-

Posts

1051 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Blogs

Events

Gallery

Downloads

Store

Everything posted by Chickenman

-

Matt: Ok now I'm officially confused. Direct grounding of the ECU to the negative Battery terminal goes against recommendations by other Manufacturers and your own information. Voltage impedance from the Starter cranking ( huge amperage draw ) can damage components in the ECU if you connect it directly to the Negative Battery terminal. Especially if you have a bad Chassis ground. And these are 40+ year old cars. And if you have a bad starter ( shorted commutator or excessively high draw ) you can blow sensitive Microelectronics in the ECU. Shane: I thought you said you had grounded the ECU to the Intake Manifold. And the Innovate WB controller to the Intake manifold but in a different point. Was that a Typo about having the ECU grounded to the Chassis? And I thought we went over the issue issues of the secondary ground in the Nissan Optical distributor requiring that the ECU ground be attached to the engine so that you have the smallest ground Loop in the Ignition circuit. Preferably Intake Manifold on our engines. As per factory design

-

You'll never be able to run pump gas with a Turbo and that high of a compression. At least.. not for very long. You may be better off selling that engine and starting all over with a dedicated Turbo build. The Flat Tops cat pistons are a weak point. The Turbo pistons are not only dished but they have much stronger ring lands and thinner rings. Cast Flat Tops, High CR, no knock sensors and Pump Gas is a recipe for disaster. Just not worth it IMHO. That Camshaft is all wrong for a Turbo car as well, and it would be really hard to Turbo the Triple Webers. You are much better off going EFI with ITB's or a Plenum manifold with a 60mm to 70mm TB.

-

Fuel pump and FPR. Not as critical on a NA motor as a Turbo motor. But if you do upgrade to a Higher Volume FP such as a Walpro 255 or Bosch 044, be aware that the stock Nissna FPR cannot properly regulate the Fuel volume put out by a higher performance pump. The Internal return orifice is simply to small. Buy a GOOD quality FPR such nas Aeromotive or Fuel Tech. Both made in USA. Do NOT buy some cheap Chines junk from E-Bay. They are crap and can't maintain accurate fuel pressures. An Aeromotive 13129 EFI regulator is a very good Product. Available from Summit or Jegs. On sale about $130.... and worth every single penny. Don't cheap out on the FPR. You can't get a stable Tune without accurately regulated Fuel Pressure. Also, do not buy Liquid Filled Fuel Pressure gauges. They vary with underhood temperatures. Buy a regular non-liquid filled gauge from Marshal or Stewart Warner. Reda the attched Technical article from Aeromotive on the problems with most Liquid Filled FP Gauges TB_903_Liquid_Filled_Pressure_Gauges_01.pdf

-

Keep the dropping resistors if you get a MS-2 and plan on using the Stock Nissan Low-Impedance resistors. From experience, the the Pulse Width Current Limiting algorithms don't want to play nice with the Stock Nissan Jecs injectors. It works well with most injectors, just not the Nissan Jecs for some strange reason. PWCL in MS-2 can be a bit " Hit or Miss". MS-3 is an entirely different matter. The PWCL works very well in that, but MS-3 uses entirely different Firmware and program coding than MS-2 If you do want to change injectors, I would recommend going to Hi-Impedance injectors. Much less problems as PWCL Get a Pallnet fuel Rail and injectors with 14mm Top and Bottom O-rings. That will give you the most choice in injectors, including most Bosch EV1 or EV6 injectors.

-

Yes, GM does make a Coolant sensor with the same threads as the Nissan one. 12 mm x1.5 I believe. By memory, 99 to 2002 Camaro with the LS motor will work. Same calibration as the 3/8 NPT GM units. Thanks for the Shout out. Steve. Been fairly busy with Tuning lately. .

-

For the Injector blower you could use one of the programmable outputs on MS. They can be configured with and/or functions.. You could configure it to run at Coolant temp >= 180 F, with a hysteresis of 10. Then add RPM of < 250. and seconds = 600. That would turn the Injector fans on for ten minutes when you shut the car off and the Coolant temp is above 180F. You can set the Timer Parameters to whatever you like. ( 300 = 5 Minutes etc )

-

Kool...

-

IAT would be better off in the air intake pipe just before the throttle body. If installed in the Intake manifold it can be subject to heat soak. If you do install it in the Intake manifold you may want to install it with a plastic insert to reduce heat transfer to the IAT body. Madkaw used a Nylon reducer bushing from a Ice making machine to isolate his Intake Manifold mounted IAT. Seems to work well. Home Depot part. $1.25 or something like that...

-

Yes, you can use the stock Coolant sensor. You cam calibrate it as a Custom Thermistor using the figures taken from the FSM. ( Which is online at Xenon ). Or you can use the Calibration for the Saab Bosch sensor in the Tuner Studio pull down menu. The 280ZX Turbo injectors would be perfect, and allow you more than enough extra volume to run a 250 HP NA engine. Yes, the distributor wheel from DIY is what you want. Makes l9ife so much simpler. Be careful when you install it. They can go in upside down, and that will really mess you ( and the ignition settings ) up. Get the Paid version of Tuner Studio. You need the Autotune feature that comes with the Paid version. I you need help with set-up and a baseline tune I do remote tuning for a very reasonable fee. Saves you a lot of headaches. Hybrid member Softopz is a distributor for Mega Squirt and 14Point7 products. BTW, good call on choosing the Spartan WB. Much, much better than Innovate products IMHO. One other thing that you should buy is the MS Tuning manual. Written by Matt Cramer and Jerry Hoffman. Excellent book.!! https://www.diyautotune.com/shop/apparel-merchandise/books/

-

And as I mentioned before. Innovate WB controllers seem to be very sensitive to voltage offsets and electrical noise. ( EMI ) More so than other manufactures. Lots of information collaborating that on numerous forums. The actual design of the WB controller is not up to the standards of other manufacturers I think an alternator change would be a good idea, to solve this particular issue.

-

But adjusting the setting in Tuner Studio is not masking anything. It is a common electrical Calibration that is done with all AFR gauges and auxiliary outputs. The 14 point sevn article explained it in Technical terms. I think you're worrying a bit too much about the " Ca;libration " Many, many industries dealing with electronics or electricity in general have to deal with voltage offsets. It is very very common to see adjustable voltage pots ( or digital voltage regulators on allsorts of electronic boards. The high end car audio industry deals with voltage offsets and ground loops all the time. You should see what an electrical plant has to do with matching frequencies and voltages before tapping into a new Power grid. That's just the way it is. You design your circuit to minimize the voltage offset. With proper ground procedures. That will take care of the big offsets. Then you fine adjust the difference in the software. The alternator issue is a different matter though. It could very well just be old or faulty. A bad rectifier bridge in the alternator will introduce electrical moise into the whole cars electrical system. Worn brushes or a worn commutator. will also create noise. A failing alternator can generate a lot of AC ripple. Which is very bad in a DC circuit. Especially for modern day electronics with digital micro processors that operate on very low voltages ( some operate with millivolts ). Edit: Even a new re-manufactured alternator can put out excessive AC ripple. Depends on how good the electronic components are inside. Rectifier bridge's and Voltage Regulator circuits can be utter pieces of crappola on " Off Shore " made Alternators. It can be a crap shoot.... Come to think of it, didn't you mention that your charging voltage was pretty low.? That is one of a failing alternator. Consider the Maxima 80 Amp internal upgrade. Newer " Small frame " design, that is much more efficient than the old 280zx Internal regulator models. The Maxima alternator can crank out 50 amps at just 1,000 rpm . Just my .02c. Others may have some incite to this as well. Good Luck with your project.

-

Did you see my E-Mail that I sent the other day, regarding the EMI suppression capacitor that must be attached to the +12 V terminal on the alternator? It is to reduce electrical noise. Also, the LC-2 ground must go to the Intake manifold ( In your case ) . You said Body above, but I think that may have been a Typo. Also, the Innovate ground wire has to go to a separate stud on the Intake manifold, not to the same stud as the ECU ground..... for the reason below. Innovate stupidly combines the Heater ground and gauge/sensor ground into one wire. Which is really dumb as the O2 heater wire is a high amperage draw and will can create a Voltage offset. Good manufacturers use a separate ground for the O2 Heater ground and that must be mounted separate from the ECU and regular AFR sensor ground. When you have a proper WB controller with two ground eyelets, the WB controller ground is " Star grounded " to the same point as the ECU ground to decrease voltage offset. Interestingly, the Innovate wiring Loom does have a separate O2 heater ground. Then for some inexplicable reason they spliced them into one wire exiting the Loom. Some people have had success with unwrapping the loom, and soldering on a separate ground wire with eyelet for the O2 heater ground. Other people have reported great success with taking a BFH .... and beating the living S**T out of their Innovate WB controller. Your call...

-

Q's on FricFrac Ms setup and injector impedance

Chickenman replied to Slowpoke's topic in MegaSquirt

Replied by E-mail. -

Q's on FricFrac Ms setup and injector impedance

Chickenman replied to Slowpoke's topic in MegaSquirt

Slowpoke. Check your User Control Panel. Just tried to PM you, but message area is grayed out. Maybe try PM'ing me? -

-

-

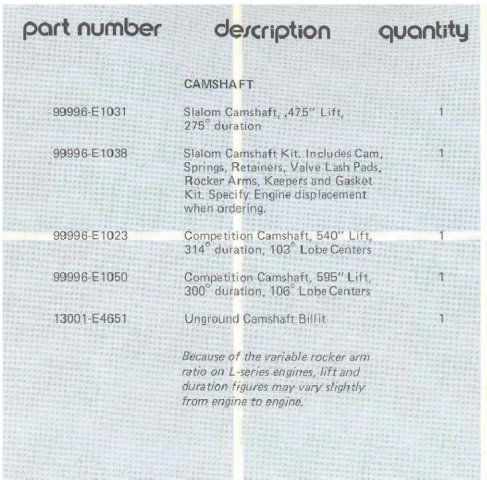

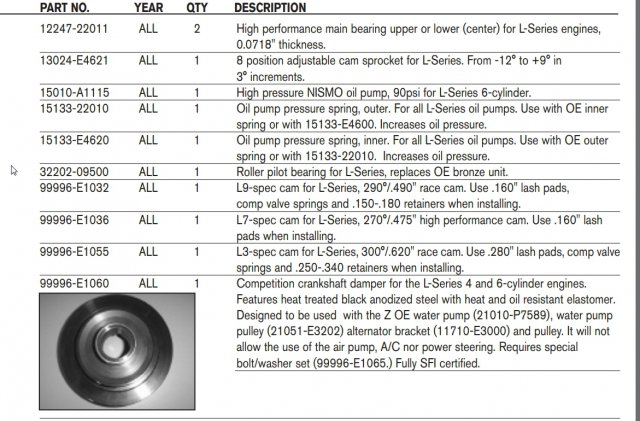

Biggest issue is with a reground Cam, you are " lift limited " by the duration profile. To get more duration at the Nose, you have to grind the Peak or Toe of the Cam. That means you've now reduced the effective " Lift " of the Cam. To get the Lift back, you have to reduce the Base-Circle Diameter or Heel of the cam. You can only go so small with a Base Circle, before you start running into geometry and Valve acceleration issues. Make the Acceleration and Deceleration ramps too aggressive, and you end up with Valve Train instability and short component life. On some re-grinds, they have to " undercut " the core diameter of the Camshaft. That means that they actually reduce the diameter of the Camshaft BETWEEN the Lobes in an effort to get the Base Circle diameter smaller. Of course that can weaken the camshaft core as well. Now, if you start off with an unground new " Billet " camshaft you can get a LOT more lift and duration than a regrinds. Because you have all that extra metal to use on the Profile. It's not unusual to see Datsun L series Race cams ground on a fresh cam Billet having .600" + Valve lift ( 1.54 Rocker ratio ) . That would be impossible on a reground Camshaft.

-

240z coilovers options for racing

Chickenman replied to Marlinfoto's topic in Brakes, Wheels, Suspension and Chassis

^ Techno toy tuning makes some very nice Weld in plates and Camber plates. You won't go wrong choosing TTT. -

280zx ignition module with Megasquirt - is it necessary?

Chickenman replied to supernova_6969's topic in Nissan L6 Forum

With the ground shield it must not be connected to the engine block or Chassis. Only to the inside ECU ground. Having grounds at both ends can induce an offset voltage into the ECU sensor ground circuit. You don't want that. Messes up sensors. I've heard of MS custom builders using a separate box outside of the main MS ECU box for exactly the reasons stated above. To reduce any internal EMI created by the Power transistor ( BIP-373 ). Very good idea with WasteSpark or COP coil drivers that would have multiple BIP373's. The Nissan Module could certainly be triggered and controlled as a Single channel dumb coil driver. That's exactly what it is. Be sure to mount it to a good heat sink though. Those modules get very hot. The distributor body acts as a heat sink from the factory. If not mounted to a heat sink it will fail in short order. The Nissna " Matchbox " module is pretty stout all by itself. You can use an old AMD style CPU Heatsink and fan to keep it cool. Fan may not even be needed. Make sure you use a good thermal conducting compound between the Module backing plate and the Heatsink.- 30 replies

-

- megasquirt

- ignition module

-

(and 1 more)

Tagged with:

-

280zx ignition module with Megasquirt - is it necessary?

Chickenman replied to supernova_6969's topic in Nissan L6 Forum

Advantages to running an external Ignition Module: 1: Ignition modules are noisy electrically ( EMI ) . For that reason, some builders of MS prefer to keep the high current Ignition coil drivers ( BIP373 IGT) outside of the ECU box. Or they build a Faraday cage around the Power Transistors. An external Module, be it a Nissan Matchbox module, aftermarket Ignition amplifier, such as a Bosch or DIY Quadspark unit or even a CDI box, will be isolated outside of the ECU as far as EMI noise is related. Very few manufacturers such as Haltech, Link Adaptronics, or AEM, ever include the High Amperage draw IGT drivers isiden the ECU. They all use external modules to reduce EMI. Logic coil drivers are not the same thing. They are low amperage circuits and don't produce the EMI that the IGT BIP-373 coil drivers Advantages of BIP 373 drivers ( IGT ) 2: The BIP373 drivers are cheap ( $8.50 each ) work well and provide a slightly cleaner install over external modules. We are referring to dumb coil packs of course. Logic coils such as LS2 do not require IGT coil drivers. Cons of external Modules. 1: More cost if one has to be purchased. Can be quite expensive if going more than a single coil. You need at least a 3 Channel coil Module for a 3 Coil Pack Wastespark system. That can be fairly expensive. Although you can sometimes find used 3 Channel Bosch modules for a reasonable price. . Audi V6 and BMW inlne 6's prior to about 2000 had these. 2: Additional wiring. The Nissan matchbox module would have to be re-wired to use the Programmable Timing curve features of the MS. And the distributor would have to be locked out. Not really a Module issue, but rather a choice of distributor type. Cons of Internal coil drivers. IE ( BIP-373 IGT coil drivers ) 1: They produce an ENI field. Nota good thing to have inside an ECU with very sensitive micro-orocessors. 2: They get hot. The more of the BIP-373 drivers you have, the more heat is pumped into the ECU case. Heat is not good for electronics. Worst case scenario for an L-6 would probably be three BIP-373's firing 3 x Waste-Spark " dumb " coil packs.- 30 replies

-

- megasquirt

- ignition module

-

(and 1 more)

Tagged with:

-

280zx ignition module with Megasquirt - is it necessary?

Chickenman replied to supernova_6969's topic in Nissan L6 Forum

Shielding should only be grounded inside the ECU. The other end should never be grounded to anything....- 30 replies

-

- megasquirt

- ignition module

-

(and 1 more)

Tagged with:

-

I think Issa has a faulty CAS sensor as well. Trigger and Tooth logs are all over the place and intermittent. Car ran great one run, then as I watched in real time, the Tooth logs took a dump and the car died. Trigger logs and Tooth logs were very broken up. Think CAS said.... Buh Bye!!

-

If using an MS1 or MS2 and stock Nissan injectors ( Low-Impedance ) then I would strongly suggest using the factory dropping resistors. For some reason the MS1 and MS2 Pulse Width Control Limiting is a bit flaky with the Nissan Jecs Low-z injectors. It's hit or miss if it works correctly. If you change to different injectors I would suggest going to Hi-Impedance to save yourself from headaches. The MS3 PWCL drivers seem to be fine. MS3 uses entirely different coding though. IMHO it's firmware is much better than Ms2. Less " quirky "

-

There are different hardware manuals for Version 3.0 and 3.57 main boards. You didn't state what you have. but here is MS2 version 3.0 main board.

.thumb.png.2657f296f14a6c66661c6e3ceb42a831.png)