he does excellent work. -

Yes, it’s the 1974 and earlier driveshafts that have the replaceable U-joints. The 1975 and up driveshafts require that the u-joints be machined out on a milling machine. This is standard practice on most 1975 and up Nissan driveshafts.

-

The dual stage throttle was definitely not used on any years of the 1981-84 USA L24E Maxima. I’ll find out the exact application dates of the 200SX and re-post.

-

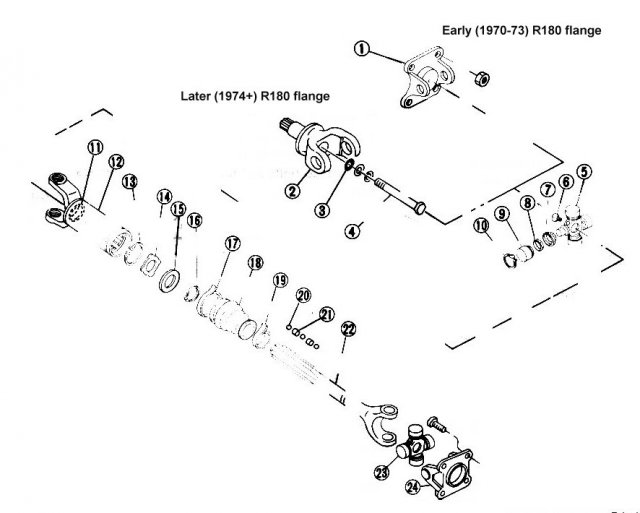

You need to use the later (1974 and up) R180 axles. These have the “single-bolt†attachment. The earlier (1970-73) R180 axles are secured to the diff in a manner similar to the R200 u-joint axles.

-

http://www.datsport.com/Racer_Brown_Menu.html

-

The 9mm bolt 133mm length rods were also used in the L24E engine up until 1981. Application would be the 1977-80 Datsun 810.

-

To respond to the original question: I’ve read that Nissan wanted to increase the cargo area in the rear deck. The S30 rear shock towers protrude into the passenger compartment. You still have shock towers with the semi-trailing arm suspension, but they are less obtrusive. Nissan just took the rear suspension parts from the 810 (except the change to rear disc brakes) and used it on the 280ZX. Commonality perhaps? Nissan also used most of the 810 front suspension on the ZX even using the same re-circulating ball power steering.

-

It’s the late version L24E engine. Same bore and stroke as the 240Z engine but it has a lighter flywheel than the earlier L engines and the rods and crank are different to accommodate a thinner connecting rod journal and the rods used the 8mm bolts. The piston used a thinner top compression ring as well. It’s also a “front sump†oil pan design, as the S30 cars used a ‘rear sump†oil pan. No more than about 115 to 120hp. However, the Maxima N47 cylinder head is desired due to its quelch shaped combustion chamber. More info available if you search using L24E and MN47.

-

Even using the special tools, it’s not easy… First, get the FSM and read the procedure in the AC section. The clutch hub must be removed using a special puller that most ac shops would have and maybe would let you borrow. I made mine by modifying a GM clutch hub puller by re-treading one end with the correct metric thread pitch. There are locknuts and shims that must be carefully removed and saved for re-use, and then the clutch pulley can be removed with a standard three-jaw puller. However, the clutch coil is attached with six Phillips head screws that have been “caulked” by the factory so they will not loosen. To remove them you can try an impact wrench but that usually just strips out the head of the screw. I generally end up removing them with a left-handed bit and drilling them out. Fortunately, Nissan supplies new Phillips screws with a new clutch, but I don’t know about the aftermarket guys. During the re-install you must set the correct clutch hub gap using shims. It sounds tough, but like changing rear wheel bearings, the first one you do will be the worst. After that they get simple (and I‘ve done about six or seven).

-

That’s ridiculous…Someone wants to get his tooling costs paid for ASAP. You can still get new triple Webers with manifold and linkage for less than that!

-

Could be because the 2+2 non turbo used the R180 CV axles, which are different than the R200 CV axles.

-

Yes. First pop out the cardboard glovebox liner and remove the blower fan and its housing. Remove the lever control faceplace to get to the cables. Remove the heater hoses and unbolt the heater core box and slide it over and out. I like to remove the passenger side seat for better access.

-

It’s the chemical reaction between R134a and the older (nitrile) rubber o-rings that causes the o-ring to shrink and possibly leak. Molecular size has nothing to do with this. In addition, the higher operating temperatures of a R134a system have a negative effect on the nitrile o-rings. The HNBR o-rings recommended for use with R134a are fully compatible with R134a (and PAG oil) and have a much wider temperature range. The problem with re-using the old Nissan Hitachi R12 compressor for a retro-fit is that no one makes any HNBR replacement seals, o-rings or gaskets for it. Yes, leaks through the hoses can be reduced by switching to a barrier hose construction (which is basically a hose within a hose that limits the amount of the smaller R134a molecules that will slowly escape through the hose wall over time), but the leakage rate through even a non-barrier hose is so small it can be ignored. Again, no one makes a barrier-type hose that replaces the stock S30 hoses. The ac systems used in the S30 Z cars do not have an orifice tube. They use a TXV system which utilizes a receiver-drier and an expansion valve. It's the CCOT systems that have an orifice tube and a accumulator. The newer parallel flow condensers are much more efficient than the serpentine types. Instead of having a single large tube (to prevent an excessive pressure drop) like a serpentine condenser a parallel flow has many parallel tubes than are smaller in diameter. This allows more of the refrigerant to be in contact with the surface area of the tube which are themselves in contact with the cooling fins. And another thing…it’s called R134a and not R134. The "a" suffix indicates a molecular structure of 1,1,1,2-Tetrafluoroethane. R-134 (without the "a" suffix) has a structure of 1,1,2,2-Tetrafluoroethane and is a compound that is not specially effective as a refrigerant. Hey, I’m no ac expert… I just worked with a refrigeration engineer on a project two years ago and he really straightened me out.

-

Nissan used the dual butterfly valve with progressive openings on some FI vehicles as well. Early 1980’s 200SX for example. Too small to be used on an engine larger than 2 liters. More common on the JDM Nissans. I’ve even seen it on a Fairlady Z.

-

1. You have to flush out and change the oil in the ac system. Mineral oil is used in all R12 systems. However, mineral oil does not mix with R134a and therefore is not usable. Instead, use PAG oil (polyalkylene glycol) or better yet, polyol ester oil (ester oil for short). Ester oil mixes with and is compatible with mineral oil and ester oil can be used with both R12 and R134a refrigerants. Because of this, it is referred to as "retrofit oil". 2. Replace the receiver-drier with one that is designed for R134a systems (contains XH-7 or XH-9 type desiccant). 3. You should really change the compressor to one that is designed to be used with R134a. R-134a operates at higher pressures than R12. Older compressors have a tendency to fail when subjected to this increased pressure. In addition, the old Hitachi compressors are known to be somewhat leaky. 4. It’s also a good idea to change to a better (larger) aftermarket condenser with a higher flow capacity. You should know that an air conditioning system converted to R134a will never cool as good as it did with R12. At its optimum a 134a retrofit will only get the cold air outlet temperature to within 3-5 degrees of the R12 system. R134a refrigerant is about 10% less efficient in removing heat than R12. IMHO, do not waste your time with a R134a retrofit. Instead, get your MACS license so you can buy R12. Another alternative to use one of the “drop in” R12 replacement refrigerants like Freeze12 or AutoFrost.

-

The important parameter about the placement of the fuel pressure regulator is to minimize the length of the vacuum line to the intake manifold. That’s why the factory mounted it on the intake manifold. This line is the analog “control signal” for the pressure regulator and the further it is away from the intake manifold the longer (in time) it takes for the regulator to respond. The newer vehicles today with the “returnless” EFI systems that do not monitor the intake manifold vacuum directly, will place the regulator directly at the output of the fuel pump (which means its located in the fuel tank).

-

You can always locate the #1 cylinder spark plug wire on the Datsun L-series distributor cap because it is identified with a raised indentation on the cap. All of the aftermarket caps I have seen also have this marking.